Method for simultaneously improving low-carbon low-alloy steel strength and plasticity

A low-alloy steel, strength technology, applied in the field of metal materials, can solve the problems of steel strength reduction, plasticity reduction, inability to achieve strong plastic matching and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

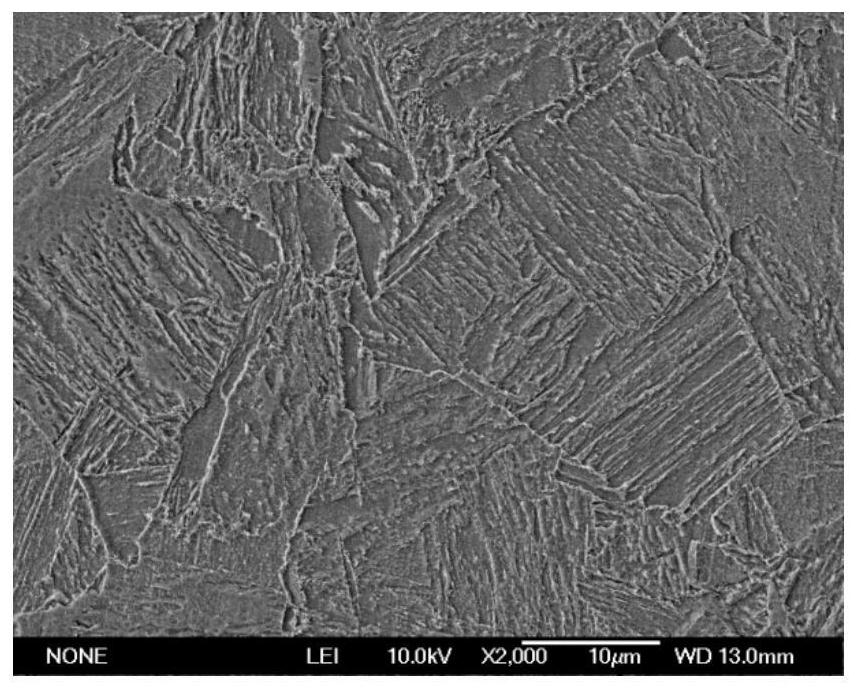

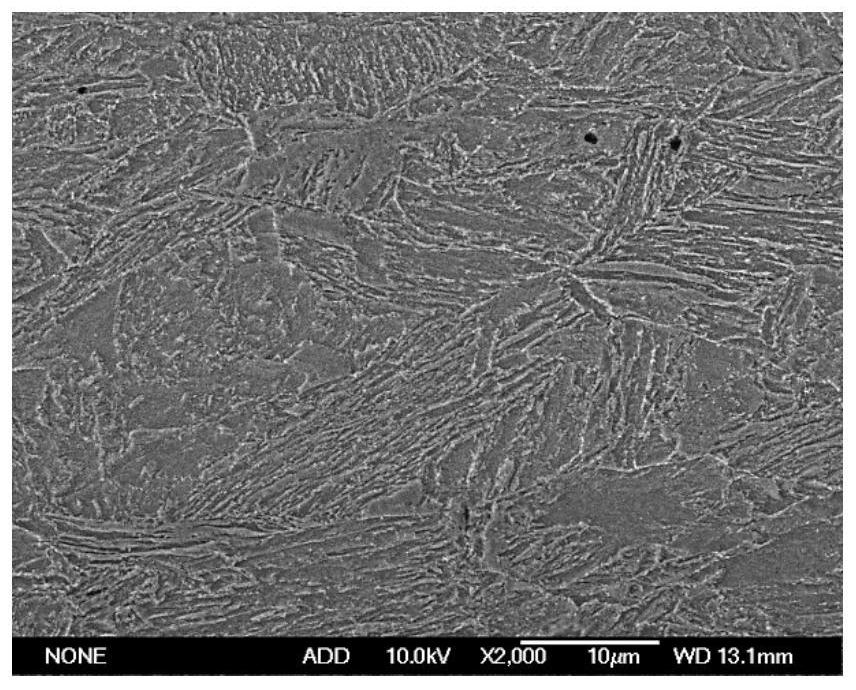

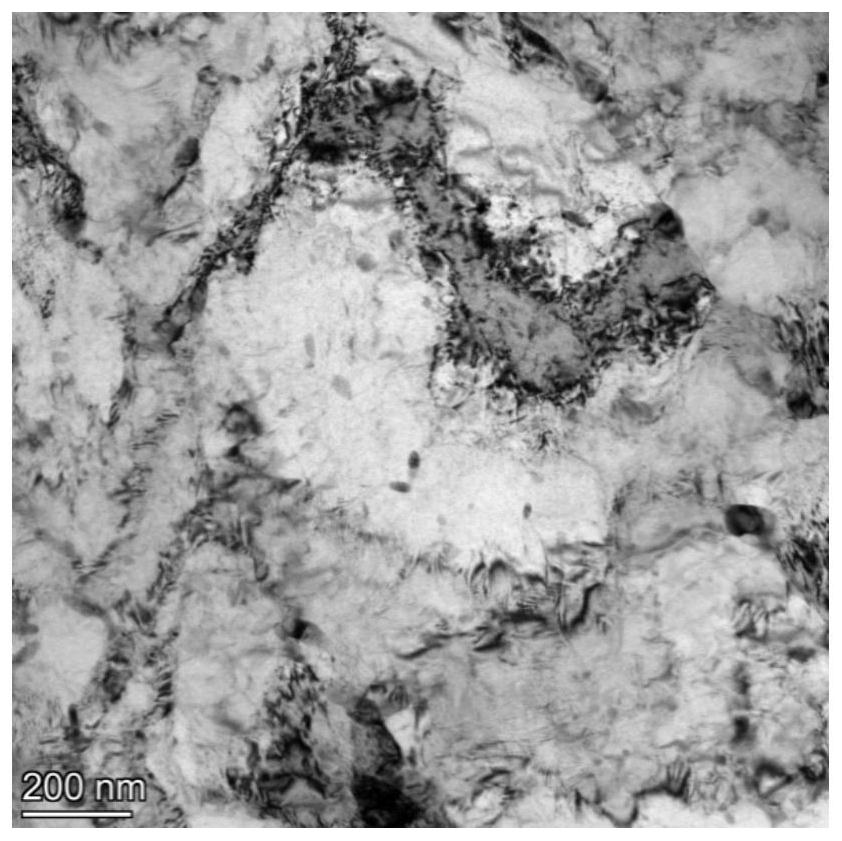

Image

Examples

Embodiment 1

[0040] A method for simultaneously improving the strength and plasticity of low-carbon low-alloy steel, the steps of the method are as follows:

[0041] (1) The low-carbon low-alloy steel piece corresponding to No. 1 in Table 1 is soaked at 820°C for 0.5h for complete austenitization treatment, and then quenched in water to room temperature to obtain the quenched low-carbon low-alloy steel ;

[0042] (2) Tempering the quenched low-carbon low-alloy steel at 550° C. for 0.5 h, and cooling to room temperature in air after the tempering treatment is completed, to obtain the tempered low-carbon low-alloy steel;

[0043](3) Take a cylindrical sample with a size of φ12×18mm on the tempered low-carbon low-alloy steel, and use a separate Hopkinson pressure bar to perform dynamic large deformation treatment on the sample, with a strain of 0.4 , with a strain rate of 10 3 the s -1 , to obtain low-carbon low-alloy steel after dynamic large deformation;

[0044] (4) The low-carbon low-...

Embodiment 2

[0048] A method for simultaneously improving the strength and plasticity of low-carbon low-alloy steel, the steps of the method are as follows:

[0049] (1) The low-carbon low-alloy steel piece corresponding to No. 2 in Table 1 was subjected to a complete austenitization treatment at 880° C. for soaking and heat preservation for 1 hour, and then quenched in water to room temperature to obtain a quenched low-carbon low-alloy steel;

[0050] (2) Tempering the quenched low-carbon low-alloy steel at 450° C. for 5 hours, and cooling to room temperature in air after the tempering treatment is completed, to obtain the tempered low-carbon low-alloy steel;

[0051] (3) Take a cylindrical sample with a size of φ12×18mm on the tempered low-carbon low-alloy steel, and use the Hopkinson compression bar to carry out dynamic large deformation treatment on the sample. The strain is 0.8, and the strain Rate 10 3 the s -1 , to obtain low-carbon low-alloy steel after dynamic large deformation;...

Embodiment 3

[0056] A method for simultaneously improving the strength and plasticity of low-carbon low-alloy steel, the steps of the method are as follows:

[0057] (1) The low-carbon low-alloy steel piece corresponding to No. 3 in Table 1 was subjected to a complete austenitization treatment at 920° C. for soaking and heat preservation for 2 hours, and then quenched in water to room temperature to obtain a quenched low-carbon low-alloy steel;

[0058] (2) Tempering the quenched low-carbon low-alloy steel at 350° C. for 3 hours, and cooling to room temperature in air after the tempering treatment is completed, to obtain the tempered low-carbon low-alloy steel;

[0059] (3) Take a cylindrical sample with a size of φ12×18mm on the tempered low-carbon low-alloy steel, and use the Hopkinson compression bar to carry out dynamic large deformation treatment on the sample. The strain is 1.2, and the strain Rate 10 3 the s -1 , to obtain low-carbon low-alloy steel after dynamic large deformation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com