Rolling method of high-performance copper-chromium-zirconium alloy plate

An alloy sheet, copper-chromium-zirconium technology, applied in metal rolling and other directions, can solve the problems of insignificant improvement of mechanical properties, long process cycle, low production efficiency, etc., achieve excellent mechanical properties and electrical conductivity matching, shorten the process flow, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

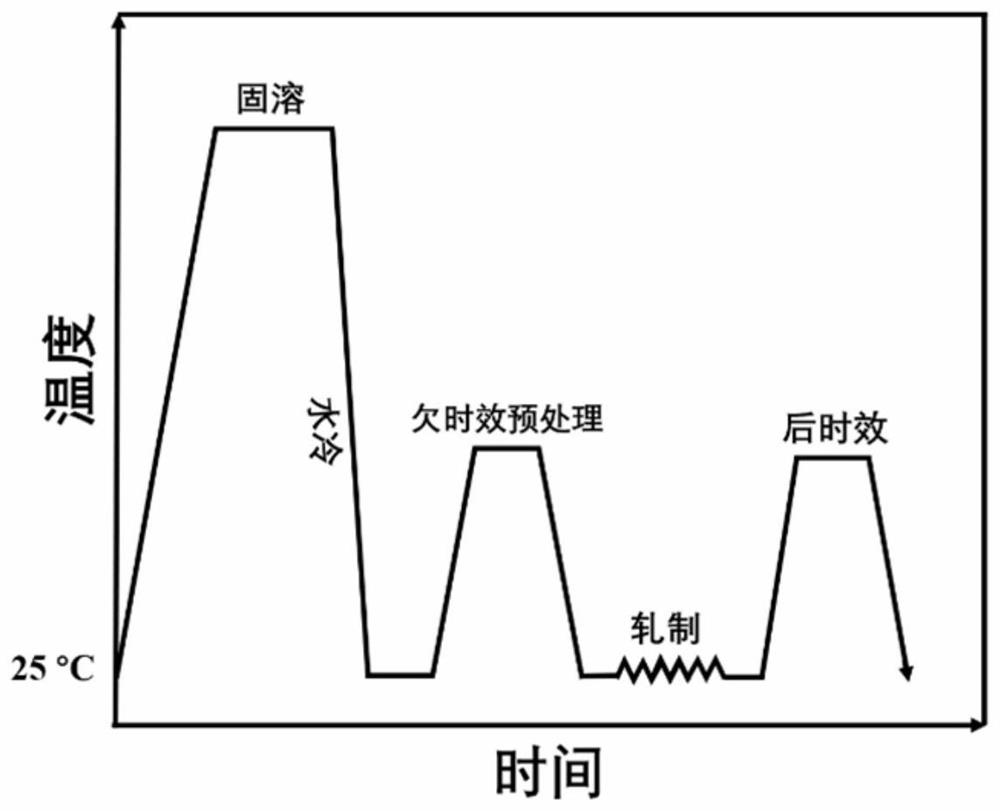

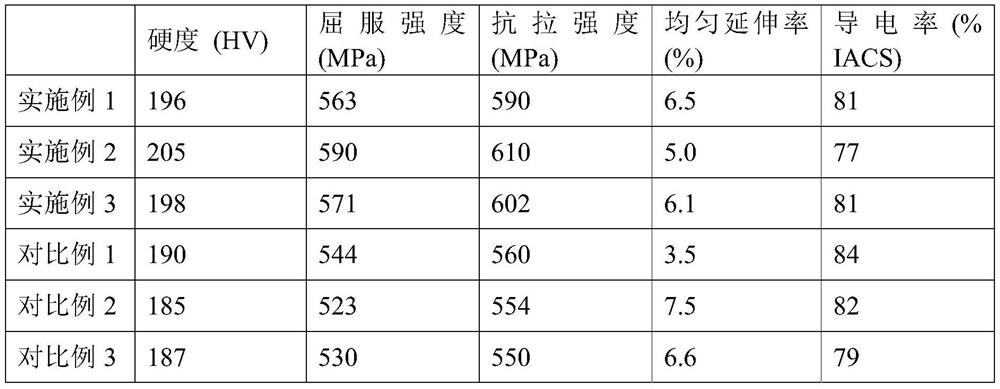

[0019] The copper-chrome zirconium alloy chemical component (mass) is: 1.04% chromium, zirconium 0.08%, iron 0.02%, nickel 0.01%, and the margin is copper. according to figure 1 The process flow is treated against the copper-chrome zirconium alloy plate. Specifically: solid solution treatment of a thickness of 10 mm copper chrome zirconium-zirconium alloy plate material, water quenching to room temperature; 420 ° C / 1H of solid copper chrome zirconium Effective pretreatment, hardness is 88% of the hardness of the flexibility in the peak, the conductivity is 84% of the peak-to-peak-to-peak-to-peak-to-peak; then the underlying copper-chromium zirconium alloy is carried out under room temperature. 80% total deformation amount rolling Treatment, the amount of deformation per second is 5%, and the rolling is used to use a common two-rolling mill; finally proceed with the alloy 420 ° C / 6h aging.

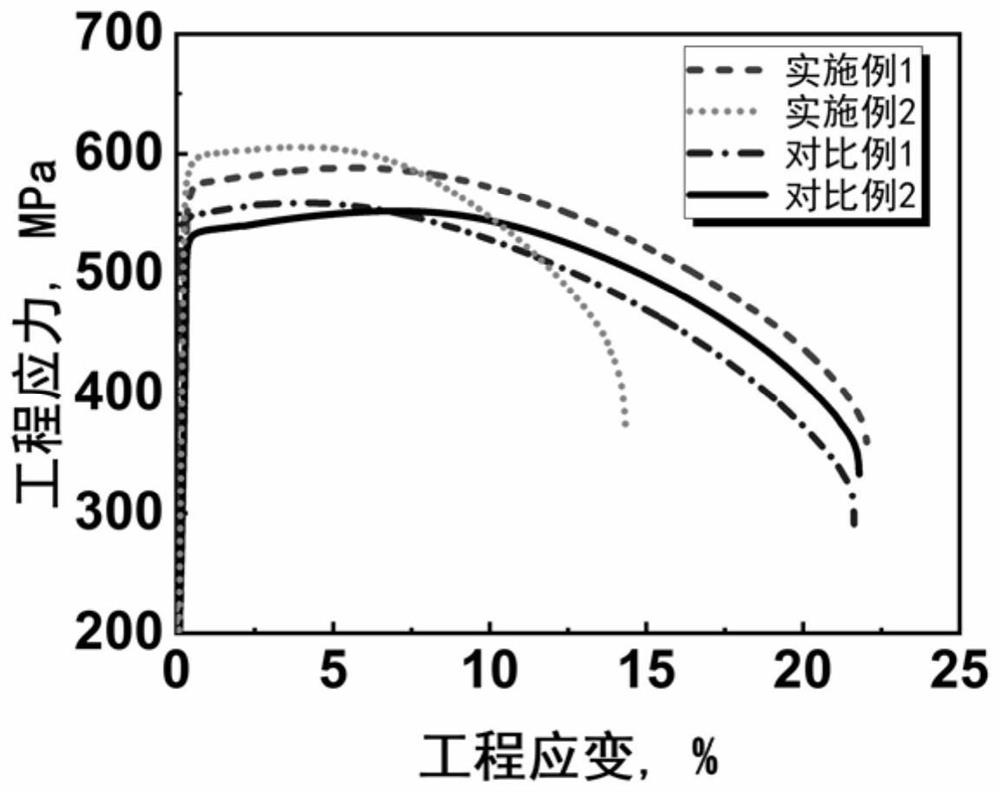

[0020] The copper chrome zirconium alloy sheet obtained by the present embodiment was...

Embodiment 2

[0022] Copper chrome zirconium alloy chemical composition (mass%) is: 0.78% chromium, zirconium 0.17%, silicon 0.02%, and the margin is copper. The thickness of 10 mm copper-chrome zirconium-zirconium-chromogenic sheet material was subjected to water to room temperature; water was quenched to room temperature; the solid-dissolved copper chrome zirconium alloy was subjected to an indefficient pretreatment of the effect, the hardness of the peak 87%, the conductivity is 81% of the peak-to-peak-efficient alloy conductivity; then the underwhelming copper-chromium zirconium alloy is carried out at room temperature, the amount of total deformation amount is carried out, and the amount of deformation per second is 5%, rolled The use of ordinary rolling mills; finally processed at 450 ° C / 0.5H.

[0023] The copper-chrome zirconium alloy sheet obtained by the present embodiment was mechanically and electrically conductive properties, the microhardness of 205 HV, the yield strength was 59...

Embodiment 3

[0025] The copper-chrome zirconium alloy chemical component (mass) is: 1.04% chromium, zirconium 0.08%, iron 0.02%, nickel 0.01%, and the margin is copper. The thickness of 10 mm copper-chrome zirconium-chromium-chromium-chromatic sac is solid solution treatment, water is quenched to room temperature; the solid copper copper-chromium zirconium alloy is adjusted by the indefficient pretration of the hardness of the hardness of the peak. 88%, the conductivity is 84% of the peak-to-peak-based alloy conductivity; then the underlying copper-chrome zirconium alloy is carried out under room temperature conditions, the amount of 85% total deformation amount is carried out, and the amount of deformation per second is 5%, rolled Using a normal two-rolling mill; finally processed the alloy 420 ° C / 6H.

[0026] The copper-chrome zirconium alloy sheet obtained by the present embodiment was mechanically and electrically conductive properties, the microhardness of 198 hV, the yield strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com