A method for simultaneously improving the strength and ductility of low-carbon low-alloy steel

A low-alloy steel, plastic technology, applied in the field of metal materials, can solve the problems of inability to achieve strong plastic matching, difficult to recover plastic, steel strength decline, etc., to maintain the deformation strengthening effect, improve the plastic deformation ability of steel, reduce carbon content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for simultaneously improving the strength and plasticity of low-carbon low-alloy steel, the steps of the method are as follows:

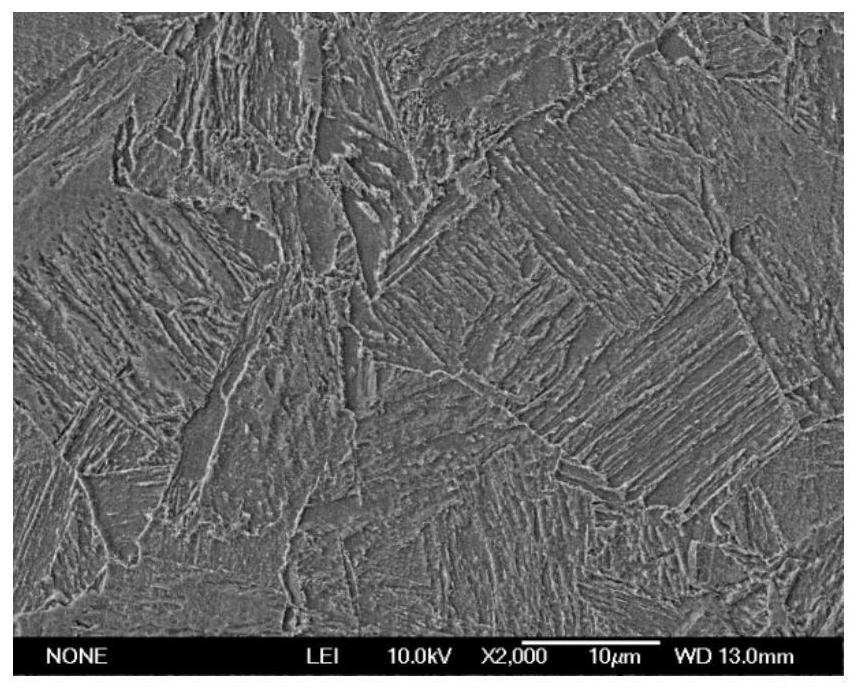

[0041] (1) The low-carbon low-alloy steel piece corresponding to No. 1 in Table 1 is soaked at 820°C for 0.5h for complete austenitization treatment, and then quenched in water to room temperature to obtain the quenched low-carbon low-alloy steel ;

[0042] (2) Tempering the quenched low-carbon low-alloy steel at 550° C. for 0.5 h, and cooling to room temperature in air after the tempering treatment is completed, to obtain the tempered low-carbon low-alloy steel;

[0043](3) Take a cylindrical sample with a size of φ12×18mm on the tempered low-carbon low-alloy steel, and use a separate Hopkinson pressure bar to perform dynamic large deformation treatment on the sample, with a strain of 0.4 , with a strain rate of 10 3 the s -1 , to obtain low-carbon low-alloy steel after dynamic large deformation;

[0044] (4) The low-carbon low-...

Embodiment 2

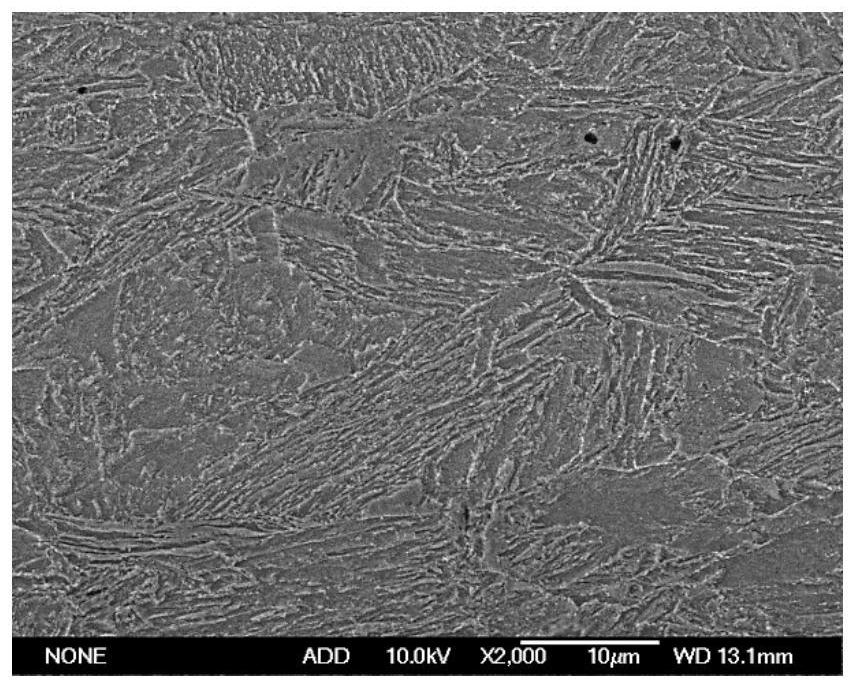

[0048] A method for simultaneously improving the strength and plasticity of low-carbon low-alloy steel, the steps of the method are as follows:

[0049] (1) The low-carbon low-alloy steel piece corresponding to No. 2 in Table 1 was subjected to a complete austenitization treatment at 880° C. for soaking and heat preservation for 1 hour, and then quenched in water to room temperature to obtain a quenched low-carbon low-alloy steel;

[0050] (2) Tempering the quenched low-carbon low-alloy steel at 450° C. for 5 hours, and cooling to room temperature in air after the tempering treatment is completed, to obtain the tempered low-carbon low-alloy steel;

[0051] (3) Take a cylindrical sample with a size of φ12×18mm on the tempered low-carbon low-alloy steel, and use the Hopkinson compression bar to carry out dynamic large deformation treatment on the sample. The strain is 0.8, and the strain Rate 10 3 the s -1 , to obtain low-carbon low-alloy steel after dynamic large deformation;...

Embodiment 3

[0056] A method for simultaneously improving the strength and plasticity of low-carbon low-alloy steel, the steps of the method are as follows:

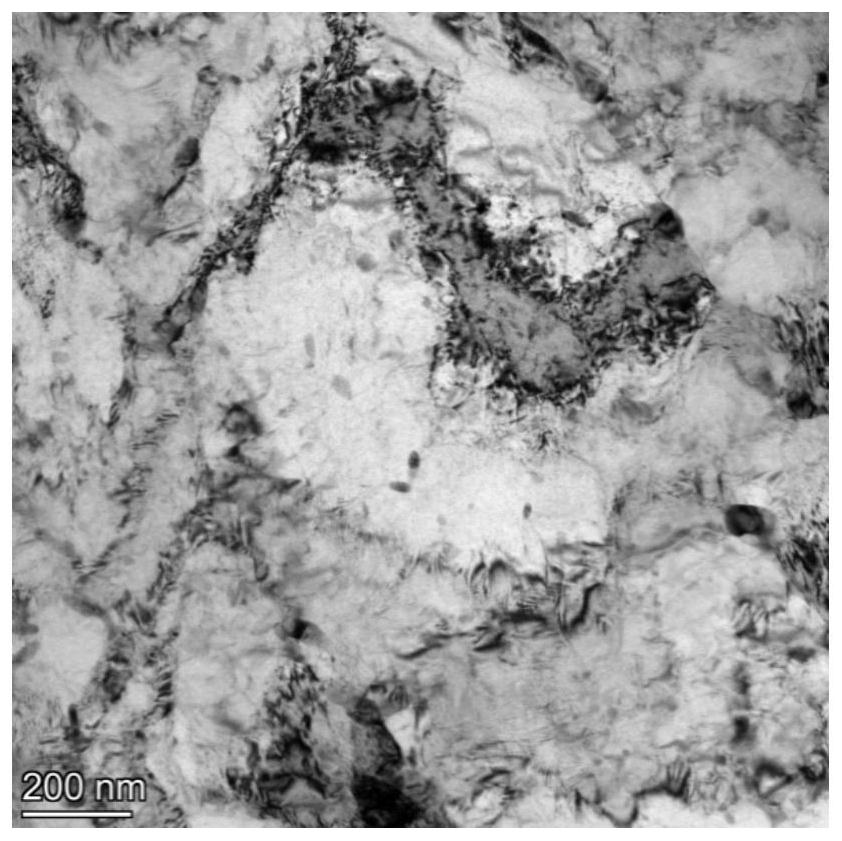

[0057] (1) The low-carbon low-alloy steel piece corresponding to No. 3 in Table 1 was subjected to a complete austenitization treatment at 920° C. for soaking and heat preservation for 2 hours, and then quenched in water to room temperature to obtain a quenched low-carbon low-alloy steel;

[0058] (2) Tempering the quenched low-carbon low-alloy steel at 350° C. for 3 hours, and cooling to room temperature in air after the tempering treatment is completed, to obtain the tempered low-carbon low-alloy steel;

[0059] (3) Take a cylindrical sample with a size of φ12×18mm on the tempered low-carbon low-alloy steel, and use the Hopkinson compression bar to carry out dynamic large deformation treatment on the sample. The strain is 1.2, and the strain Rate 10 3 the s -1 , to obtain low-carbon low-alloy steel after dynamic large deformation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com