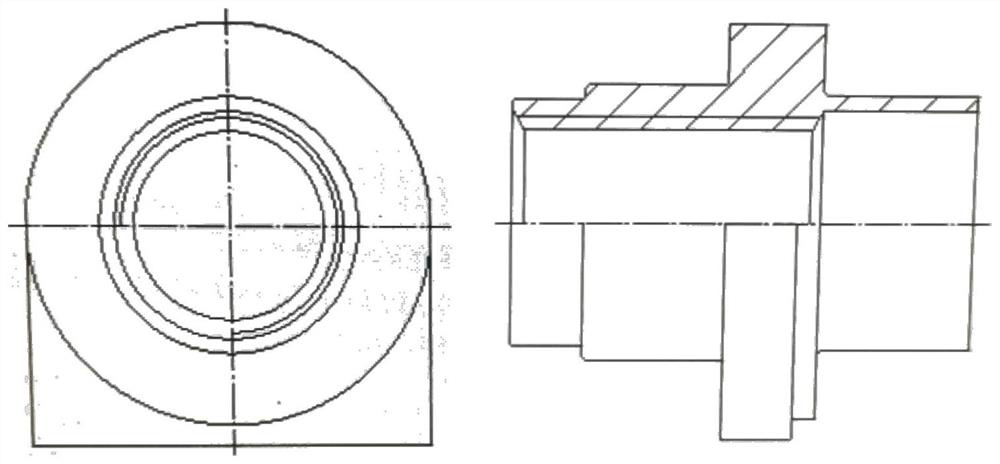

Afterheat heat treatment method for guaranteeing grain size of GH738 supporting plate self-locking nut

A technology of GH738 and heat treatment method, which is applied in the field of residual temperature heat treatment to ensure the grain size of GH738 pallet self-locking nuts, can solve the problems affecting grain refinement and grain growth, and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

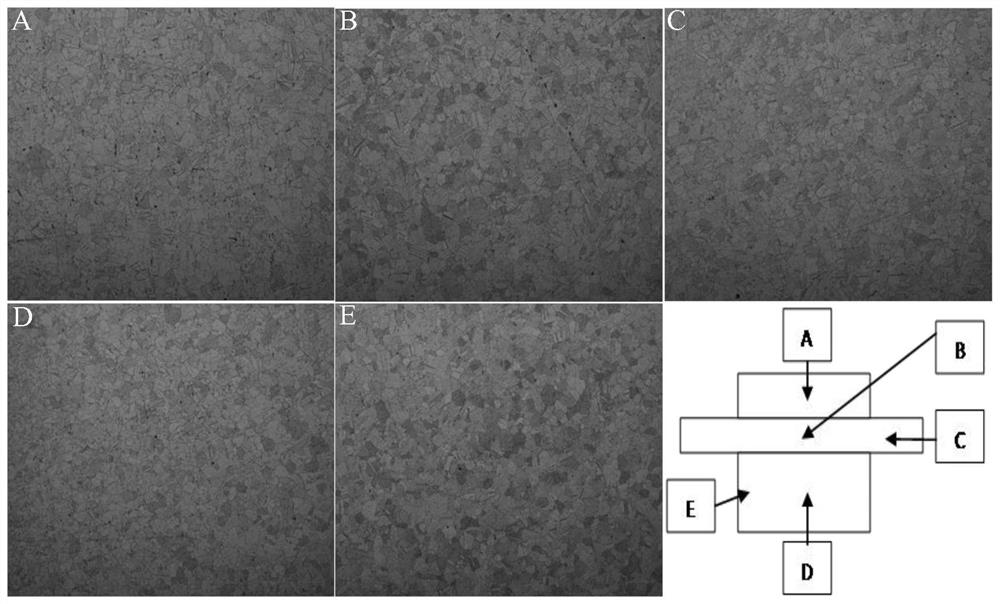

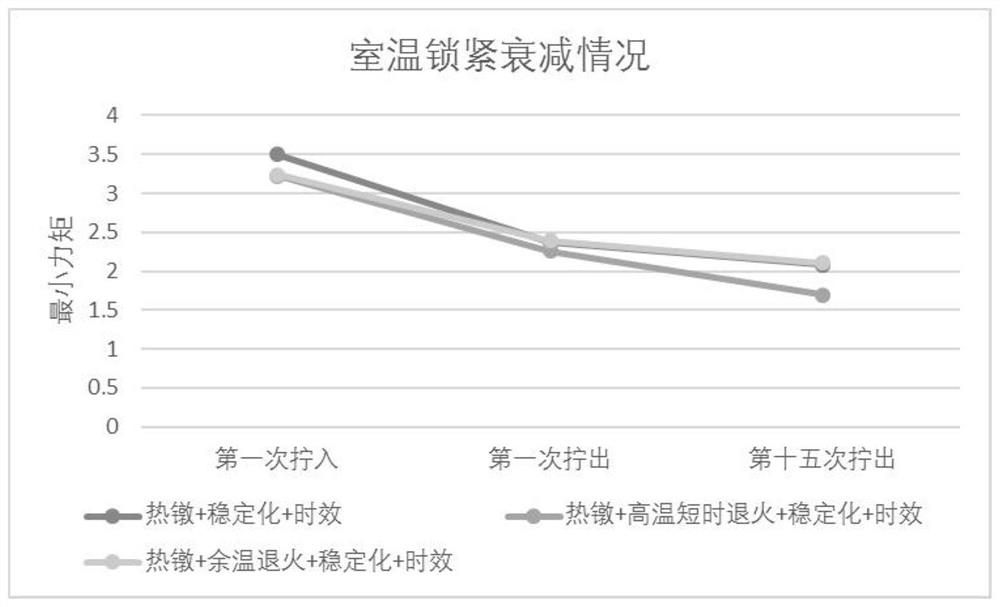

Method used

Image

Examples

Embodiment 1

[0028] A residual temperature heat treatment method to ensure the grain size of the GH738 pallet self-locking nut, specifically including the following process:

[0029] (1) Hot heading forming: The initial forging temperature of the billet is controlled at 1020-1150°C, and the induction heater is used for heating. The heater setting parameter is 180-200A, and the heating time is 10-11 seconds. The overall heating is completed after heating. Hot heading forming.

[0030] (2) Remaining temperature annealing treatment: After hot heading forming, use the remaining temperature of hot heading forming (residual temperature is above 600°C), quickly put it into the heating furnace and keep it at 1070°C for 5-7 minutes, and then air cool or quickly heat it out of the furnace Cool to room temperature; during the heating process, the heating furnace adopts a mesh belt furnace, the furnace temperature uniformity is ±10°C, and the temperature control accuracy is ±1°C;

[0031] (3) Machini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com