Ultrahigh-plasticity rare earth wrought magnesium alloy and preparation method of extruded plate thereof

A technology for deforming magnesium alloys and magnesium alloys, applied in the field of alloy materials, can solve the problems of difficult forming, low texture strength, and low room temperature plasticity, and achieve the effects of reducing anisotropy, improving sheet texture, and promoting formation and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Alloy smelting: use pure Mg ingot, Mg-20Er master alloy and Mg-Zr master alloy as raw materials, mix according to Er: 3.0%, Zr: 0.6%, and the balance is Mg, melt the alloy ingredients and pass semi-continuous casting into a magnesium alloy ingot. Semi-continuous casting process: Preheat the alloy raw material to 80°C, put it into the crucible, sprinkle the covering agent, then raise the temperature to 700°C, and melt it under the protection of SF6 and CO2 atmosphere; after all the melting, remove the slag and refine for 15 minutes ; After refining, remove the slag, keep it warm for 30 minutes; take a sample and analyze the composition, if the composition is qualified, lower the temperature to 690°C for semi-continuous casting.

[0028] S2. Heat treatment: The magnesium alloy ingot obtained in S1 is subjected to solution treatment and air-cooled, the solution temperature is 450° C., and the solution time is 12 hours.

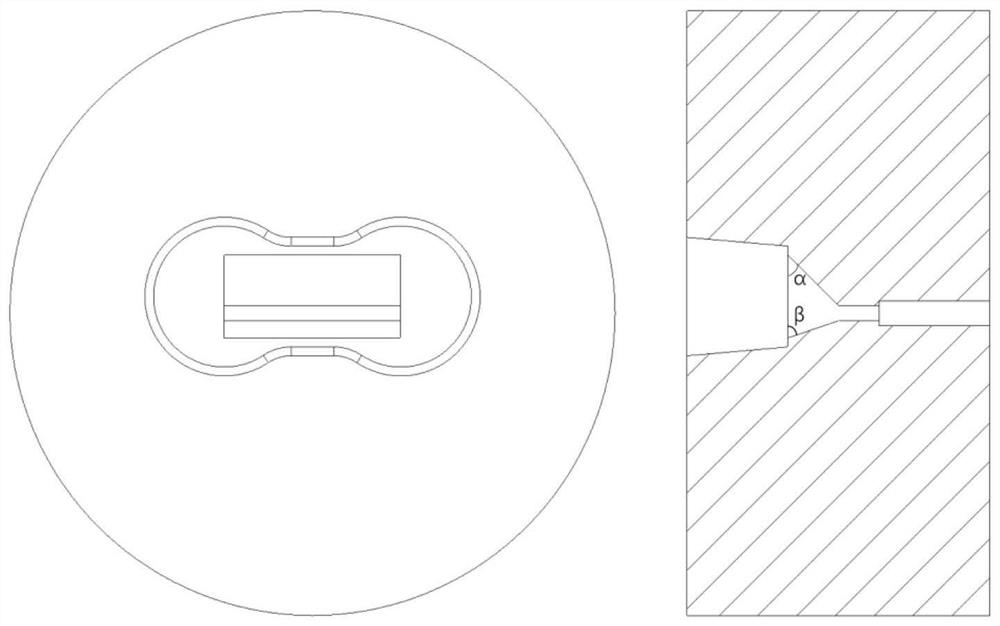

[0029] S3. Forging treatment: preheat the magne...

Embodiment 2

[0037] S1. Alloy smelting: using pure Mg ingot, Mg-20Gd master alloy and Mg-Zr master alloy as raw materials, Gd: 2.0%, Zr: 0.6%, and the balance is Mg for batching, alloy ingredients are melted and passed through semi-continuous casting into a magnesium alloy ingot. Semi-continuous casting process: Preheat the alloy raw material to 80°C, put it into the crucible, sprinkle the covering agent, then raise the temperature to 700°C, and melt it under the protection of SF6 and CO2 atmosphere; after all the melting, remove the slag and refine for 15 minutes ; After refining, remove the slag, keep it warm for 30 minutes; take a sample and analyze the composition, if the composition is qualified, lower the temperature to 690°C for semi-continuous casting.

[0038] S2. Heat treatment: The magnesium alloy ingot obtained in S1 is subjected to solution treatment and air-cooled, the solution temperature is 450° C., and the solution time is 12 hours.

[0039] S3. Forging treatment: preheat...

Embodiment 3

[0045] S1. Alloy smelting: using pure Mg ingot, Mg-20Gd master alloy, Mg-20Er master alloy and Mg-Zr master alloy as raw materials, Gd: 1.5%, Er: 1.5%, Zr: 0.6%, and the balance is Mg. The ingredients are melted and cast into magnesium alloy ingots through semi-continuous casting. Semi-continuous casting process: Preheat the alloy raw material to 80°C, put it into the crucible, sprinkle the covering agent, then raise the temperature to 700°C, and melt it under the protection of SF6 and CO2 atmosphere; after all the melting, remove the slag and refine for 15 minutes ; After refining, remove the slag, keep it warm for 30 minutes; take a sample and analyze the composition, if the composition is qualified, lower the temperature to 690°C for semi-continuous casting.

[0046] S2. Heat treatment: The magnesium alloy ingot obtained in S1 is subjected to solution treatment and air-cooled, the solution temperature is 450° C., and the solution time is 12 hours.

[0047] S3. Forging trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com