Wrought magnesium alloy containing neodymium samarium light rare earth elements and high Mn content and preparation method thereof

A light rare earth element and deformed magnesium alloy technology, applied in the field of magnesium alloy materials, can solve the problems of adding alloy cost and density, and achieve the effect of promoting the dynamic recrystallization process, ensuring strength and toughness, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

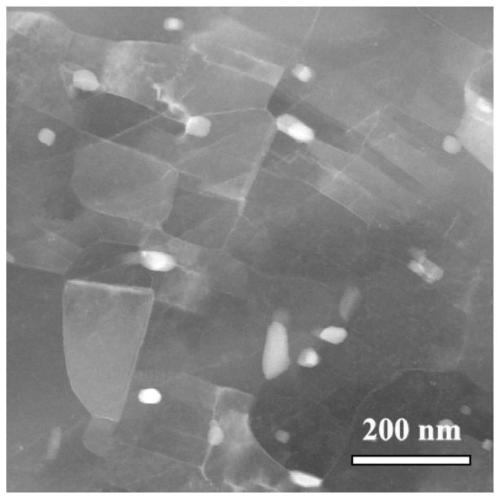

Image

Examples

Embodiment 1

[0020] Deformed magnesium alloy containing neodymium, samarium, light rare earth elements and high Mn content Mg-0.3Ca-0.5Al-0.5Zn-0.5Mn-0.3Sm / Nd, the composition is by mass percentage: 0.3 wt.%Ca; 0.5 wt.% Al; 0.5 wt.%Zn; 0.3 wt.%Mn; 0.3 wt.%Sm+Nd, the balance being Mg.

[0021] The preparation method of the deformed magnesium alloy containing neodymium, samarium light rare earth elements and high Mn content of the present embodiment is:

[0022] (1) Weigh the following components according to mass percentage: 0.3 wt.%Ca; 0.5 wt.%Al; 0.5 wt.%Zn; 0.3 wt.%Mn; 0.3 wt.%Sm+Nd, the balance is Mg; Magnesium-manganese master alloy with a manganese content of 6 wt.%, the metal purity is above 99%;

[0023] (2) Ingot smelting: Under the protection of protective gas, add the raw materials in two batches: the first batch: add pure magnesium and heat to 740~780°C, stir well and wait until it is completely melted; the second batch: add Pure calcium, pure samarium, pure neodymium, magnesi...

Embodiment 2

[0028] Deformed magnesium alloy containing neodymium, samarium, light rare earth elements and high Mn content Mg-0.8Ca-0.3Al-1.0Zn-1.0Mn-1.5Sm / Nd, the composition is: 0.8 wt.%Ca; 0.3 wt.% Al; 1.0 wt.%Zn; 1.0 wt.%Mn; 1.5 wt.%Sm+Nd, the balance being Mg.

[0029] The preparation method of the deformed magnesium alloy containing neodymium, samarium light rare earth elements and high Mn content of the present embodiment is:

[0030] (1) Weigh the following components according to mass percentage: 0.8 wt.%Ca; 0.3 wt.%Al; 1.0 wt.%Zn; 1.0 wt.%Mn; 1.5 wt.%Sm+Nd, the balance is Mg; Magnesium-manganese master alloy with a manganese content of 6 wt.%, the metal purity is above 99%;

[0031] (2) Ingot smelting: Under the protection of protective gas, add the raw materials in two batches: the first batch: add pure magnesium and heat to 740~780°C, stir well and wait until it is completely melted; the second batch: add Pure calcium, pure samarium, pure neodymium, magnesium-manganese master...

Embodiment 3

[0036] Wrought magnesium alloy Mg-1.8Ca-1.3Al-1.5Zn-2.8Mn-3.0Sm / Nd containing neodymium, samarium light rare earth elements and high Mn content, the composition is: 1.8 wt.%Ca; 1.3 wt.% Al; 1.5 wt.%Zn; 2.8 wt.%Mn; 3.0 wt.%Sm+Nd, the balance being Mg.

[0037] The preparation method of the deformed magnesium alloy containing neodymium, samarium light rare earth elements and high Mn content of the present embodiment is:

[0038] (1) Weigh the following components according to mass percentage: 1.8 wt.%Ca; 1.3 wt.%Al; 1.5 wt.%Zn; 2.8 wt.%Mn; 3.0 wt.%Sm+Nd, the balance is Mg; Magnesium-manganese master alloy with a manganese content of 6 wt.%, the metal purity is above 99%;

[0039] (2) Ingot smelting: Under the protection of protective gas, add the raw materials in two batches: the first batch: add pure magnesium and heat to 740~780°C, stir well and wait until it is completely melted; the second batch: add Pure calcium, pure samarium, pure neodymium, magnesium-manganese master a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com