Heterogeneous metal stirring friction welding method

A friction stir, welding method technology, applied in welding equipment, metal processing equipment, non-electric welding equipment and other directions, can solve the problem of not being able to directly weld, and achieve the effect of ensuring strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

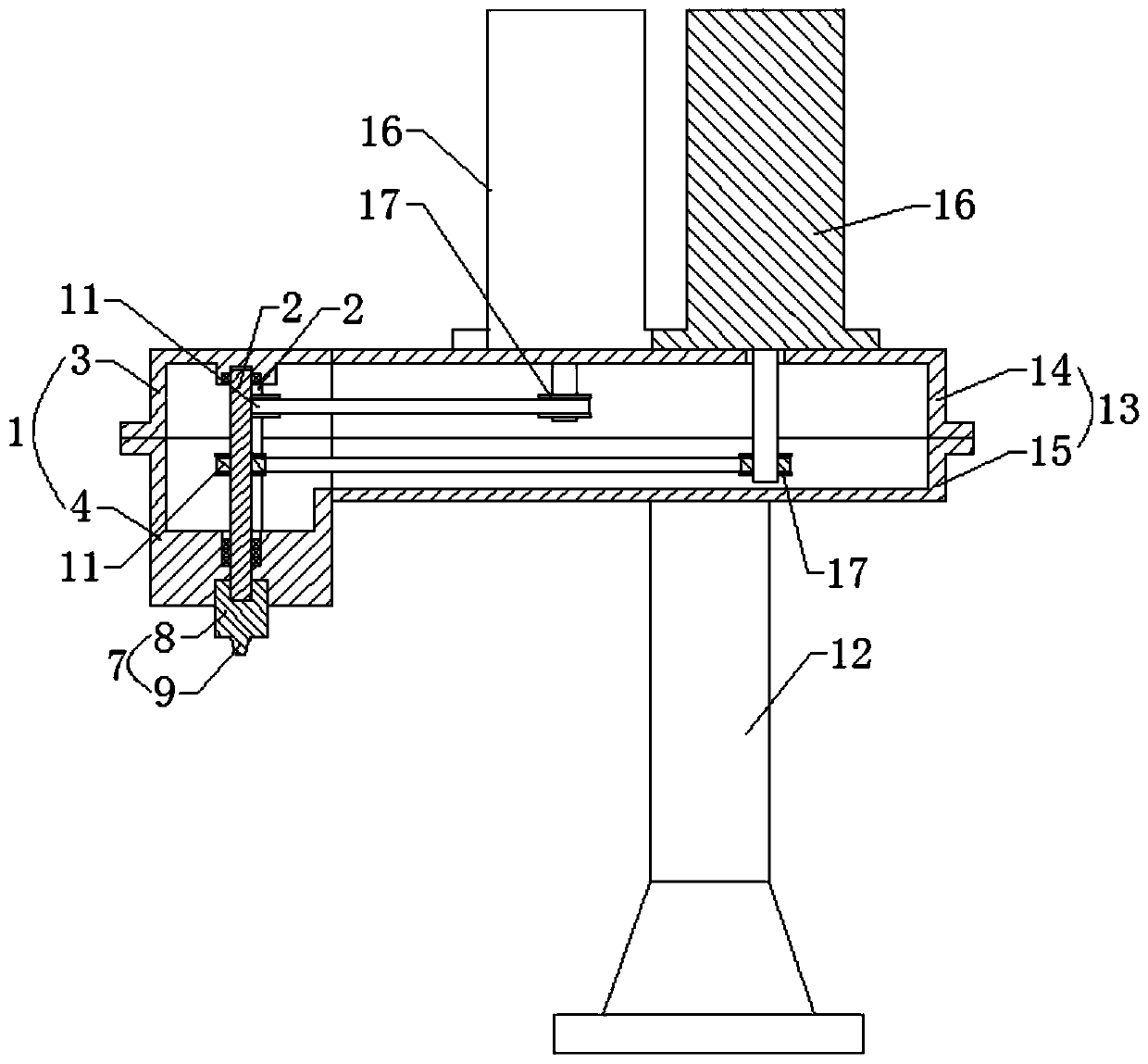

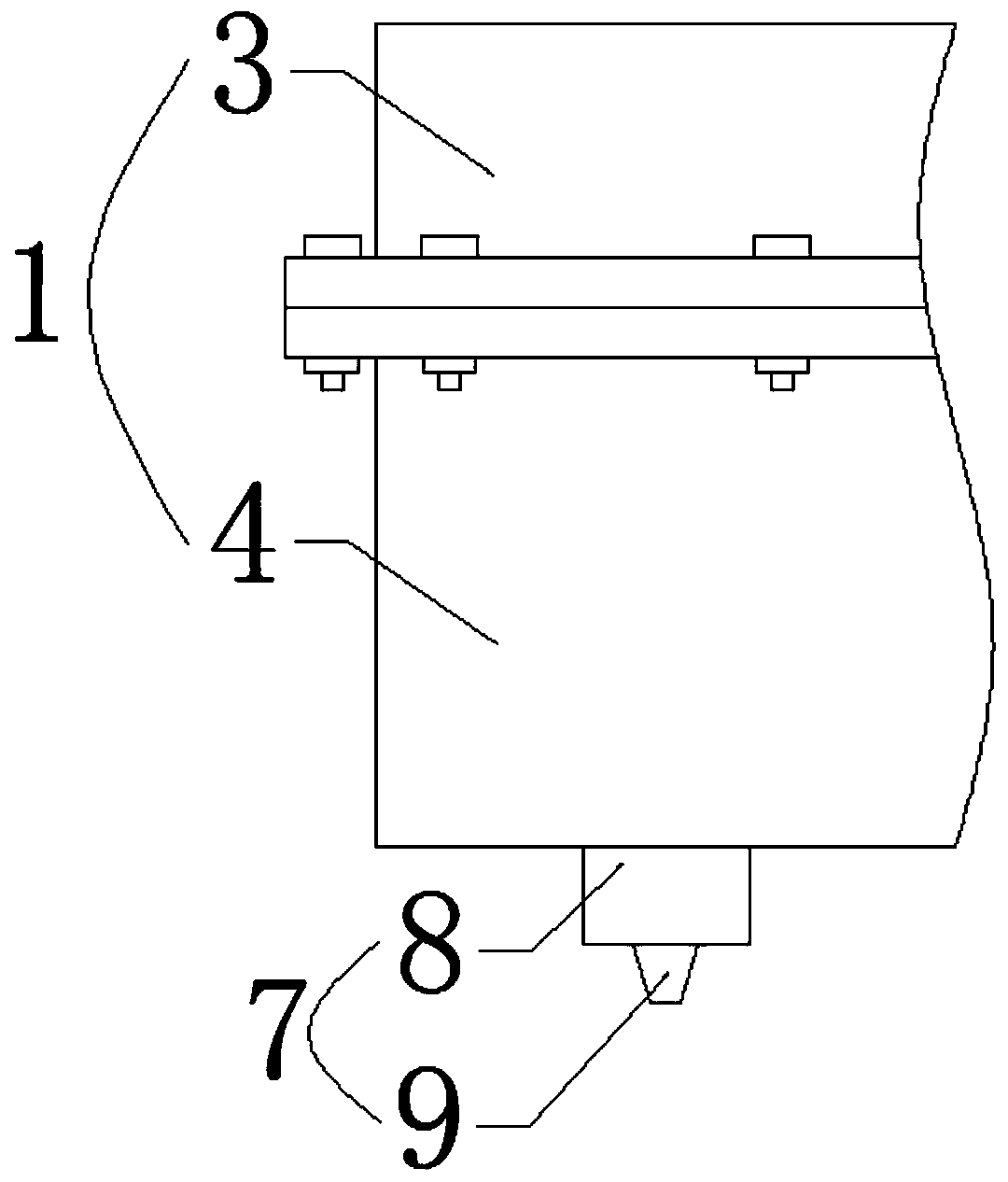

[0037] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

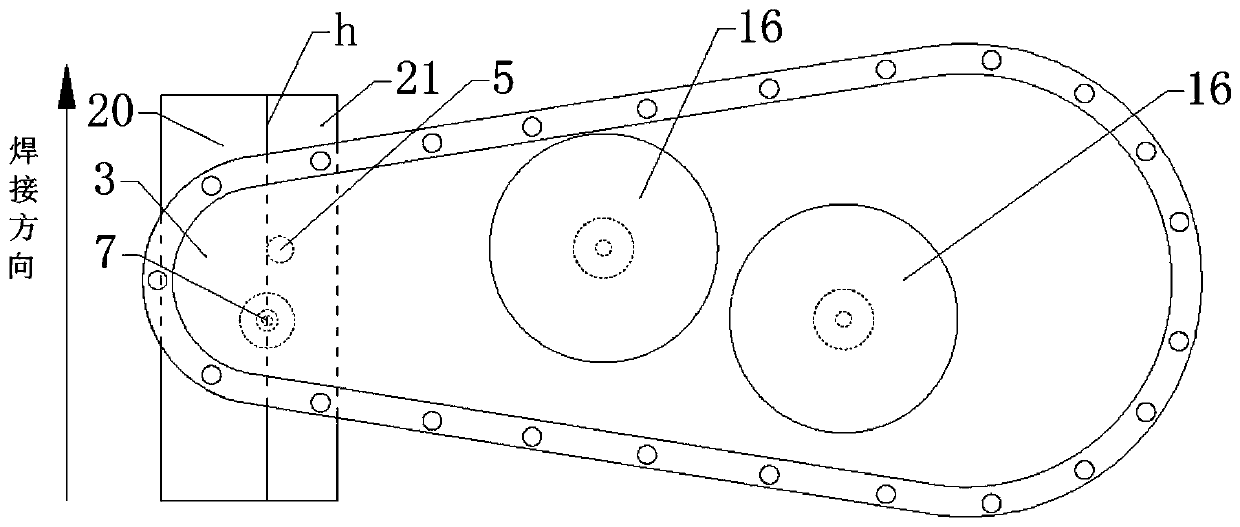

[0038] like Figure 1 to Figure 6 Shown, a kind of dissimilar metal friction stir welding method is characterized in that it is carried out according to the following steps:

[0039] Step 1. Cleaning: cleaning the first metal plate 20 with a high melting point and the second metal plate 21 with a low melting point to remove impurities and oil stains on the surfaces of the first metal plate 20 and the second metal plate 21;

[0040] Step 2, drying: drying the first metal plate 20 and the second metal plate 21;

[0041] Step 3. Welding: flatten the first metal plate 20 and the second metal plate 21 at the same level and press them against each other. To form the seam h to be welded, place the first metal plate 20 and the second metal plate 21 horizontally directly under the welding device, the welding device includes an outer shell 1 and two rotating parts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com