Super-thick Q355-grade hot-rolled H-shaped steel with good low-temperature toughness and production method thereof

A low-temperature toughness and production method technology, applied in temperature control, metal rolling, etc., can solve problems such as difficulty in ensuring strength and toughness, large rolling temperature difference, and large environmental pollution, and achieve low production costs and high mechanical properties of products. Excellent, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

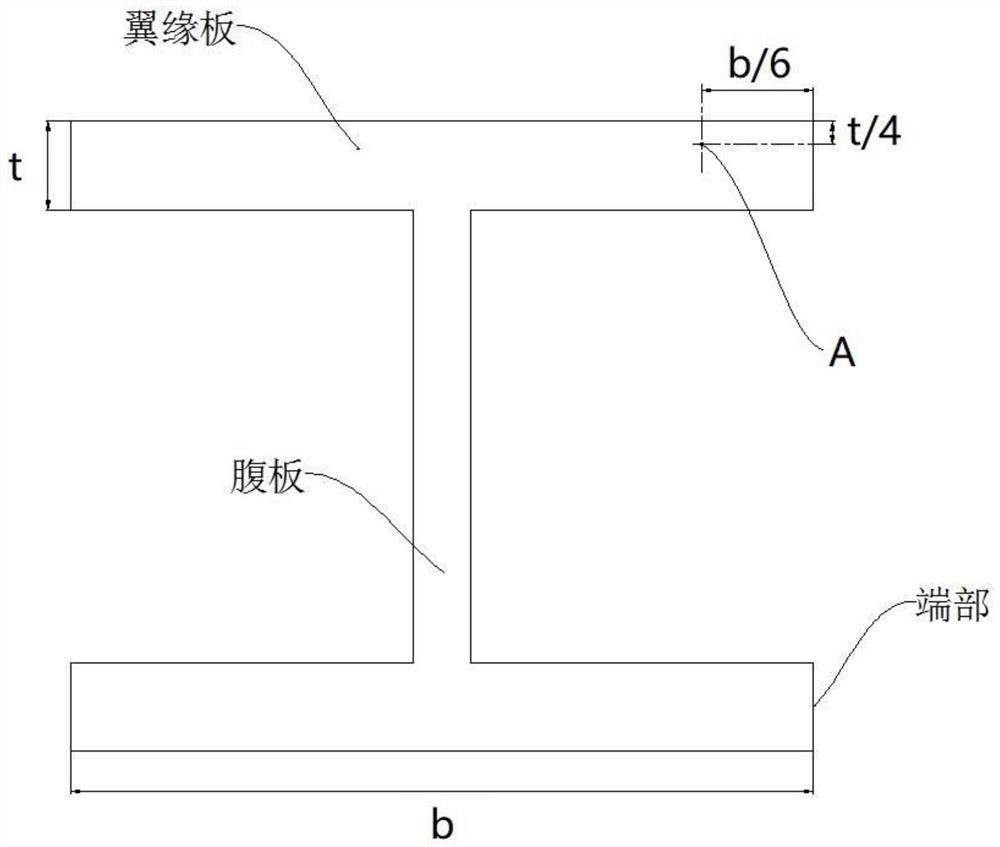

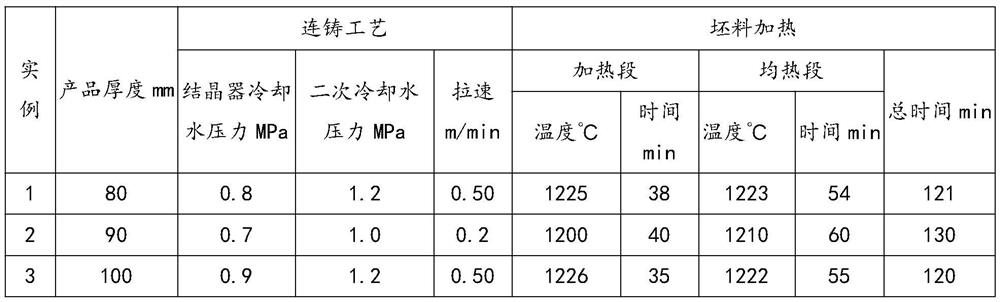

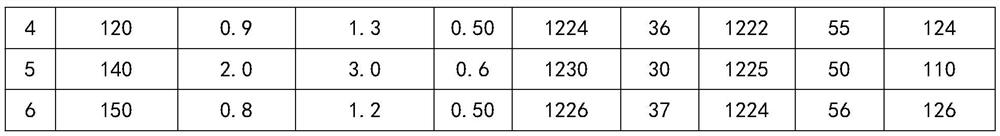

[0031] An ultra-thick Q355 hot-rolled H-shaped steel with good low-temperature toughness, the flange thickness t is 80-150mm, and the chemical composition is calculated by mass percentage, including C: 0.12-0.18%, Si: 0.10-0.50%, Mn: 1.20- 1.60%, Al: 0.02~0.06%, Nb: 0.02~0.06%, N: 0.0040~0.0100%, P≤0.015%, S≤0.005%, the rest is Fe and unavoidable impurities; CEV≤0.42%, Pcm≤ 0.25%,

[0032] Where CEV is obtained by the formula CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15,

[0033] Pcm is obtained by the formula Pcm=C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B;

[0034] The compositional design considerations are as follows:

[0035] The C content is set at 0.12 to 0.18%. C (carbon) is an element effective in strengthening steel, and is also an element that remarkably deteriorates the weldability of steel. Therefore, the lower limit of the C content is set to 0.12%. When the C content is greater than 0.18%, the carbon equivalent CEV and welding crack sensitivity index P of the H-beam wil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com