Patents

Literature

46results about How to "Weakened base texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

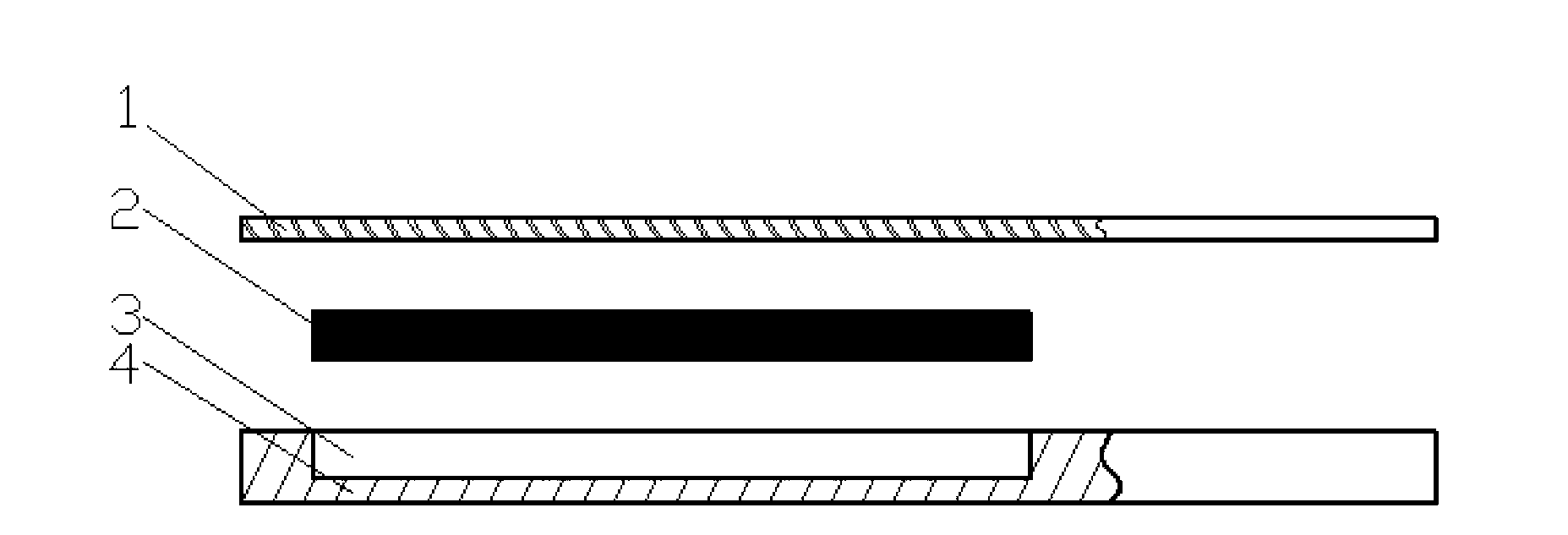

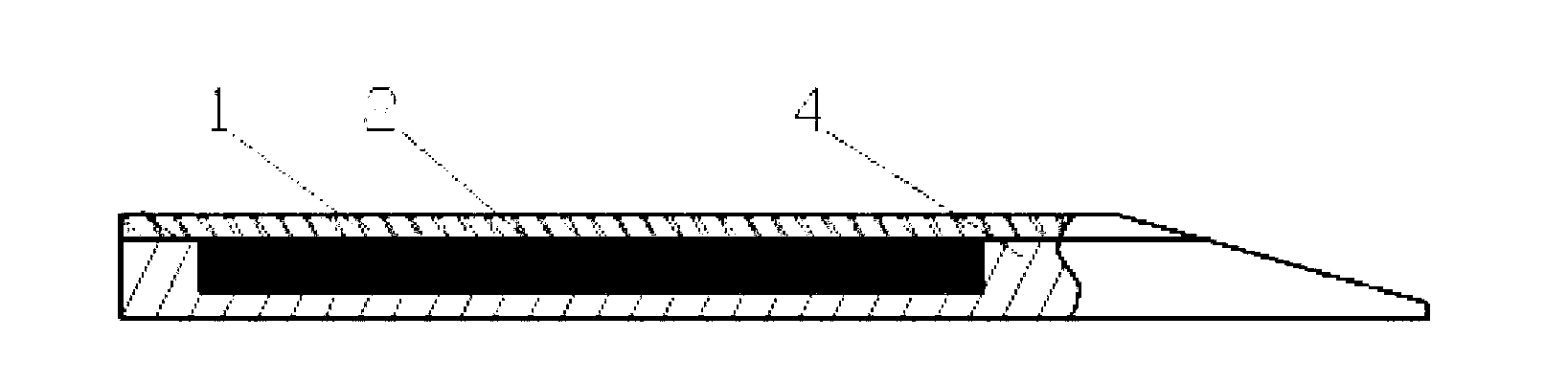

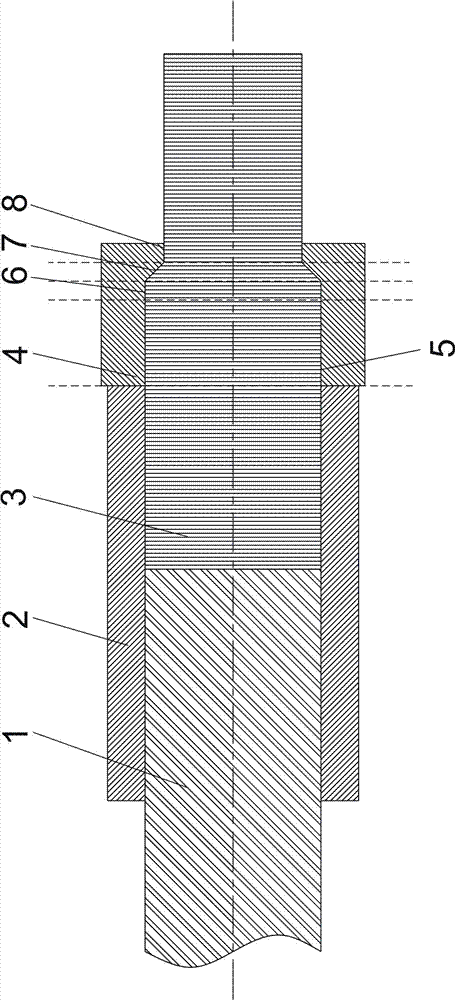

Rolling method of magnesium alloy packaged by aluminum plate

ActiveCN102909217AAvoid temperature dropWeakened base textureMetal rolling arrangementsAluminiumSurface plate

The invention relates to a rolling method of magnesium alloy packaged by an aluminum plate. The rolling method is designed by aiming at the defects of severe temperature drop and bad formability of magnesium alloy plates in the conventional rolling process. Pretreatment to the magnesium alloy plates after rolling comprises the following steps: step 1, setting an aluminum bottom plate to be a groove with a proper shape; step 2, placing the magnesium alloy in the groove and taking an aluminum face plate for covering the surface of the magnesium alloy; and step 3, welding the aluminum bottom plate with the aluminum face plate by adopting the welding process and setting a bevel. With the adoption of the rolling method, temperature drop of the magnesium alloy plate in the rolling process can be prevented, base face texture of the plates is obviously weakened, edge crack of the magnesium alloy caused by low temperature in the rolling process is reduced simultaneously, the deformability is improved, the time is saved, and the work efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

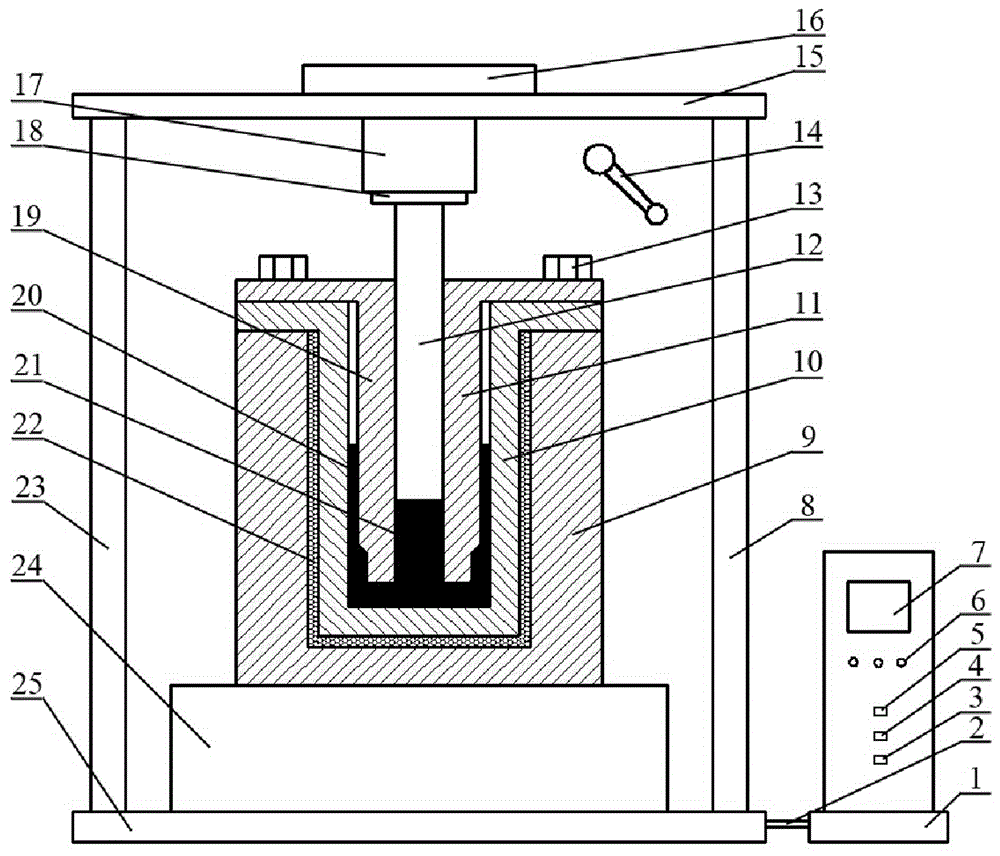

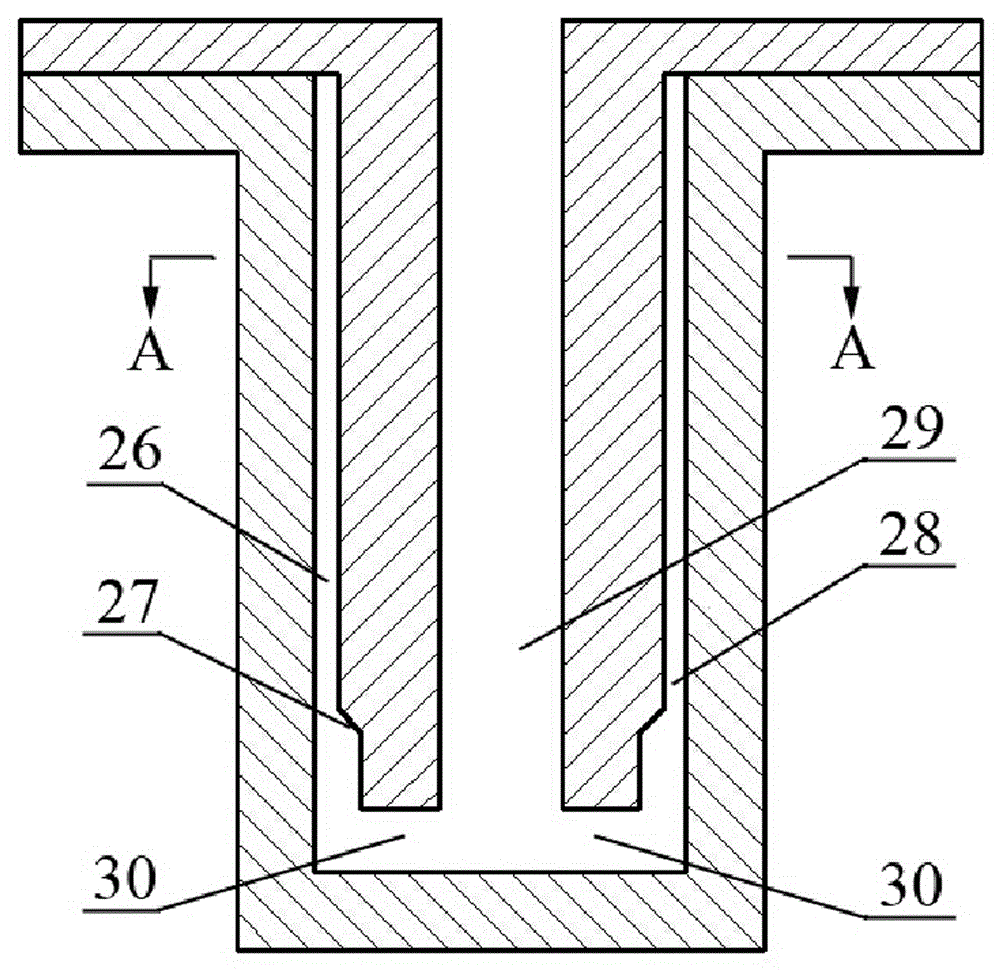

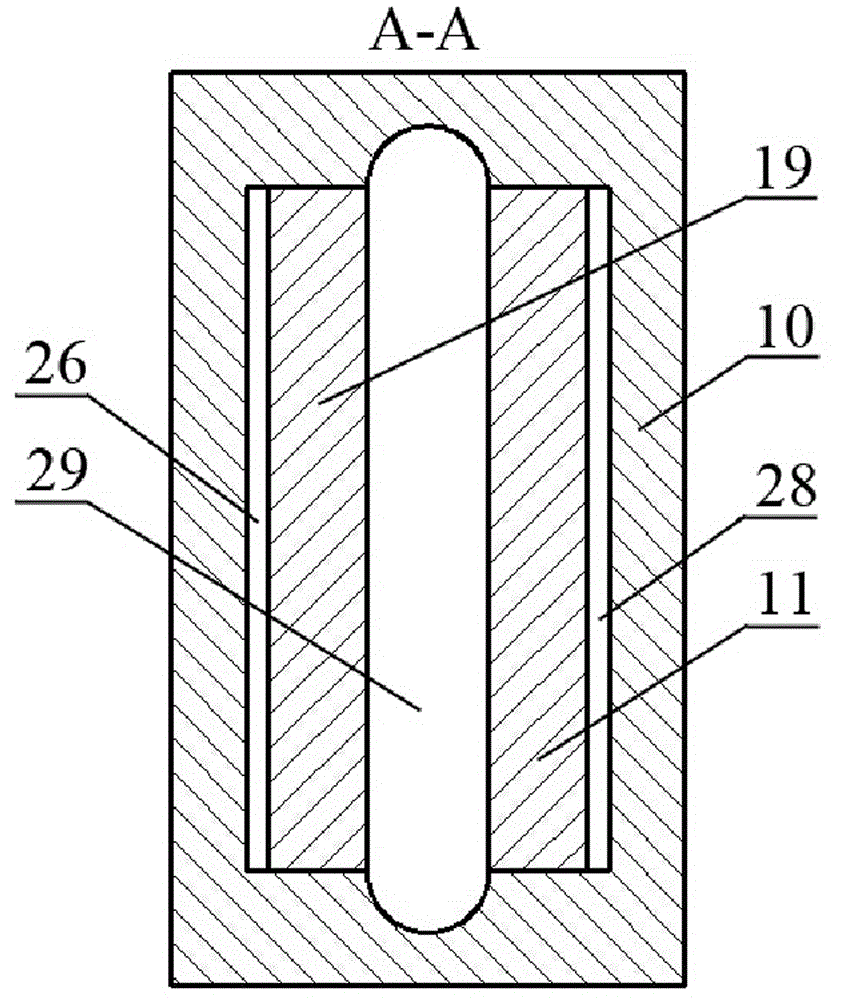

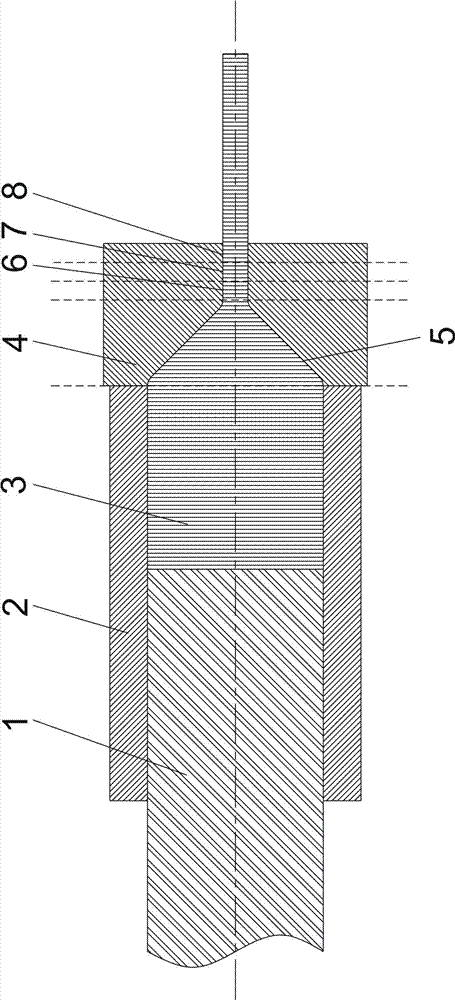

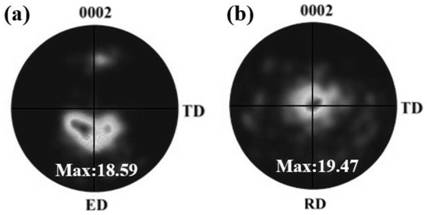

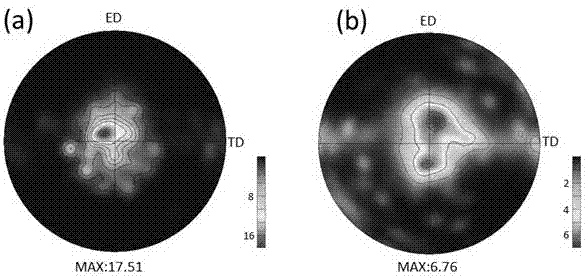

Extrusion processing method of high-performance magnesium alloy sheet material

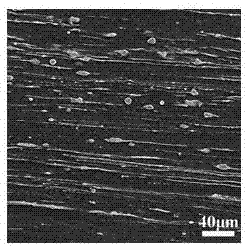

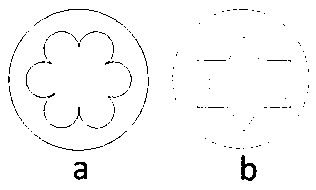

InactiveCN104815864ARefined grain structureWeakened base textureExtrusion diesShearing deformationCrystallite

The invention relates to enhancing of performances and improvement of a processing method of a magnesium alloy sheet material and particularly relates to an extrusion processing method of the high-performance magnesium alloy sheet material and belongs to the field of the technical fields of plastic processing and mechanical performance enhancing of nonferrous metals. In the invention, by means of the novel extrusion processing method, the magnesium alloy material is subjected to distribution, two cross-section-varying angular extrusion deformations and differential shear deformation during the extrusion process, wherein crystal grain tissue is continuously fined and the c axis of the crystal grains is continuously turned so that the basal texture is continuously weakened, thereby refining the crystal grain tissue, weakening the basal texture and enhancing the mechanical performances. By means of the method, two high-performance magnesium alloy sheet materials can be produced just by one extrusion operation. The processing method is simple, is low in cost, is high in efficiency and is easy to carry out, is excellent in large-scale application prospect and is a very excellent processing method for producing the magnesium alloy sheet material.

Owner:TAIYUAN UNIV OF TECH

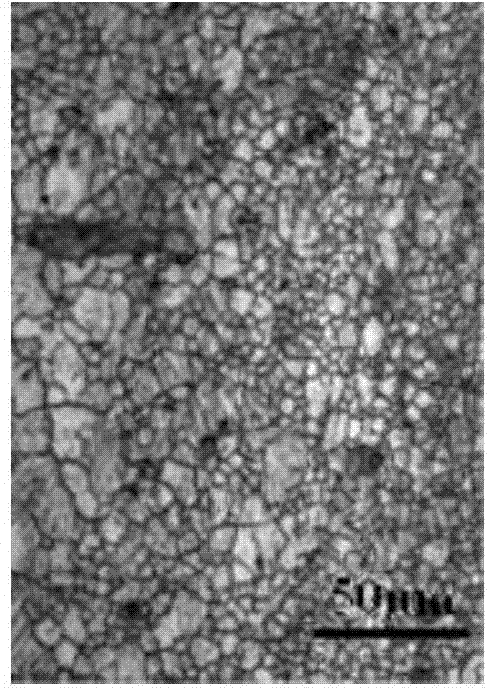

Method for preparing fine-grained magnesium alloy with superplastic deformability

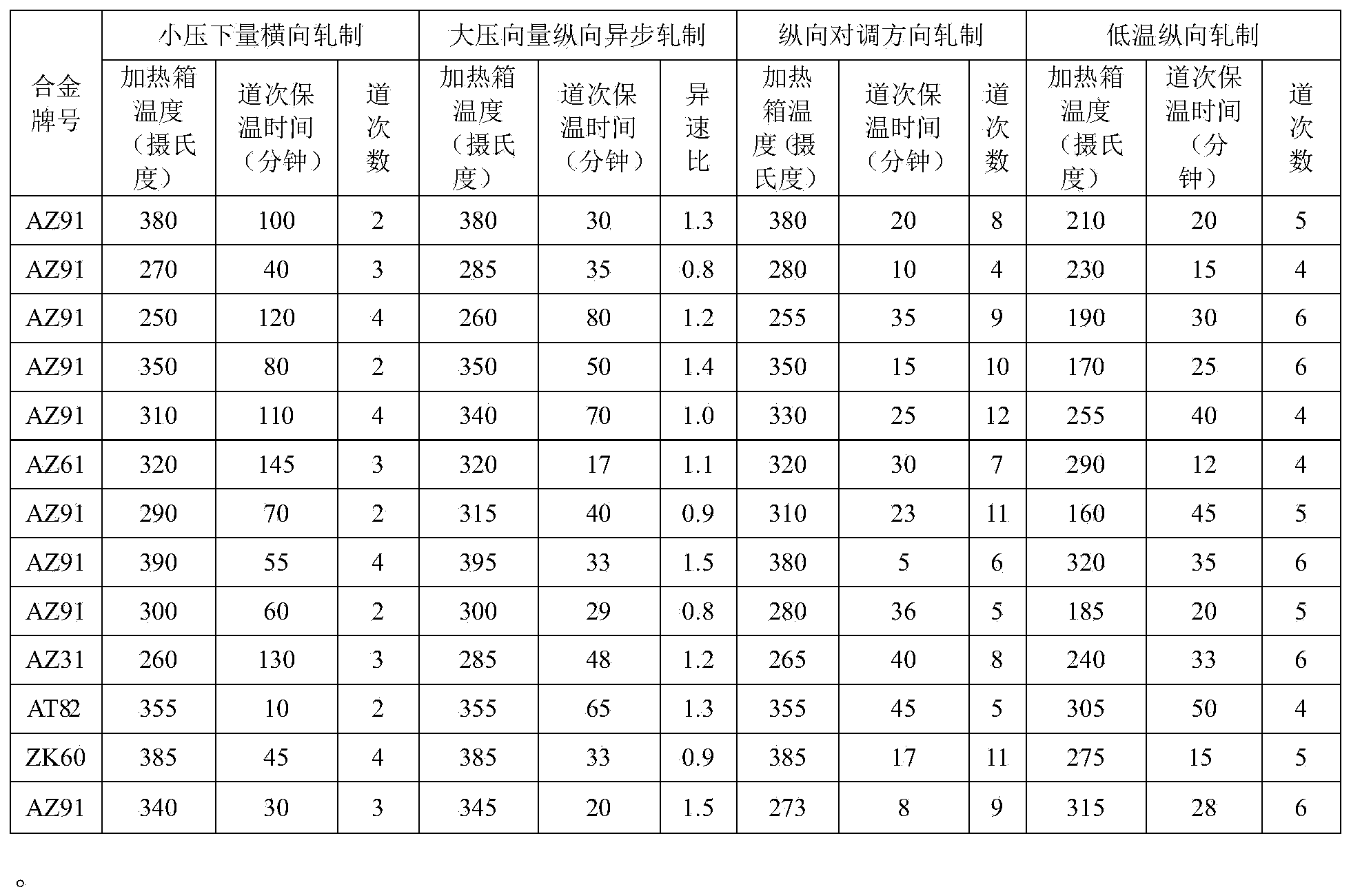

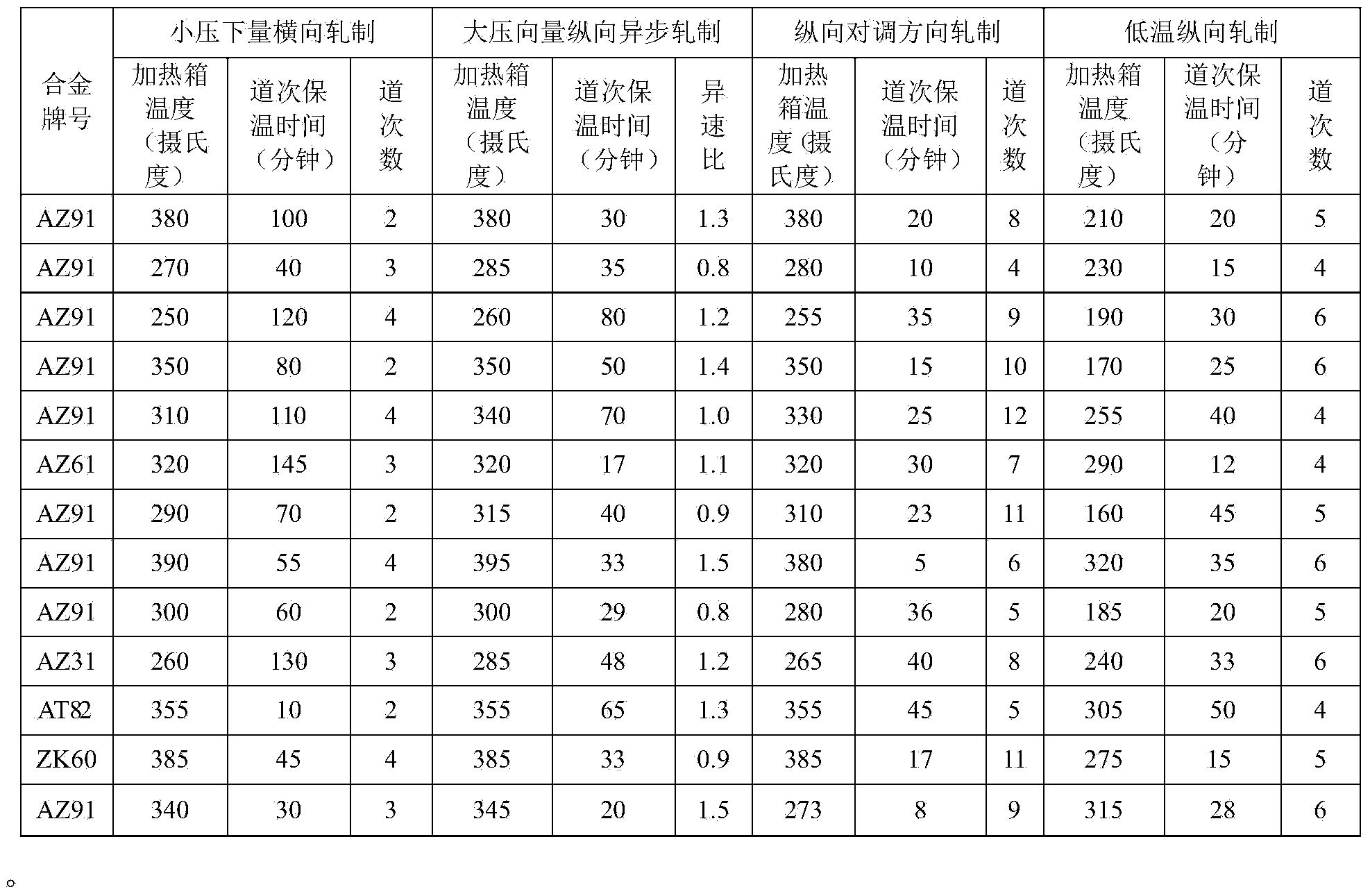

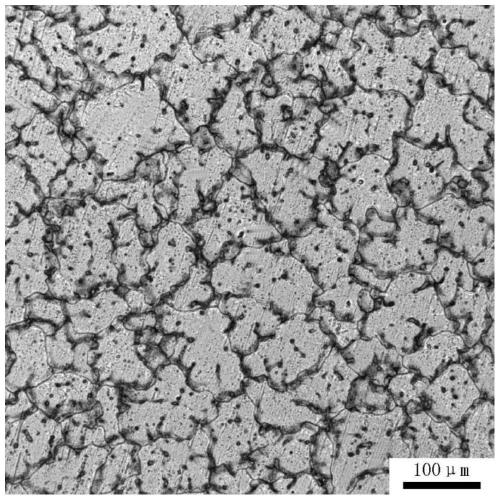

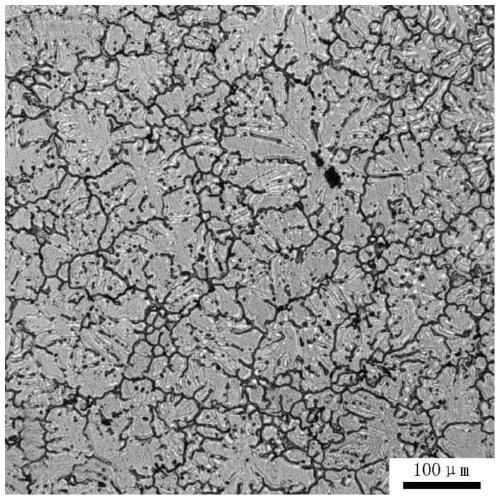

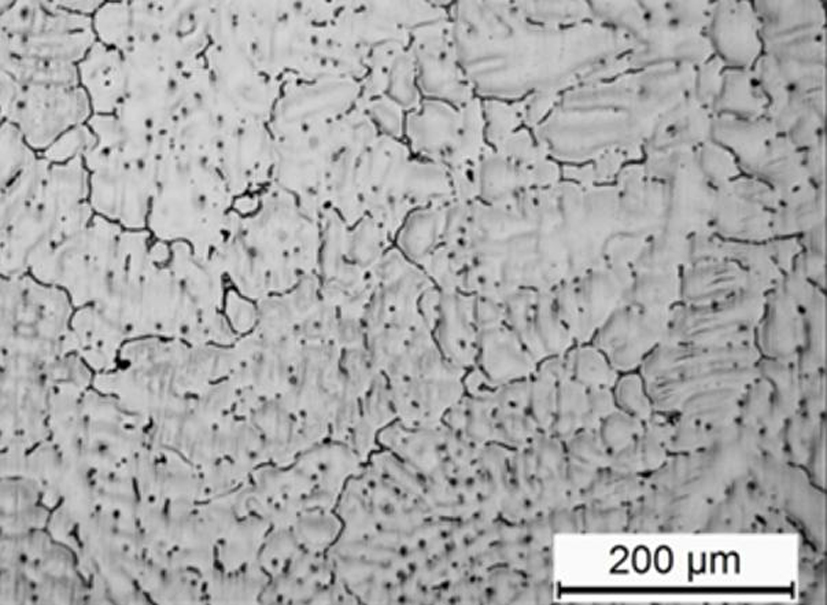

The invention relates to a method for rolling fine-grained magnesium alloy with superplastic deformability. The method comprises the steps of low-rolling-reduction transverse rolling, high-rolling-reduction longitudinal asynchronous rolling, longitudinal reversed-direction rolling, low-temperature longitudinal rolling and annealing, and comprises the specific steps of heating a commercial magnesium alloy blank in a heating box, standing to preserve heat for a period of time after heating to a preset temperature, firstly pushing the magnesium alloy blank to an entrance of a rolling roller along the transverse direction, carrying out transverse rolling firstly, then, carrying out high-rolling-reduction longitudinal asynchronous rolling, then, carrying out longitudinal 180-degree-reversed rolling, then, carrying out low-temperature longitudinal rolling, and finally, carrying out low-temperature long-time annealing treatment or high-temperature short-time annealing treatment. According to the method, cracking during the rolling of the magnesium alloy can be reduced, the crystal grain of the magnesium alloy is refined, the texture is weakened, and the high-temperature plasticity of the magnesium alloy is improved; moreover, the process is simple and easy to operate, large-sized wide-width sheet materials can be prepared, and the formability of the magnesium alloy is improved remarkably, so that the method is applicable to the mass production of superplastic magnesium alloy and is prone to popularization and application.

Owner:JILIN UNIV

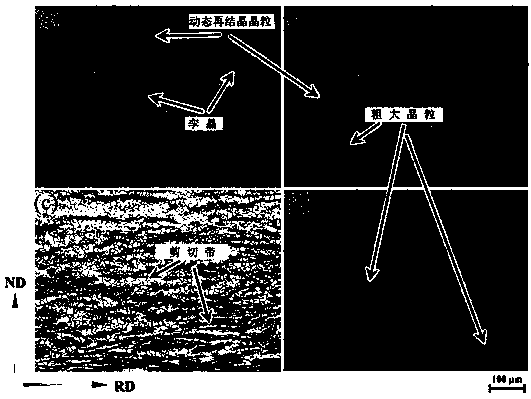

High-plasticity magnesium alloy and preparation method thereof

The invention discloses a high-plasticity magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by mass: 3-4% of Zn, 0.1-0.6% of Ca, 0.05-0.8% of Mn, and the balance of Mg and inevitable impurities. Ca and Mn are added in a magnesium zinc alloy to prominently refine alloy grains; in hot extrusion process, the dynamic recrystallization can be promoted to stop growth of recrystallized grains, so that the strength and the plasticity of the alloy are synchronously improved, the base surface texture of the alloy can be prominently weakened, and the plasticity of the alloy is improved; in addition, through separation of a second phase and dispersion and separation of nanoscale Mn particles, the strength of the alloy can be effectively improved; the magnesium alloy is high in plasticity; and the component-optimized alloy can reach the ductility of 25-29.8%, the yield strength of 160-205 MPa and the tensile strength of 270-289 MPa.

Owner:CHONGQING UNIV

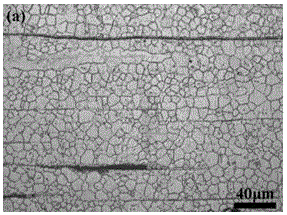

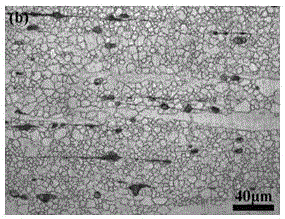

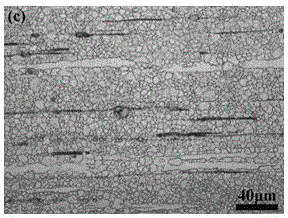

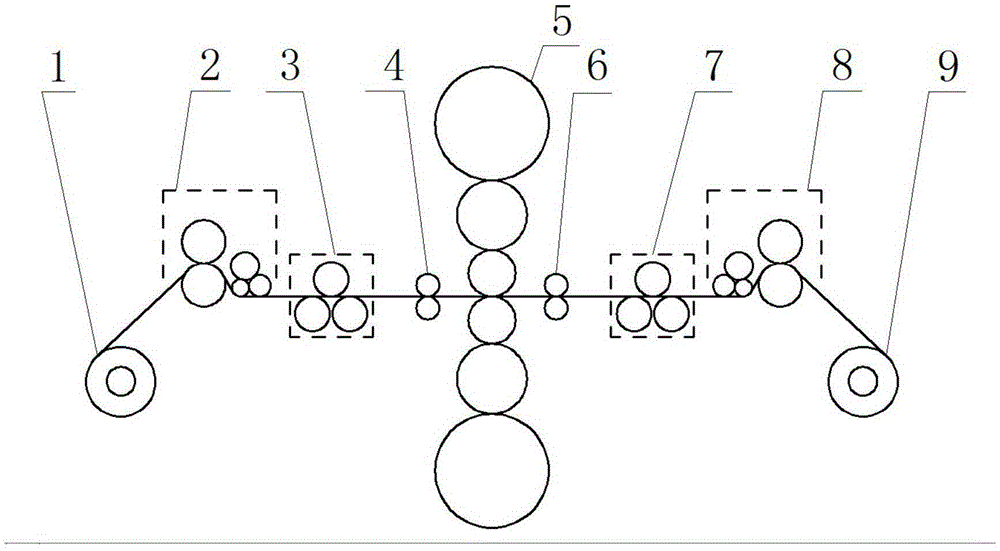

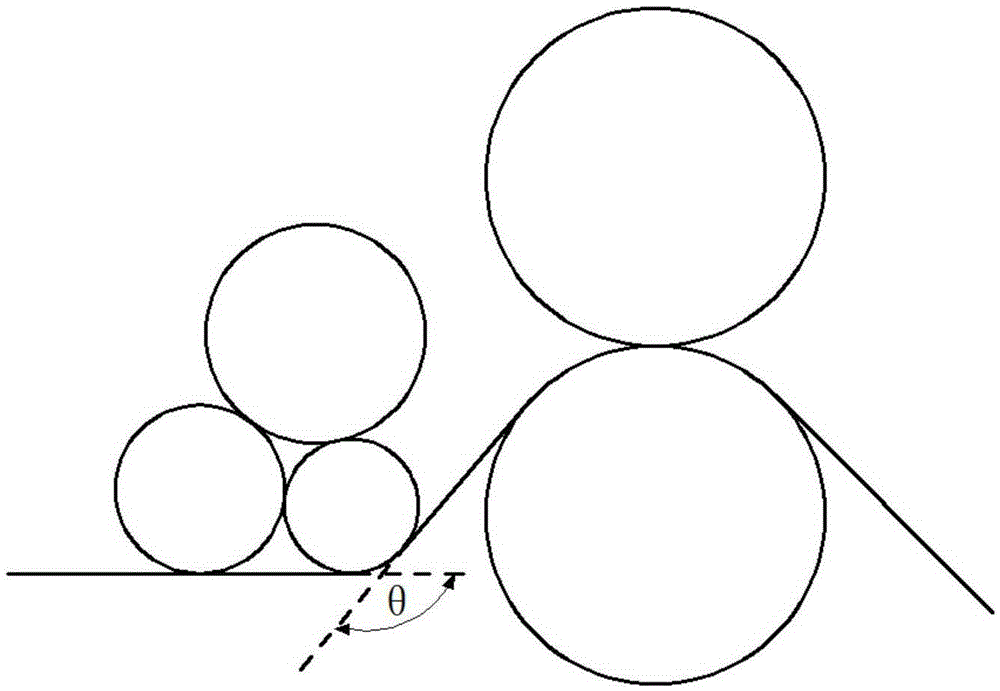

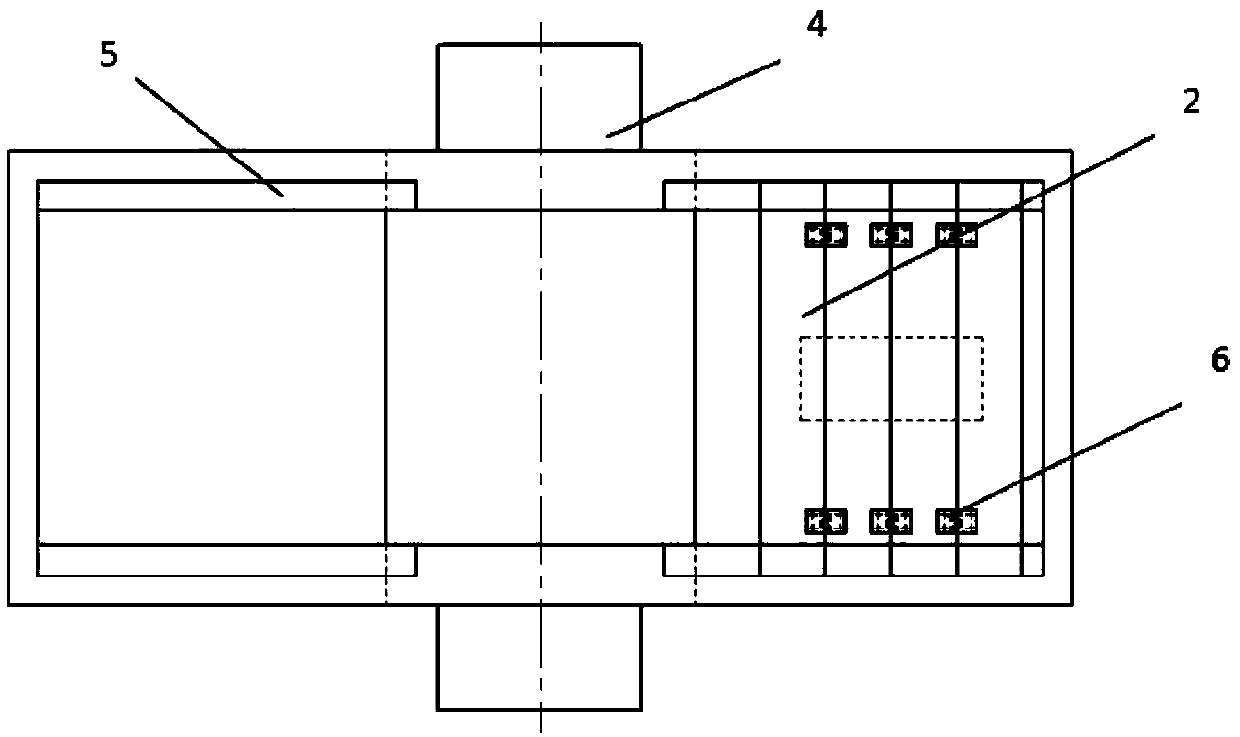

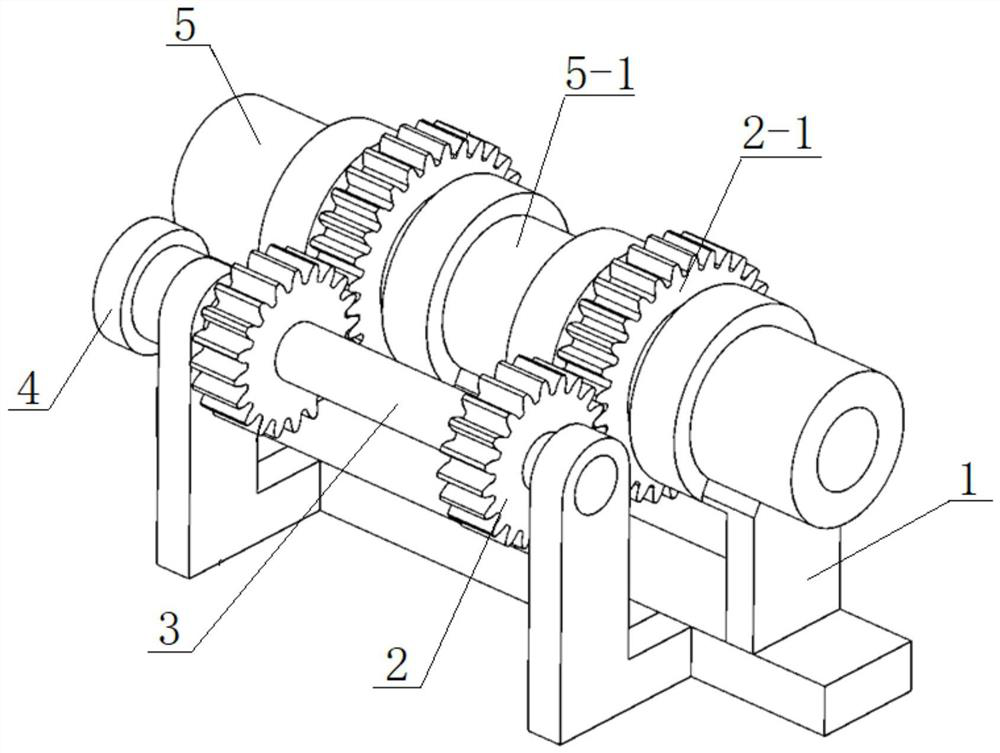

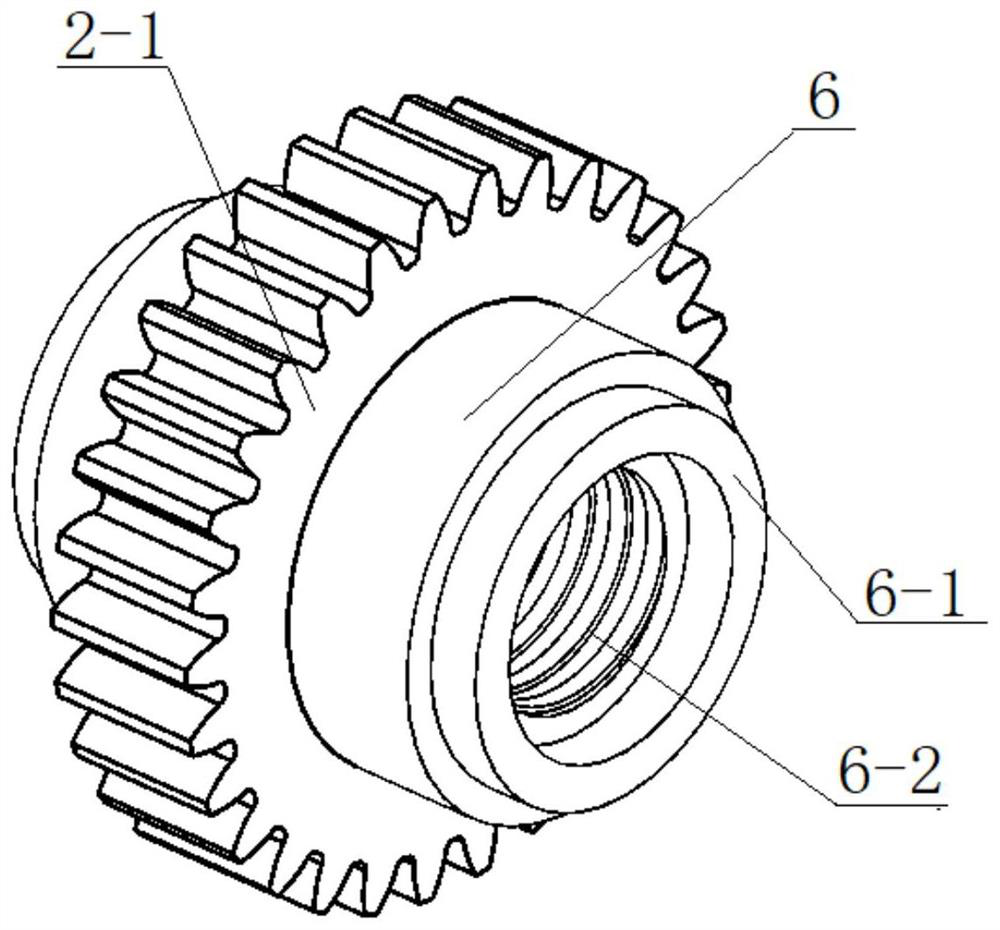

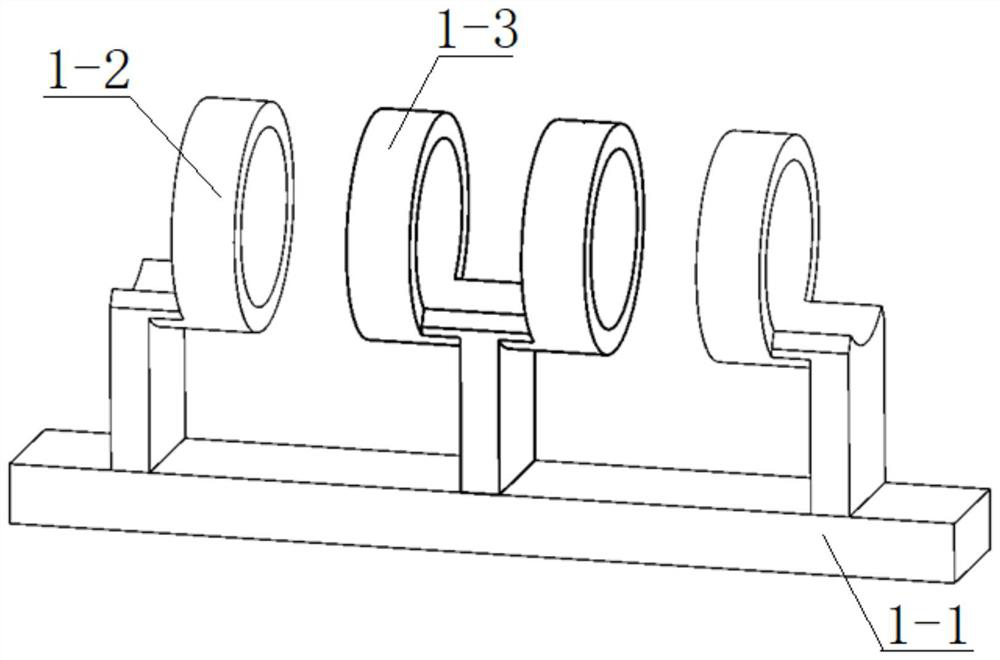

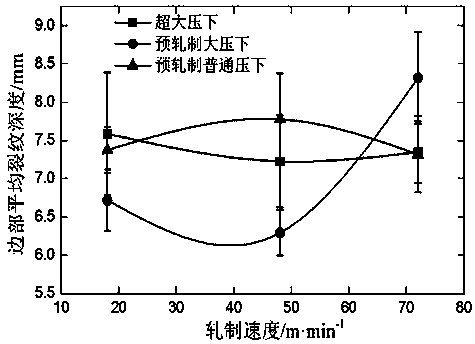

Magnesium alloy sheet strip coupling and deformation combined rolling system and rolling method thereof

ActiveCN105290108ASolve the mechanical propertiesSolve the shapeMetal rolling arrangementsCouplingMetallurgy

The invention relates to a magnesium alloy sheet strip coupling and deformation combined rolling system and a rolling method thereof, and mainly solves the technical problems of strong mechanical anisotropy, bad plate shape and edge crack defects and low yield of rolled magnesium alloy sheet strips in a traditional rolling process and low production efficiency in an equal channel angular rolling method. The magnesium alloy sheet strip coupling and deformation combined rolling system consists of two uncoiling-coiling machines, two five-roller shearing and bending large deformation adjusting devices, two three-roller straightening machines, two roller clamping and feeding devices and a six-roller reversible rolling machine, wherein the uncoiling-coiling machines, the five-roller shearing and bending large deformation adjusting devices, the three-roller straightening machines and the roller clamping and feeding devices are arranged at the front and back edges of the six-roller reversible rolling machine in sequence to realize reciprocating rolling of magnesium alloy sheet strips. The rolling method of the rolling system comprises the following steps: the reciprocating rolling is performed for uncoiled magnesium alloy strip coils in sequence through the equipment; and the system is stopped when the finished product rolling is finally finished.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

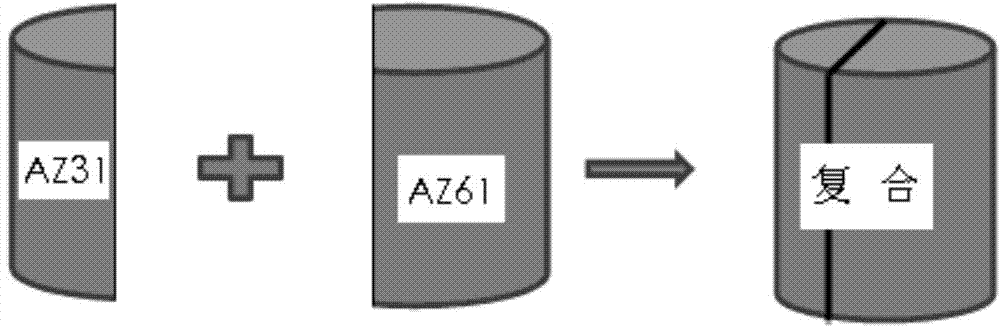

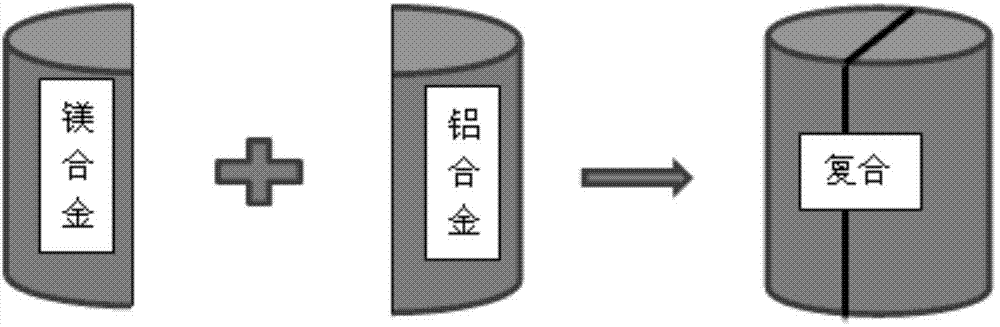

Extruding method for texture-weakened magnesium alloy sheet

A disclosed extruding method for a texture-weakened magnesium alloy sheet comprises: 1) getting at least two heterogenous magnesium alloy blocks or magnesium alloy and aluminium alloy, superposing and fixing; 2) putting the superposed magnesium alloy block or the magnesium-alloy aluminium-alloy block obtained in the step 1) into an extrusion cylinder for extruding, and enabling the alloy block to be synchronously extruded from the extrusion die orifice, so as to obtain a magnesium-magnesium or magnesium-aluminium composite sheet; and 3) removing the aluminium layer or the relatively-thin magnesium layer on the composite sheet, so as to obtain the texture-weakened magnesium alloy sheet, wherein the magnesium alloy is preferably AZ31, AZ61 and AZ80 wrought magnesium alloy, and aluminium alloy is preferably 5052 and 6063. Thickness-direction metal mixing does not happen in the magnesium alloy sheet or the magnesium-alloy aluminium-alloy sheet during extrusion, also the two sides of the sheet when being extruded possesses a relatively large flow velocity difference, thus shear stress is introduced into the same magnesium alloy block, and the effects of refining crystal grain and weakening texture are given play. By employing the method of firstly performing combination and extrusion and then peeling off the relatively-thin magnesium layer, the crystal grain is obviously refined, and the texture is weakened.

Owner:CHONGQING UNIV

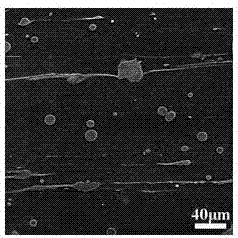

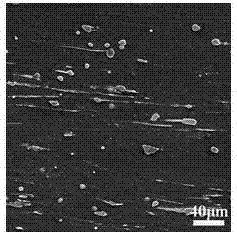

Rolling machining method for improving microstructure texture and mechanical property of magnesium alloy sheet strip

InactiveCN105234173AWeaken base textureControllable grain sizeMetal rolling arrangementsCrystalliteGrain boundary

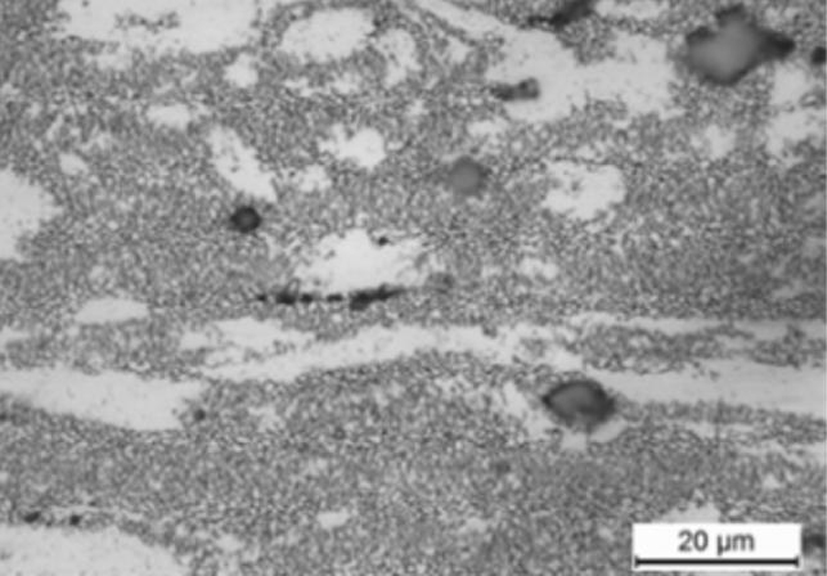

The invention discloses a rolling machining method for improving the microstructure texture and the mechanical property of a magnesium alloy sheet strip. Cooling continuous rolling is carried out on a magnesium alloy cogging panel, wherein the rolling starting temperature ranges from 250 DEG C to 500 DEG C, the number of continuous rolling times is two to eight, and one-time rolling reduction ranges from 2% to 20%; 200 DEG C-450 DEG C intermediate annealing is carried out after continuous rolling, wherein the annealing time ranges from 1 min to 60 min; and then the cooling continuous rolling step is repeatedly executed until the thickness of a magnesium alloy sheet reaches the needed size. According to the rolling machining method, through a cooling continuous rolling technology, base face slippage, taper face slippage and twinborn and grain boundary slippage can be started at the same time in the rolling process of the magnesium alloy sheet strip; meanwhile, the continuous rolling process facilitates grain accumulation coordinated deflection, and the base face texture inclines and is weakened; and the grain size of the magnesium alloy sheet strip is controllable through combination of the annealing process, and the mechanical property of a magnesium alloy is obviously improved.

Owner:GUIZHOU UNIV

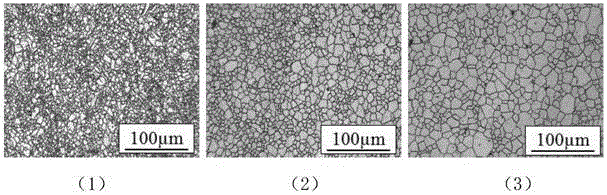

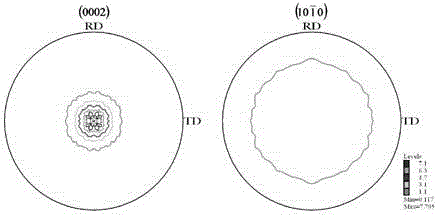

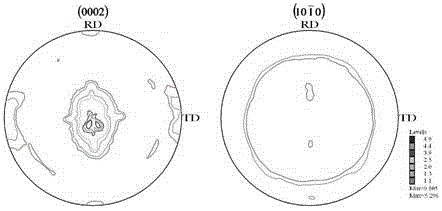

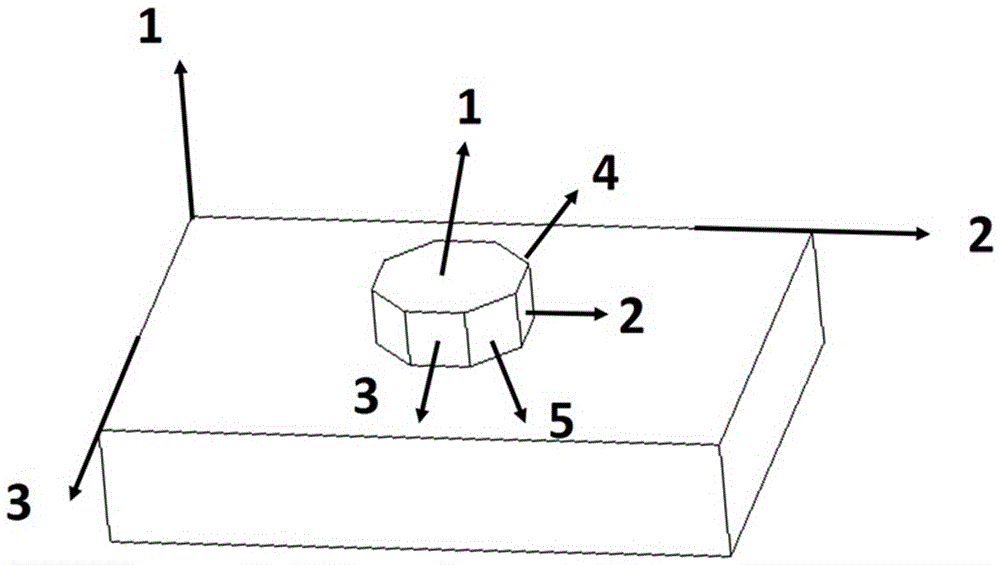

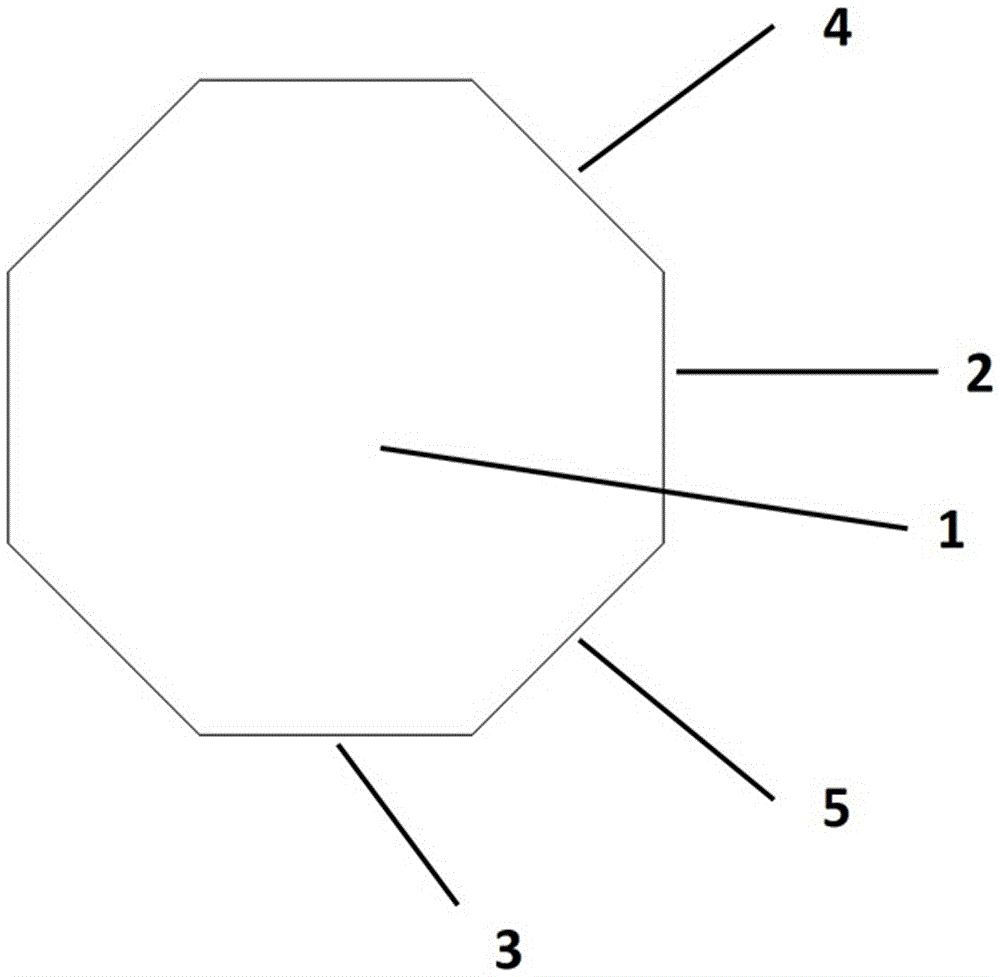

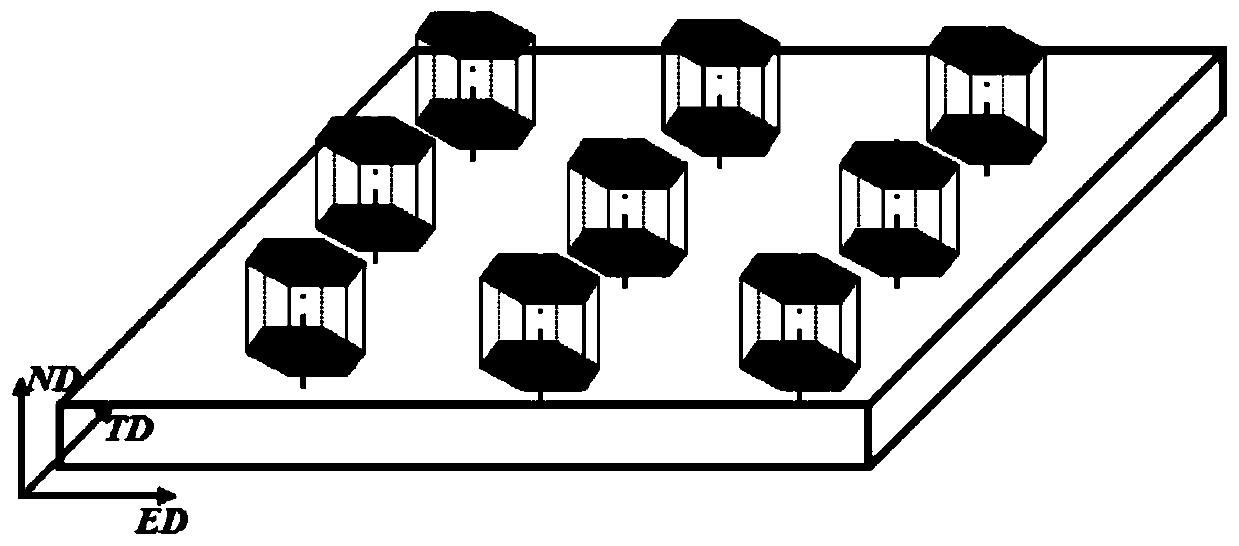

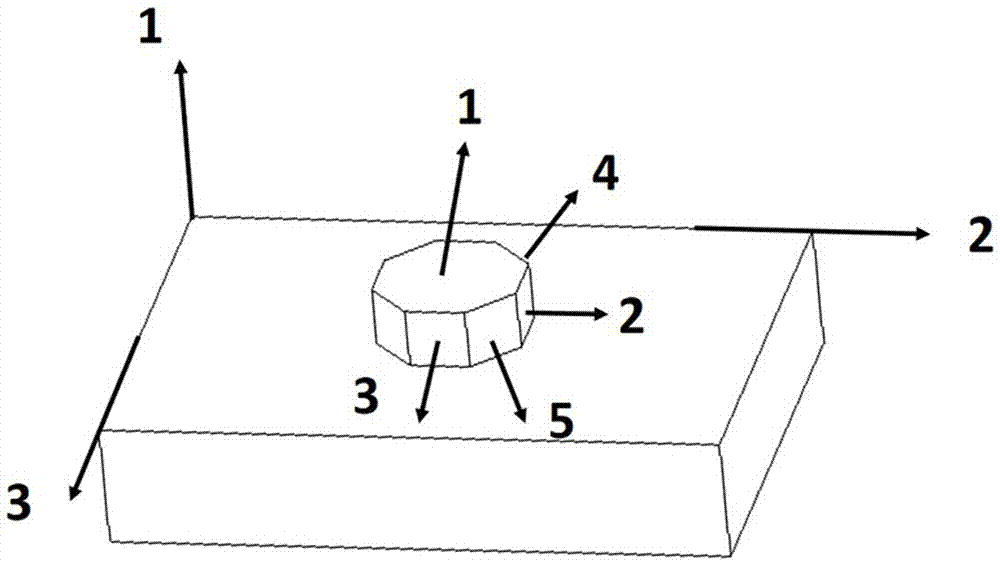

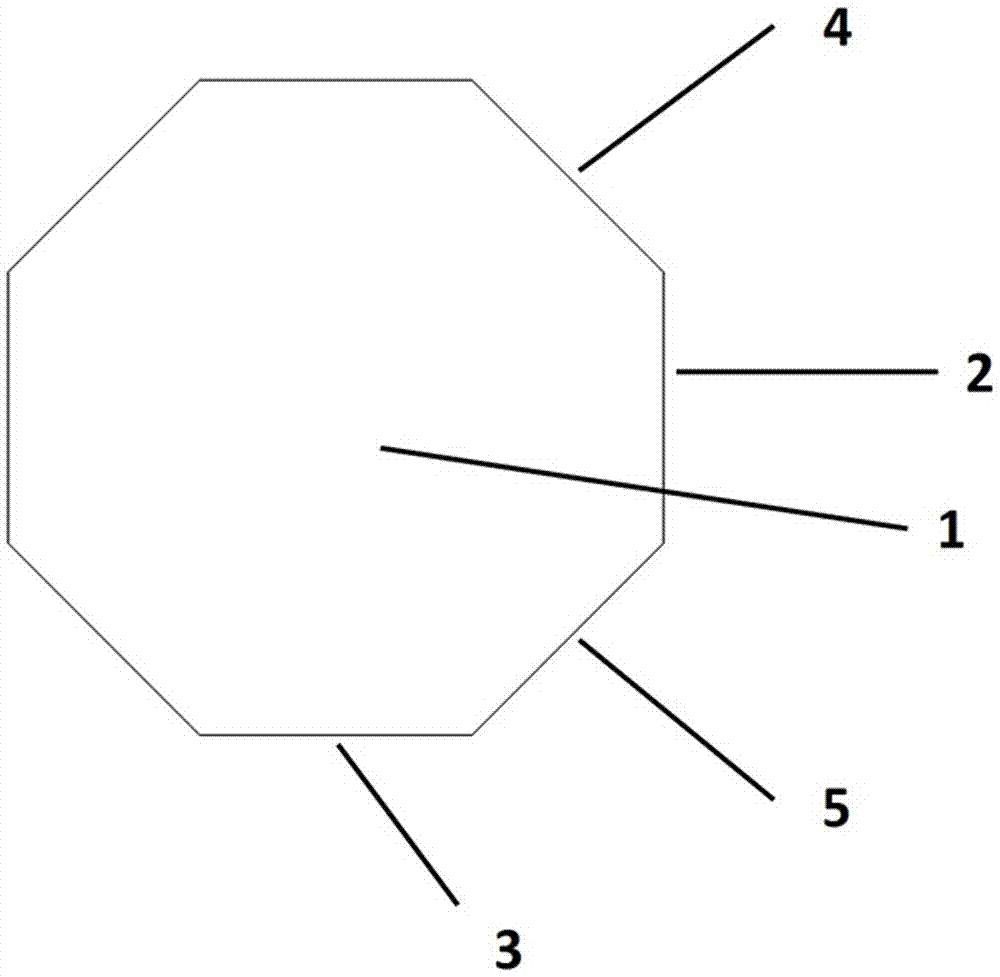

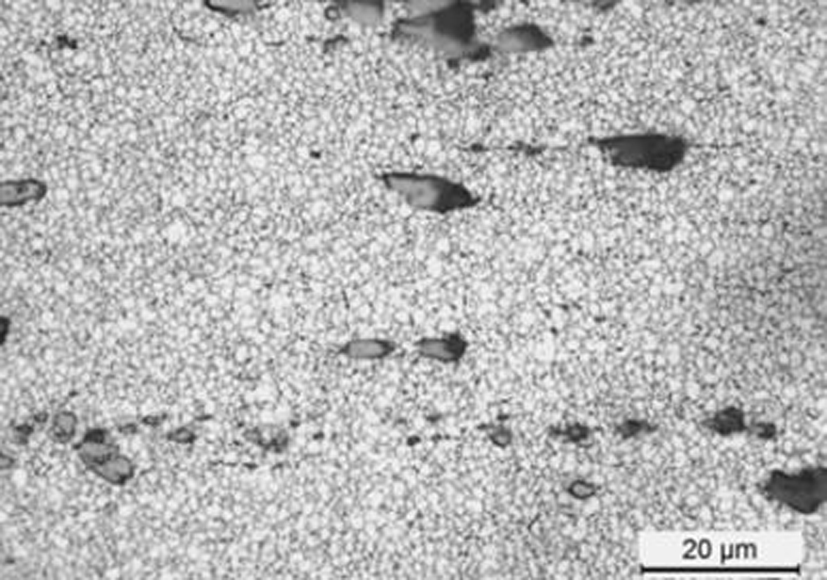

Magnesium alloy grain refining method

The invention discloses a magnesium alloy grain refining method. The method comprises the steps that a regular eight-edge prism plate is designed, multi-direction combination is conducted by selecting a specific direction, circulating multi-direction room-temperature deformation is conducted along the combination, and middle-temperature short-time annealing is conducted after the deformation amount is accumulated to a certain extent. The plate is subjected to combined deformation in the specific direction, primary contraction twin, secondary contraction twin and primary stretching twin are introduced, mutual cross partition between the different twins is brought into full play so that grains can be refined, in the annealing process, the deformation storage energy in the twins is high, and abundant nucleation positions can be provided, so that even recrystallized small grains are obtained in a short time, the basal texture of a magnesium alloy plate is weakened, and accordingly the strength and the forming performance of the magnesium alloy plate are greatly improved.

Owner:FUZHOU UNIV

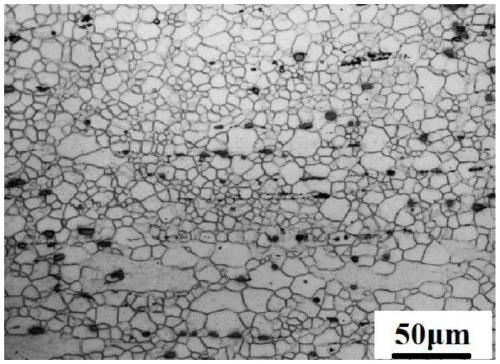

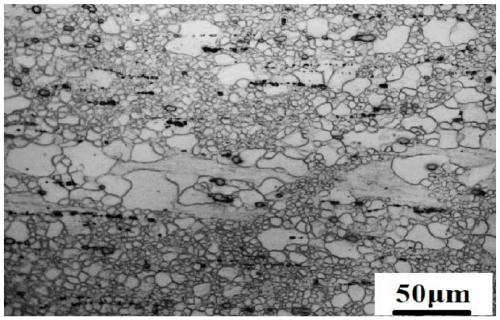

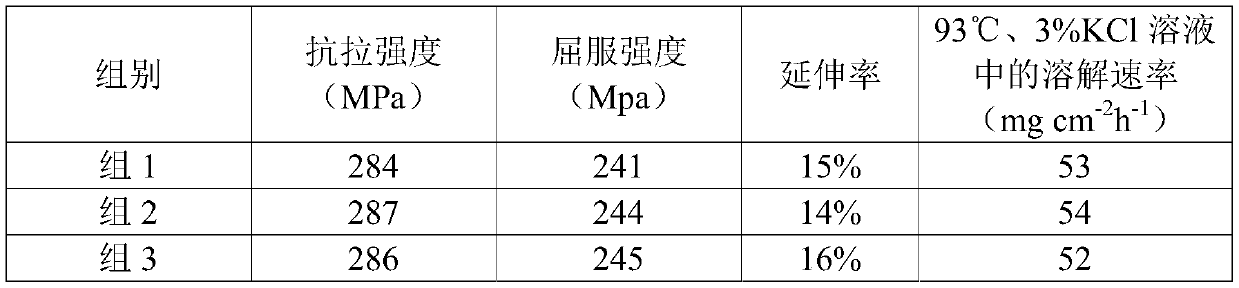

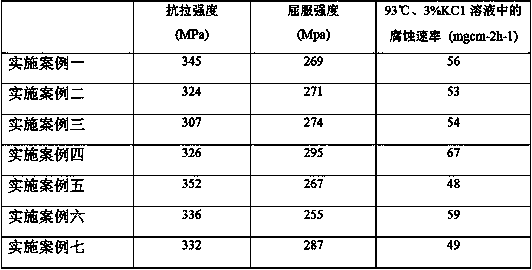

Low-cost soluble magnesium alloy and preparation method and application thereof

The invention belongs to the technical field of metal materials and processing, and relates to a low-cost soluble magnesium alloy and a preparation method and application thereof. The low-cost solublemagnesium alloy is used for preparing spare parts related to a multi-stage sliding sleeve sectional fracturing technology in shale oil and gas production. The alloy is Mg-Al-Ca-Mn-Cu-Ni magnesium alloy and comprises the following components in percentage by mass: 0.20-0.50wt% of Al, 0.20-1.00wt% of Ca, 0.30-1.10wt% of Mn, 0.10-1.20wt% of Cu, 0.10-0.50wt% of Ni, and the balance Mg and inevitable impurity elements. According to the low-cost soluble magnesium alloy prepared by the method, the tensile strength is not less than 280MPa; the yield strength is not less than 240MPa; the ductility is not less than 14%; and the dissolving rate in 3% KCl solution under the temperature of 93 DEG C is 50-60mg cm<-2>h<-1>.

Owner:重庆昱华新材料科技有限公司

Method for improving plasticity of magnesium alloy sheets

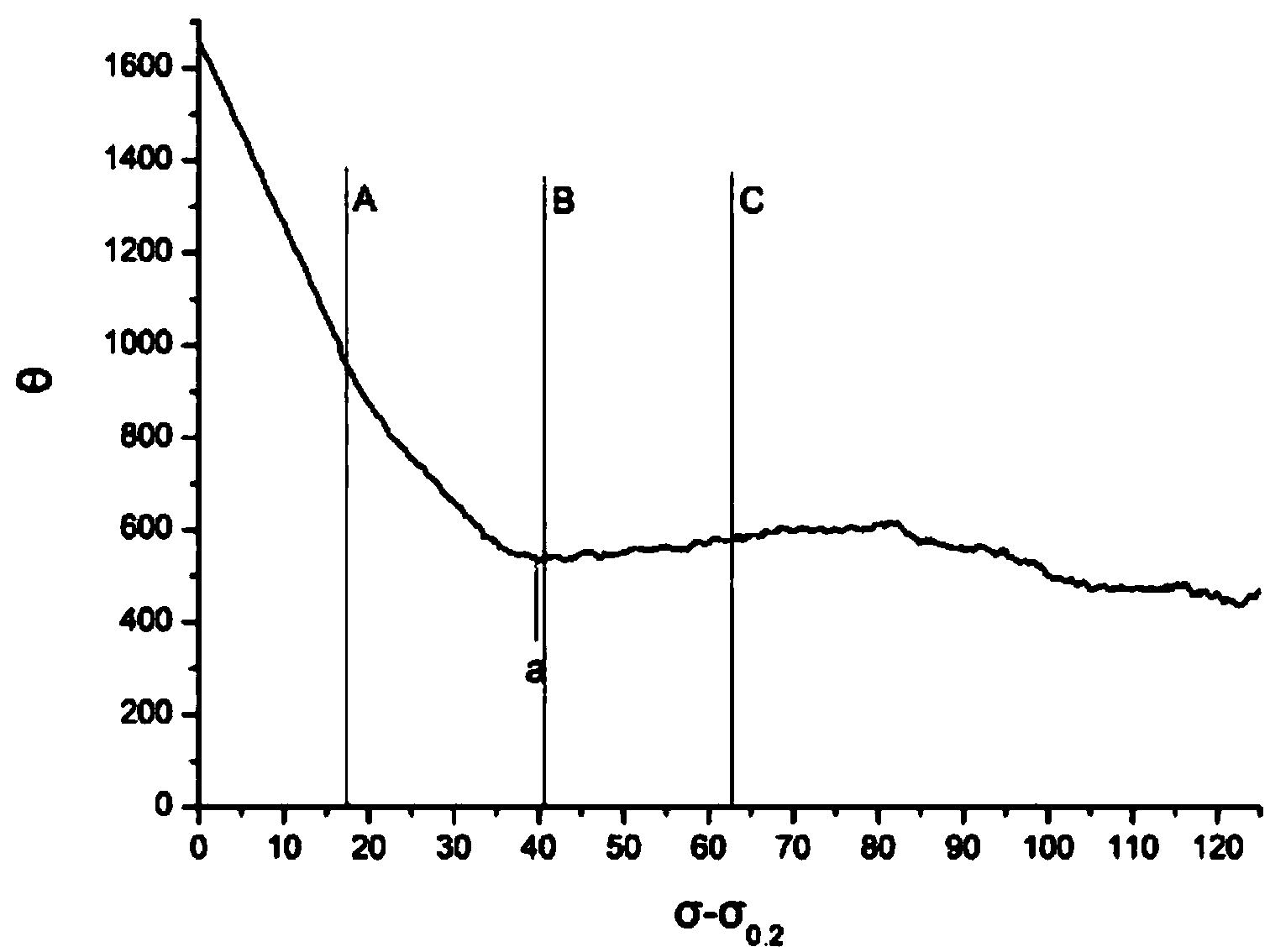

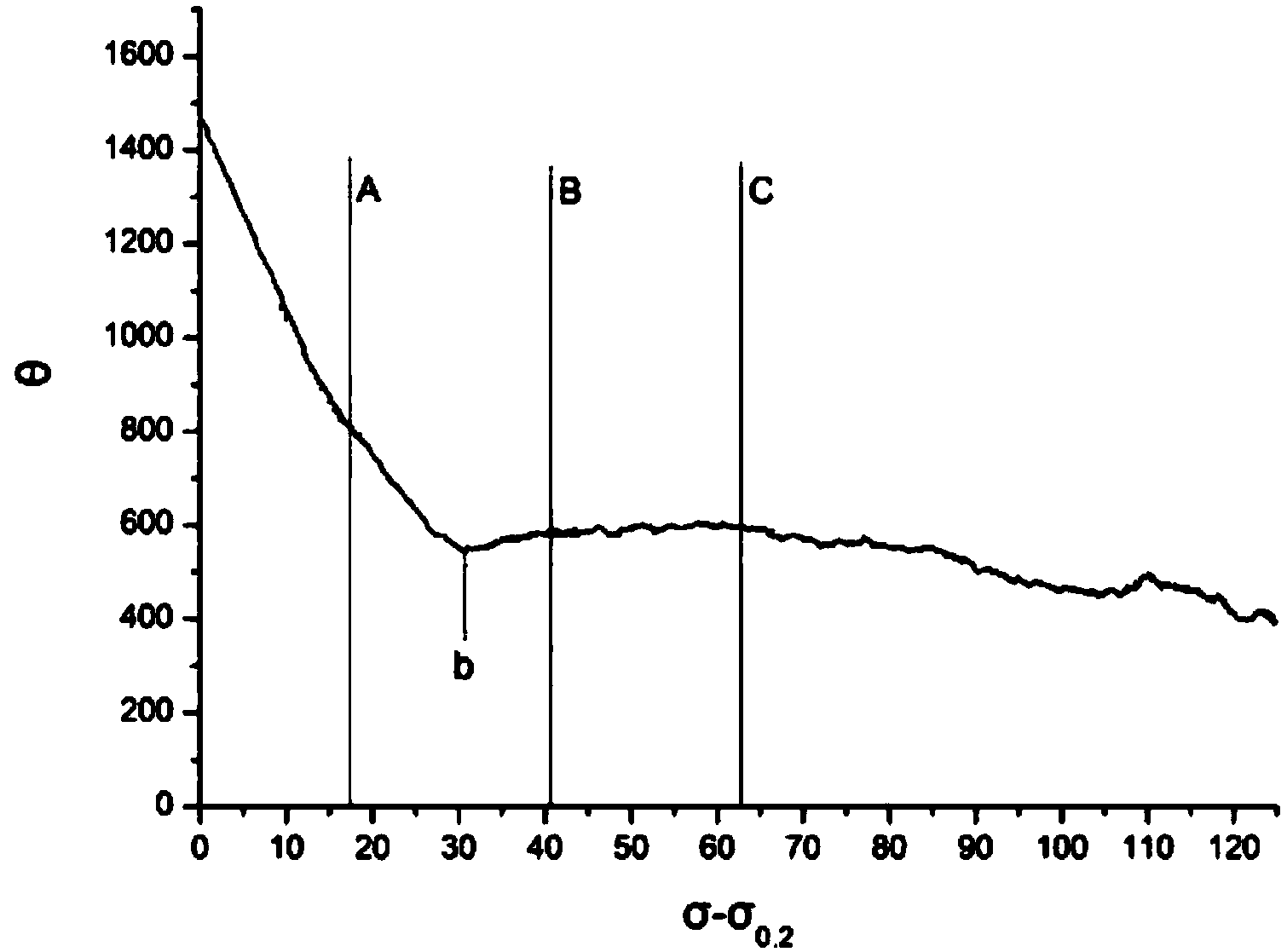

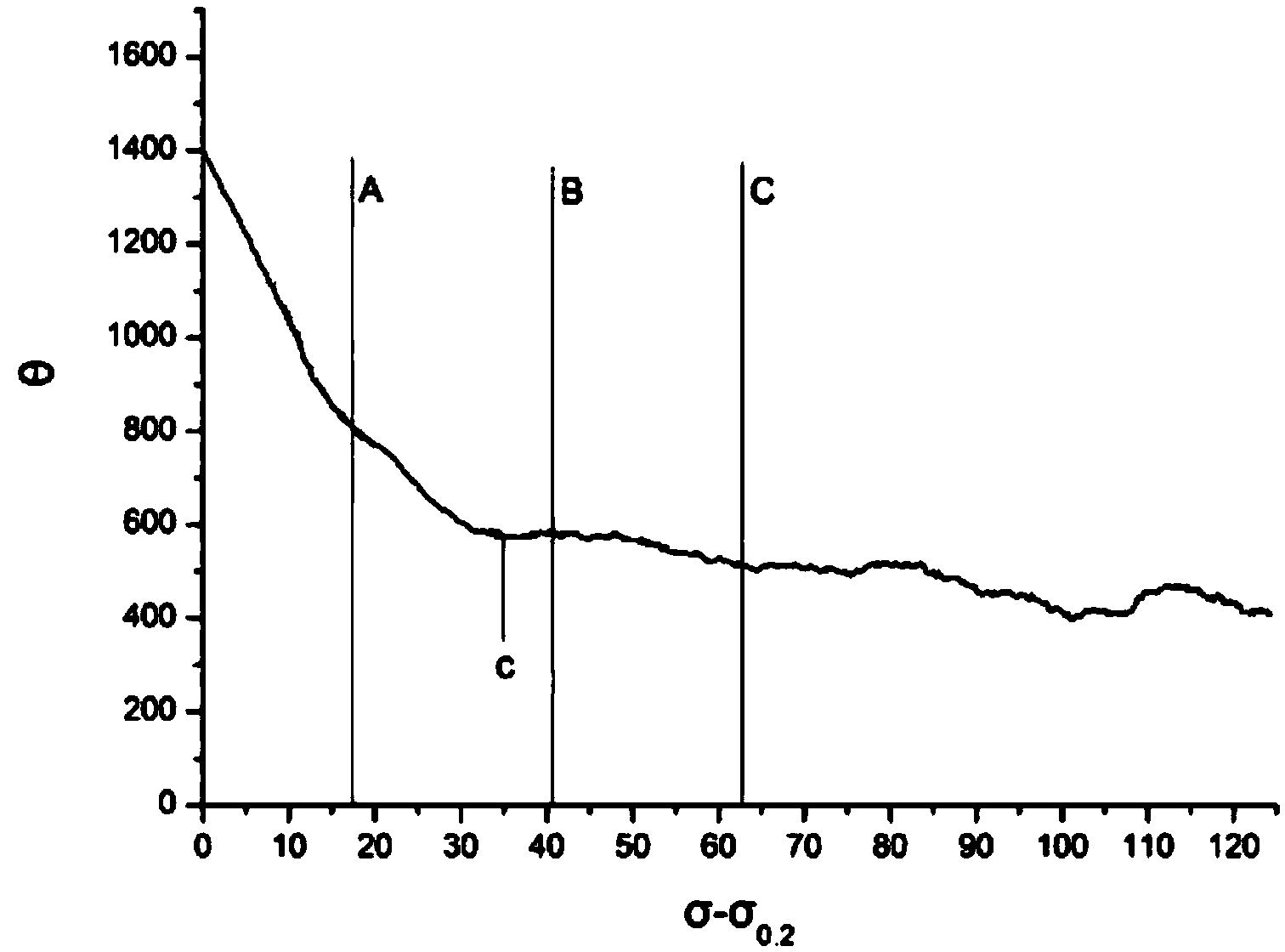

InactiveCN103911571AImprove plasticityMeet the expected mechanical performance indexStress concentrationStress–strain curve

The invention discloses a method for improving plasticity of magnesium alloy sheets. The method comprises the following steps: (S1) sampling, respectively drawing a true stress-strain curve, and drawing a work hardening curve capable of determining the relationship between the work hardening rate and the strength according to the true stress-strain curve; (S2) finding the biggest inflection point, which is defined as a critical value, from the work hardening curve obtained in the step S1; (S3) referring to the critical value obtained in the step S2, firstly prestretching a magnesium alloy sheet material to the work hardening stage of the material; and (S4) annealing the material which is prestretched in the step S3 so as to remove stress concentration, thereby obtaining the magnesium alloy sheet product with improved plasticity. The method can be used for pointedly improving the plasticity of the magnesium alloy sheets with different components and basal textures, thereby obtaining the magnesium alloy sheets reaching the expected mechanical performance index and consequently providing a reliable guarantee for the follow-up industrial production of the magnesium alloy sheets.

Owner:CHONGQING ACADEMY OF SCI & TECH

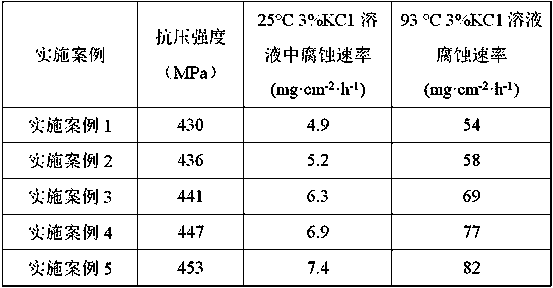

High-crush-resisting rapid degradation magnesium alloy and preparation method thereof

The invention discloses a high-crush-resisting rapid degradation magnesium alloy and a preparation method thereof. The alloy is prepared from, by mass percent, 5.0-10wt% of Zn, 1.20-6.0wt% of Cu, 1.50-3.0wt% of Ni, 1.50-5.0wt% of Nd, 0.5-1.5wt% of Ca and the balance Mg and the other impurity elements. According to the high-crush-resisting rapid degradation magnesium alloy and the preparation method thereof, Cu, Nd, Ca and other alloy elements are added to improve the crush resistance of a material, and the degradation rate is increased through Cu and Ni. According to the prepared high-crush-resisting rapid degradation magnesium alloy, the corrosion rate in a 3% KC1 solution at the temperature of 25 DEG C can reach 7.4 mg cm<-2>h<-1>, and the corrosion rate in the 3% KC1 solution at the temperature of 93 DEG C can reach 88 mg cm<-2>h<-1>; and high crush resisting strength is achieved, and the high-crush-resisting rapid degradation magnesium alloy and the preparation method thereof are suitable for the field of shale gas extraction with a rapid corrosion requirement.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

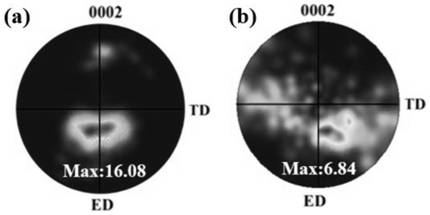

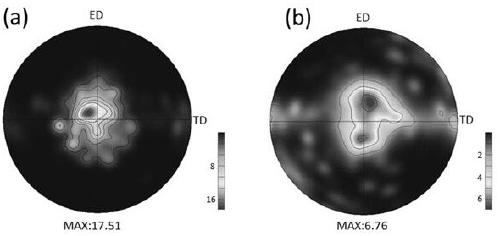

Method for achieving ATX series magnesium alloy plate texture weakening through asymmetric extrusion

ActiveCN112570480ACumulative strain increasesGood for solid solution strengtheningExtrusion diesIngotMachining

The invention discloses a method for achieving ATX series magnesium alloy plate texture weakening through asymmetric extrusion, and belongs to the technical field of magnesium alloy extrusion machining. The method comprises the following steps that an ATX series magnesium alloy ingot blank is homogenized, then a magnesium alloy plate is prepared by conventional extrusion, and the extruded plate ispreheated and put in an asymmetric extrusion die for being extruded. The central axis of a forming channel hole of the asymmetric extrusion die does not coincide with the central axis of an extrusiondie cavity, the proportions of blanks located on the left side and the right side of the forming channel hole in the die cavity are different, extra upsetting deformation is generated in the extrusion process of part of the blanks, the whole extrusion deformation process can be regarded as upsetting and extrusion deformation composite superposition, and therefore, the texture of the finally obtained asymmetric extrusion plate is obviously weakened compared with that of an initial extrusion plate. The asymmetric extrusion die is simple and convenient to manufacture, simple in technological operation and easy to implement, and has a good industrial application prospect.

Owner:JILIN UNIV

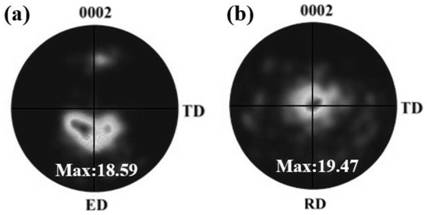

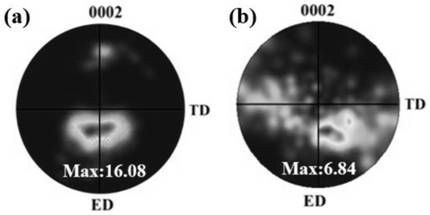

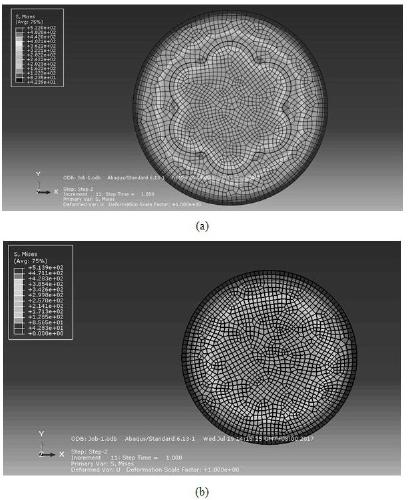

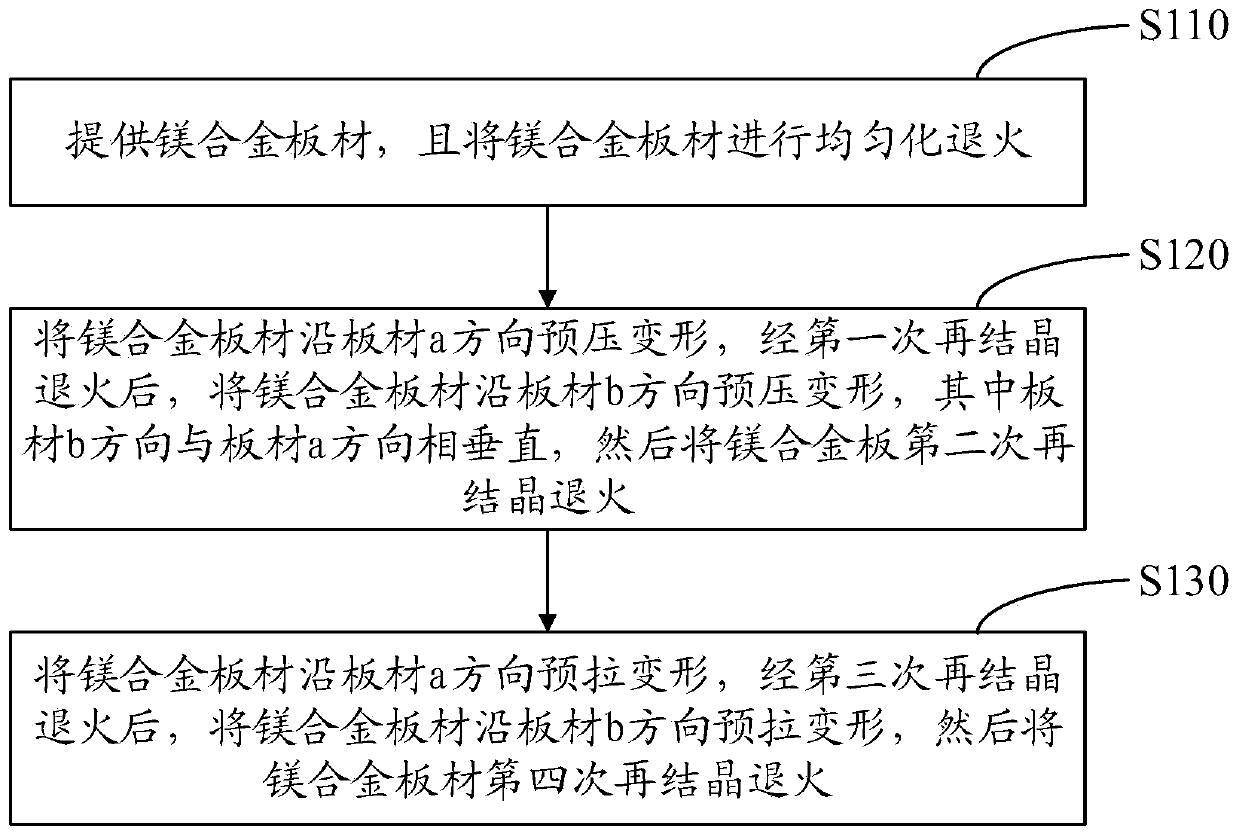

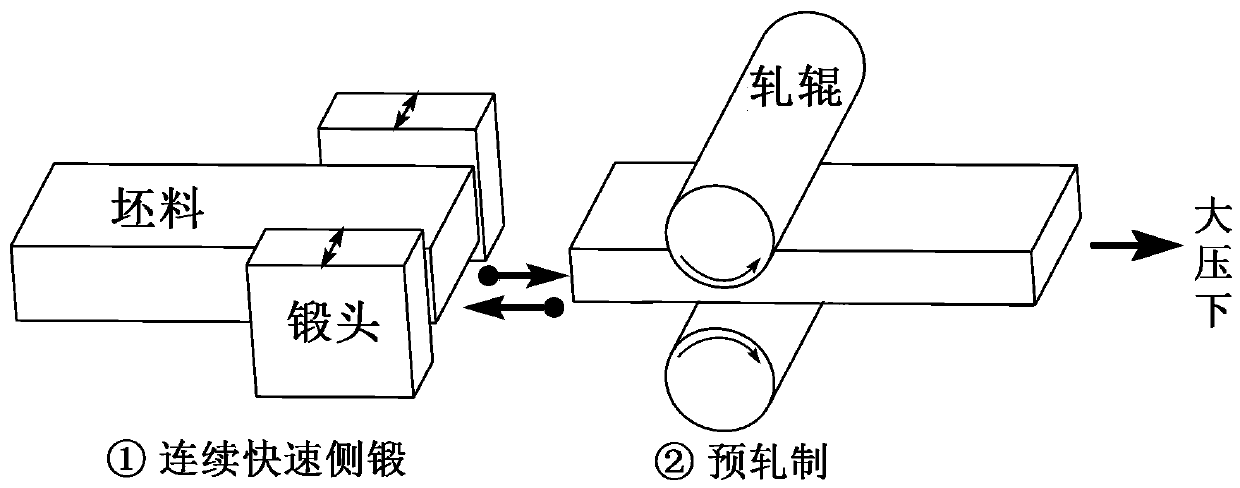

A method for preparing high formability magnesium alloy sheet by composite deformation

ActiveCN109182859BIncreased cupping value at room temperatureGrain refinementMetal rolling arrangementsThermal treatmentCompressive deformation

The invention relates to a method for preparing a high-formation-property magnesium alloy panel by composite deformation. According to the method, a compression deformation process is carried out between two rolling deformation processes, and thermal treatment is carried out before each rolling deformation process and the compression deformation process; a rolling process and a compression deformation process in different deformation directions are coupled, the grain orientation of a magnesium alloy sheet is adjusted and controlled, grains are refined, and the textures of base surfaces are weakened, so that the room-temperature cup drawing value of the magnesium alloy sheet is substantially increased after the composite deformation, and the room-temperature forming property of the deformedmagnesium alloy sheet is effectively improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

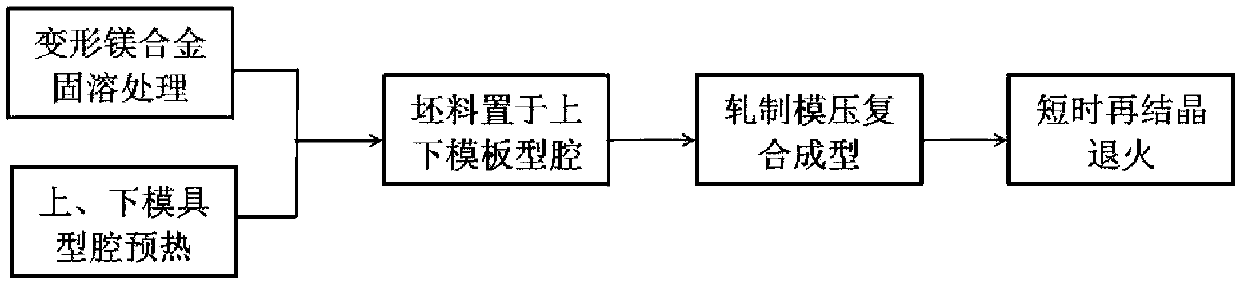

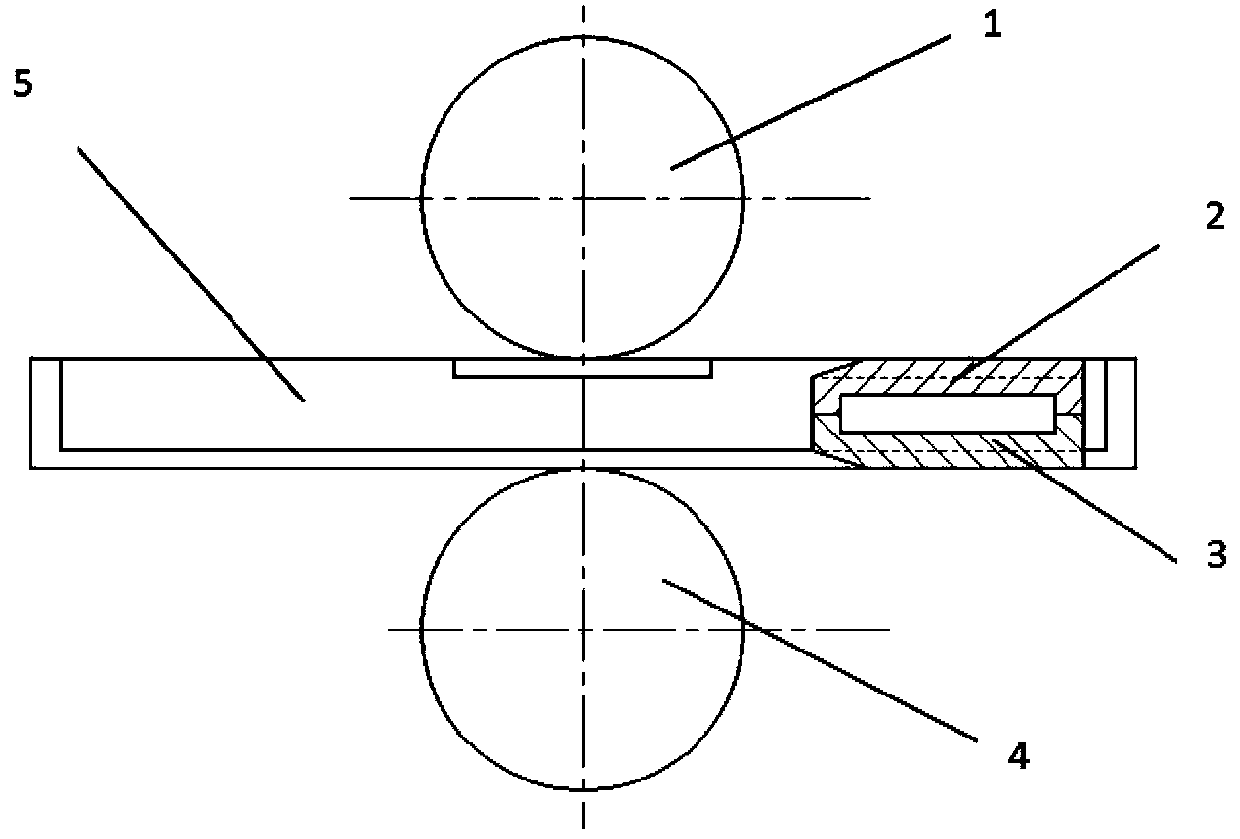

Magnesium alloy variable section rolling and die pressing compound forming device and forming method

The invention discloses a magnesium alloy variable section rolling and die pressing compound forming device and method and belongs to the field of nonferrous metal plastic forming. The magnesium alloyvariable section rolling and die pressing compound forming device and method mainly aim to achieve magnesium alloy variable section rolling forming, and solve the problem of magnesium alloy variablesection forming. According to the magnesium alloy variable section rolling and die pressing compound forming device and method, due to a composite process of rolling and die pressing forming, a variable section magnesium alloy is rolled. According to a specific machining process: firstly, a rolled blank material is placed in a groove between an upper mold plate and a lower mold plate; the upper mold plate and the lower mold plate are fed into a feeding position in a guide rail groove, and are driven into an upper roller and a lower roller through friction force; and due to closing of the uppermold plate and the lower mold plate, die pressing forming of the blank material in cavities of the upper mold plate and the lower mold plate is formed. Due to the machining process, a variable section magnesium alloy workpiece uniform in structure and optimized in performance can be obtained.

Owner:JILIN UNIV

High-yield-ratio wrought magnesium alloy and preparation method thereof

The invention discloses high-yield-ratio wrought magnesium alloy and a preparation method thereof. The high-yield-ratio wrought magnesium alloy comprises, by mass, 3%-4% of Zn, 0.7%-0.95% of Ca, 0.05%-0.33% of Mn, and the balance Mg and inevitable impurities. According to the prepared alloy, a large quantity of Mg-Zn-Ca ternary phases are separated out in the extrusion direction in the extrusion process and evenly distributed in a magnesium matrix, and thus two-phase reinforcement is achieved; a non-recrystallized area in a large proportion has strong texture, and thus the texture reinforcing effect is achieve; a large quantity of nanoscale Mg particles are dispersed and separated out to achieve the dispersion reinforcing effect, growth of recrystallized grains is restrained in the hot extrusion process, and thus the grain refining effect is achieved; and by adding Ca and Mn, the obvious grain refining effect can be achieved, both the strength and toughness of the alloy are improved, the basal texture of the alloy can be weakened through Ca, and thus the plasticity of materials is improved. In this way, the prepared alloy has high strength and a high yield ratio, and high plasticity of the alloy is maintained.

Owner:CHONGQING UNIV

Preparation process and extrusion die for magnesium alloy pipe under multiple strain paths

PendingCN112718901ARefined grain structureWeakened base textureExtrusion diesGraphiteMechanical property

The invention provides a preparation process and an extrusion die for a magnesium alloy pipe under multiple strain paths. The preparation process comprises the following steps of: preparing a rod-shaped magnesium alloy blank and high-temperature graphite powder; performing heat treatment on the magnesium alloy blank, and slowly cooling in air; performing extrusion preheating treatment again; putting the heated magnesium alloy blank into an extruder, heating an extrusion male die and an extrusion female die in the extruder, and putting the magnesium alloy blank into the extruder; extruding and deforming for multiple times because a shearing and extruding channel is corrugated; and polishing and cleaning the extruded magnesium alloy pipe. According to the preparation process and the extrusion die for the magnesium alloy pipe under the multiple strain paths, the technical problems of strong extrusion texture, severe tension-compression asymmetry, low grain refinement degree and the like existing in the conventional magnesium alloy processing method are solved, and the comprehensive mechanical property of magnesium alloy is improved.

Owner:HARBIN INST OF TECH -WEIHAI INNOVATION PARK WEIHAI

Weak-basal-texture high-strength magnesium-lithium alloy and preparation method thereof

ActiveCN114277295AGuaranteed StrengthHigh strengthFurnace typesHeat treatment furnacesUltimate tensile strengthHeat treating

The invention discloses a weak-basal-texture high-strength magnesium-lithium alloy and a preparation method thereof. The weak-basal-texture high-strength magnesium-lithium alloy is prepared from the following components in percentage by mass: 1-5% of Li, 0.3-0.6% of Ca, 0.1-0.2% of Ce, 0.1-0.2% of Y, less than or equal to 0.2% of total impurity elements and the balance of Mg. Through alloying, rolling and heat treatment, the strength of the magnesium-lithium alloy can be improved while the basal texture of the magnesium-lithium alloy is weakened.

Owner:ZHENGZHOU UNIV

Two-way compound extrusion die of magnesium alloy sheet strips and extrusion molding method thereof

ActiveCN106881369AImprove uniformityWeakened base textureExtrusion diesRounded RectangleMaterials science

The invention discloses a two-way compound extrusion die of magnesium alloy sheet strips and an extrusion molding method thereof. The two-way compound extrusion die comprises a die body, wherein the left end of the die body is connected with an extrusion cylinder; a front extrusion channel, a transition channel, a side extrusion channel and an outlet channel which are in butted communication with each other are arranged from left to right in the die body along an axial direction of the die body; the left end of the front extrusion channel is in butted communication with an extrusion cavity of the extrusion cylinder; cross sections of parts on two sides of a random butted communication part are same in shape and equal in area; cross sections of the front extrusion channel and the side extrusion channel are gradually diminished from left to right; cross sections of the extrusion cylinder of the extrusion cylinder, the transition channel and the outlet channel are equal from left to right; the cross section of the extrusion cavity of the extrusion cylinder and a cross section of a magnesium alloy billet are same in shape and equal in area; the cross sections of the right end of the front extrusion channel, the transition channel, the side extrusion channel and the outlet channel are shaped as rounded rectangle. Through the two-way compound extrusion die and the extrusion molding method thereof, high-plasticity magnesium alloy sheet strips can be manufactured.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

A Method for Realizing Texture Weakening of Atx Series Magnesium Alloy Sheets Using Asymmetric Extrusion

The invention discloses a method for realizing the weakening of the texture of an ATX series magnesium alloy plate by adopting asymmetric extrusion, and belongs to the technical field of magnesium alloy extrusion processing. In the invention, the ATX series magnesium alloy ingot is homogenized firstly, then the magnesium alloy plate is prepared by conventional extrusion, and finally the extruded plate is preheated and put into an asymmetric extrusion die for extrusion. Since the central axis of the forming channel hole of the asymmetric extrusion die does not coincide with the central axis of the extrusion die cavity, the proportion of the billets on the left and right sides of the forming channel hole in the mold cavity is different, and extra parts of the billet will be upset during the extrusion process. Coarse deformation, the entire extrusion deformation process can be regarded as the combined superposition of upsetting and extrusion deformation, so the texture of the finally obtained asymmetric extruded sheet is obviously weaker than that of the initial extruded sheet. The asymmetric extrusion die is easy to manufacture, simple to operate and easy to implement, and has good industrial application prospects.

Owner:JILIN UNIV

Low-cost rapid-corrosion magnesium alloy and preparation method thereof

The invention discloses a low-cost rapid-corrosion magnesium alloy and a preparation method thereof. The alloy comprises the following elements of, by mass, 3.0wt%-25wt% of Al, 0.20wt%-1.0wt% of Ca, 2.0wt%-15wt% of Zn, 1.20wt%-3.0wt% of Cu, 1.50wt%-5.0wt% of Fe and the balance Mg and other impurity elements. According to the low-cost rapid-corrosion magnesium alloy and the preparation method thereof, a Mg-Al-Ca-Zn-Cu-Fe alloy is adopted, the grain size of a cast ingot is refined through the Ca, then the segregation of the cast ingot is reduced, the Cu and the Fe in the material are uniformly distributed, fine dispersed Mg2Cu and Mg2Fe are formed, and the purpose of rapid corrosion dissolution is achieved; meanwhile, the basal texture of the magnesium alloy is weakened, so that the elongation of the material is improved; and in addition, the Ca has flame-retardant and anti-oxidation effects, so that the ignition point of the alloy is improved, and therefore, the using amount of protective gas is reduced in the smelting process, and no gas protection is required during the homogenization process.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

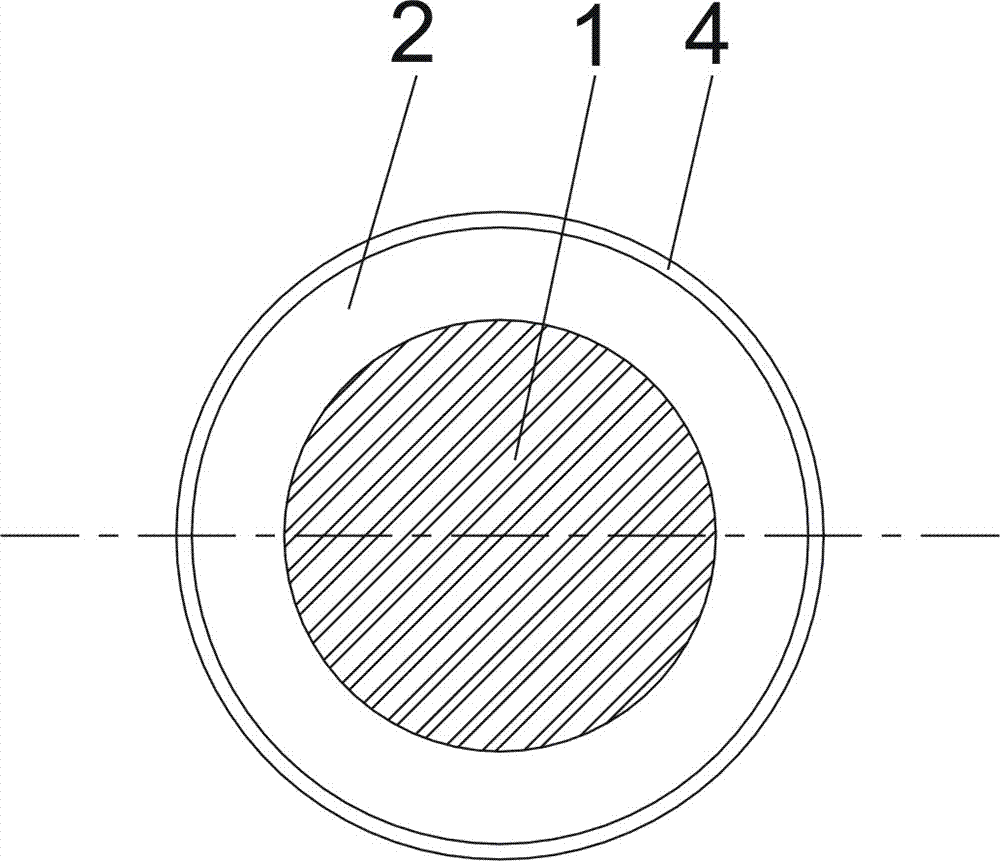

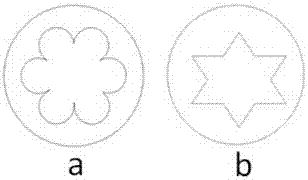

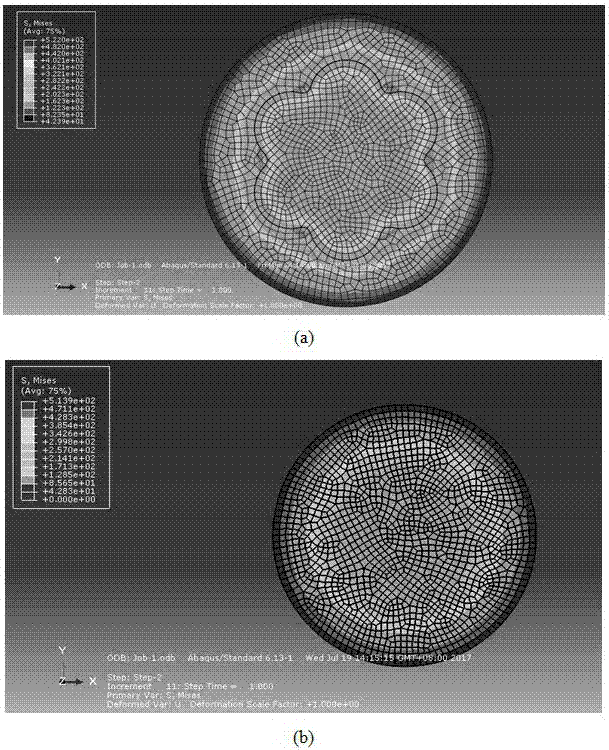

Squeezing method for regulating and controlling texture of magnesium alloy sheet by utilizing hook-face interface structure

ActiveCN107497874AImprove secondary molding capabilitiesWeaken the strong base textureStressed stateMachining process

The invention discloses a squeezing method for regulating and controlling the texture of a magnesium alloy sheet by utilizing a hook-face interface structure. The squeezing method comprises the following steps that (1) two magnesium alloy base materials are combined into a cylindrical blank in an internal and external nested mode and fixed, the internal base material forms a core material, the external base material forms a packing material, and the junction surface of the two magnesium alloy base materials has the same or corresponding hook-face interface structure; and (2) the combined cylindrical blank is subjected to squeezing to be processed into a sheet at the hot squeezing temperature. According to the squeezing method for regulating and controlling the texture of the magnesium alloy sheet by utilizing the hook-face interface structure, the interface of a magnesium alloy is in an unsymmetrical stress state different from a traditional squeezing processing process in the combined squeezing process, the stress state can result in different degrees of deflection of the grain orientation, finally the basal texture of a magnesium alloy component is weakened, and promoting of the secondary forming capability of the squeezed sheet is facilitated.

Owner:CHONGQING UNIV

A kind of high ductility magnesium alloy and preparation method thereof

The invention discloses a high-plasticity magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by mass: 3-4% of Zn, 0.1-0.6% of Ca, 0.05-0.8% of Mn, and the balance of Mg and inevitable impurities. Ca and Mn are added in a magnesium zinc alloy to prominently refine alloy grains; in hot extrusion process, the dynamic recrystallization can be promoted to stop growth of recrystallized grains, so that the strength and the plasticity of the alloy are synchronously improved, the base surface texture of the alloy can be prominently weakened, and the plasticity of the alloy is improved; in addition, through separation of a second phase and dispersion and separation of nanoscale Mn particles, the strength of the alloy can be effectively improved; the magnesium alloy is high in plasticity; and the component-optimized alloy can reach the ductility of 25-29.8%, the yield strength of 160-205 MPa and the tensile strength of 270-289 MPa.

Owner:CHONGQING UNIV

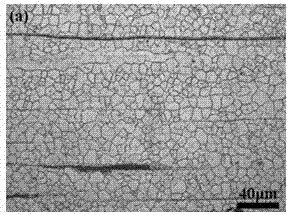

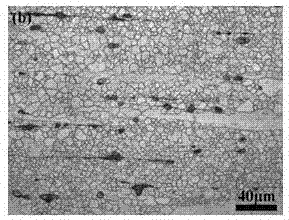

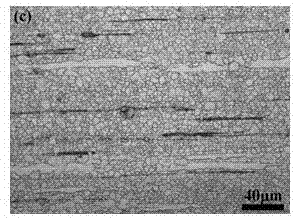

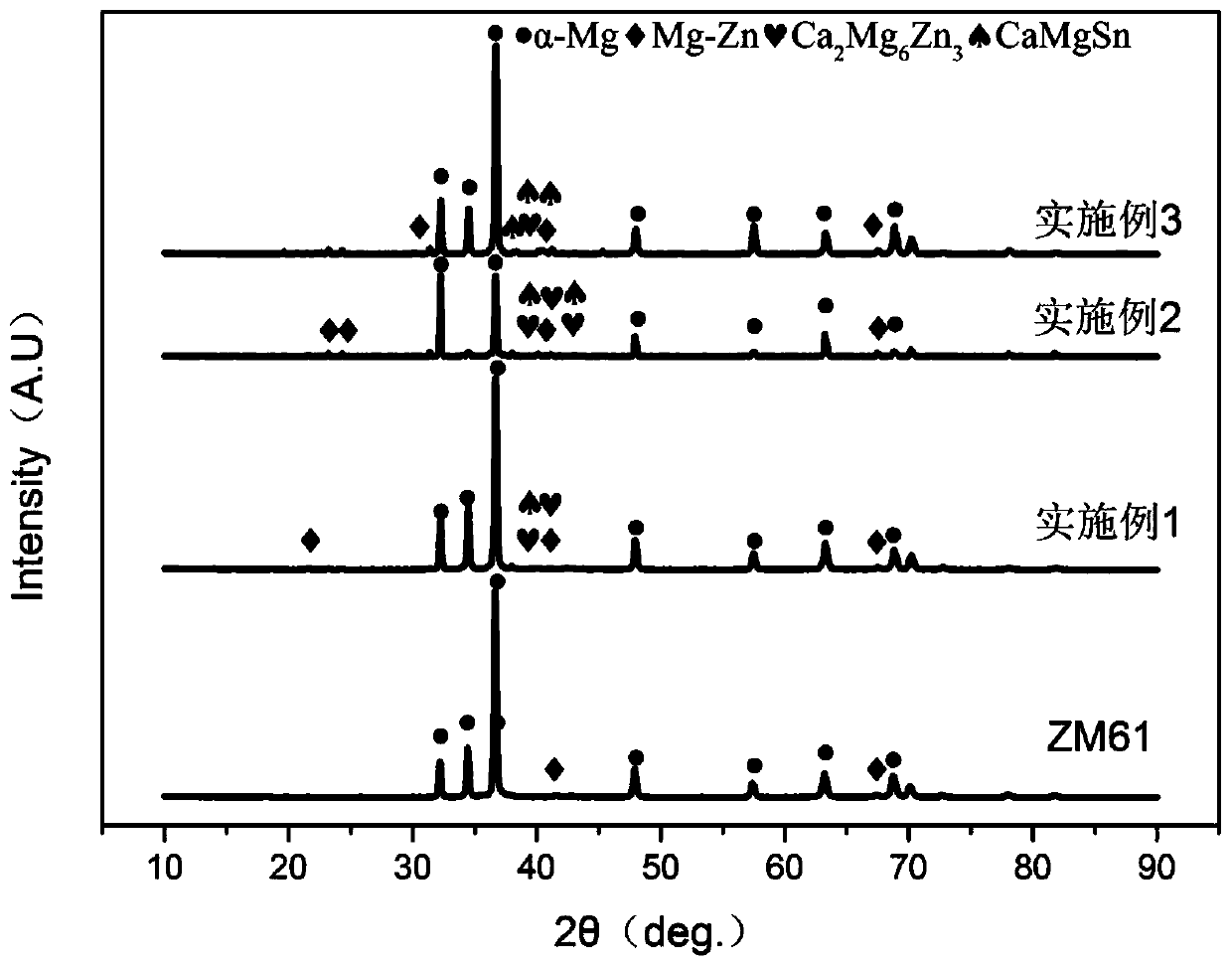

High-strength and high-plasticity magnesium zinc manganese tin calcium alloy and preparation method thereof

The invention relates to a high-strength and high-plasticity magnesium zinc manganese tin calcium alloy and a preparation method thereof and belongs to the technical field of magnesium alloy production. The alloy comprises the following compositions including 5.0-7.0% of Zn, 0.5-1.5% of Mn, 0.45-0.6% of Ca, 0.35-2.5% of Sn, smaller than or equal to 0.15% of inevitable impurities and the balance magnesium. By reasonably setting the compositions in the alloy, the use amount of all the compositions and the preparation technology, it can be ensured that the prepared alloy has high strength and plasticity, and the preparation method is simple, low in cost and beneficial for industrialized production.

Owner:CHONGQING UNIV

A kind of high yield ratio deformed magnesium alloy and its preparation method

Owner:CHONGQING UNIV

Method for preparing magnesium-based composite board through asymmetric deformation processing and magnesium-based composite board

PendingCN114798731AWeakened base textureImprove plastic deformation abilityMeasuring devicesProfile control deviceMetallic materialsHeat conservation

The invention belongs to the technical field of metal materials and plastic processing, and particularly relates to a method for preparing a magnesium-based composite board through asymmetric deformation processing and the magnesium-based composite board. The method comprises the steps that (1) a magnesium board and an aluminum board are subjected to heat preservation treatment at different temperatures, so that the temperature of the magnesium board is higher than that of the aluminum board, and the temperature difference between the magnesium board and the aluminum board ranges from 160 DEG C to 200 DEG C; (2) stacking and fixing in an aluminum / magnesium / aluminum sequence, and then carrying out single-pass rolling forming; and (3) annealing treatment is carried out at the temperature of 150-300 DEG C. On one hand, a temperature field within a certain range can be formed at the interface of the magnesium plate and the aluminum plate, the deformation resistance difference between the magnesium plate and the aluminum plate is reduced, the magnesium plate and the aluminum plate obtain similar plastic deformation within the respective temperature ranges, and therefore the plastic forming capacity of the magnesium-based composite plate is improved; on the other hand, the technological process is shortened, the grain size of the composite board is refined, the mechanical property of the composite board is improved, and the interface bonding strength is improved.

Owner:GUANGDONG INST OF NEW MATERIALS

An extrusion method for controlling the texture of magnesium alloy sheets by using the surface interface structure

ActiveCN107497874BImprove secondary molding capabilitiesWeaken the strong base textureStressed stateMagnesium alloy

The invention discloses a squeezing method for regulating and controlling the texture of a magnesium alloy sheet by utilizing a hook-face interface structure. The squeezing method comprises the following steps that (1) two magnesium alloy base materials are combined into a cylindrical blank in an internal and external nested mode and fixed, the internal base material forms a core material, the external base material forms a packing material, and the junction surface of the two magnesium alloy base materials has the same or corresponding hook-face interface structure; and (2) the combined cylindrical blank is subjected to squeezing to be processed into a sheet at the hot squeezing temperature. According to the squeezing method for regulating and controlling the texture of the magnesium alloy sheet by utilizing the hook-face interface structure, the interface of a magnesium alloy is in an unsymmetrical stress state different from a traditional squeezing processing process in the combined squeezing process, the stress state can result in different degrees of deflection of the grain orientation, finally the basal texture of a magnesium alloy component is weakened, and promoting of the secondary forming capability of the squeezed sheet is facilitated.

Owner:CHONGQING UNIV

A method for preparing high-performance magnesium alloy plate

ActiveCN110129695BImprove room temperature formabilityHigh strengthUltimate tensile strengthMaterials science

The invention discloses a method for preparing a high-performance magnesium alloy plate. The method comprises the following steps that a magnesium alloy plate is provided and subjected to homogenizingannealing; the magnesium alloy plate is subjected to pre-pressing deformation in the a direction of the plate, after first-time recrystallization annealing is conducted, the magnesium alloy plate issubjected to pre-pressing deformation in the b direction of the plate, the b direction of the plate is perpendicular to the a direction of the plate, and the magnesium alloy plate is subjected to second-time recrystallization annealing; and the magnesium alloy plate is subjected to pre-pulling deformation in the a direction of the plate, after third-time recrystallization annealing is conducted, the magnesium alloy plate is subjected to pre-pulling deformation in the b direction of the plate, and then the magnesium alloy plate is subjected to four-time recrystallization annealing. According tothe preparation method, the base surface structure can be weakened, the plate strength and the forming performance are high, the finished product yield is high, and the comprehensive cost can be reduced.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of magnesium alloy grain refinement method

The invention discloses a magnesium alloy grain refining method. The method comprises the steps that a regular eight-edge prism plate is designed, multi-direction combination is conducted by selecting a specific direction, circulating multi-direction room-temperature deformation is conducted along the combination, and middle-temperature short-time annealing is conducted after the deformation amount is accumulated to a certain extent. The plate is subjected to combined deformation in the specific direction, primary contraction twin, secondary contraction twin and primary stretching twin are introduced, mutual cross partition between the different twins is brought into full play so that grains can be refined, in the annealing process, the deformation storage energy in the twins is high, and abundant nucleation positions can be provided, so that even recrystallized small grains are obtained in a short time, the basal texture of a magnesium alloy plate is weakened, and accordingly the strength and the forming performance of the magnesium alloy plate are greatly improved.

Owner:FUZHOU UNIV

A method for improving rolling forming of magnesium alloy plate and strip

ActiveCN108994079BImprove uniformityHigh tensile strengthTemperature control deviceMetal rolling arrangementsRoll formingNon-ferrous metal

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com