Rolling method of magnesium alloy packaged by aluminum plate

A magnesium alloy and aluminum plate technology, applied in the direction of metal rolling, etc., can solve the problems of temperature drop, base surface texture weakening, and poor surface quality, so as to prevent temperature drop, base surface texture weakening, and reduce edge cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

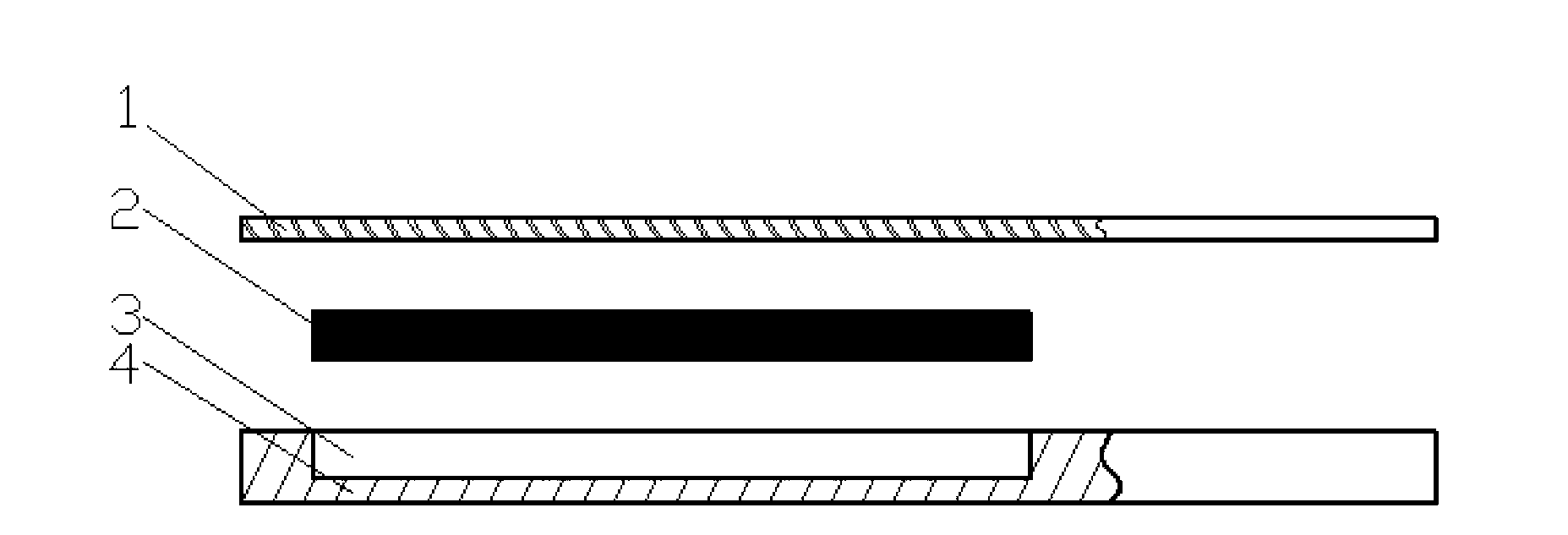

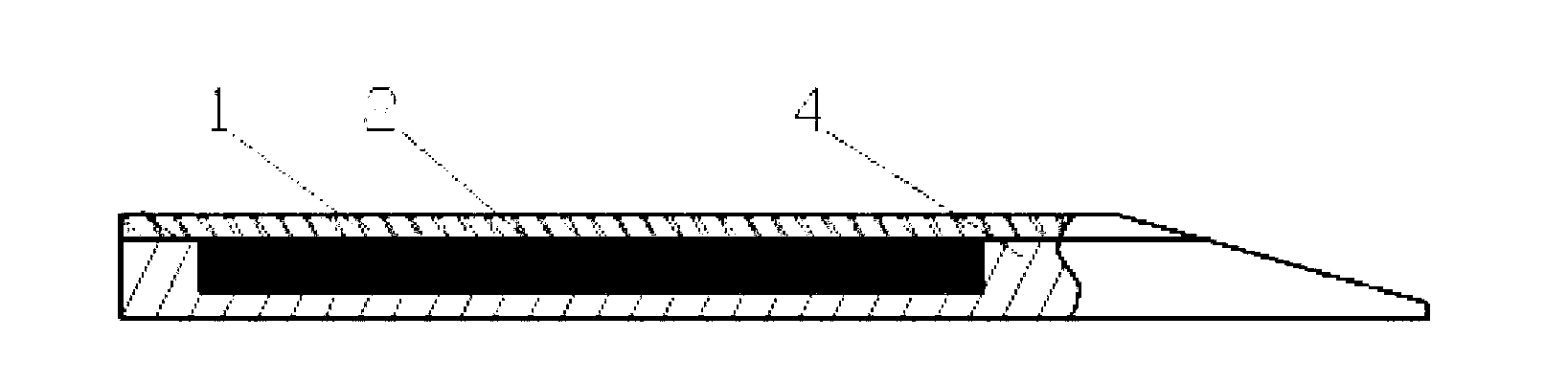

[0038] This embodiment relates to a rolling method of a magnesium alloy covered by an aluminum plate, comprising the following steps: taking an aluminum panel 1, a magnesium alloy 2, and an aluminum bottom plate 4 provided with a groove 3 matching the shape of the magnesium alloy 2;

[0039] The grade of the aluminum plate is 6063 series aluminum alloy; the composition and mass fraction of the 6063 series aluminum alloy are: Si0.20~0.6%, Cu≤0.10%, Mg0.45~0.9%, Zn≤0.10%, Mn≤ 0.10%, Ti≤0.10%, Cr≤0.10%, Fe≤0.350%, and the balance is aluminum.

[0040] Place the magnesium alloy 2 in the groove 3, take the aluminum panel 1 to cover the surface of the magnesium alloy 2; the size of the magnesium alloy 2 is: 150×70×10mm (length×width×thick); the magnesium alloy The brand ZE20, the composition and mass fraction of the ZE20 magnesium alloy are: Zn2.0%, Ce0.5%, and the balance is Mg;

[0041] The aluminum base plate 4 and the aluminum face plate 1 are welded by a welding process, and g...

Embodiment 2

[0046] The implementation method of this embodiment is the same as that of the embodiment, except that the grade of the magnesium alloy is AZ31; the components and mass fractions of the AZ31 magnesium alloy are: Al 3-3.2%, Zn 0.8%, Mn 0.4 %, the balance is Mg; the aluminum plate is pure aluminum; the size of the magnesium alloy is: 150×70×10mm (length×width×thick);

[0047] Implementation effect: AZ31 magnesium alloy plate is rolled with aluminum plate at 300℃, and the size of the plate after processing is 250×90×20mm (length×width×thickness).

[0048] The preheating temperature of the magnesium alloy sheet is 350°C, and the time is 30min; the roll is heated to 200°C and kept warm; the rolling speed is 10mm / s, and the two-step continuous rolling process is adopted, that is, two continuous rolling passes and then put into the furnace For intermediate annealing, the deformation amount per pass is 15%, the intermediate annealing time is 10min, and the final rolling plate thickness ...

Embodiment 3

[0051] The implementation method of this example is the same as Example 1, the difference is that the grade of the magnesium alloy is GWK, and the components and mass fractions of the GWK series magnesium alloy are: Gd 6-10%, Y 1-3% , the balance being Mg.

[0052] The size of the magnesium alloy is 150×70×10mm (length×width×thick);

[0053] The total size of the alloy plate after the aluminum plate is wrapped is 250×90×20mm (length×width×thick);

[0054] Implementation effect: Rolling at 400°C. Before rolling, the preheating temperature of the alloy plate is 400°C, and the preheating time is 50 minutes. During the rolling process, the temperature of the roll is raised to 200°C and kept warm. The rolling speed 10mm / s;

[0055] Two-step continuous rolling process is adopted, that is, continuous rolling for two passes and then annealing in the furnace. The deformation of each pass is 20%, and the intermediate annealing time is 10 minutes;

[0056] After rolling, observe the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com