Catalytic cracker without settler

A catalytic cracking unit, non-settling technology, applied in the field of petrochemical industry, can solve the coking problem can not be solved well, to achieve the effect of eliminating the retention of coking coke, ensuring long-term operation, and reducing the surface area of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

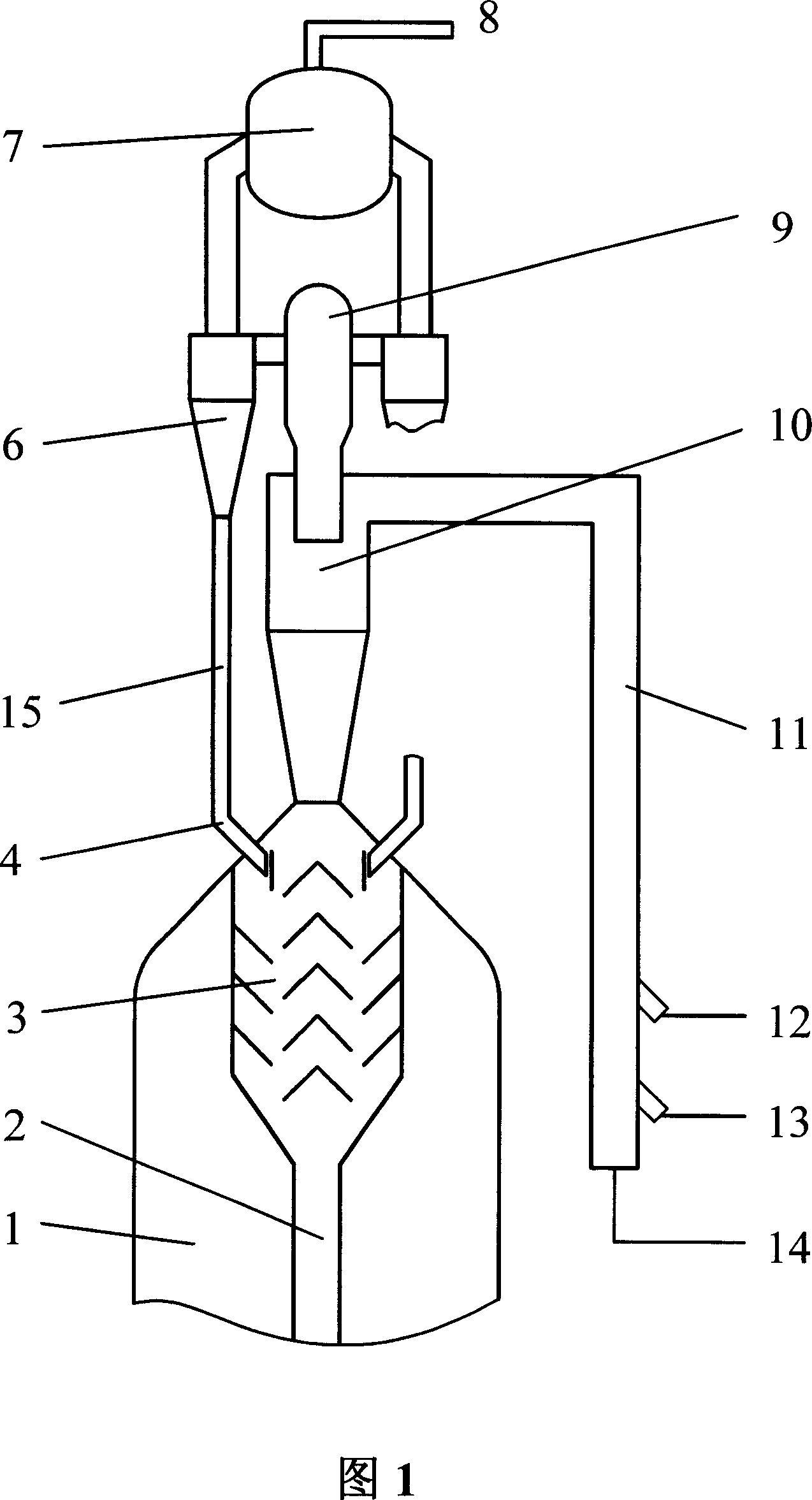

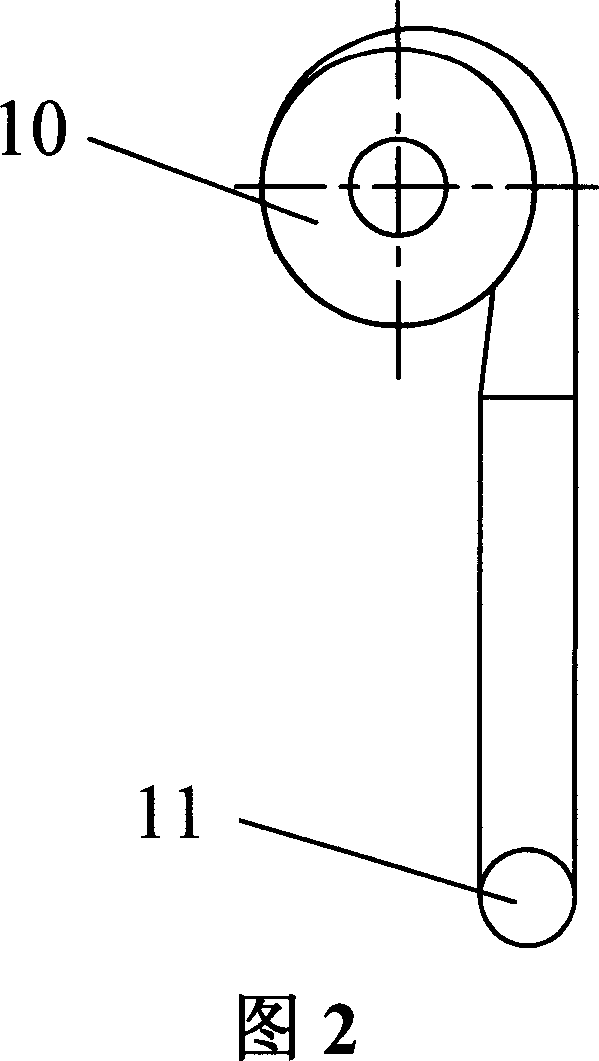

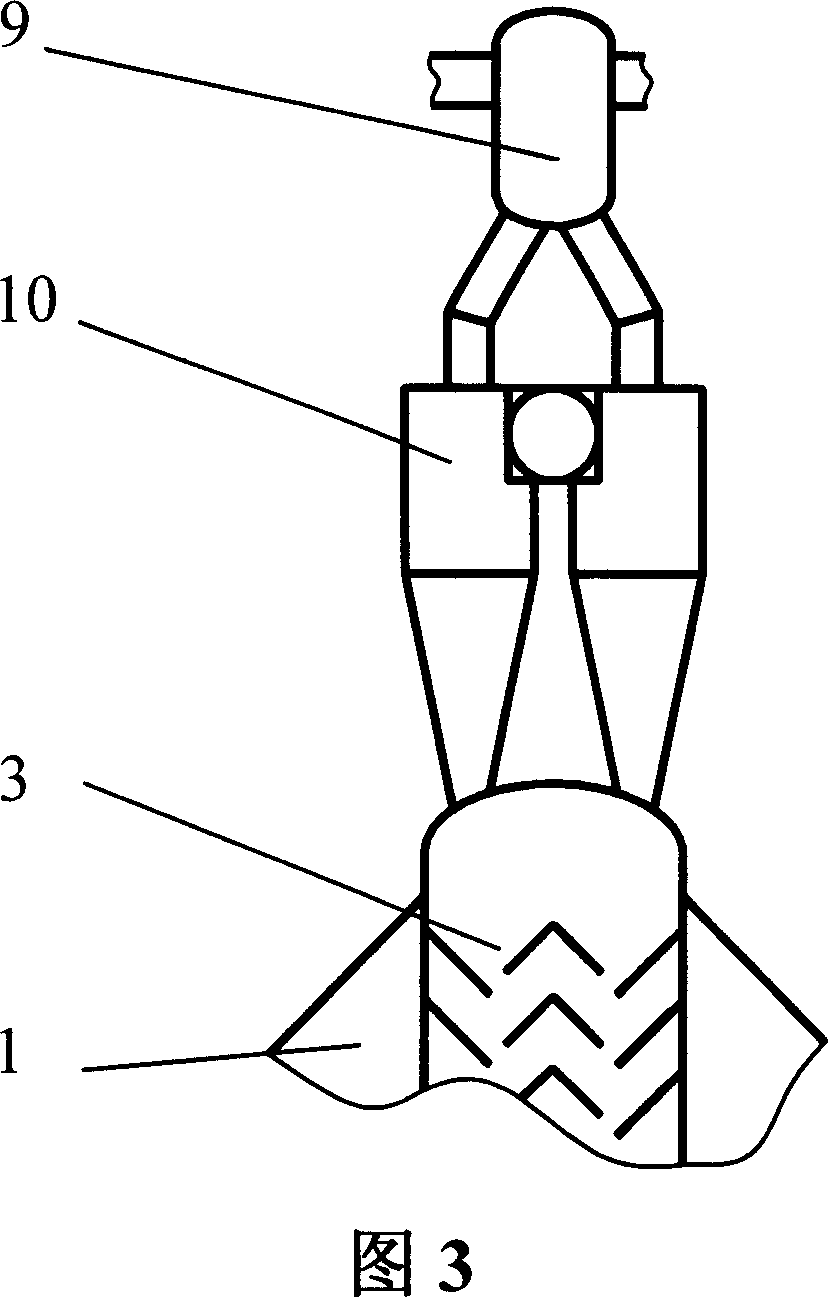

[0042] When using the non-settler fluid catalytic cracking unit of the present invention, the raw oil 12 and the regenerated oil 13 enter the riser 11 to mix with the regenerated catalyst from the regenerator, and mix and flow upward under the action of the lifting steam or the lifting dry gas 14, and at the same time A catalytic cracking reaction occurs. The reaction oil gas and catalyst enter the first-stage cyclone separator 10 at the outlet of the riser 11 for primary separation. The separated oil gas and the oil gas stripped from the stripper 3 are combined with steam, and carry a small amount of unseparated fine catalyst particles through the The ascending pipe of the first-stage cyclone separator enters the air-distributing chamber 9, and then enters the second-stage cyclone separator 6 for separation. The catalyst separated by the primary cyclone separator 10 directly enters the stripper 3 from the cone at the lower part of the primary cyclone separator, while the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com