Extrusion processing method of high-performance magnesium alloy sheet material

A technology for extrusion processing and magnesium alloys, applied in metal extrusion dies and other directions, can solve the problems of limiting the use range of magnesium alloys, reducing the mechanical properties of alloys, and reducing plasticity and toughness, achieving good large-scale application prospects and improving mechanical properties. , weakening the effect of basal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

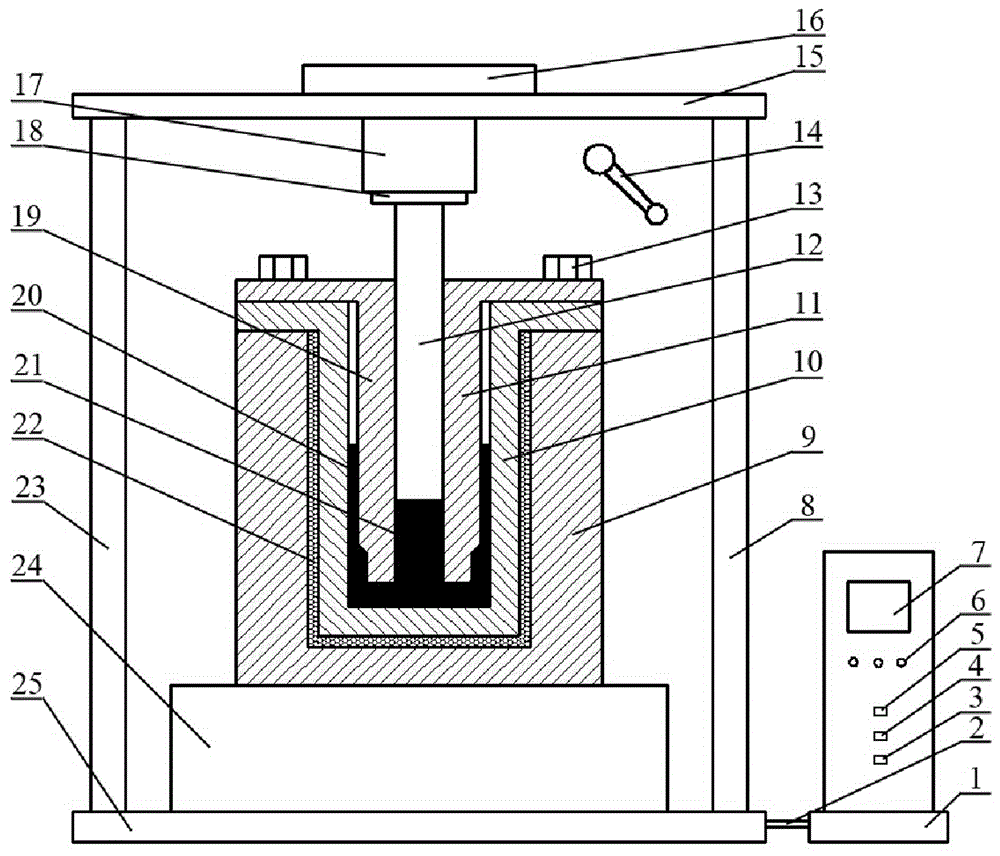

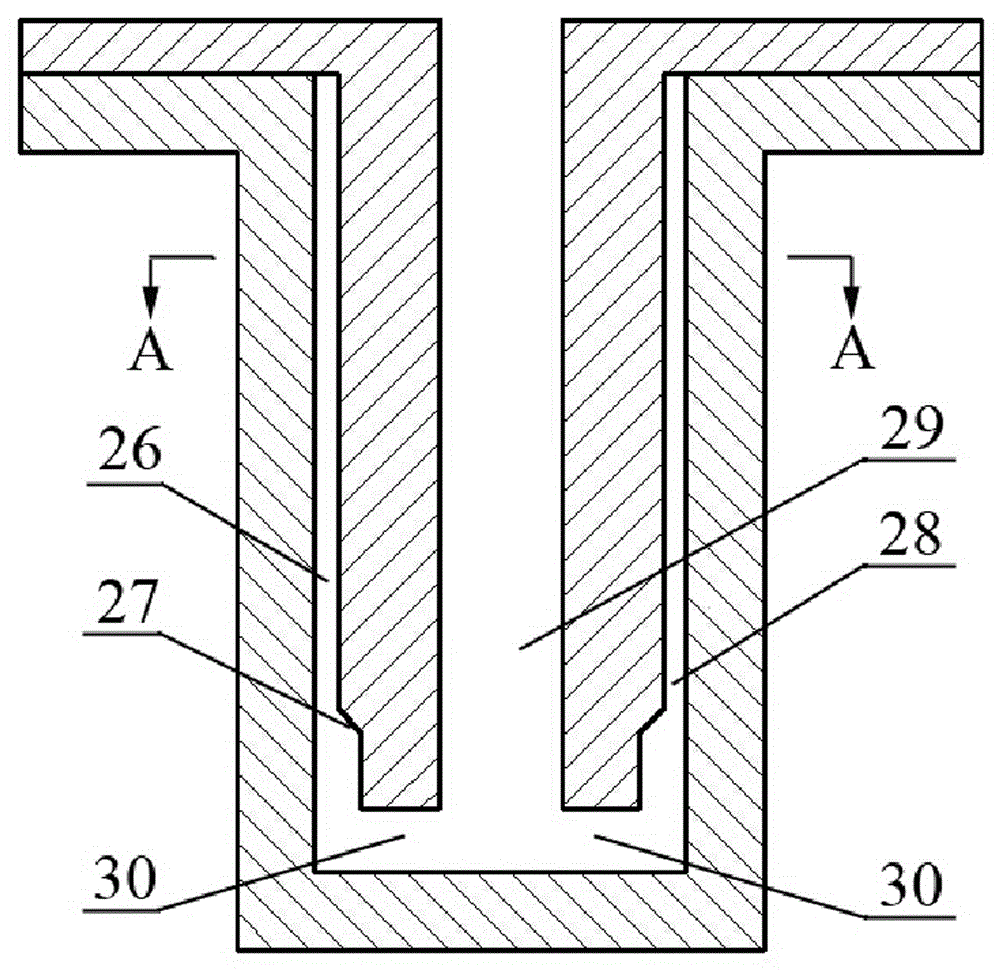

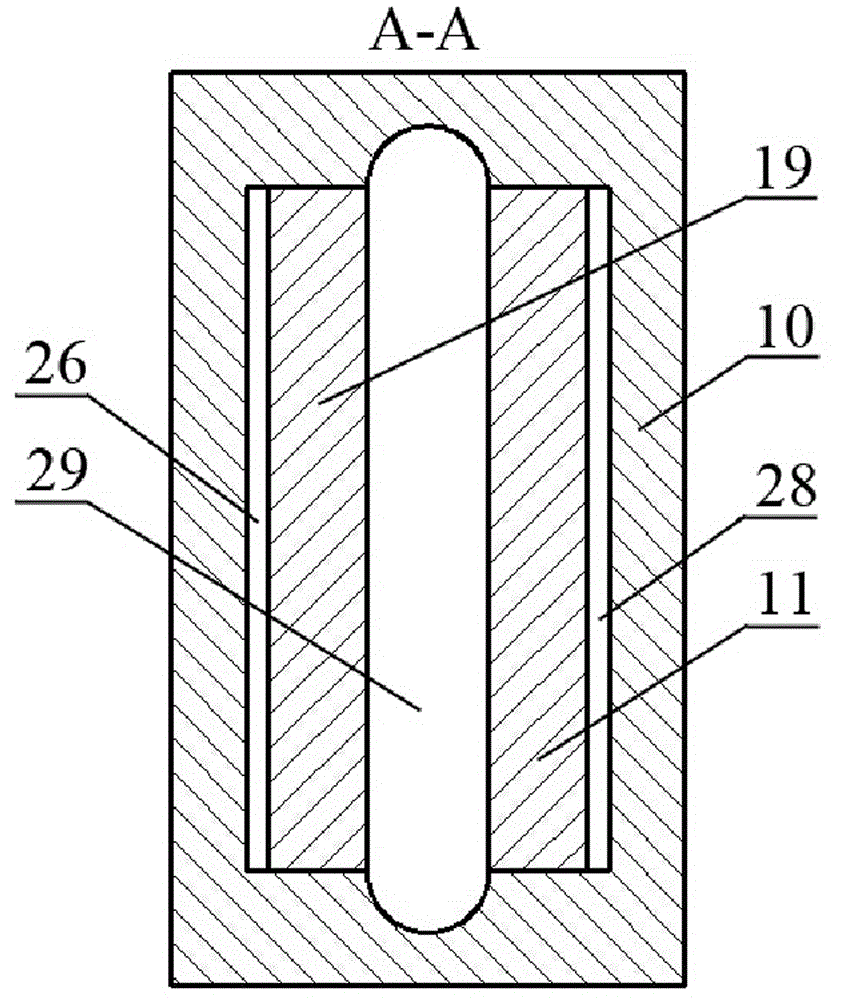

[0046] A method for extrusion processing of a high-performance magnesium alloy plate, using the following steps:

[0047] (1) Selected materials and chemical reagents

[0048] Select the materials and chemical reagents required for preparation, and control their purity and concentration:

[0049] Magnesium alloy block blank: solid block, containing 96% magnesium, 3.0% aluminum, and 1.0% zinc;

[0050] Sandpaper: solid solid;

[0051] High temperature graphite: solid powder;

[0052] Absolute ethanol: liquid liquid, 99.7%;

[0053] Acetone: liquid liquid, 99.0%;

[0054] (2) Pretreatment of magnesium alloy block blanks

[0055] ① Grinding the outer surface of the magnesium alloy block blank 21 with 1200-mesh sandpaper to remove oil stains, and then polishing with 2400-mesh sandpaper to make the surface clean and smooth;

[0056] ②Acetone and absolute ethanol are added into the cleaning tank according to the volume ratio of 3:2, stirred and mixed, and configured as acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com