High-crush-resisting rapid degradation magnesium alloy and preparation method thereof

A rapid degradation, magnesium alloy technology, applied in metal materials and application fields, can solve the problems of temporary plugging tools, such as difficult drilling, high labor and material costs, and difficulty in cleaning, so as to save drilling and recycling processes, improve construction efficiency, Increase the effect of ignition point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

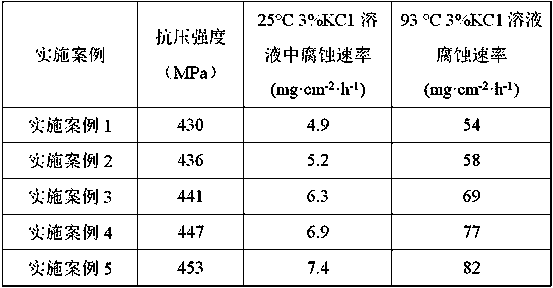

Examples

Embodiment 1

[0022] Example 1 A high compressive and rapidly degradable magnesium alloy

[0023] The high compressive and rapidly degradable magnesium alloy is a Mg-Zn-Cu-Ni-Nd-Ca magnesium alloy, which consists of the following elements by mass percentage: Zn 5.00wt%, Cu 1.20wt%, Ni 1.50wt%, Nd 1.50wt% %, Ca 0.5wt%, and the rest are Mg and unavoidable impurity elements. The raw materials are weighed according to the ratio, and the above-mentioned raw materials are pure magnesium ingots, pure zinc ingots, pure copper ingots, pure nickel ingots, Mg-Nd master alloys, and Mg-Ca master alloys. Before smelting, heat the raw material and mold for 30 minutes to remove moisture and preheat; preheat the crucible to 400°C, spray the solvent evenly on the inner wall of the crucible; put the preheated metal ingot into the crucible and raise the temperature to 720°C, and stir Raise the temperature to 750°C and let stand, heat for 30 minutes and then cool down to 700°C for pouring. The casting mold is ...

Embodiment 2

[0024] Example 2 A High Compressive Rapidly Degradable Magnesium Alloy

[0025] The high compressive and rapidly degradable magnesium alloy is a Mg-Zn-Cu-Ni-Nd-Ca magnesium alloy, which consists of the following elements by mass percentage: Zn 7.00wt%, Cu 2.40wt%, Ni 1.90wt%, Nd 2.70wt% %, Ca 0.8wt%, and the rest are Mg and unavoidable impurity elements. Raw materials are weighed according to the ratio, and the above-mentioned raw materials are used to weigh pure magnesium ingots, pure zinc ingots, pure copper ingots, pure nickel ingots, Mg-Nd master alloys, and Mg-Ca master alloys. Before smelting, heat the raw material and mold for 30 minutes to remove moisture and preheat; preheat the crucible to 400°C, spray the solvent evenly on the inner wall of the crucible; put the preheated metal ingot into the crucible and raise the temperature to 720°C, and stir Raise the temperature to 750°C and let stand, heat for 30 minutes and then cool down to 700°C for pouring. The casting mo...

Embodiment 3

[0026] Example 3 A high compressive and rapidly degradable magnesium alloy

[0027] The high compressive and rapidly degradable magnesium alloy is a Mg-Zn-Cu-Ni-Nd-Ca magnesium alloy, which consists of the following elements by mass percentage: Zn 8.00wt%, Cu 3.60wt%, Ni 2.30wt%, Nd 4.10wt% %, Ca 1.0wt%, and the rest are Mg and unavoidable impurity elements. The raw materials are weighed according to the ratio, and the above-mentioned raw materials are pure magnesium ingots, pure zinc ingots, pure copper ingots, pure nickel ingots, Mg-Nd master alloys, and Mg-Ca master alloys. Before smelting, heat the raw material and mold for 30 minutes to remove moisture and preheat; preheat the crucible to 400°C, spray the solvent evenly on the inner wall of the crucible; put the preheated metal ingot into the crucible and raise the temperature to 720°C, and stir Raise the temperature to 750°C and let stand, heat for 30 minutes and then cool down to 700°C for pouring. The casting mold is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com