Rolling machining method for improving microstructure texture and mechanical property of magnesium alloy sheet strip

A magnesium alloy plate and processing method technology, applied in the direction of metal rolling, etc., can solve the problems of small pass reduction, limited processing deformation, and high plate preparation cost, achieve controllable grain size, and weaken basal surface texture. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

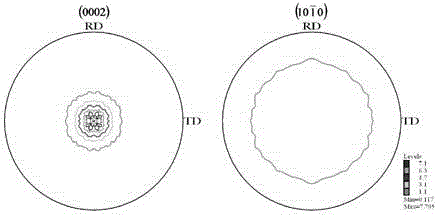

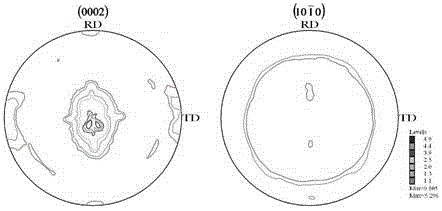

[0032] AZ31 magnesium alloy hot-rolled slab, its macro-texture {0001} pole figure is as follows figure 1 shown. figure 1 The macroscopic pole figure shows that the hot-rolled slab has a strong basal texture, and the highest strength is 7.795. The AZ31 magnesium alloy hot-rolled slab with an initial thickness of 7mm was opened for continuous cooling and rolling. The rolling path was one-way synchronous rolling. The secondary reduction is about 5%; after the continuous rolling, carry out intermediate annealing at 350°C for 30 minutes, and then repeat the aforementioned continuous cooling and rolling until the thickness of the magnesium alloy sheet reaches the required size.

Embodiment 2

[0034] The macro-texture {0001} pole figure of AZ31 magnesium alloy hot-rolled slab with an initial thickness of 4 mm is as follows figure 1 shown. figure 1 The macroscopic pole figure shows that the hot-rolled slab has a strong basal texture, and the highest strength is 7.795. The AZ31 magnesium alloy hot-rolled slab is opened for continuous cooling and rolling. The rolling path is unidirectional asynchronous rolling (different speed ratio is 1.1-1.5), the starting rolling temperature is 350°C, and the number of continuous rolling is 2 passes. , the single-pass reduction is about 10%; after continuous rolling, intermediate annealing at 350°C is performed for 15 minutes, and then the aforementioned continuous cooling rolling is repeated until the thickness of the magnesium alloy sheet reaches the required size.

Embodiment 3

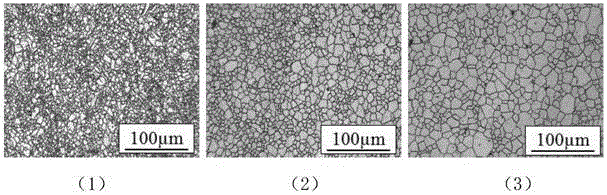

[0036] AZ31 magnesium alloy hot-rolled slabs with an initial thickness of 4 mm were subjected to continuous rolling with cooling, the rolling path was multi-directional rolling, and the rolling method was asynchronous rolling (different speed ratio 1.5), and the starting rolling temperature was 400 °C , the number of continuous rolling is 4 passes, and the reduction in a single pass is about 5%; after the continuous rolling, an intermediate annealing at 350°C is carried out, the annealing time is 15 minutes, and then the aforementioned continuous rolling at lower temperature is repeated to obtain the total reduction About 40% of the rolled plate is subjected to final annealing at 250°C×1h, 300°C×1h, and 350°C×1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com