Method for preparing antimony-doped tin oxide electrochromic film

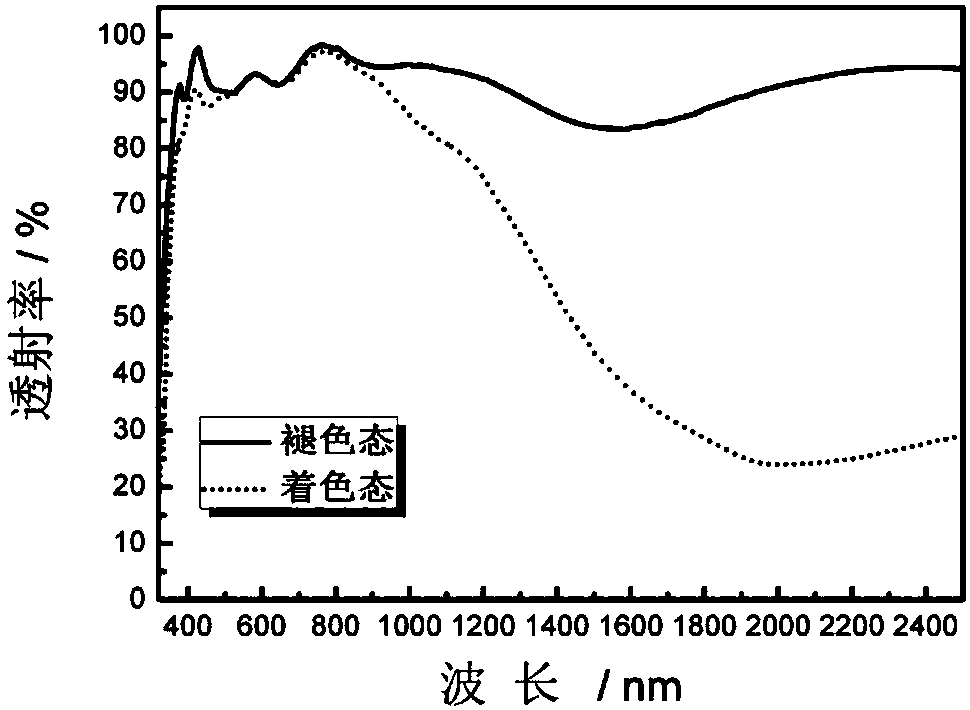

An antimony-doped tin oxide and electrochromic technology, applied in the field of optoelectronics, can solve the problems of not being suitable for mass production, high loss rate of TCO nanoparticles, and long material preparation time, so as to achieve high film preparation efficiency and short coating time , the effect of controllable grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing an antimony-doped tin oxide electrochromic film, the specific steps are as follows:

[0018] Step 1, preparation of spraying liquid: first add antimony trichloride to acetylacetone, stir at 50°C-60°C for 30 minutes, then add tin tetrachloride pentahydrate, continue to stir at 50°C-60°C for 1 hour, wait After the mixed solution was cooled to room temperature, acetic anhydride was added thereto and stirred at room temperature for 30 minutes, and finally absolute ethanol was added, and stirred at room temperature for 20 minutes to obtain the ATO spray solution;

[0019] In step 1, the ratio of raw materials for configuring ATO spraying liquid is: the molar ratio of tin tetrachloride, antimony chloride, absolute ethanol, acetylacetone and acetic anhydride is 1:0.01~0.05:45~50:4~7.2: 1.0~2.0;

[0020] Step 2, preparation of ATO thin film: first put the soda-lime glass substrate into the heating furnace and heat it to 350°C-450°C...

Embodiment 1

[0027] A preparation method of an antimony-doped tin oxide electrochromic film, the specific steps are as follows:

[0028] First, prepare the spraying solution: add 0.65 g of antimony trichloride to 114.23 g of acetylacetone, stir magnetically at 50°C for 30 minutes, then add 100g of tin tetrachloride pentahydrate, and continue to stir magnetically at 50°C for 1 hour to obtain orange yellow solution. After the solution was cooled to room temperature, 29.12 g of acetic anhydride was added thereto and stirred at room temperature for 30 min, and finally 591.23 g of absolute ethanol was added and stirred at room temperature for 20 min to obtain a stable ATO spray solution. Among them, the proportion of the spraying liquid is: the molar ratio of tin tetrachloride, antimony chloride, absolute ethanol, acetylacetone and acetic anhydride is 1:0.01:45:4:1.0.

[0029] Next, ultrasonic spray pyrolysis was used to form the film. Clean the ordinary soda-lime glass substrate and heat it ...

Embodiment 2

[0032] A preparation method of an antimony-doped tin oxide electrochromic film, the specific steps are as follows:

[0033] First, prepare the spraying solution: add 2.60 g of antimony trichloride to 171.34 g of acetylacetone, stir magnetically at 55°C for 30 minutes, then add 100g of tin tetrachloride pentahydrate, and continue to stir magnetically at 55°C for 1 hour to obtain orange yellow solution. After the solution was cooled to room temperature, 43.68 g of acetic anhydride was added thereto and stirred at room temperature for 30 min, and finally 617.57 g of absolute ethanol was added and stirred at room temperature for 20 min to obtain a stable ATO spray solution. Among them, the ratio of the spraying liquid is: the molar ratio of tin tetrachloride, antimony chloride, absolute ethanol, acetylacetone and acetic anhydride is 1:0.04:47:6:1.5.

[0034] Next, ultrasonic spray pyrolysis was used to form the film. Clean the ordinary soda-lime glass substrate and heat it in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Coloring time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com