Machining process capable of improving punching performance of magnesium alloy plate and belt

A technology of magnesium alloy plate and processing method, which is applied in metal processing and other directions, can solve problems such as poor stamping performance and unfavorable grain orientation, and achieve the effects of high processing efficiency, simple equipment, and reduced yield strength and yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

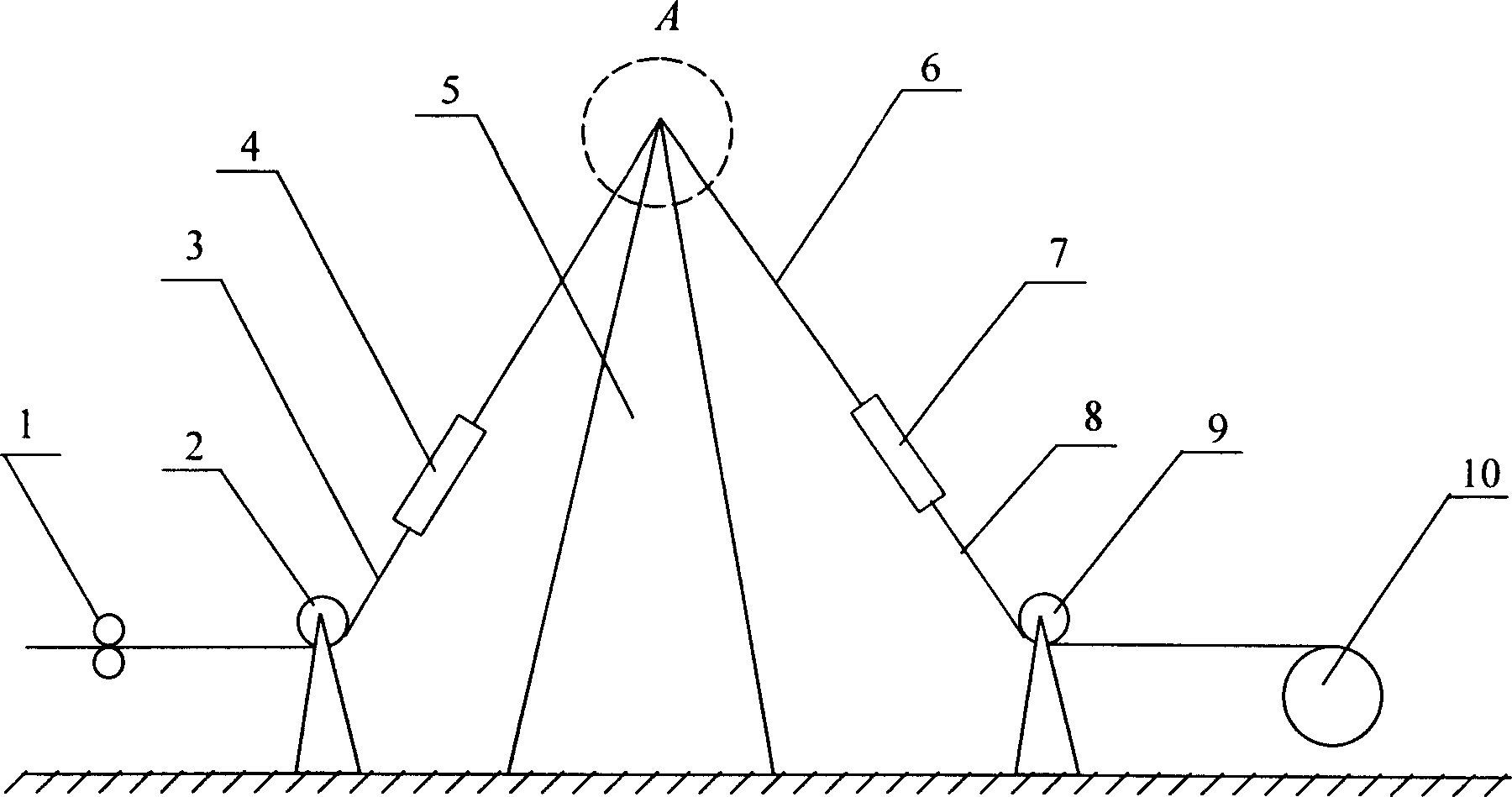

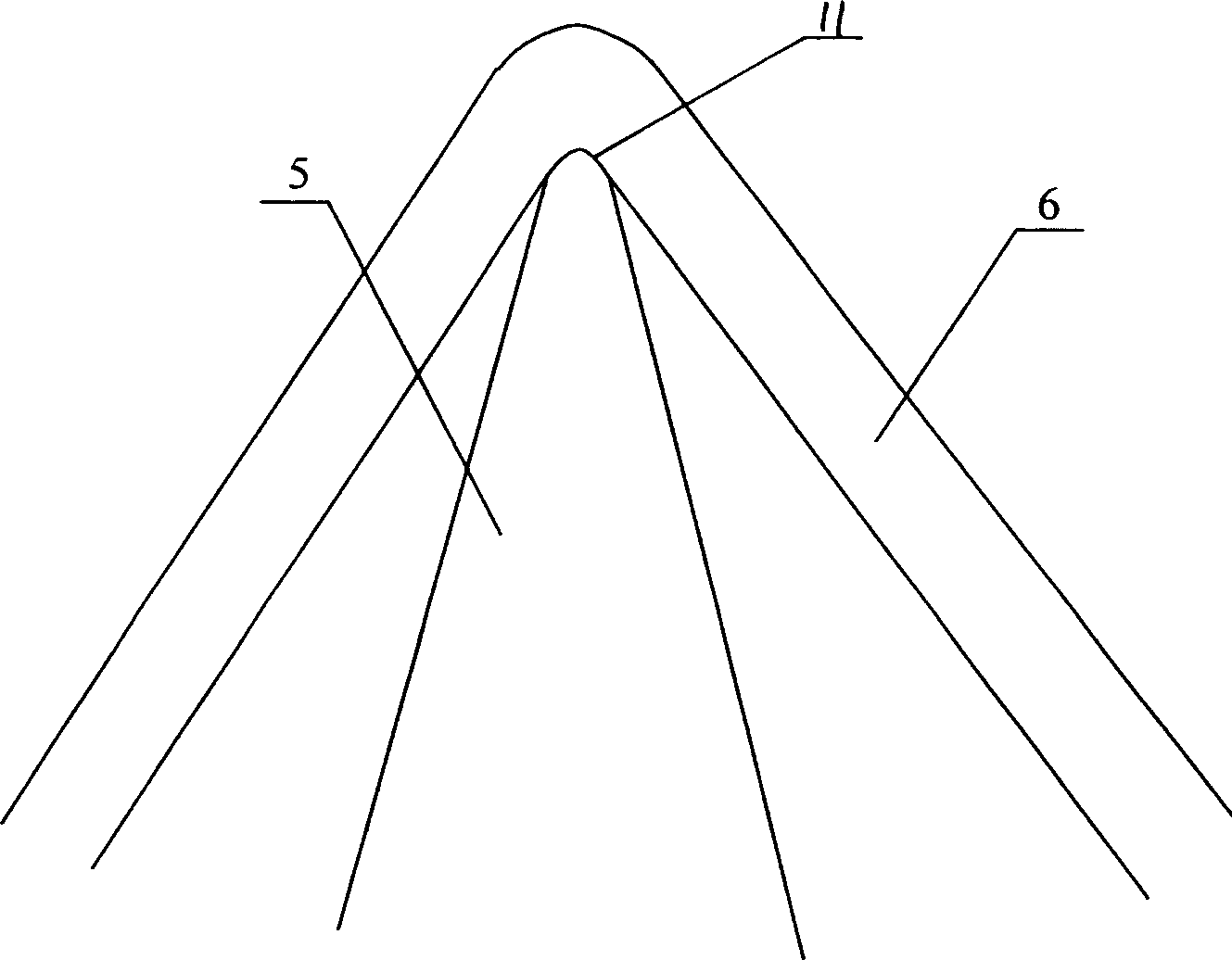

[0018] combined with figure 1 Explain that a magnesium alloy plate 6 with a thickness of 1.0mm is placed on the fixed bracket 5, the front end of the plate is connected with the flexible belt 8 by the clamp 7, the rear end of the plate is connected with the flexible belt 3 by the clamp 4, and the other end of the flexible belt 8 Fixed on the surface of the reel 10. Driven by the motor, the reel 10 moves at a speed of 10m / min. By adjusting the pressure between the pinch roller 1 and the two rollers, the tension on the magnesium alloy plate is controlled to be 30 MPa. After the magnesium alloy plate 6 is bent for one pass, the motor drives the pinch roller 1 to reverse, and the reel 10 also reverses at the same time, so as to ensure that the magnesium alloy plate 6 is not under tension during the movement. Repeat the above steps, the number of bending passes is 5. Then it is straightened on a roller leveler, and finally it is fully softened and annealed at 260°C for 60 minute...

Embodiment 2

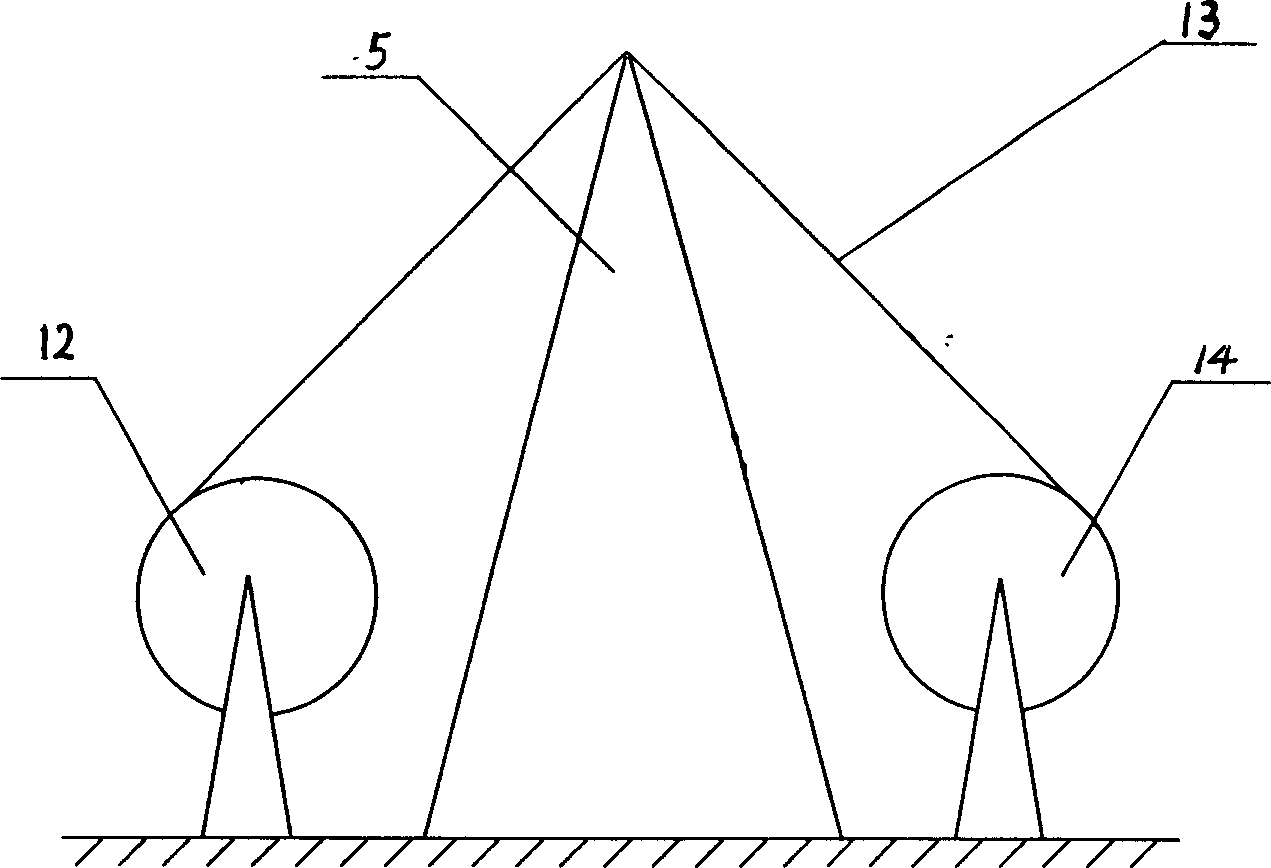

[0020] see image 3 , the coiled magnesium alloy strip 13 with a thickness of 0.6mm is placed on the uncoiler 12, the front end of the strip crosses the top of the fixed bracket 5 and is connected to the coiler 14, and the coiler is driven by the motor to drive the magnesium alloy strip The strip moves at a speed of 20m / min, and the tension on the magnesium alloy strip 13 is adjusted to 40MPa through the uncoiler 12 and the coiler 14 . After one pass is finished, the coiled material is taken off from the coiler 14, loaded on the uncoiler 12 and repeats the above steps. After 10 bending passes, stress relief annealing was carried out at 135°C for 120min. The arc radius of the contact part between the fixing bracket 5 and the magnesium alloy strip 14 is 1.0mm, and the bending angle of the magnesium alloy strip 13 is 90° when bending, and lubricated by cold rolling lubricating oil. After bending, the yield strength decreased from 172MPa to 120MPa, the yield strength ratio decre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com