A Method for Inhibiting Edge Cracks of Magnesium Alloy Sheets by Transverse Wrinkling

A technology for magnesium alloys and plates, applied in metal rolling and other directions, can solve the problems of specification limitation, plate edge crack anisotropy, complex process, etc., to achieve low cost, improve rolling formability, and weaken base surface texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, corrugated roll-flat roll combined rolling method for preparing magnesium alloy sheet

[0034] Step 1, the magnesium alloy plate is preheated.

[0035] The AZ31B magnesium alloy plate with a specification of 100*60*3 (unit: mm) was kept in a heating furnace at a temperature of 400°C for 15 minutes.

[0036] Step 2, the first corrugated roll rolling of the magnesium alloy sheet.

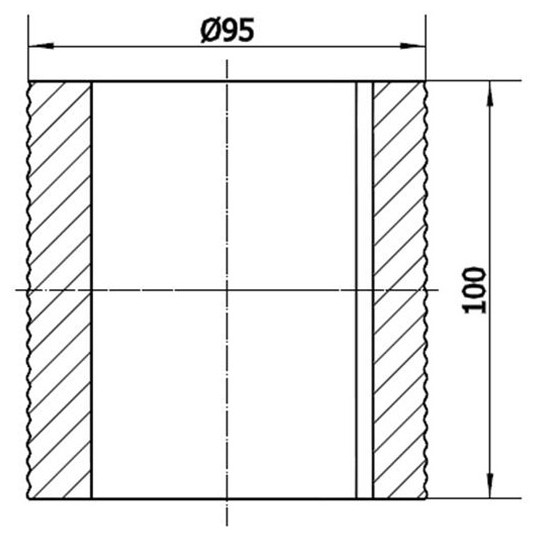

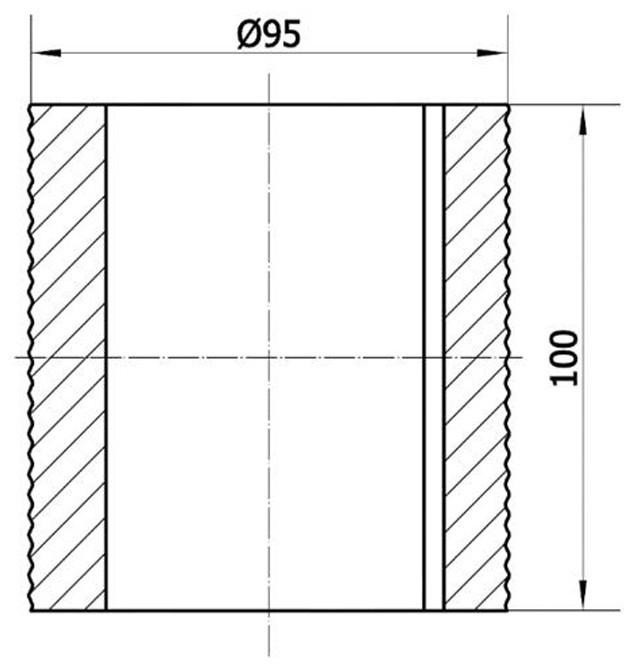

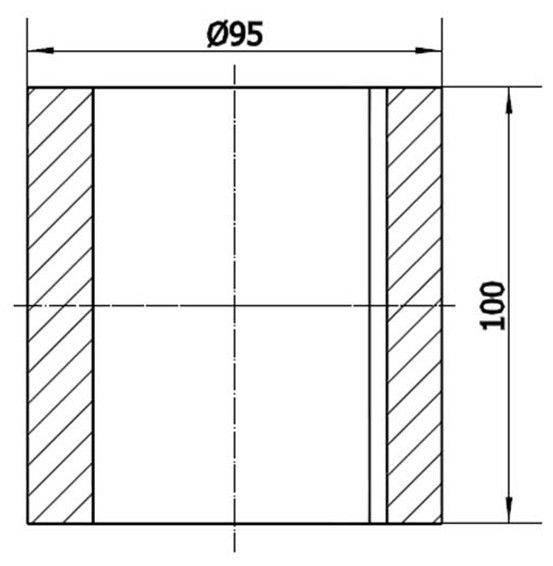

[0037] The heated magnesium plate is rolled for the first pass on a rolling mill with a roll diameter of Φ95mm. The upper and lower rolls are both longitudinal wave corrugated rolls (where the peak of the upper roll corresponds to the trough of the lower roll), and the rolling speed is 0.15m / s .

[0038] Step 3, the magnesium alloy plate is returned to the furnace for heating.

[0039] Put the AZ31B magnesium alloy plate rolled in the first pass back into the heating furnace and continue to keep warm at 400° C. for 15 minutes.

[0040] In step 4, the magnesium alloy plate is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com