Preparation process and extrusion die for magnesium alloy pipe under multiple strain paths

A preparation process and extrusion die technology, applied in the preparation process and extrusion die field of magnesium alloy pipes under multi-strain paths, can solve the problem of strong extrusion texture, low degree of grain refinement, tension-compression asymmetry, etc. problems, to achieve good electrical and thermal conductivity, good electromagnetic shielding performance, and broaden the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

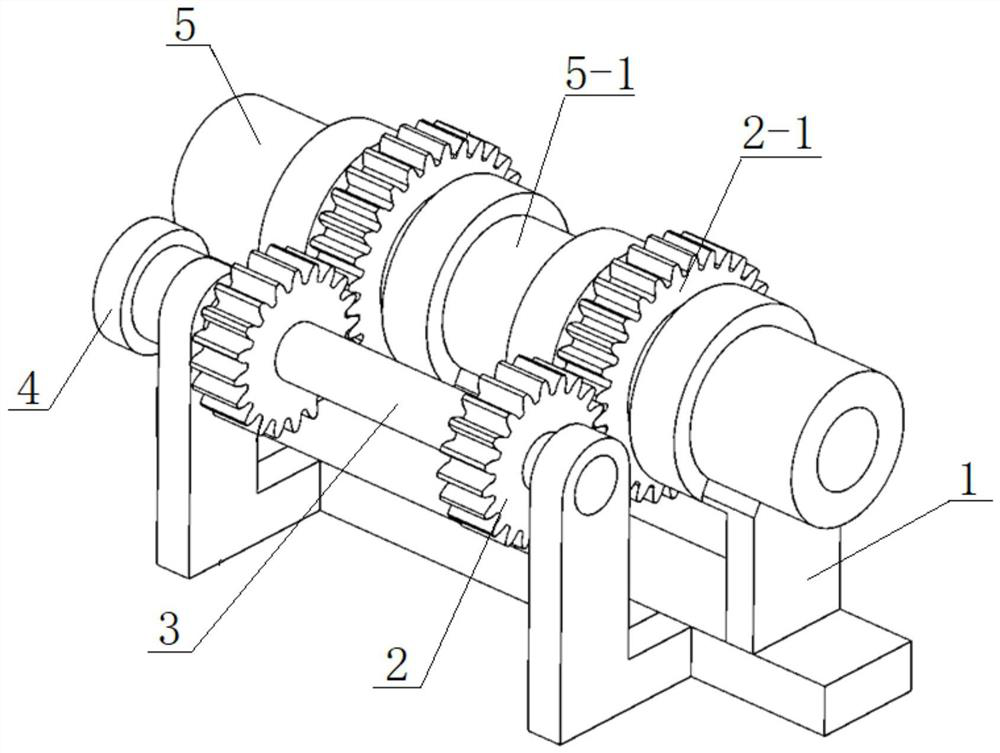

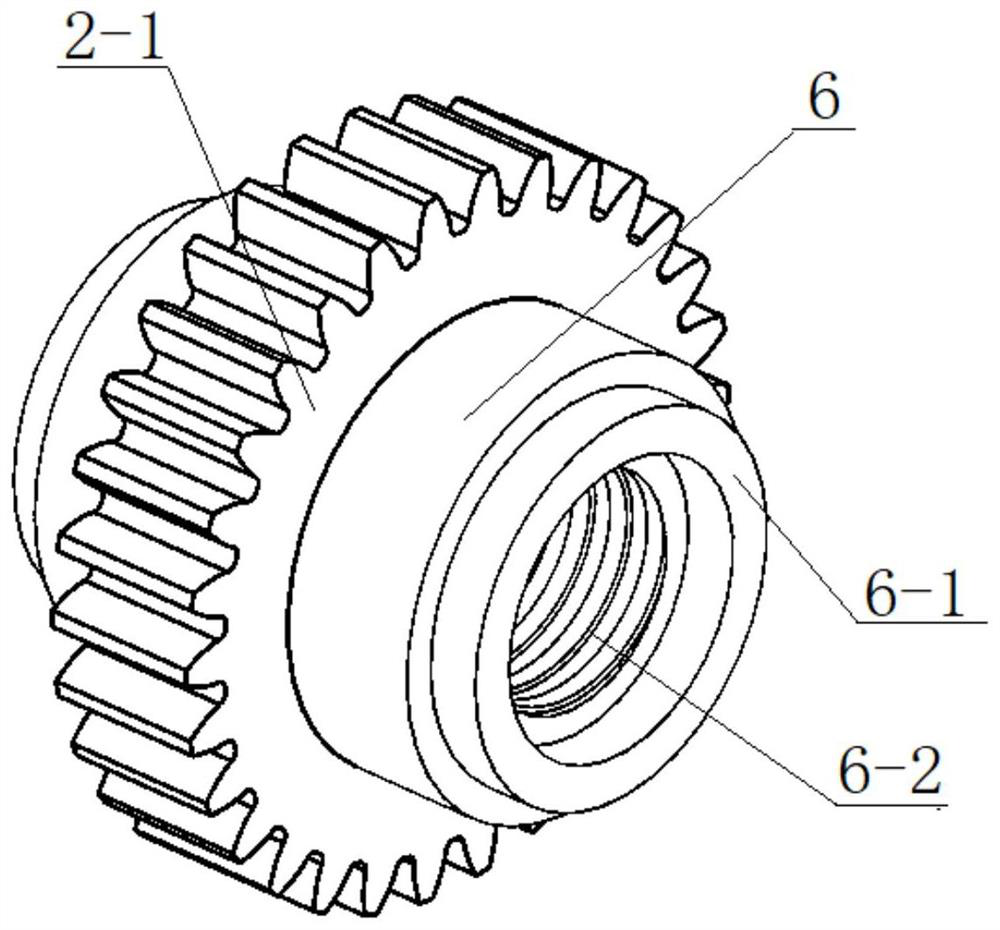

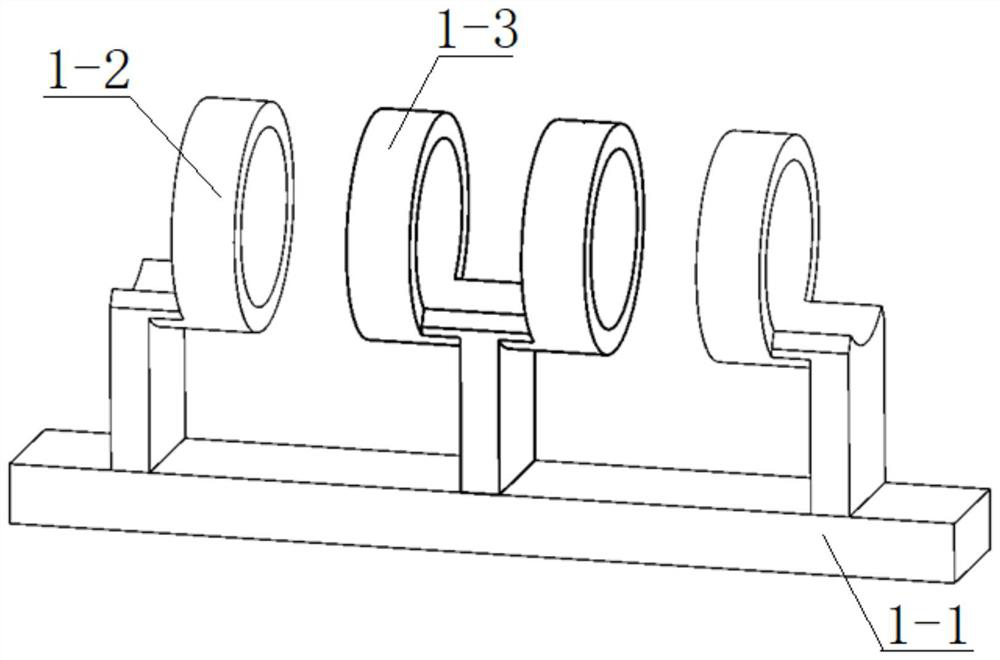

[0031] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

[0032] A preparation process for magnesium alloy pipes under multiple strain paths, characterized in that it comprises the following steps:

[0033] Step S1: preparing rod-shaped magnesium alloy blanks and high-temperature graphite powder;

[0034] Step S2: performing heat treatment on the magnesium alloy blank, and slowly cooling in air;

[0035] Step S3: Carry out extrusion preheating treatment again;

[0036] Step S4: placing the heated magnesium alloy billet in an extruder, and placing the magnesium alloy billet in the extruder after the extrusion punch and die are heated;

[0037] Since the shear extrusion channel is corrugated, it can produce multiple extrusion deformations;

[0038] Step S5: Grinding and cleaning the extruded magnesium alloy pipe.

[0039] In step S4, the inner surface of the extrusion die i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com