Magnesium alloy sheet strip coupling and deformation combined rolling system and rolling method thereof

A technology of magnesium alloy and sheet strip, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low production efficiency, strong mechanical anisotropy, low yield, etc., to improve performance and production efficiency, The effect of overcoming micro-crack defects on the board surface and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

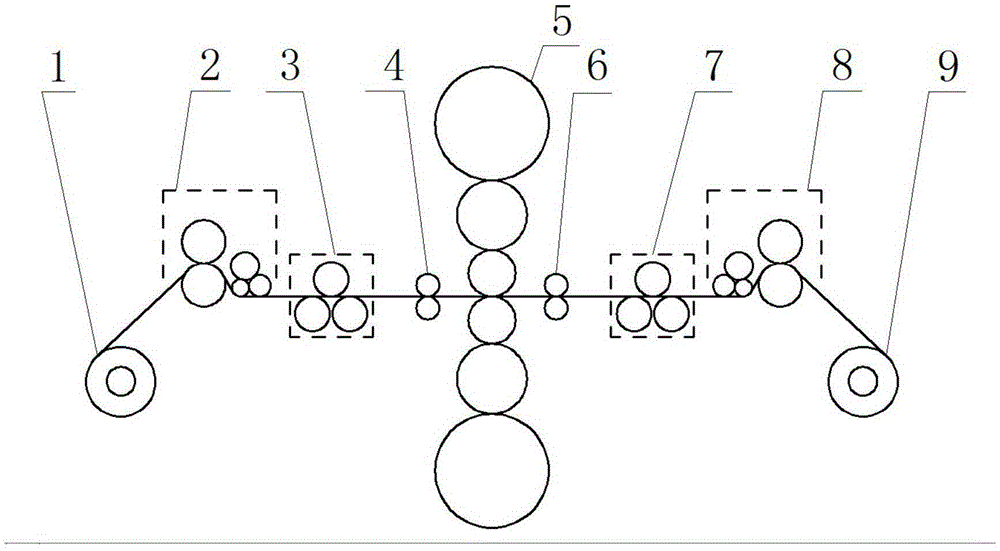

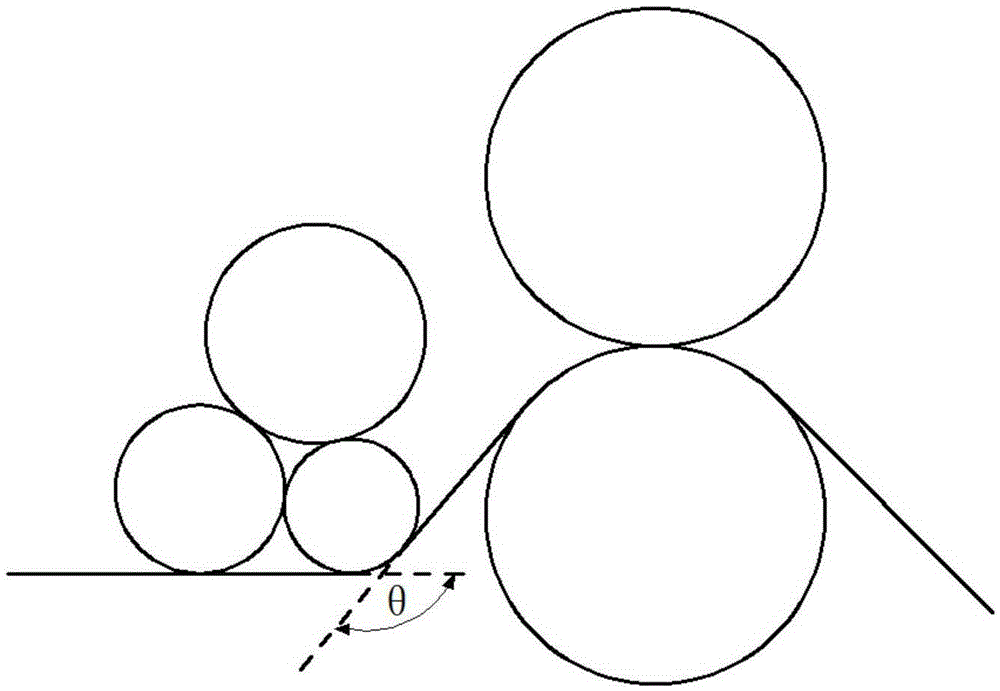

[0018] Such as figure 1 and figure 2 As shown, a magnesium alloy sheet strip coupling deformation combined rolling system in this embodiment consists of two uncoiling-coilers 1,9, two five-roll shear bending large deformation adjustable devices 2,8, Two three-roll straightening machines 3, 7, two pinch roll devices 4, 6 and six-roll reversing rolling mill 5, the first uncoiler-coiler 1, the first five-roll shear bending large deformation can be adjusted Device 2, the first three-roll leveler 3 and the first pinch roll device 4 are sequentially arranged in front of the six-roll reversing mill 5, the second pinch roll device 6, the second three-roll leveler 7. The second five-roll shear bending large deformation adjustable device 8 and the second uncoiler-coiler 9 are sequentially arranged behind the six-roll reversing mill 5 to realize recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com