Extruding method for texture-weakened magnesium alloy sheet

An extrusion method and magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of severe anisotropy, uneven lateral distribution, and failure to meet the requirements of use well, and achieve magnesium alloy grain refinement, basal surface weaving, etc. The effect of weakening the structure and refining the grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for co-extruding a magnesium alloy composite sheet in this embodiment comprises the following steps:

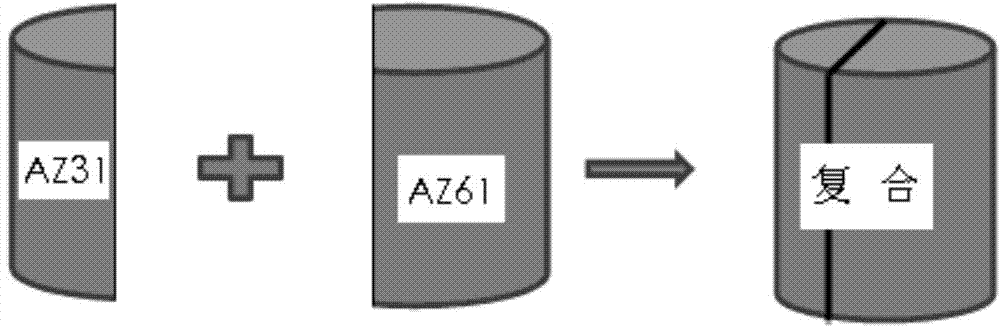

[0031] 1) Take two semi-cylindrical AZ31 magnesium alloy ingots and AZ61 magnesium alloy ingots respectively (the thickness of AZ61 is about 1 / 4 of that of AZ31);

[0032] 2) Cleaning step 1) The cut surface of the obtained semi-cylindrical AZ31 magnesium alloy ingot and AZ61 magnesium alloy ingot is polished to smooth and smooth;

[0033] 3) The semi-cylindrical AZ31 magnesium alloy ingot and the AZ61 magnesium alloy ingot in step 2) are superimposed together (the cut surfaces are opposite, such as figure 1 shown) and fixed with aluminum wire (to avoid macroscopic relative sliding during the extrusion process, and the plates should be tightly fitted without gaps);

[0034] 4) extruding the composite in step 3) at 400°C to obtain a composite sheet;

[0035] 5) The AZ61 magnesium alloy layer of the composite sheet is removed by mechanical cutting or grindin...

Embodiment 2

[0038] The method for co-extruding a magnesium alloy composite sheet in this embodiment comprises the following steps:

[0039] 1) Take AZ31 magnesium alloy ingot block and AZ80 magnesium alloy ingot block respectively (wherein the thickness of AZ80 magnesium alloy block is 1 / 5 of AZ31 magnesium alloy);

[0040] 2) AZ31 magnesium alloy ingot and AZ80 magnesium alloy ingot in grinding and cleaning step 1);

[0041] 3) stacking the AZ31 magnesium alloy ingot and the AZ80 magnesium alloy ingot in step 2) together and fixing them with aluminum wire;

[0042] 4) Heating the complex in step 3) to 400°C for 1 hour and extruding to obtain the product;

[0043] 5) The AZ80 magnesium alloy on the outer side, which plays a protective and auxiliary forming role, is removed by mechanical cutting or grinding to obtain the AZ31 magnesium alloy plate to be prepared.

Embodiment 3

[0045] The method for co-extruding a magnesium alloy composite sheet in this embodiment comprises the following steps:

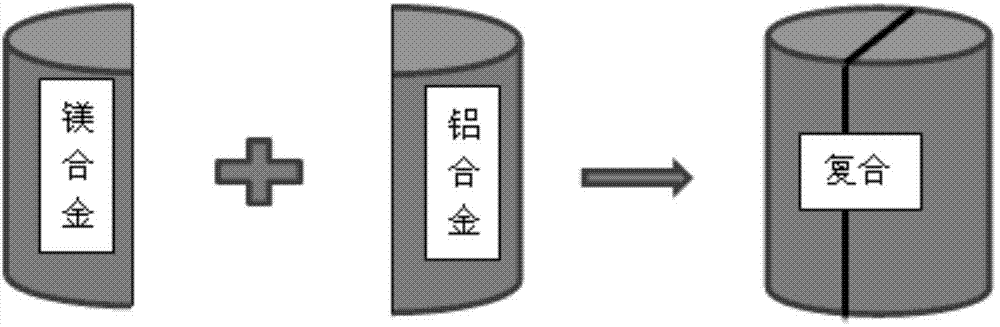

[0046] 1) Take two cylindrical magnesium alloy ingots (AZ31) and aluminum alloy ingot 5052 of the same size and cut them along the central axis;

[0047] 2) Cleaning step 1) The cut surface of the obtained semi-cylindrical magnesium alloy and aluminum alloy ingot is polished to smooth and smooth;

[0048] 3) stack the semi-cylindrical magnesium alloy and aluminum alloy ingots after step 2) grinding (the cutting planes are opposite, such as image 3 shown) and fixed with aluminum wire (to avoid macroscopic relative sliding during extrusion);

[0049] 4) Heating the complex in step 3) to 380° C. for 1 hour and then placing it in an extrusion device for extrusion;

[0050] 5) 400°C tempering treatment step 4) extruded plate to obtain the product;

[0051]6) The aluminum alloy layer of the composite plate is removed by mechanical cutting or grinding to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com