Magnesium alloy grain refining method

A technology for grain refinement and magnesium alloy, applied in the field of magnesium alloy grain refinement, can solve the problems of poor forming ability, poor room temperature deformation ability, low room temperature plasticity, etc., and achieves abundant nucleation positions and high internal deformation storage energy. , the effect of improving strength and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A method for refining magnesium alloy grains, specifically comprising the following steps:

[0023] (1) Production and processing in accordance with GB / T5154-2003 standard, after semi-continuous casting, hot-rolled blanking treatment is carried out between 350°C and 450°C, and then annealed and leveled at 400°C;

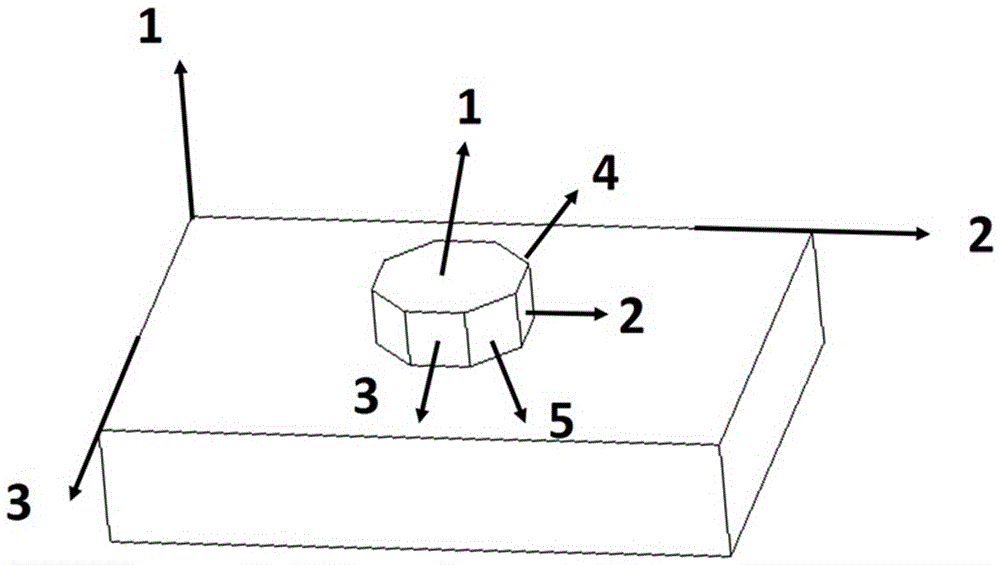

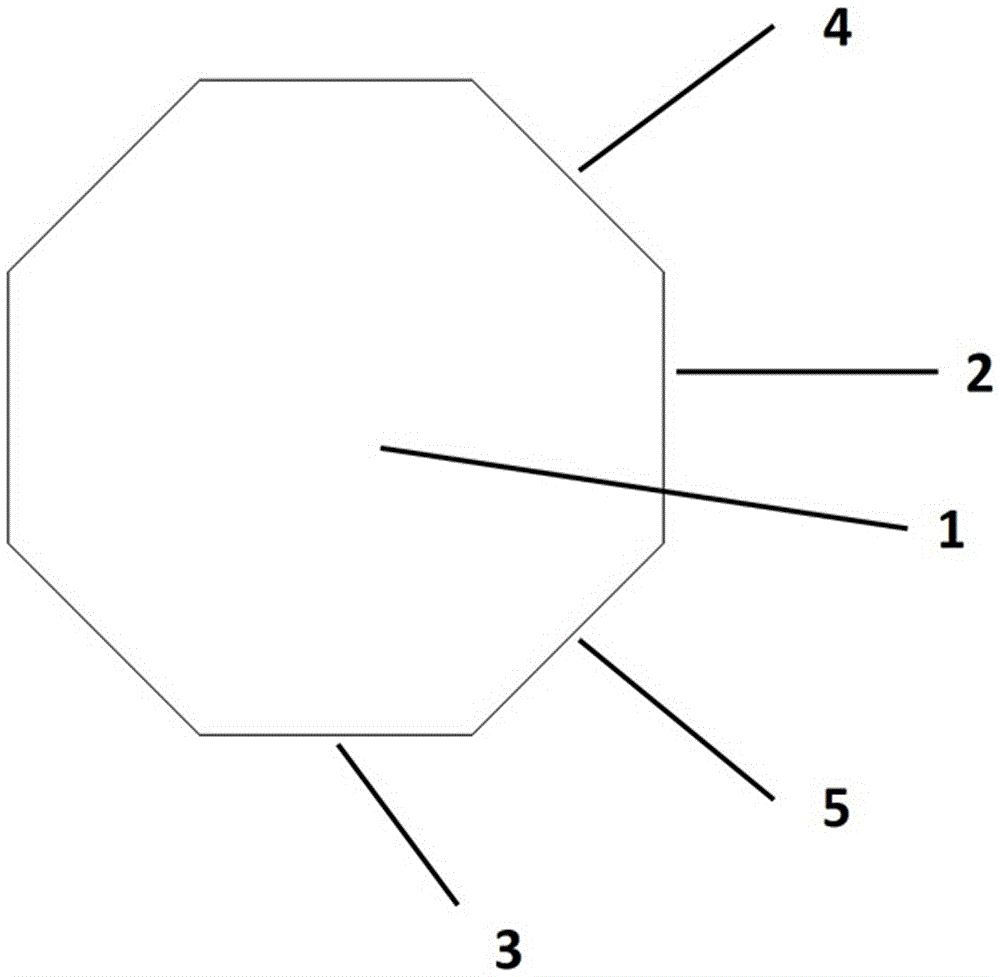

[0024] (2) Design regular octagonal prism plates: design regular octagonal prism plates on hot-rolled slabs so that they have 5 different deformation directions, such as figure 1 As shown, direction 1 indicates the rolling direction (ND) of the plate, direction 2 indicates the rolling direction (RD) of the plate, direction 3 indicates the transverse direction (TD) of the plate, and direction 4 indicates the direction 45TD at an angle of 45° to the transverse direction of the plate , direction 5 represents another direction 45TD' which forms an angle of 45° with the transverse direction of the plate;

[0025] (3) Combination of multiple deformation directions:...

Embodiment 1

[0030] The size of the regular octagonal prism taken off from the hot-rolled slab is: the upper and lower surfaces are regular octagons, the side length is 200 mm; the thickness is also 200 mm. Multi-directional cycle forging is carried out at room temperature, the strain rate is 1mm / min, and the combination of one cycle direction is: ND-RD-45TD-TD-45TD'. First deform 10% along the ND direction, then deform 4% along the RD direction, then deform 8% along the 45TD direction, then deform 5% along the TD direction, and finally deform 5% along the 45TD’ direction to complete a cycle. A combination of transformations can accumulatively deform 32%. This process can be cycled 10 times, and the cumulative deformation is 320%. The deformed sample is subjected to medium-temperature short-time heat treatment, the annealing temperature is 200° C., and the annealing time is 25 minutes. After annealing, a recrystallized equiaxed grain structure with a grain size of 650-750 nm can be obtain...

Embodiment 2

[0032] The size of the regular octagonal prism taken off from the hot-rolled slab is: the upper and lower surfaces are regular octagons, the side length is 200 mm; the thickness is also 200 mm. Multi-directional cycle forging is carried out at room temperature, the strain rate is 5mm / min, and the combination of one cycle direction is: ND-RD-45TD-TD-45TD'. First deform 12% along the ND direction, then deform 5% along the RD direction, then deform 10% along the 45TD direction, then deform 5% along the TD direction, and finally deform 5% along the 45TD’ direction to complete a cycle. A deformation combination can accumulatively deform 37%. This process can be cycled 7 times, and the cumulative deformation is 259%. The deformed sample is subjected to medium-temperature short-time heat treatment, the annealing temperature is 250° C., and the annealing time is 20 minutes. After annealing, a recrystallized equiaxed grain structure with a grain size of 700-800 nm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com