A kind of preparation method of high plasticity heat deformation rare earth magnesium alloy

A technology of hot deformation and rare earth magnesium, applied in the field of magnesium alloys, can solve the problems of increasing recrystallized structure, possessing strength, difficult to achieve high plasticity, etc., and achieve the effect of weakening the basal texture, improving strength and plasticity, and reducing casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

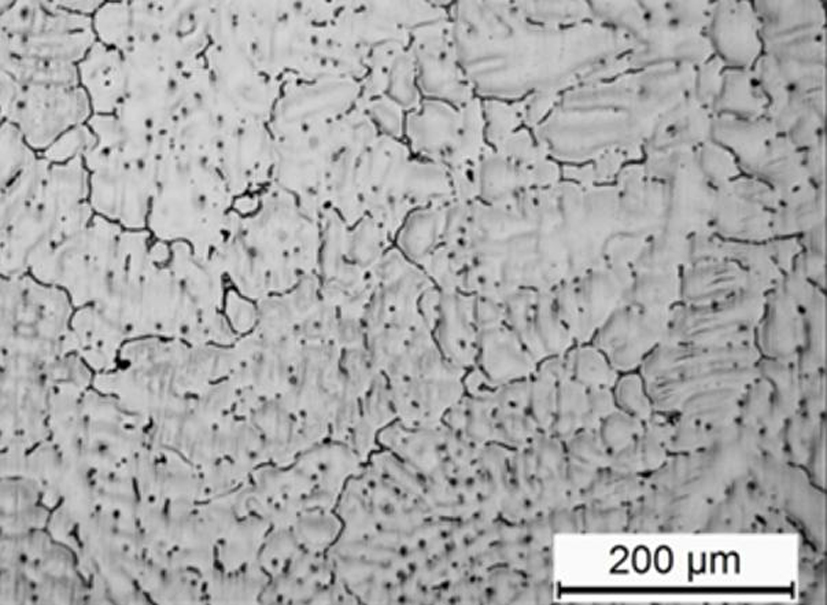

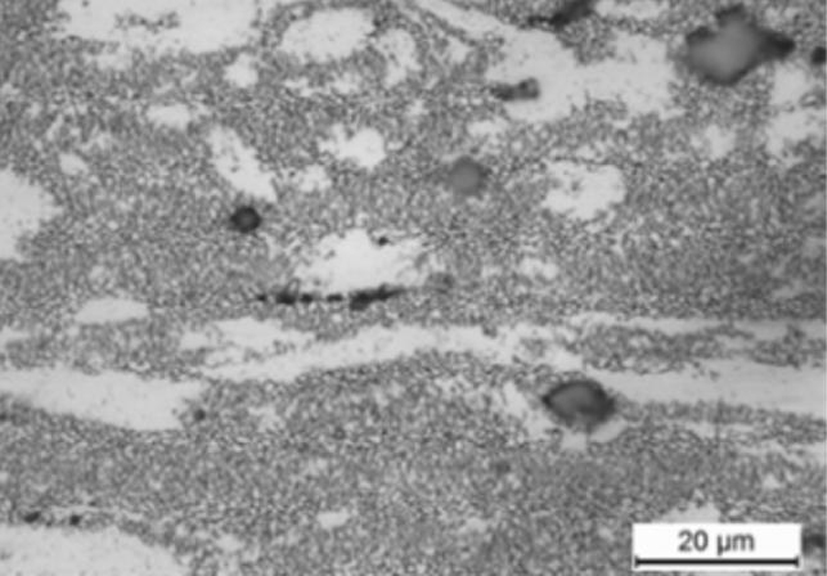

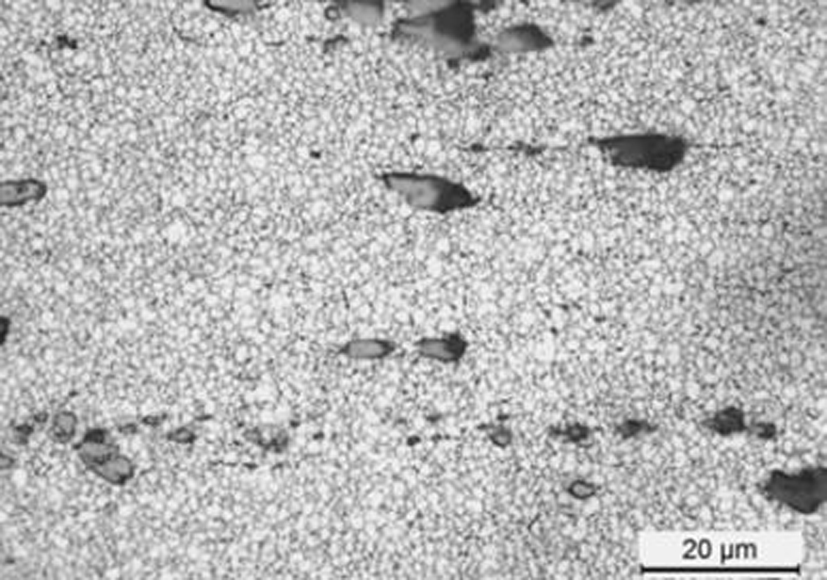

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0028] The ratio of the prepared magnesium alloy in this example is: 4%Zn, 0.5%Ca, 2%Gd and 93.5%Mg.

[0029] A method for preparing a high-plasticity heat-deformable rare-earth magnesium alloy, comprising the following steps:

[0030] S1. Select raw materials according to the weight percentage content. The mass ratio of magnesium block, zinc grain, Mg-Gd master alloy and pure calcium is 91.5:4:2:0.5; coat the coating agent evenly on the inner wall of the melting furnace, and The outer surface of the block is evenly coated with covering agent;

[0031] S2. The magnesium block is placed in the smelting furnace through the crucible, the door of the smelting furnace is closed, the protective gas is introduced into the smelting furnace, the temperature of the smelting furnace is raised to 780°C and kept warm until the magnesium block is completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com