Mouldless cast forming method of frozen clay sand

A clay sand and clay technology, which is applied in the field of sand casting, can solve the problems of unsuitable direct cutting sand casting, low tensile (compressive) strength and low surface hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

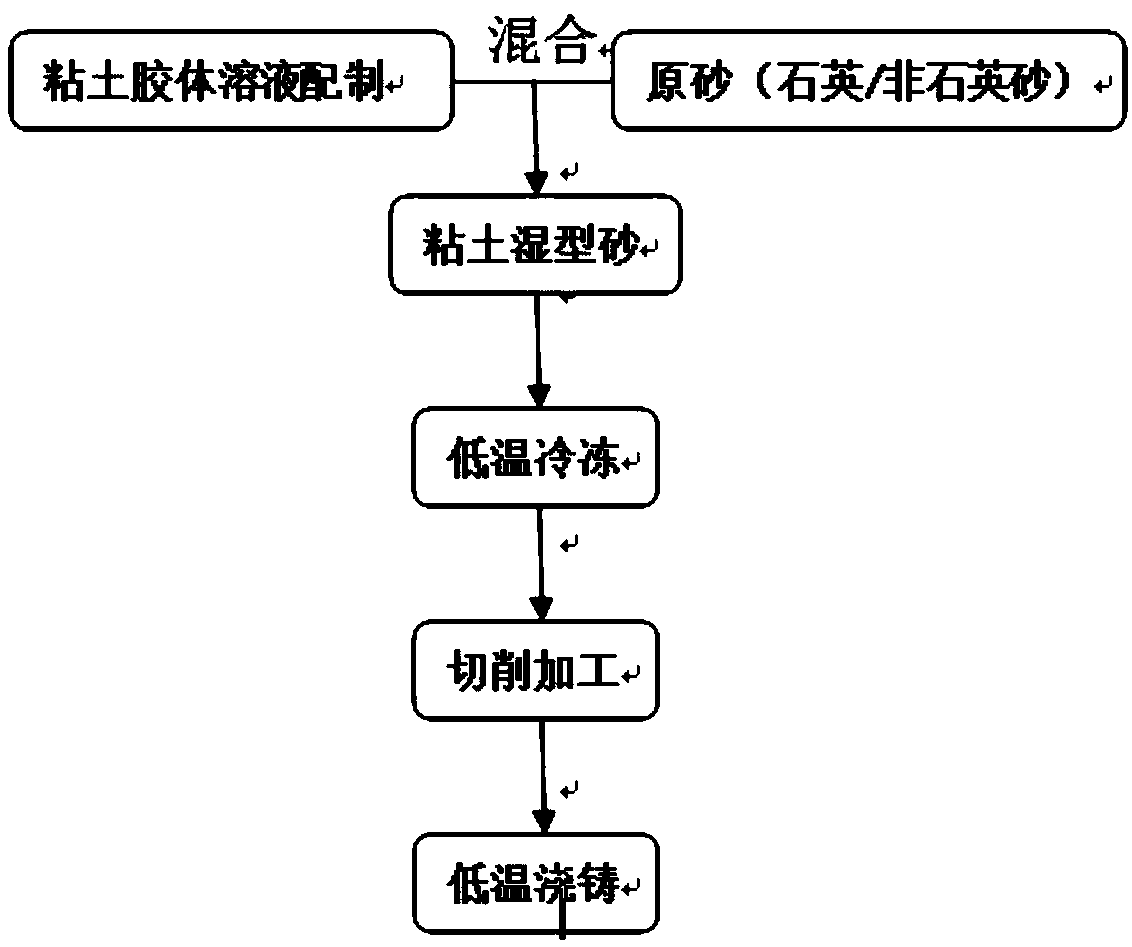

[0020] The present invention is directed at a method of moldless casting of frozen clay sand. The selected casting sand can be quartz sand, non-quartz sand or a mixture of several kinds of sand in any proportion according to the different requirements of the casting, and the mesh number can be 40 / 70. , Any gradation of 50 / 100, 70 / 140, 100 / 200. Clay powder such as bentonite accounts for 20.0%-50.0% of the mass fraction of pure water, and clay binder accounts for 5%-12% of the mass fraction of molding sand. Put the mixed clay molding sand into the low-temperature molding sand box, solidify and form the clay sand blank in a low temperature environment of -15°C to -40°C, and then transport the frozen clay sand blank to the freezing environment of the moldless molding machine In the process, the sand mold (core) is directly cut by the milling cutter.

[0021] The specific implementation steps of the present invention are as follows:

[0022] Step 1: According to the technical req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com