Two-fluid bimetal compound poured crushing hammer manufacturing method

A technology of double-liquid bimetal and manufacturing method, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of reducing the service life of the hammer head, many casting defects, and difficult control of the process, so as to strengthen the bonding strength and reduce casting defects , to avoid the effect of cold insulation slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] A method for manufacturing a double-liquid bimetallic composite casting breaking hammer head, comprising the following steps:

[0030] a. According to the shape and size of the crushing hammer, use sodium silicate self-hardening quartz sand to form the core, and paint the zircon powder alcohol-based quick-drying paint on the surface of the sand mold;

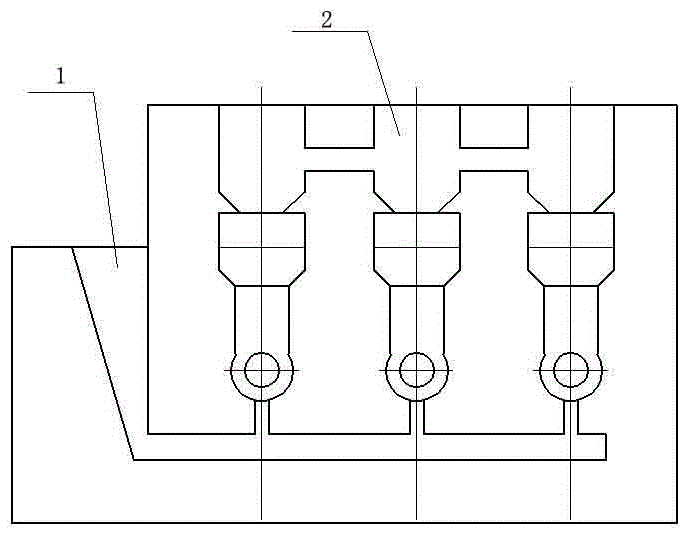

[0031] b. Set the hammer handle gating system 1 at the low position of the sand mold, set the hammer head gating system 2 at the top of the sand mold, and the upper plane of the gate of the hammer handle gating system 1 is level with the hammer head and the hammer handle; figure 2 shown.

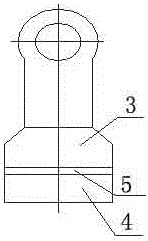

[0032] c. Two intermediate frequency furnaces are used to smelt high-chromium cast iron and low-carbon alloy steel at the same time. The hammer handle part 3 is made of low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com