A method for improving rolling forming of magnesium alloy plate and strip

A magnesium alloy plate and strip rolling technology, which is applied in metal rolling, temperature control, metal processing equipment, etc., can solve the problems of unfavorable slab forming and increased cost, achieve good improvement effect and reduce edge temperature drop , the effect of controlling widthwise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

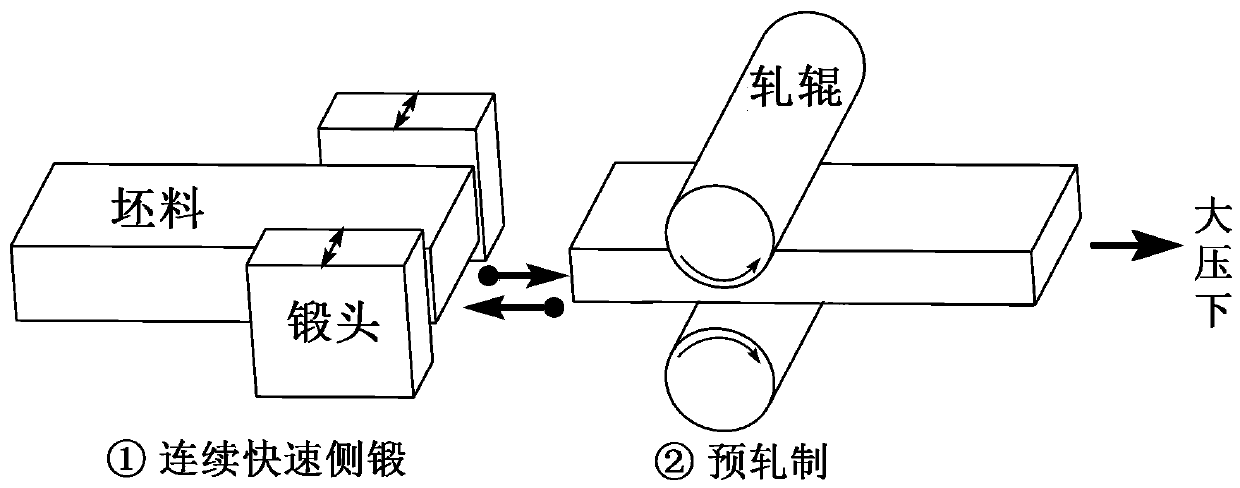

[0052] A method for improving the rolling and forming of magnesium alloy plates and strips is a pre-rolling and large-pressure blanking method, and the schematic diagram of the pre-rolling large-pressure blanking is shown in figure 1 ②, the schematic diagram of the process flow is shown in Figure 9 , including the following steps:

[0053] Step 1: Pre-rolling

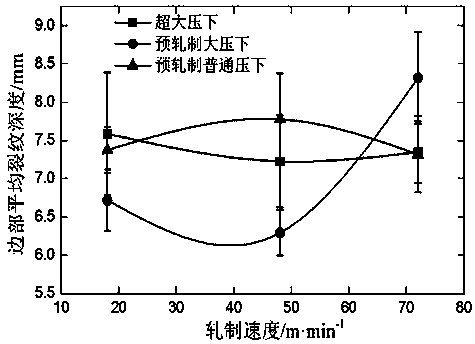

[0054] The slab blank with a size of 150mm×80mm×30mm is heated to 400°C in an orbital box-type resistance heating furnace and transferred to a two-roll cold rolling mill. The rolls of the two-roll cold rolling mill are subjected to 8% reduction in the first pass Pre-rolling to obtain the pre-rolled billet; wherein, the rolling temperature of the two-roll cold rolling mill is room temperature, and the rolling speed is set to 18m / min, 48m / min and 72m / min respectively for three groups of parallel experiments ;

[0055] Step 2: Rolling under heavy pressure

[0056] Immediately afterwards, the billet after the pre-rolli...

Embodiment 2

[0061] A method for improving the rolling and forming of magnesium alloy plate and strip is a pre-rolling large-pressure blanking method, which specifically includes the following steps:

[0062] Step 1: Pre-rolling

[0063] Use a heating device to heat the rolls of the two-roll mill to keep the roll temperature at 150±10°C, heat the slab blank with a size of 800mm×340mm×220mm to 350°C in an orbital box-type resistance heating furnace, and transfer it to the two-roll mill Carry out pre-rolling with 8% reduction in the first pass to obtain the billet after pre-rolling;

[0064] Step 2: Rolling under heavy pressure

[0065] Subsequently, the pre-rolled billet is subjected to a second pass of high-reduction rolling with a reduction of 80% at a rolling speed of 48 m / min. After rolling, the macroscopic appearance of the plate and the properties of different positions in the width direction of the plate were analyzed.

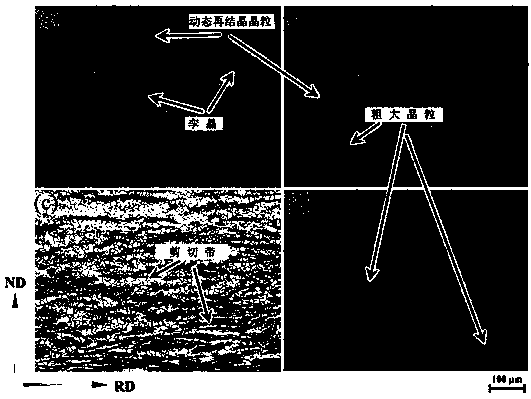

[0066] See Figure 5 ,From Figure 5 It can be obtained th...

Embodiment 3

[0069] A method for improving the rolling forming of magnesium alloy plates and strips, which is a method of continuous rapid side forging and pre-rolling intersecting and then large-pressure blanking method. figure 1 ①+②, the schematic diagram of the process flow is shown in Figure 10 , including the following steps:

[0070] Step 1: Continuous rapid side forging

[0071] Use a heating device to heat the rolls of the two-roll mill to keep the temperature of the rolls at 150±10°C, heat the slab blank with a size of 1000mm×520mm×450mm to 350°C in an orbital box-type resistance heating furnace, and use a small tonnage forging machine Carry out the first pass of 10% continuous rapid side forging to obtain the blank after side forging;

[0072] Step 2: Pre-rolling

[0073] The billet after side forging is sent to the two-roll mill for pre-rolling with a reduction of 8% in the second pass to obtain the billet after pre-rolling;

[0074] Step 3: Rolling under heavy pressure

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com