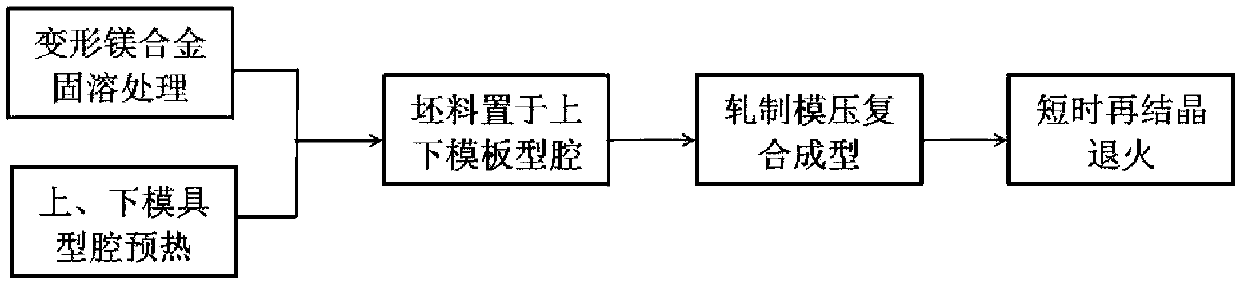

Magnesium alloy variable section rolling and die pressing compound forming device and forming method

A technology of composite molding and variable cross-section, which is applied in the field of plastic forming of non-ferrous metals, can solve problems such as easy cracking and poor plasticity, and achieve the effects of refined grains, optimized performance, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 selects extruded MM31 magnesium alloy plate.

[0026] 1) Cut the extruded MM31 magnesium alloy plate to be processed into the desired shape.

[0027] 2) Heating the magnesium alloy billet to 400°C, heating up to a predetermined temperature and then keeping it warm for 20 minutes;

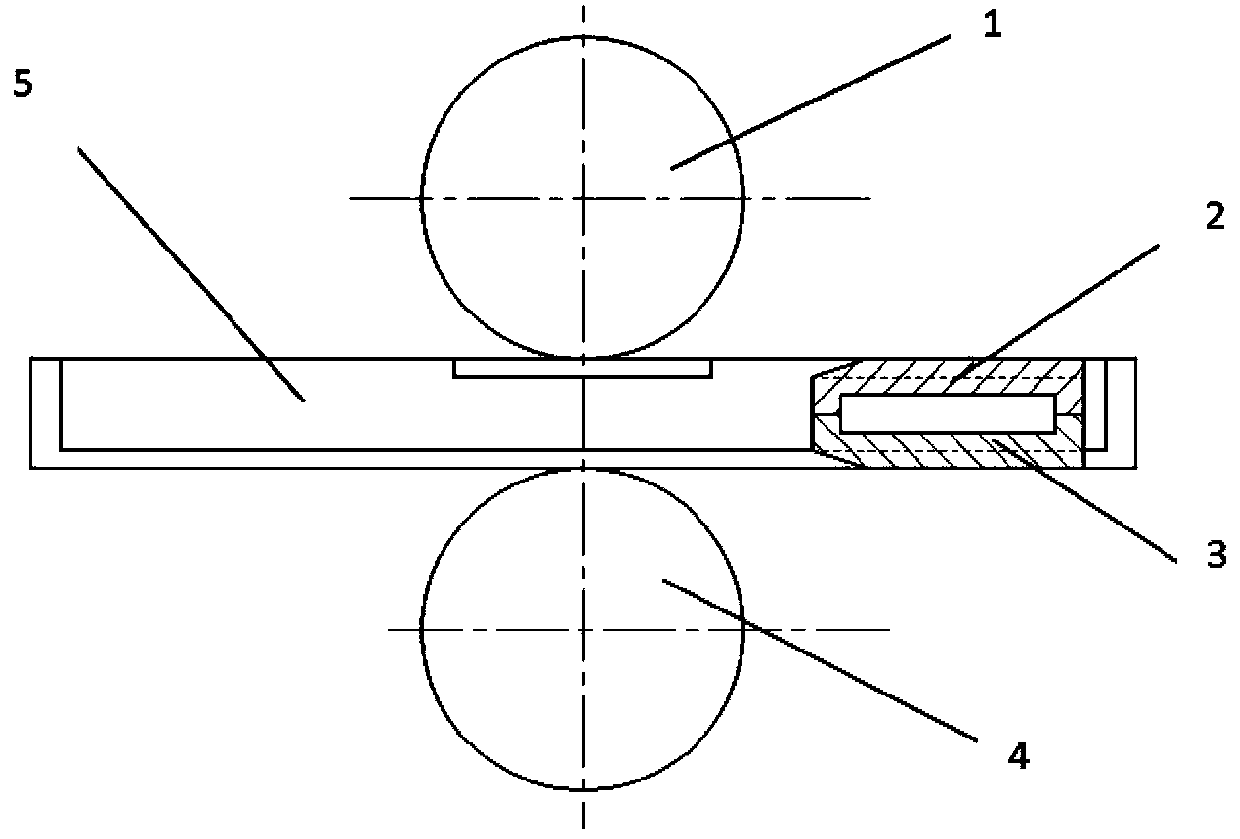

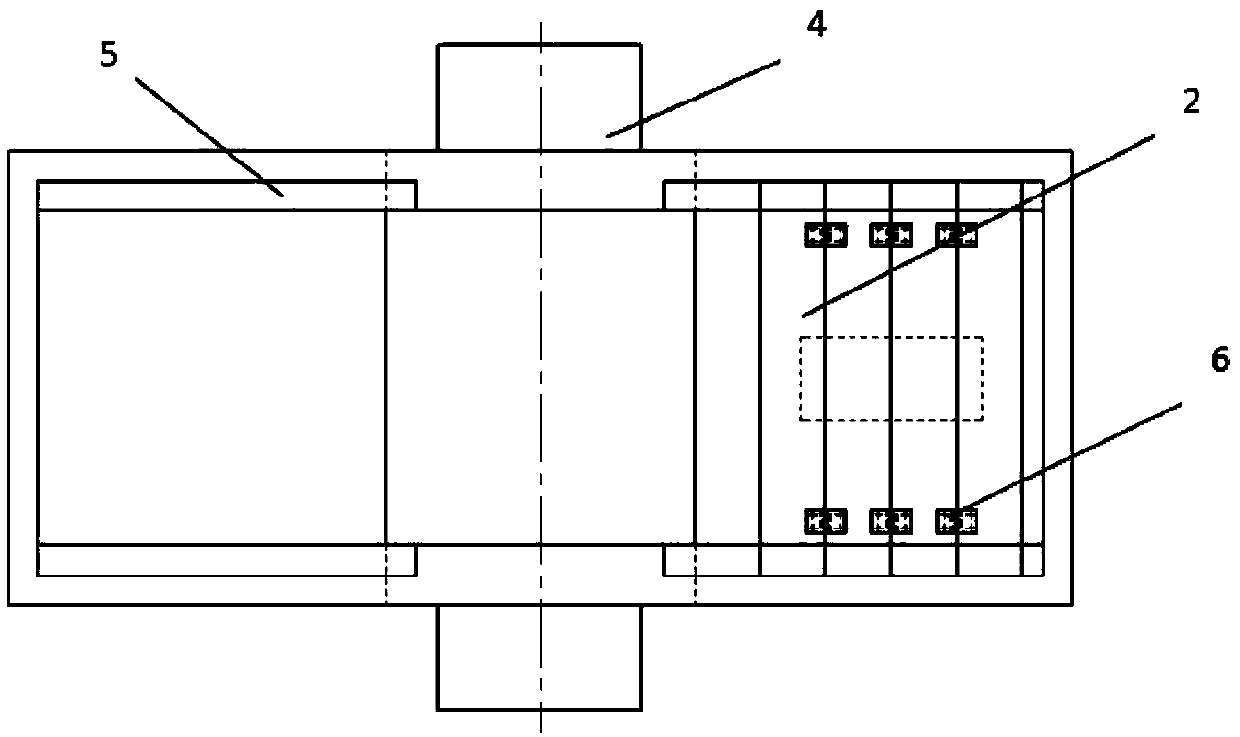

[0028] 3) Heat the cavity surfaces of the upper template 2 and the lower template 3 to 100°C with an external heating device;

[0029] 4) putting the magnesium alloy blank into the cavity of the mould;

[0030] 5) Send the magnesium alloy variable-section rolling-molding composite molding die to the feeding position, and the rolls drive the mold to pass through the rollers to realize variable-section rolling-molding composite molding. The rolling speed is 8m / min, the distance between the rollers is 30mm, and the thickness of the upper template is 15mm, the thickness of the lower template is 15mm.

[0031] 6) After forming, short-term recrystallization annealing treatment is ca...

Embodiment 2

[0033] Example 2 uses a multi-element and small amount of magnesium alloy plate Mg-1.2Sn-0.8Zn-0.5Mn (wt.%).

[0034] 1) Cut the multi-element and small amount magnesium alloy plate Mg-1.2Sn-0.8Zn-0.5Mn (wt.%) to be processed into the desired shape.

[0035] 2) Heating the magnesium alloy billet to 350°C, raising the temperature to a predetermined temperature and keeping it warm for 10 minutes;

[0036] 3) Heat the cavity surfaces of the upper template 2 and the lower template 3 to 100°C with an external heating device;

[0037] 4) putting the magnesium alloy blank into the cavity of the mould;

[0038] 5) Send the magnesium alloy variable-section rolling-molding composite molding die to the feeding position, and the rolls drive the mold to pass through the rollers to realize variable-section rolling-molding composite molding. The rolling speed is 10m / min, the distance between the rollers is 40mm, and the thickness of the upper template 20mm, the thickness of the lower templ...

Embodiment 3

[0041] Embodiment 3 uses deformed aluminum alloy 6022.

[0042] 1) Cut the deformed aluminum alloy 6022 to be processed into the desired shape.

[0043] 2) Heat the aluminum alloy billet to 450°C, heat it up to the predetermined temperature and keep it warm for 30 minutes;

[0044] 3) Heat the cavity surfaces of the upper template 2 and the lower template 3 to 100°C with an external heating device;

[0045] 4) putting the aluminum alloy blank into the cavity of the mould;

[0046] 5) Send the aluminum alloy variable-section rolling-molding composite molding die to the feeding position, and the rollers drive the mold to pass through the rollers to realize the variable-section rolling-molding composite molding. The rolling speed is 20m / min, the distance between the rollers is 50mm, and the thickness of the upper template 25mm, the thickness of the lower template is 25mm.

[0047] 6) Short-term annealing treatment is carried out on the workpiece according to requirements after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com