Low-cost soluble magnesium alloy and preparation method and application thereof

A magnesium alloy and soluble technology, which is applied in the field of low-cost soluble magnesium alloy and its preparation, can solve the problems of low mechanical properties, uneven and stable dissolution process, coarse grains, etc., so as to reduce ingot segregation, reduce deformation resistance, reduce effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

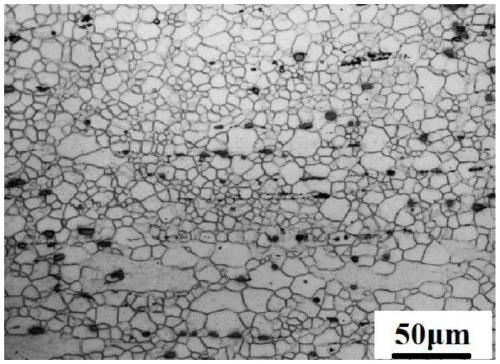

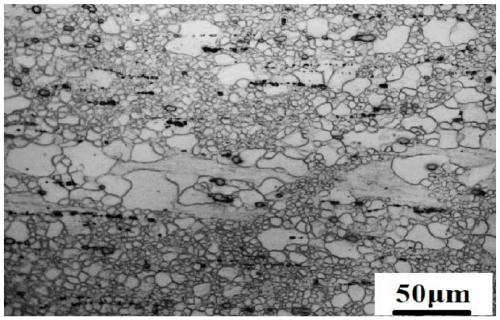

[0028] The second aspect of the present invention provides the above-mentioned low-cost soluble magnesium alloy preparation method, comprising the following steps: weighing pure magnesium ingot, pure aluminum ingot, Mg-Ca master alloy, Mg-Mn master alloy, Mg-Cu master alloy Alloy, Mg-Ni master alloy; Introduce protective gas and smelt, cast into ingot; Homogenize the ingot, cut into billets of corresponding size and peel; Hot extrusion into rods; The hot extrusion The extrusion conditions are: extrusion temperature 350-400°C, extrusion ratio 4-10, extrusion speed 10-20m / min; preferably extrusion temperature 350°C. The method of the invention has small extrusion ratio, high extrusion speed, and reduces equipment loss.

[0029] Further, the hot extrusion conditions are: an extrusion temperature of 350° C., an extrusion ratio of 8, and an extrusion speed of 20 m / min. The soluble magnesium alloy prepared under this hot extrusion condition has the best properties such as solubilit...

Embodiment 1

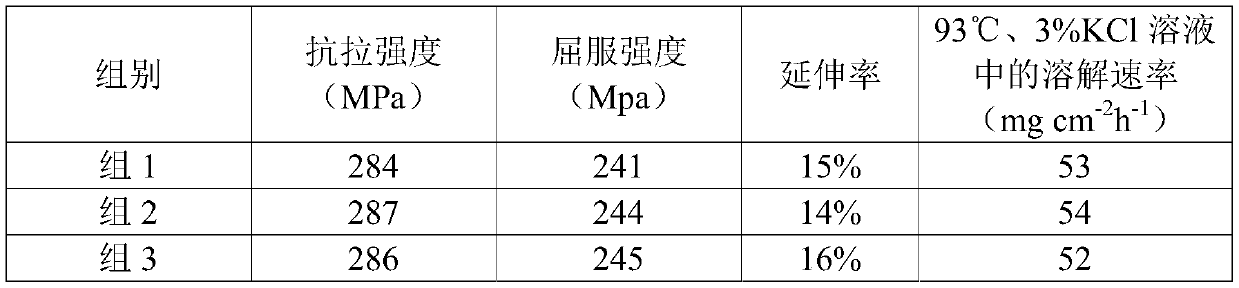

[0036] Embodiment 1 A kind of low-cost soluble magnesium alloy

[0037] The low-cost soluble magnesium alloy is Mg-Al-Ca-Mn-Cu-Ni magnesium alloy, which is composed of the following elements in mass percentage: Al 0.50wt%, Ca 0.90wt%, Mn 0.55wt%, Cu 0.40wt%, Ni 0.30wt%, the rest is Mg and unavoidable impurity elements.

Embodiment 2

[0038] Embodiment 2 A kind of low-cost soluble magnesium alloy

[0039] The low-cost soluble magnesium alloy is Mg-Al-Ca-Mn-Cu-Ni magnesium alloy, which is composed of the following elements in mass percentage: Al 0.40wt%, Ca 0.50wt%, Mn 0.45wt%, Cu 0.90wt%, Ni 0.10wt%, the rest is Mg and unavoidable impurity elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com