An extrusion method for controlling the texture of magnesium alloy sheets by using the surface interface structure

A technology of interface structure and extrusion method, applied in the field of magnesium alloy sheet, regulating the texture of magnesium alloy extruded sheet, can solve the problems of reducing the stamping and forming performance of the sheet, and achieve the effect of improving the secondary forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

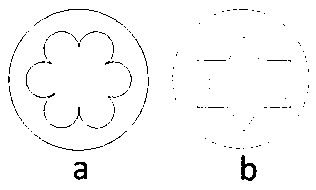

[0030] The initial size of the two AZ31 ingots is φ80×75mm, and then they are placed in a resistance wire heating furnace for homogenization heat treatment. Next, wire cutting is used to cut the magnesium ingot into a cross-section projected as a plum-blossom composite surface, one of which is the core material and the other is the packaging material. After the composite interface is polished and degreased, the AZ31 substrate core material and packaging material are nested together inside and outside and fixed with magnesium strips. cross section as figure 1 as shown in a. Next, compound extrusion is carried out on it, the extrusion temperature is 400° C., and the thickness of the final composite plate is 3 mm.

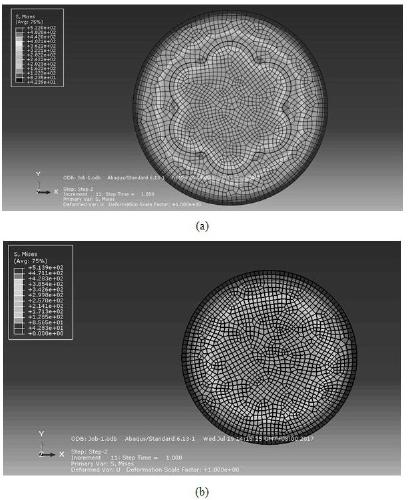

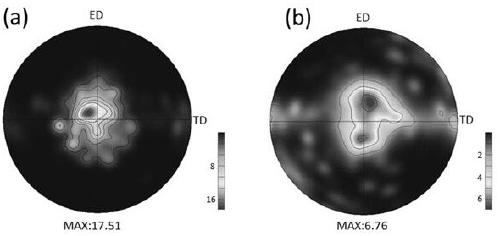

[0031] figure 2 It is a finite element analysis simulation comparison diagram of the stress state at the interface when the quincunx-shaped interface structure and the conventional structure are co-extruded in Example 1 of the present invention. It can be seen t...

Embodiment 2

[0033] The initial size of the AZ31 and ZK60 ingots is φ80×75mm, and then they are placed in a resistance wire heating furnace for homogenization heat treatment. Next, use wire cutting to cut the magnesium ingot into a cross-section and project it into a plum-blossom composite surface, where AZ31 is the core material and ZK60 is the packaging material. After the composite interface is polished and degreased, the AZ31 core material and the ZK60 packaging material are nested inside and outside and fixed with magnesium strips. Next, it is subjected to extrusion compounding, the extrusion temperature is 400° C., and the thickness of the final composite plate is 3 mm.

Embodiment 3

[0035] The initial size of the two magnesium alloy ZK60 ingots is φ80×75mm, and then they are placed in a resistance wire heating furnace for homogenization heat treatment. Next, the magnesium ingots were cut into cross-sectional projections into hexagonal composite surfaces using wire cutting. After the composite interface is polished and degreased, the ZK60 substrate core material and packaging material are nested together inside and outside and fixed with magnesium strips. cross section as figure 1 as shown in b. And perform composite extrusion on it, the extrusion temperature is 400° C., and the thickness of the final composite sheet is 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com