High-strength and high-plasticity magnesium zinc manganese tin calcium alloy and preparation method thereof

A magnesium-zinc-manganese-tin-calcium, high-plasticity technology, which is applied in the field of high-strength and high-plasticity magnesium-zinc-manganese-tin-calcium alloy and its preparation, can solve the problems of limiting the application of magnesium alloys, difficult plastic deformation, and low room temperature strength, and achieves low cost , inhibition of grain growth, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

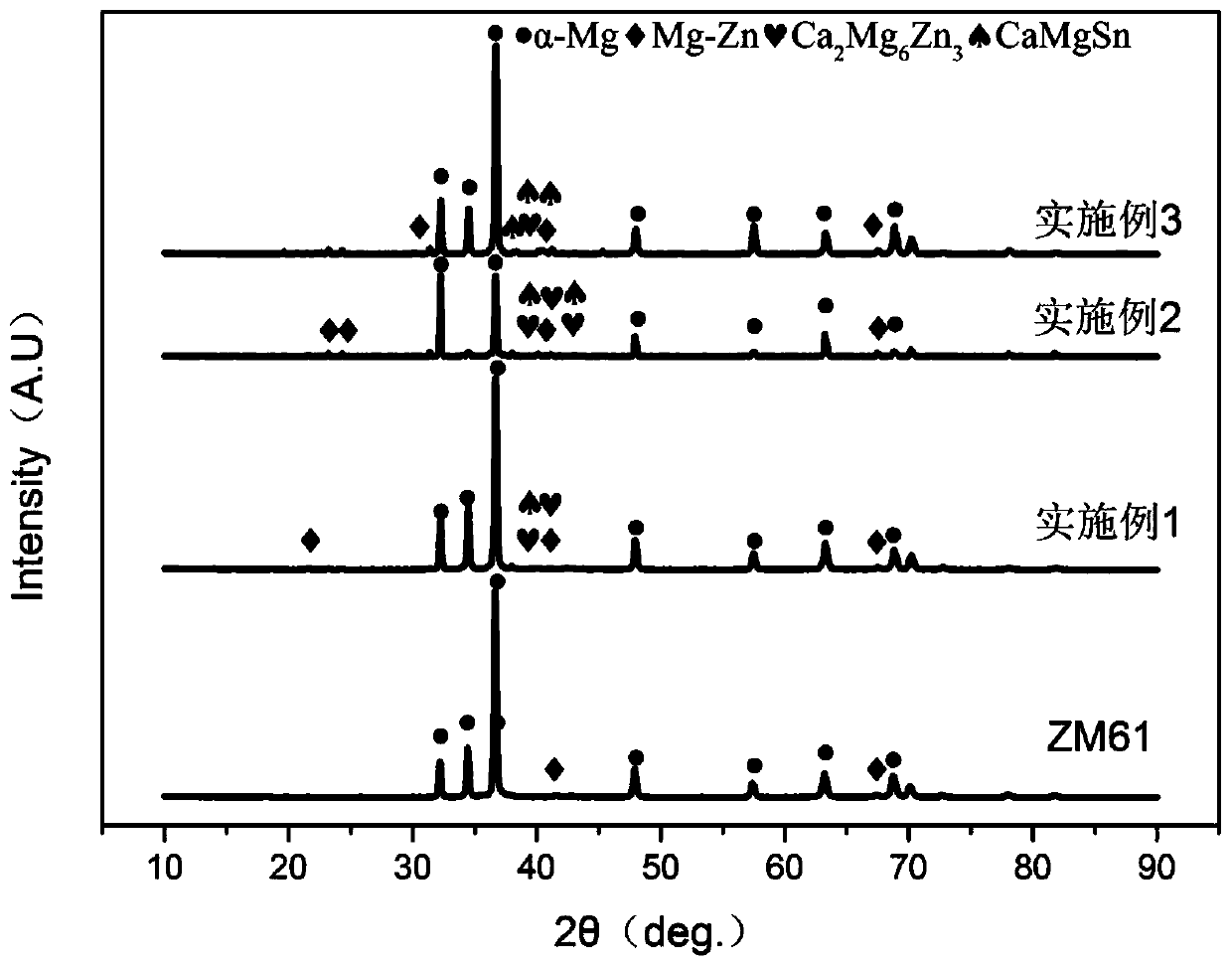

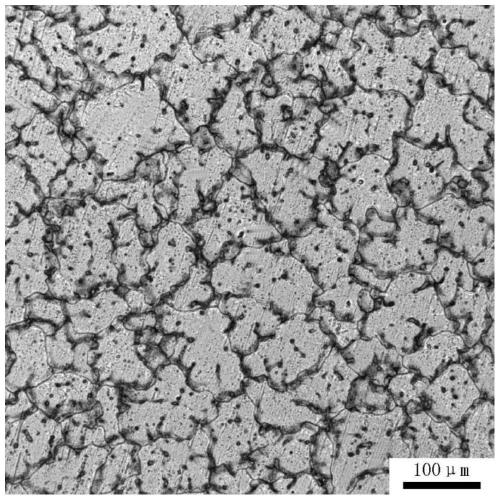

Embodiment 1

[0032] A high-strength and high-plasticity magnesium-zinc-manganese-tin-calcium alloy, the magnesium-zinc-manganese-tin-calcium alloy includes the following components in terms of mass percentage: Zn: 5.7%; Mn: 0.68%; Ca: 0.53%; Sn: 0.45%; Unavoidable impurities ≤ 0.15%; the balance is magnesium, and the magnesium alloy is prepared as follows:

[0033] (1) Smelting: According to the mass percent of each component in this magnesium-zinc-manganese-tin-calcium alloy, take magnesium ingot, zinc particle, tin ingot, manganese content and be that the magnesium-manganese master alloy of 2.7wt% and calcium content are 30wt% Magnesium-calcium master alloys, magnesium ingots, zinc particles, tin ingots, magnesium-manganese master alloys and magnesium-calcium master alloys are completely melted together at 750°C, and then cooled to 720°C within 8 minutes to keep the temperature and stand until impurities settle, after water cooling Ingots are made;

[0034] (2) Plastic processing: turn ...

Embodiment 2

[0036] A high-strength and high-plasticity magnesium-zinc-manganese-tin-calcium alloy, which comprises the following components in terms of mass percentage: Zn: 6.08%; Mn: 0.59%; Ca: 0.5%; Sn: 0.95%; Unavoidable impurities ≤ 0.15%; the balance is magnesium, and the magnesium alloy is prepared as follows:

[0037] (1) Smelting: According to the mass percent of each component in this magnesium-zinc-manganese-tin-calcium alloy, take magnesium ingot, zinc particle, tin ingot, manganese content and be that the magnesium-manganese master alloy of 2.7wt% and calcium content are 30wt% Magnesium-calcium master alloys, magnesium ingots, zinc particles, tin ingots, magnesium-manganese master alloys and magnesium-calcium master alloys are completely melted at 780°C, and then cooled to 730°C within 10 minutes and kept at rest until the impurities settle. After water cooling Ingots are made;

[0038] (2) Plastic processing: turn the ingot prepared in step (1), then raise the temperature to...

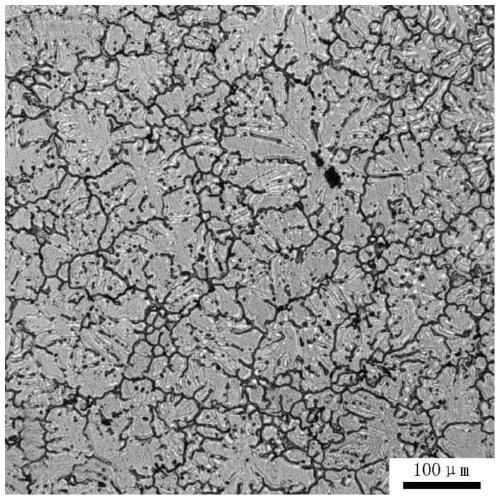

Embodiment 3

[0040] A high-strength and high-plasticity magnesium-zinc-manganese-tin-calcium alloy, the magnesium-zinc-manganese-tin-calcium alloy includes the following components in terms of mass percentage: Zn: 5.89%; Mn: 0.61%; Ca: 0.51%; Sn: 1.87%; Unavoidable impurities ≤ 0.15%; the balance is magnesium, and the magnesium alloy is prepared as follows:

[0041](1) Smelting: According to the mass percent of each component in this magnesium-zinc-manganese-tin-calcium alloy, take magnesium ingot, zinc particle, tin ingot, manganese content and be that the magnesium-manganese master alloy of 2.7wt% and calcium content are 30wt% Magnesium-calcium master alloys, magnesium ingots, zinc grains, tin ingots, magnesium-manganese master alloys and magnesium-calcium master alloys are completely melted at 760°C, and then cooled to 710°C within 5 minutes and kept at rest until impurities settle. After water cooling Ingots are made;

[0042] (2) Plastic processing: turn the ingot obtained in step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com