A Method for Realizing Texture Weakening of Atx Series Magnesium Alloy Sheets Using Asymmetric Extrusion

A magnesium alloy, asymmetric technology, applied in the field of ATX magnesium alloy sheet texture weakening, magnesium alloy hot extrusion forming, can solve the problems of low processing efficiency, technical difficulty, texture weakening, etc., to achieve sufficient deformation, easy The effect of increasing the deformation zone and reducing the dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

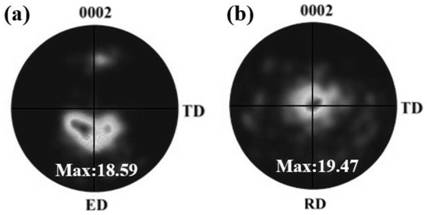

[0031] The Mg-2Al-0.8 SN-0.18CA (ATX2102) magnesium alloy ingot was taken up and treated: first heated to 320 ° C for 2 h, and then heated to 430 ° C for 3 h, and finally held at 490 ° C for 2 h. Subsequently, the ATX2102 magnesium alloy ingot after homogenization is conventional extrusion, the extrusion rate is 15 mm / s, the extrusion temperature is 410 ° C, the extrusion ratio is 30, and the width is 60 mm, the thickness of 10 mm ATX2102 magnesium alloy sheet. Installing an asymmetric extrusion mold on a vertical hydraulic press, the molded passage of the mold divides the cavity to the left and right sides, uniformly coating the moisture graphite lubricant surface on the surface of the cavity and the blank, and heated to The 350 ° C and 370 ° C were insulated for 2 h, and the extrusion ratio 30 was discharged from 2 mm / s, cooled to room temperature, and finally obtained an ATX2102 magnesium alloy sheet having a width of 10 mm thick.

Embodiment 2

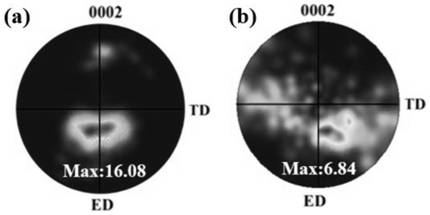

[0033] MTA (ATX2103) magnesium alloy ingot was taken up and treated with a homogenization treatment: first heated to 330 ° C for 2 h, and then heated to 420 ° C for 3 h, and finally held at 480 ° C for 2 h. Subsequently, the ATX2103 magnesium alloy ingot after homogenization is conventional extrusion, the extrusion rate is 20 mm / s, the extrusion temperature is 400 ° C, the extrusion ratio is 25, and the width is 50 mm, the thickness of 8 mm ATX2103 magnesium alloy sheet. Installing an asymmetric extrusion mold on a vertical hydraulic press, the molded passage of the mold divides the cavity to the left and right sides, uniformly coating the moisture graphite lubricant surface on the surface of the cavity and the blank, and heated to 370 ° C and 390 ° C were held for 2 h, and the extrusion ratio 25 was discharged from 3 mm / s, cooled to room temperature, and finally obtained an ATX2103 magnesium alloy plate having a width of 8 mm thick.

Embodiment 3

[0035] Mental treatment was taken after the magnesium alloy ingot of Mg-2Al-0.8 S-0.5 Ca (ATX2105) was first heated to 350 ° C for 2 h, and then heated to 420 ° C for 3 h, and finally held at 490 ° C for 2 h. Subsequently, the ATX2105 magnesium alloy ingot after homogenization is conventionally extruded, the extrusion rate is 25 mm / s, the extrusion temperature is 400 ° C, the extrusion ratio is 25, and the width is 55 mm, the thickness of 10 mm ATX2105 magnesium alloy sheet. Installing an asymmetric extrusion mold on a vertical hydraulic press, the molded passage of the mold divides the cavity to the left and right sides, uniformly coating the surface of the cavity and the blank surface, and heated to 400 ° C and 420 ° C were insulated for 2 h, and the extrusion ratio was 27.5, and unmistically squeezed at 3 mm / s, cooled to room temperature, and finally obtained an ATX2105 magnesium alloy sheet having a width of 10 mm thickness of 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com