A preparation method of fine-grained and weak-textured blank for medicine-shaped mask

A technology of liner and billet, which is applied in the direction of manufacturing tools, furnace types, heat treatment equipment, etc., can solve the problems of low yield rate of equal-channel extrusion materials, large width and length direction anisotropy, and affecting the damage efficiency of liner covers, etc. , to achieve the effect of improving damage performance, good uniformity of material structure, and good matching between material strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

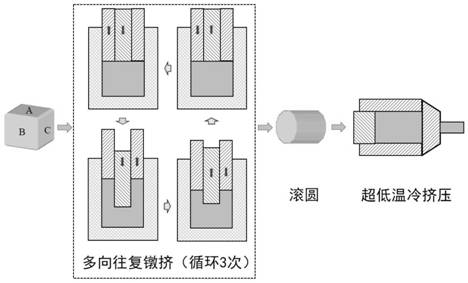

[0036] A preparation method of a fine-grained weak-textured tissue blank for a medicine-type cover, which specifically comprises the following steps:

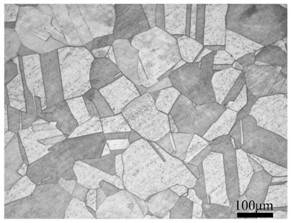

[0037] (1) Electron beam melting and purification: commercial T2 copper billet 80mm×80mm×1000mm is used, and the average grain size is about 150μm ( figure 2 ). Remove surface oil, oxide scale and other substances by alkaline washing and pickling. An electron beam melting furnace with a power of 900kW is used for secondary electron beam melting and purification. The side length of the copper mold is 150mm, and the vacuum degree of the melting chamber is ≥2×10 -3 Pa, the first melting speed is 120kg / h, and the drawing speed is 5mm / min; the second melting speed is 60kg / h, and the drawing speed is 3mm / min. Using modern material analysis methods, the content of impurity elements is shown in Table 1, which significantly reduces the content of impurity elements, and the copper content reaches four levels of 9 or more.

[0038] Ta...

Embodiment 2

[0052] A preparation method of a fine-grained weak-textured tissue blank for a medicine-type cover, which specifically comprises the following steps:

[0053] (1) Electron beam smelting and purification: A commercial T3 copper round bar is Φ90×1000mm, and the average grain size is about 180μm. Remove surface oil, oxide scale and other substances by alkaline washing and pickling. An electron beam melting furnace with a power of 900kW is used for secondary electron beam melting and purification. The side length of the copper mold is 180mm, and the vacuum degree of the melting chamber is ≥2×10 -3 Pa, the first melting speed is 140kg / h, and the drawing speed is 6mm / min; the second melting speed is 90kg / h, and the drawing speed is 4mm / min. Using modern material analysis methods, the content of impurity elements is shown in Table 2, which significantly reduces the content of impurity elements, and the copper content reaches the level of more than 4 9s.

[0054] Table 2 Ingot conte...

Embodiment 3

[0069] A preparation method of a fine-grained weak-textured blank for a medicine-type cover, which specifically comprises the following steps:

[0070] (1) Electron beam smelting and purification: commercial T2 bars are used, Φ70×1000mm, and the average grain size is about 110μm. Remove surface oil, oxide scale and other substances by alkaline washing and pickling. An electron beam melting furnace with a power of 900kW is used for secondary electron beam melting and purification. The side length of the copper crystallizer is 110mm, and the vacuum degree of the melting chamber is ≥2×10 -3 Pa, the first melting speed is 80kg / h, and the drawing speed is 4mm / min; the second melting speed is 50kg / h, and the drawing speed is 2mm / min. Using modern material analysis methods, the content of impurity elements is shown in Table 3, which significantly reduces the content of impurity elements, and the copper content reaches four levels of 9 or more.

[0071] Table 3 Ingot content of impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com