Low-cost rapid-corrosion magnesium alloy and preparation method thereof

A rapid corrosion, magnesium alloy technology, applied in the field of metal materials and processing, can solve the problems of long degradation time and high cost of magnesium alloy materials, and achieve the effects of improving ignition point, high processing rate and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

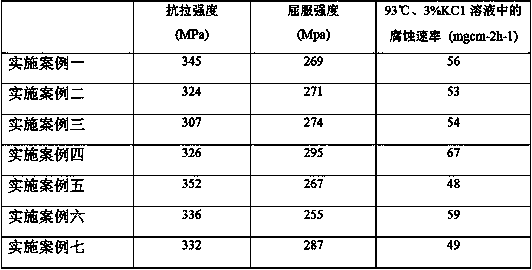

Examples

preparation example Construction

[0018] The second aspect of the present invention provides a method for preparing a low-cost rapid corrosion magnesium alloy, comprising the following steps: weighing pure magnesium ingots, pure aluminum ingots, Mg-Ca master alloys, Mg-Zn master alloys, and Mg-Cu master alloys; Introduce protective gas and smelt, pour into ingot; homogenize the ingot, cut into billets of corresponding size and peel; hot extrude into rods; the hot extrusion conditions are: extrusion temperature 350 -400°C, extrusion ratio of 4-10, extrusion speed of 10-20m / min; preferred extrusion temperature of 350°C. The method of the invention has small extrusion ratio, high extrusion speed, and reduces equipment loss.

[0019] Further, the hot extrusion conditions are: an extrusion temperature of 350° C., an extrusion ratio of 8, and an extrusion speed of 20 m / min. The solubility and tensile strength of the rapidly corroded magnesium alloy prepared under the hot extrusion conditions are , Elongation and ot...

Embodiment 1

[0024] Example 1 A low-cost rapid corrosion magnesium alloy

[0025] Described low-cost rapid corrosion magnesium alloy is Mg-Al-Ca-Zn-Cu-Fe magnesium alloy, is made up of the element of following mass percent: Al 13.00wt%, Zn 9.0wt%, Ca 0.4wt%, Cu 2.0wt% , Fe3.0wt%, and the rest are Mg and unavoidable impurity elements. Raw materials are weighed according to the ratio, and the above-mentioned raw materials are pure magnesium ingots, pure aluminum ingots, Mg-25%Ca master alloys, and Mg-30%Cu master alloys; 2 +SF 6 Under the protective condition of mixed gas (volume ratio: 300:1), melt at 720°C, hold for 60 minutes, stir for 10 minutes, and refine for 20 minutes.

[0026] The ingot of Example 1 was subjected to homogenization treatment at 520° C. for 2 hours, the cooling method was air cooling, and then cut into corresponding billets and peeled. The blank obtained in the previous step is extruded into a rod through an extruder at an extrusion temperature of 350°C, an extrusi...

Embodiment 2

[0027] Embodiment 2 A kind of low-cost rapid corrosion magnesium alloy

[0028] The low-cost rapid-corrosion magnesium alloy is a Mg-Al-Ca-Zn-Cu-Fe magnesium alloy, which consists of the following elements by mass percentage: Al 25.00wt%, Zn 2.0wt%, Ca 0.2wt%, Cu 3.0wt% , Fe 1.5wt%, and weigh the raw materials according to the proportion. The above-mentioned raw materials are pure magnesium ingots, pure aluminum ingots, Mg-25%Ca master alloys, Mg-10%Zn master alloys, and Mg-30%Cu master alloys; 2 +SF 6 Under the protective condition of mixed gas (volume ratio: 400:1), melt at 740°C, keep warm for 40min, stir for 5min, and refine for 30min. The billet obtained in the previous step was extruded into a rod through an extruder at an extrusion temperature of 400 °C, an extrusion ratio of 8, and an extrusion speed of 20 m / min.

[0029]The ingot of Example 2 was subjected to homogenization treatment at 500°C for 2 hours, the cooling method was air cooling, and then cut into corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com