Manufacturing mold and method of high-strength high-toughness fine-grain light alloy tubing

A high-strength-toughness, light-alloy technology, which is applied to the preparation molds of high-strength and toughness fine-grained light alloy pipes and the field of preparation thereof, can solve the problem of shrinkage, porosity, reduction of mechanical properties of light alloys, and unfavorable secondary processing of thin pipes. and other problems, to achieve the effects of good strong plasticity, shortened production cycle, and optimization of mold structure parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

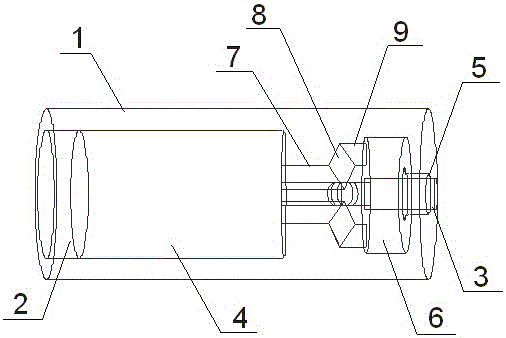

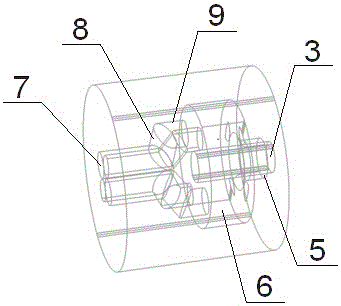

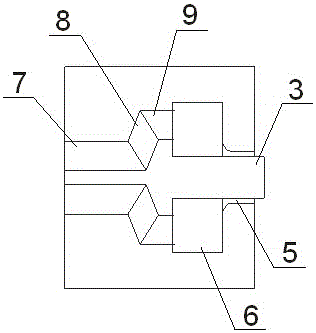

[0026] Example: see figure 1 , figure 2 as well as image 3 , a high-strength toughness fine-grained light alloy pipe preparation die, including extrusion cylinder 1, extrusion pad 2 and forming mandrel 3. The extrusion barrel 1 has a feed section 4 and a discharge section 5, and the squeeze pad 2 is arranged in the feed section 4 and can move freely in the feed section 4; during specific implementation, the squeeze pad 2 It is a columnar disc structure with a radius of R, and is connected with the extruding rod of the extruder when working. The length of the feed section 4 of the extrusion cylinder 1 is L, and the inner diameter is 2 (R+1) mm, so that the gap between the extrusion pad 2 and the extrusion cylinder 1 is as small as possible for better push the billet.

[0027] Between the feed section 4 and the discharge section 5, a partition section and a welding chamber 6 are provided. During the process, the billet channels are evenly distributed around the axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com