Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation

A deformation heat treatment, al-cu-li technology, applied in the field of aerospace components, can solve the problems of difficult realization of Al-Cu-Li alloy recrystallization control, low structure stability, secondary recrystallization, etc. Solvent treatment process, high degree of recrystallization of structure, and effect of reducing anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

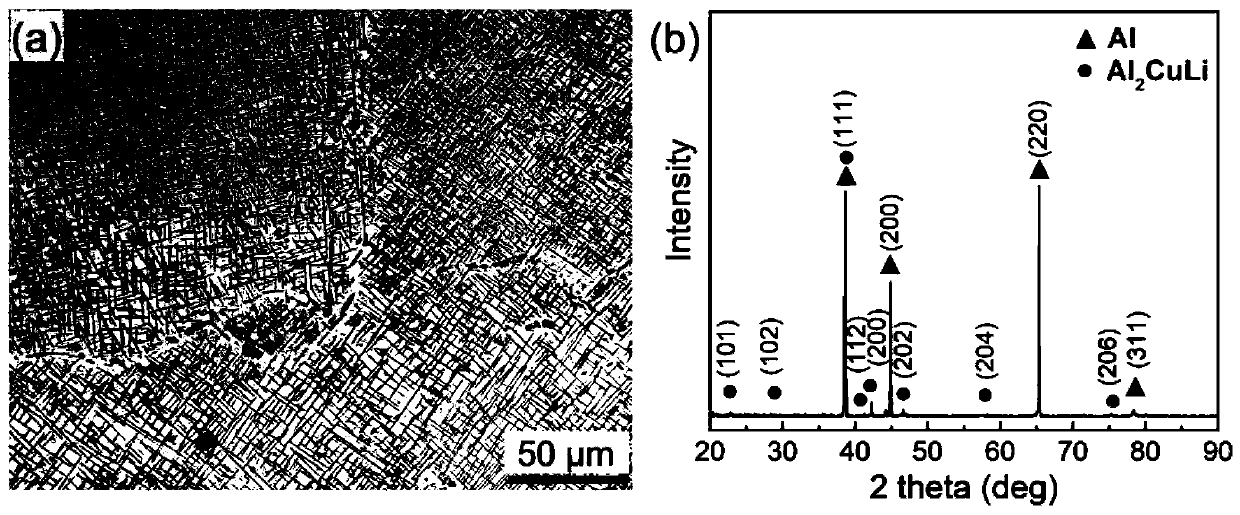

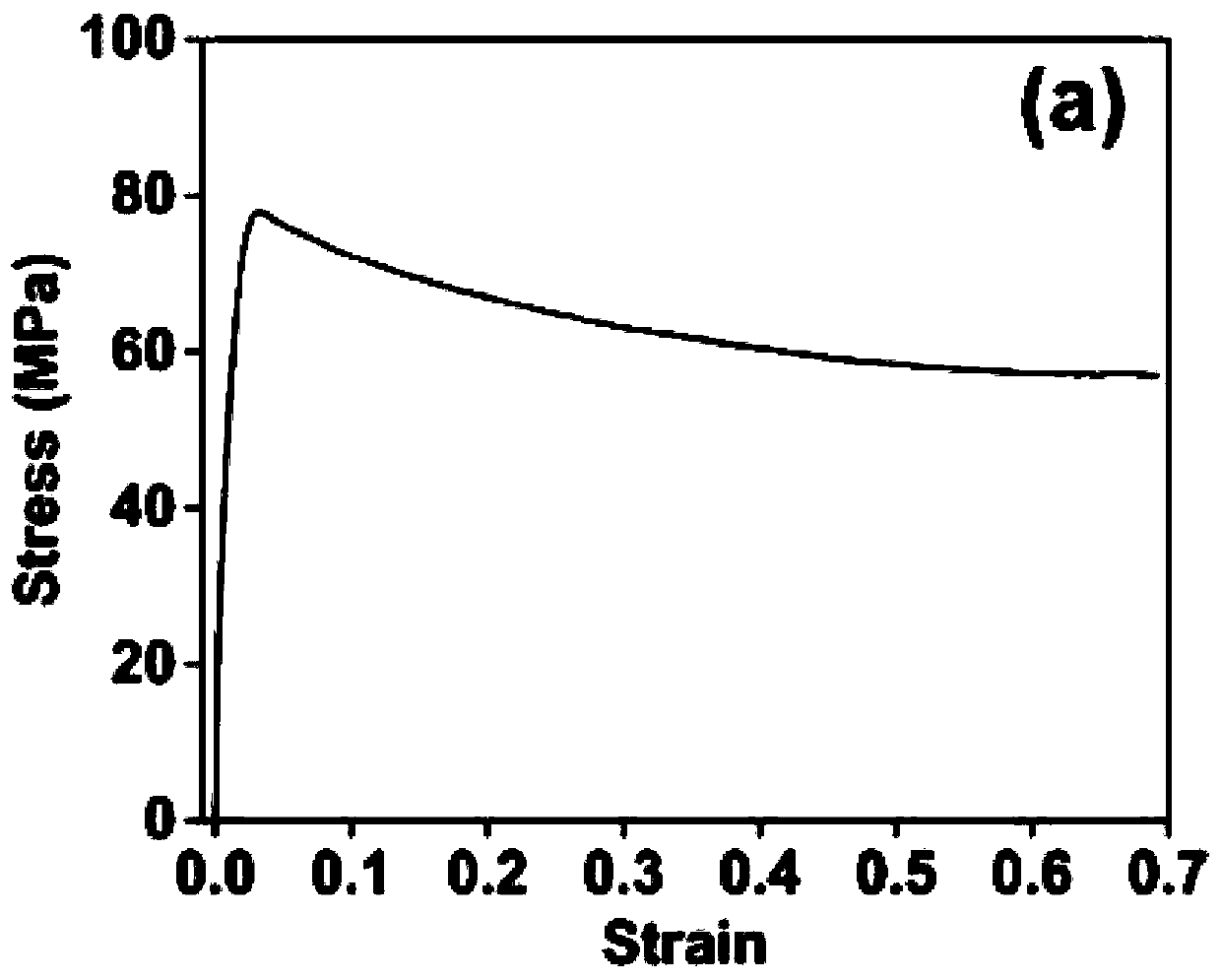

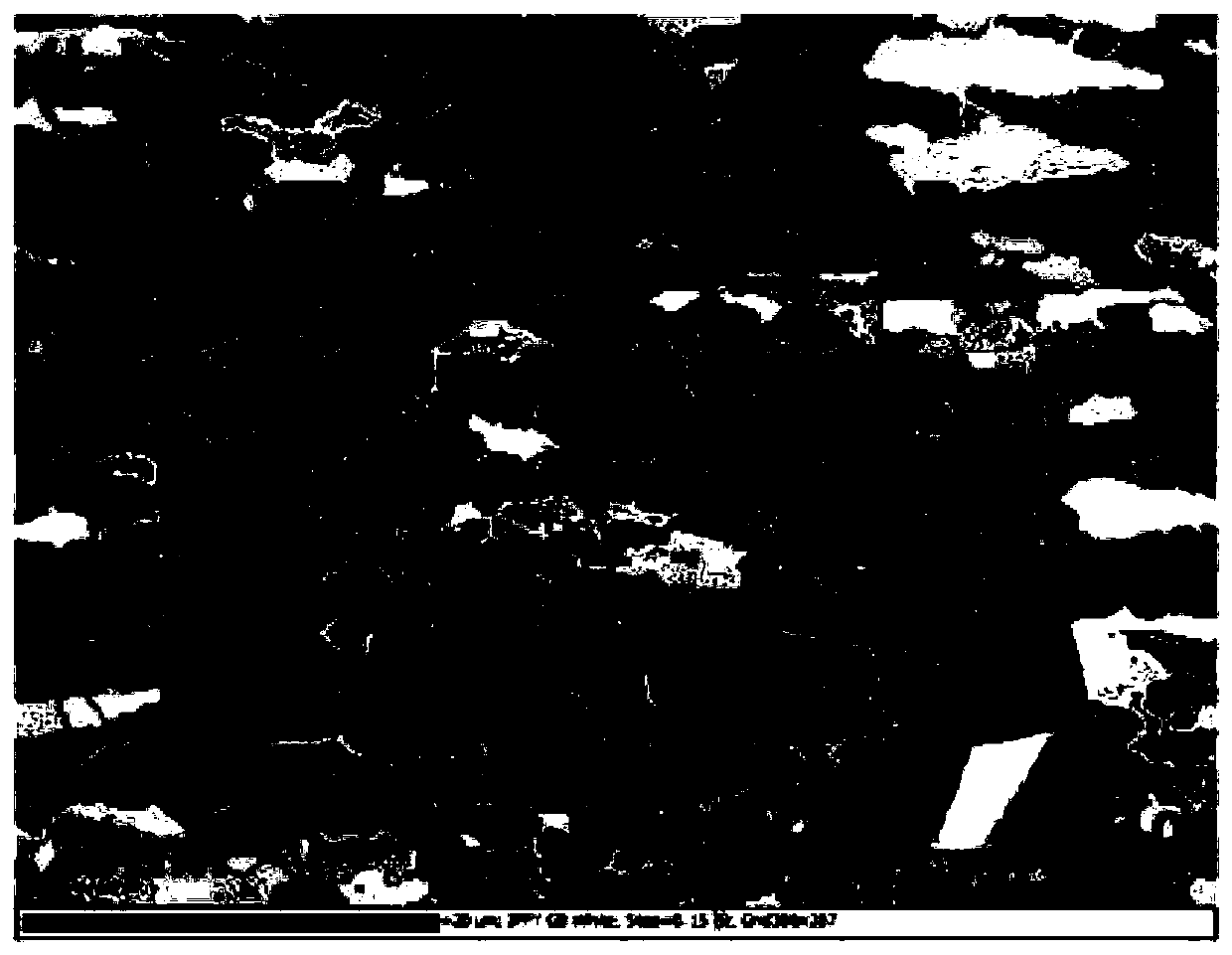

[0035] Example 1. In this example, through the homogenization pretreatment before hot deformation-hot deformation-high temperature annealing treatment, the Al-Cu-Li alloy has successfully obtained low deformation resistance, high stability recrystallization structure, and remarkable fine grain effect. The alloy composition used in this example is Al-3.8Cu-1.3Li-0.6Mg-0.6Zn-trace Mn / Zr.

[0036] Step 1. Pretreatment: the alloy ingot is pretreated by two-stage homogenization annealing, the alloy ingot is placed in an air furnace, and the first stage homogenization annealing is performed first: the temperature is raised to 400°C at a speed of 10°C / s, Temperature unevenness ≤±10℃, hold for 6h; after that, carry out the second-stage homogenization annealing: raise the temperature to 520℃ at a rate of 10℃ / s, control the temperature unevenness ≤±5℃, and control the maximum temperature ≤525 ℃, after holding for 48h, it was cooled to room temperature with the furnace for 20h.

[0037]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com