A kind of high energy absorption superfine grain magnesium alloy and preparation method thereof

A magnesium alloy and ultra-fine-grained technology, which is applied in the field of high-energy-absorbing ultra-fine-grained magnesium alloy and its preparation, can solve the problems of uneven deformation texture of magnesium alloy structure, poor plastic deformation ability of magnesium alloy, and reduced material ductility. Achieve the effects of eliminating internal stress, improving dynamic precipitation, and increasing the degree of recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

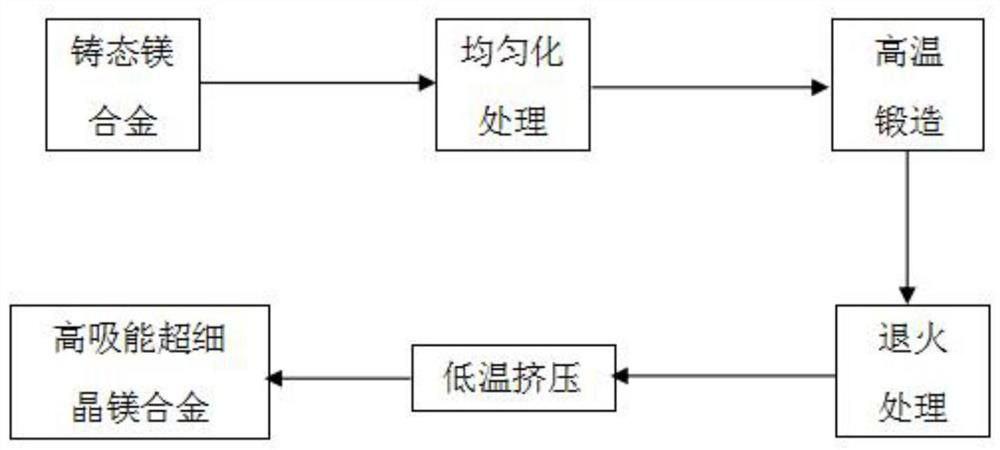

[0024] The invention provides a method for preparing a high-energy-absorbing ultrafine-grained magnesium alloy, which comprises the following steps:

[0025] (1) homogenize the as-cast magnesium alloy to obtain a homogenized magnesium alloy;

[0026] (2) Forging the homogenized magnesium alloy obtained in the step (1) at 440-530° C. to obtain a forged magnesium alloy;

[0027] (3) annealing the wrought magnesium alloy obtained in the step (2) to obtain an annealed magnesium alloy;

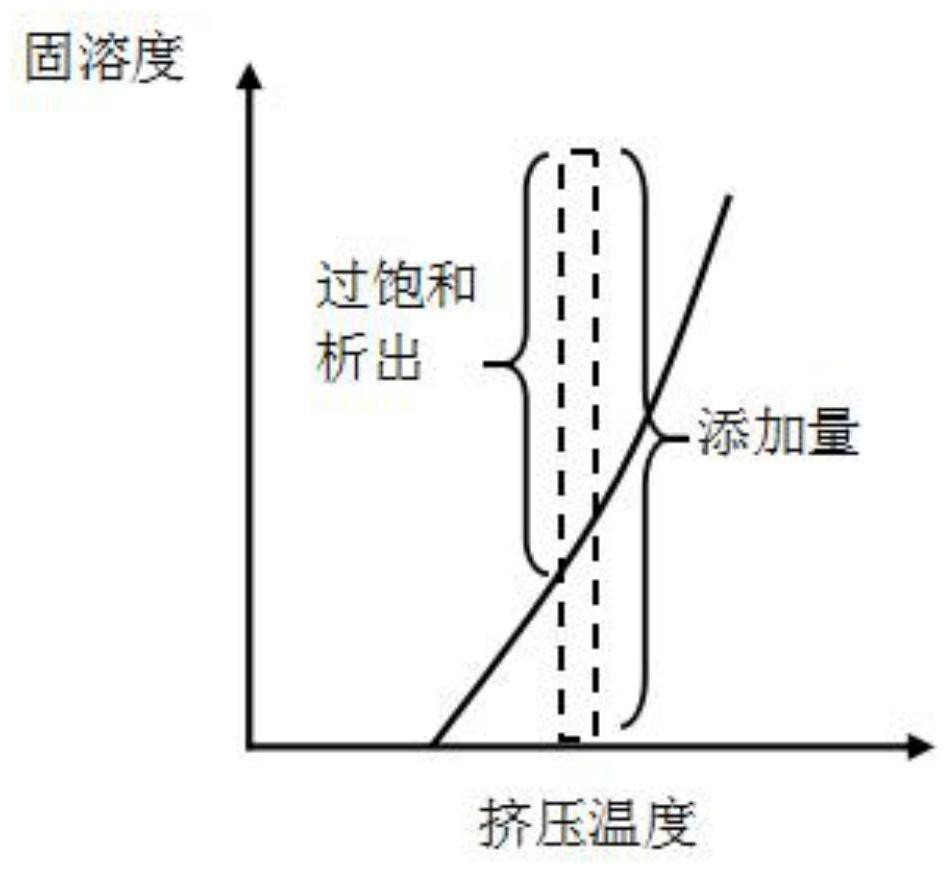

[0028] (4) Extruding the annealed magnesium alloy obtained in the step (3) at 100-150° C. to obtain a high-energy-absorbing ultrafine-grained magnesium alloy;

[0029] The high-energy-absorbing ultra-fine-grained magnesium alloy is a Mg-Mn-RE magnesium alloy or a Mg-Mn-Zn-based magnesium alloy; the sum of the mass percentages of Mn and RE / Zn in the high-energy-absorbing ultra-fine-grained magnesium alloy is Not more than 2%.

[0030] In the present invention, the high-energy-absorbing ultrafine-...

Embodiment 1

[0050] Step 1: Heating the pure magnesium ingot to 720°C in a protective gas atmosphere to melt, then adding Mg-Mn master alloy first in order, and finally adding Mg-Ce master alloy, cooling the melt to 700°C for semi-continuous casting, Obtain the as-cast magnesium alloy Mg-0.9Mn-0.5Ce, wherein the electromagnetic frequency is 40Hz, the casting speed is 160mm / min, and the cooling water volume is 16m 3 / h;

[0051] Step 2: Homogenize the as-cast magnesium alloy obtained in Step 1 at 500° C. for 24 hours to obtain a homogenized magnesium alloy:

[0052] Step 3: Forging the homogenized magnesium alloy obtained in Step 2 at 500° C. to obtain a forged magnesium alloy, wherein the forging is a single-pass deformation with a total deformation of 35%;

[0053] Step 4: annealing the wrought magnesium alloy obtained in step 3 at 430° C. for 1 hour to obtain an annealed magnesium alloy;

[0054] Step 5: extruding the annealed magnesium alloy obtained in the step 4 at 120°C, the extrus...

Embodiment 2

[0057] Step 1: Heat the pure magnesium ingot to 730°C for melting under protective gas atmosphere, then add the Mg-Mn master alloy first in order, and finally add the Mg-Nd master alloy, cool the melt down to 700°C for semi-continuous casting, Obtain the as-cast magnesium alloy Mg-0.9Mn-0.5Nd, wherein the electromagnetic frequency is 45Hz, the casting speed is 180mm / min, and the cooling water volume is 16m 3 / h;

[0058] Step 2: Homogenize the as-cast magnesium alloy obtained in Step 1 at 520° C. for 24 hours to obtain a homogenized magnesium alloy:

[0059] Step 3: Forging the homogenized magnesium alloy obtained in the step 2 at 500° C. to obtain a forged magnesium alloy, wherein the forging is single-pass deformation, and the total deformation is 40%;

[0060] Step 4: annealing the wrought magnesium alloy obtained in step 3 at 430° C. for 1.5 hours to obtain an annealed magnesium alloy;

[0061] Step 5: extruding the annealed magnesium alloy obtained in the step 4 at 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com