A kind of preparation method of high strength and high damping cualmn shape memory alloy

A memory alloy, high damping technology, applied in metal rolling, elongation control, etc., can solve the problems of micro-area porosity, holes and composition segregation, and eliminate CuAlMn shape memory alloy casting defects, etc., to improve thermal stability and mechanical properties, eliminate casting defects, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is a comparative example.

[0037] The first step, solution treatment:

[0038] Put the CuAlMn shape memory alloy raw material prepared by CN105568019B into a box furnace with a temperature of 850°C for solid solution treatment for 15 minutes;

[0039] The second step, quenching treatment:

[0040] The CuAlMn shape memory alloy prepared from CN105568019B after the first step of solid solution treatment is taken out of the box furnace, and then placed in water at 27°C for quenching treatment, thereby preparing Cu-11.9Al-2.5Mn shape memory alloy .

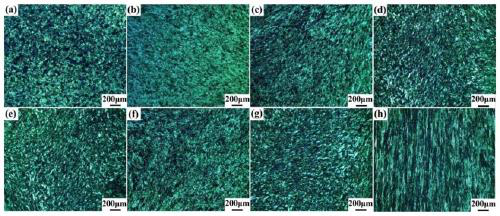

[0041] figure 1 (a) is the metallographic phase of the CuAlMn shape memory alloy (marked as #1CuAlMn shape memory alloy in Table 1 below) perpendicular to the rolling direction obtained in Example 1 after solution treatment at 850°C for 15 minutes and quenched state photo; by figure 1 (a) It can be seen that the CuAlMn shape memory alloy prepared in this comparative example presents equiaxed crystals with dis...

Embodiment 2

[0043] The first step, solution treatment:

[0044] Put the CuAlMn shape memory alloy raw material prepared by CN105568019B into a box furnace with a temperature of 830°C for solid solution treatment for 17 minutes;

[0045] The second step, groove rolling and quenching treatment:

[0046] The CuAlMn shape memory alloy prepared from CN105568019B after the first step of solid solution treatment is taken out from the box furnace, sent between the rolls of the groove rolling machine, and grooved for 8 passes along the length direction of the alloy. During the groove rolling, after the 3rd groove rolling and the 6th groove rolling, they were returned to the furnace for 8 minutes, the total deformation of the alloy sample was 80%, and the last rolling After the end, groove rolling is carried out in the same rolling groove again, and then the alloy sample is placed in 0°C water for quenching treatment, thus producing a high-strength and high-damping Cu-11.9Al-2.5Mn shape memory all...

Embodiment 3

[0049] The first step, solution treatment:

[0050] Put the CuAlMn shape memory alloy raw material prepared by CN105568019B into a box furnace with a temperature of 850°C for solid solution treatment for 15 minutes;

[0051] The second step, groove rolling and quenching treatment:

[0052] The CuAlMn shape memory alloy prepared from CN105568019B after the first step of solid solution treatment is taken out from the box furnace, and sent between the rolls of the groove rolling machine, and the groove rolling is carried out one pass along the length direction of the alloy. The total deformation of the alloy sample is 20%, and then groove rolling is carried out in the same rolling groove, and then the alloy sample is placed in 27°C water for quenching treatment, thereby producing a high-strength and high-damping Cu-11.9Al-2.5Mn shape memory alloy.

[0053] figure 1 (c) is the CuAlMn shape memory alloy obtained in Example 3, which has been subjected to solution treatment at 850...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com