Patents

Literature

85results about How to "Reduce flow stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

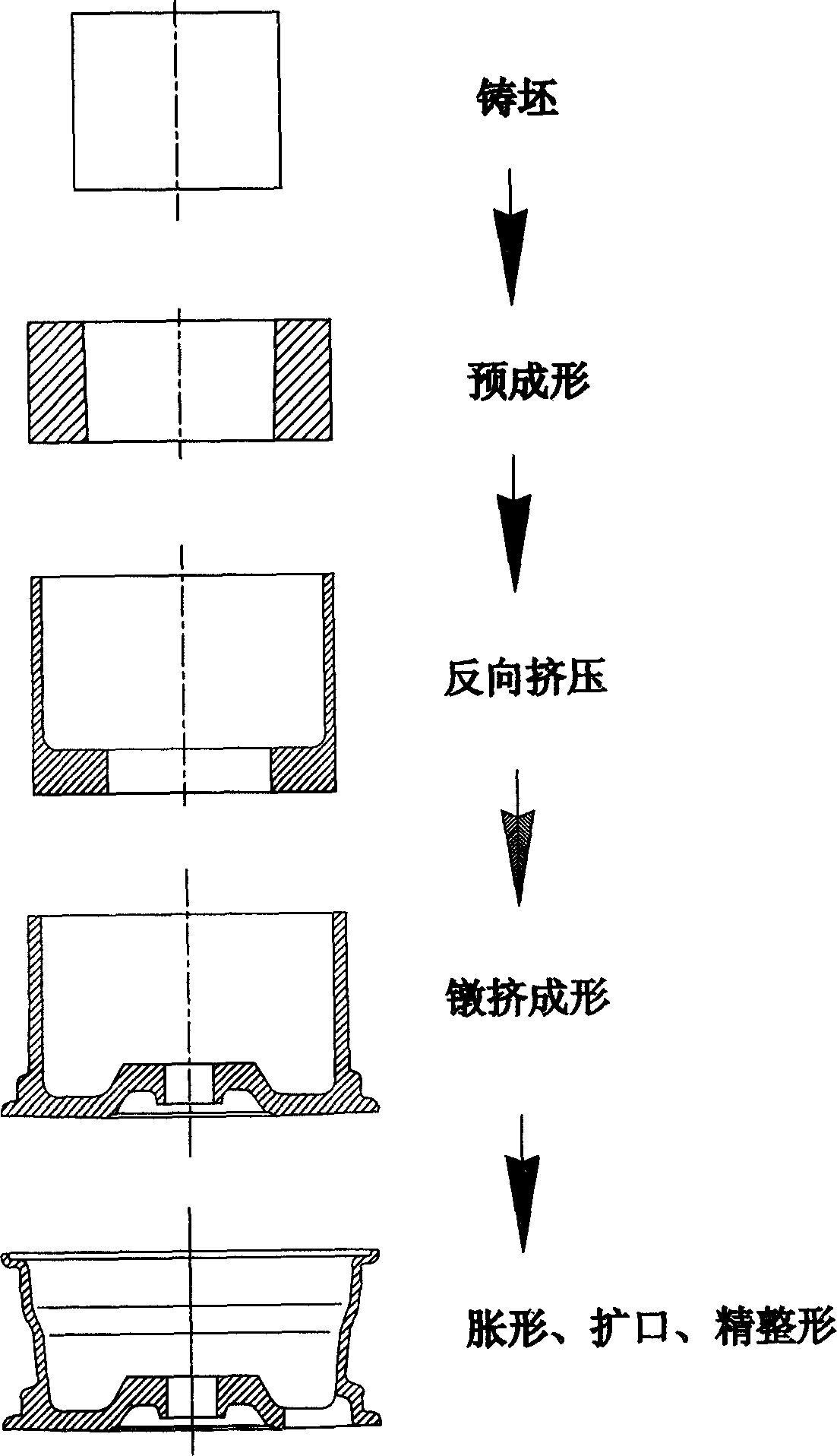

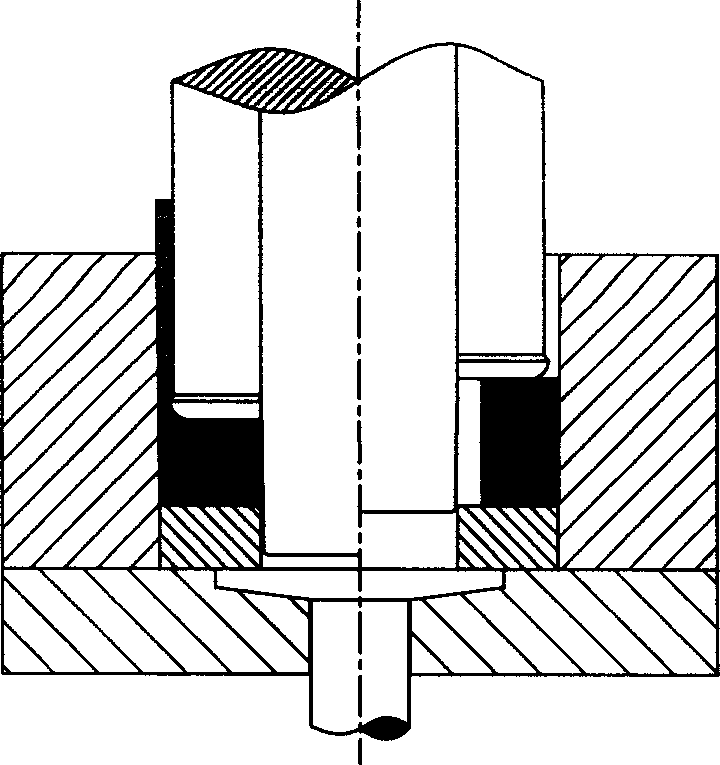

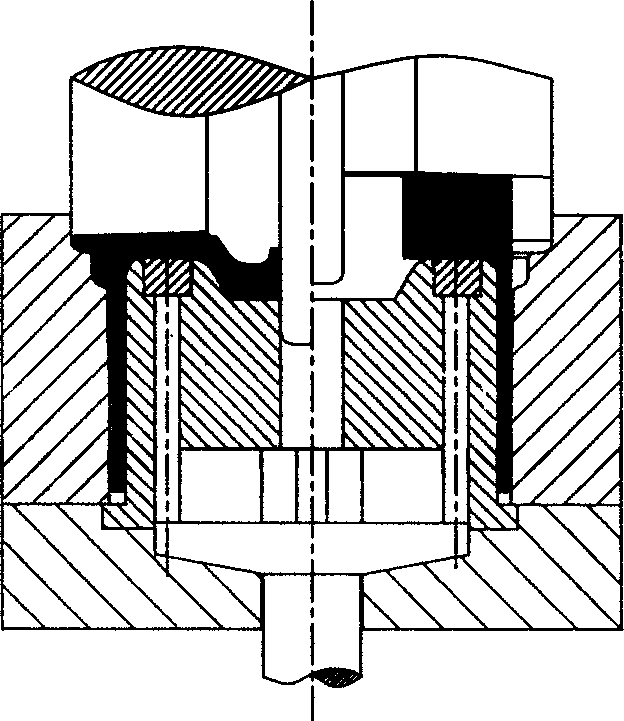

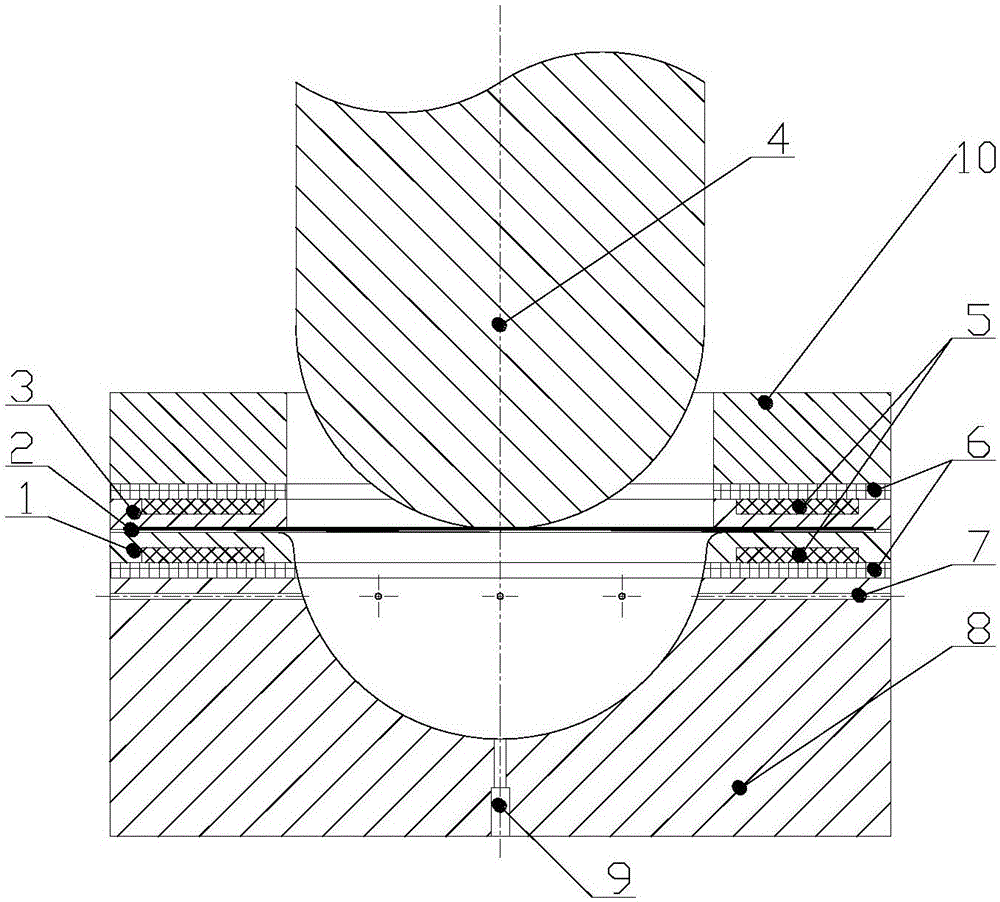

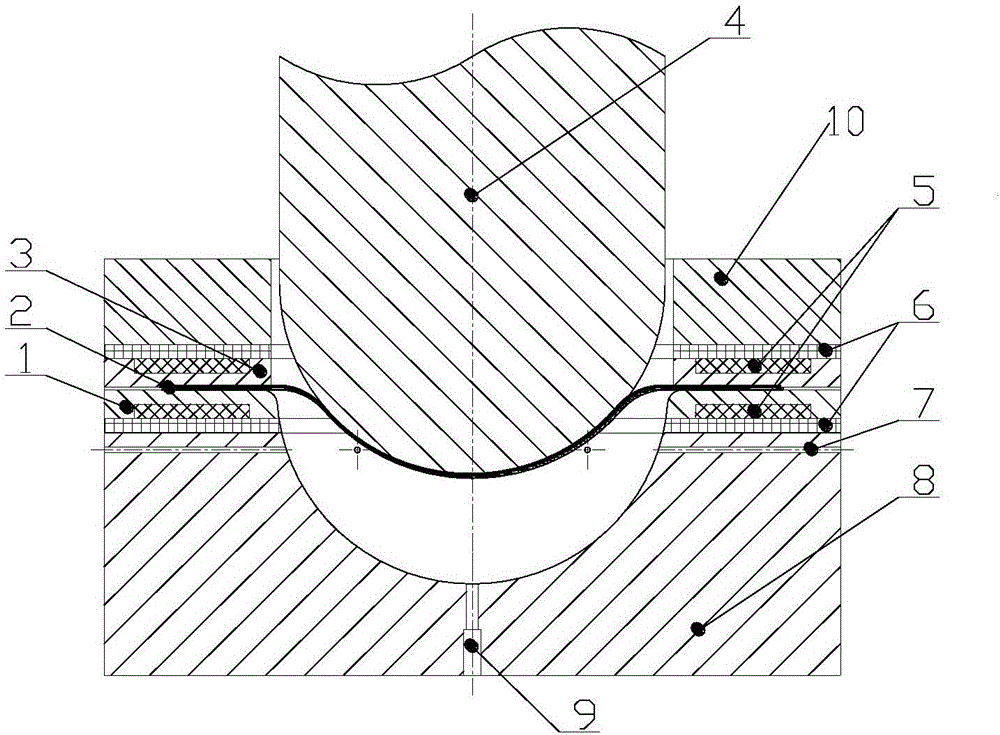

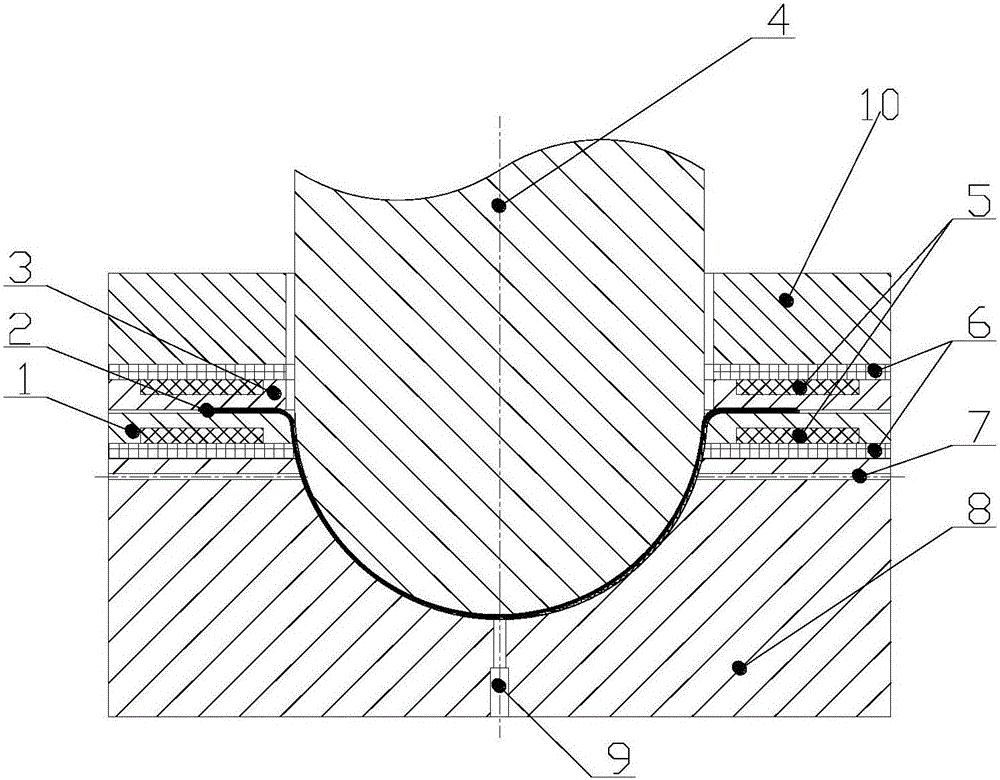

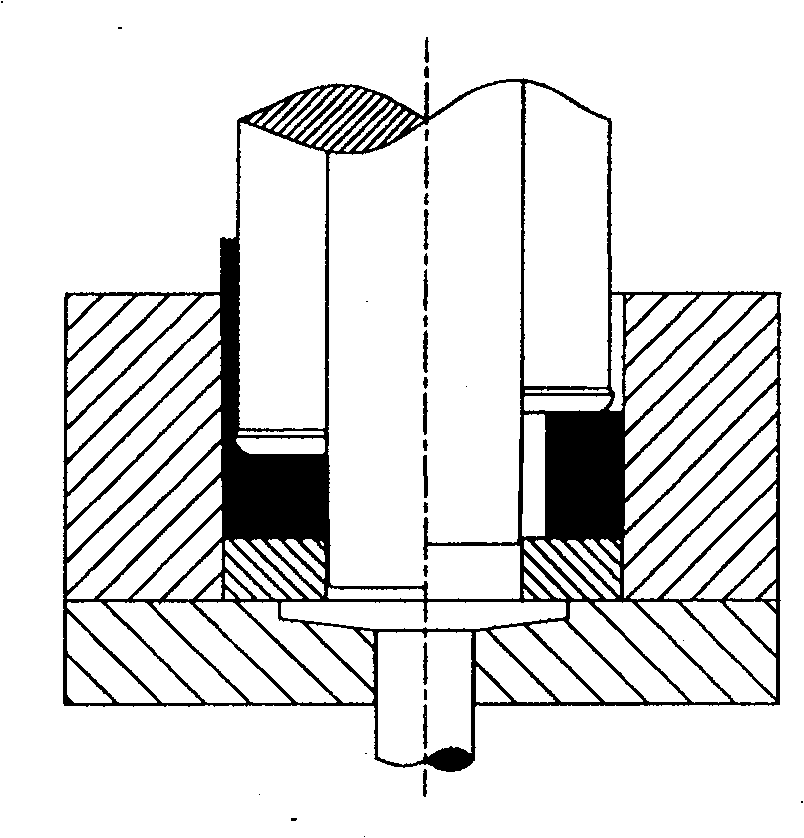

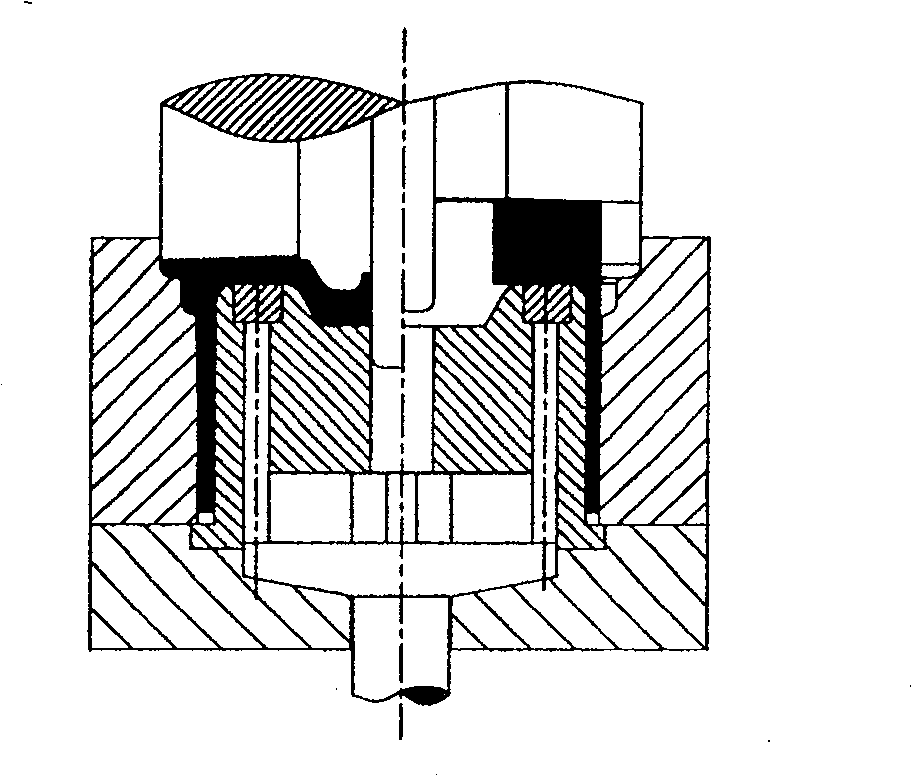

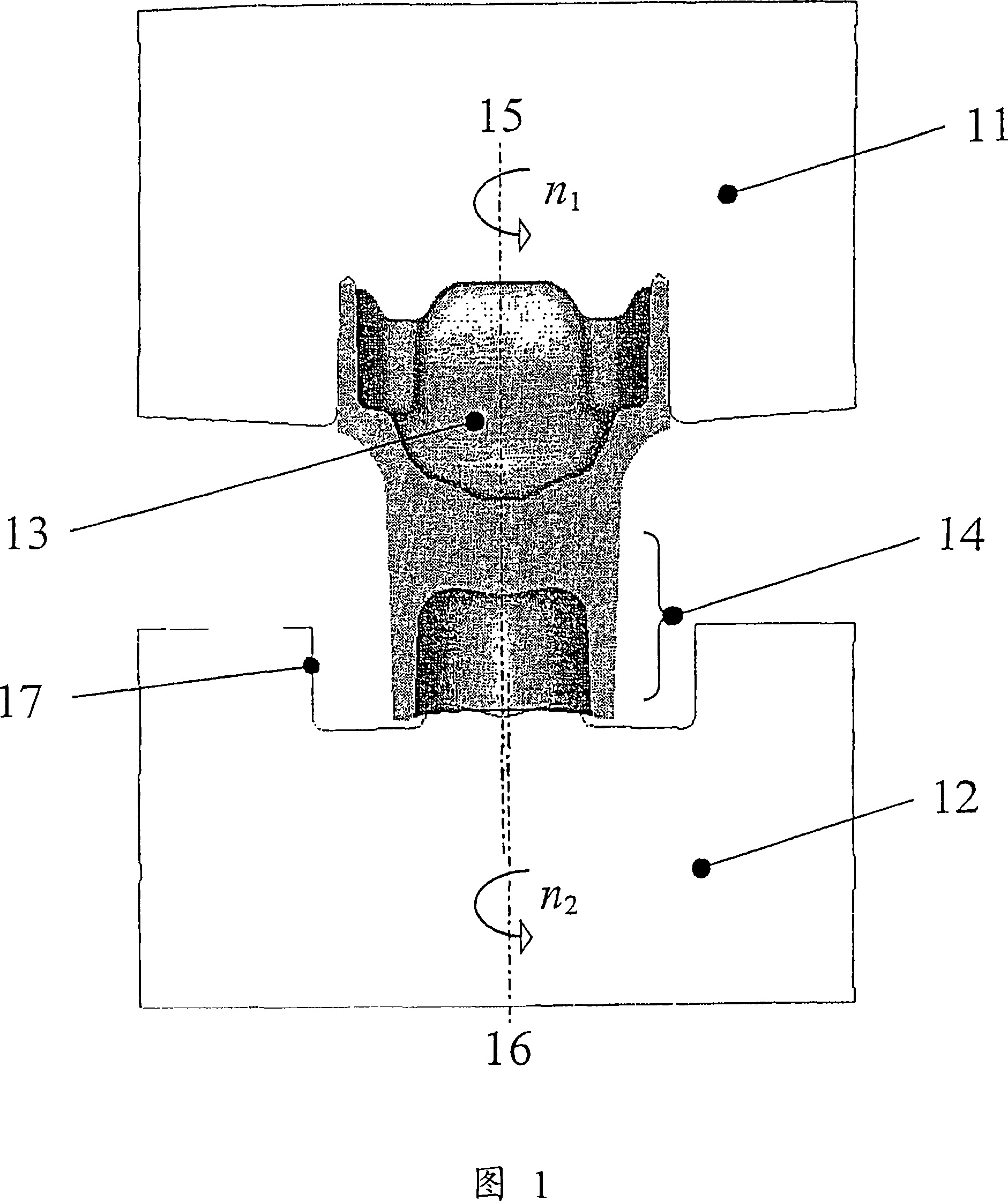

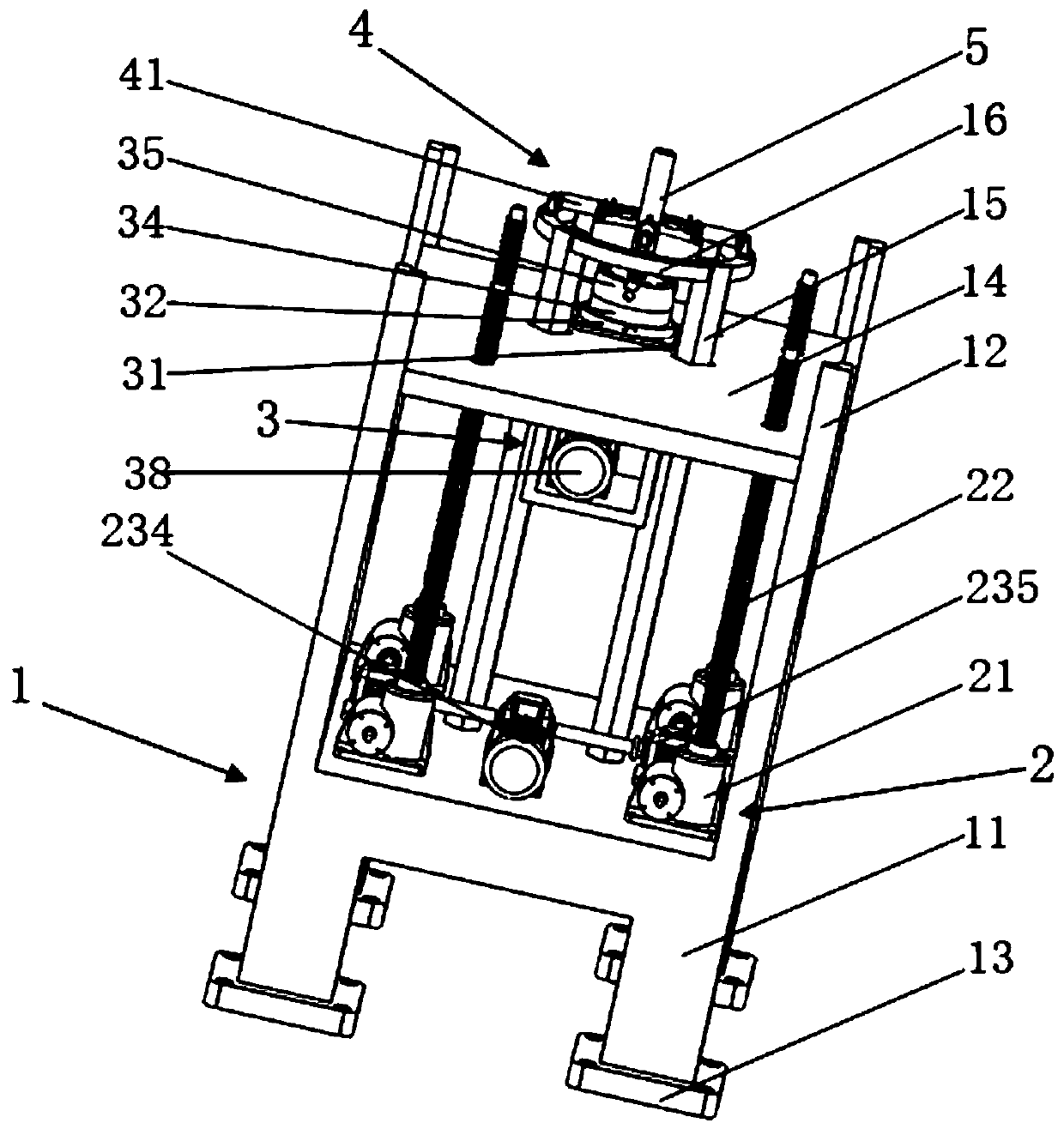

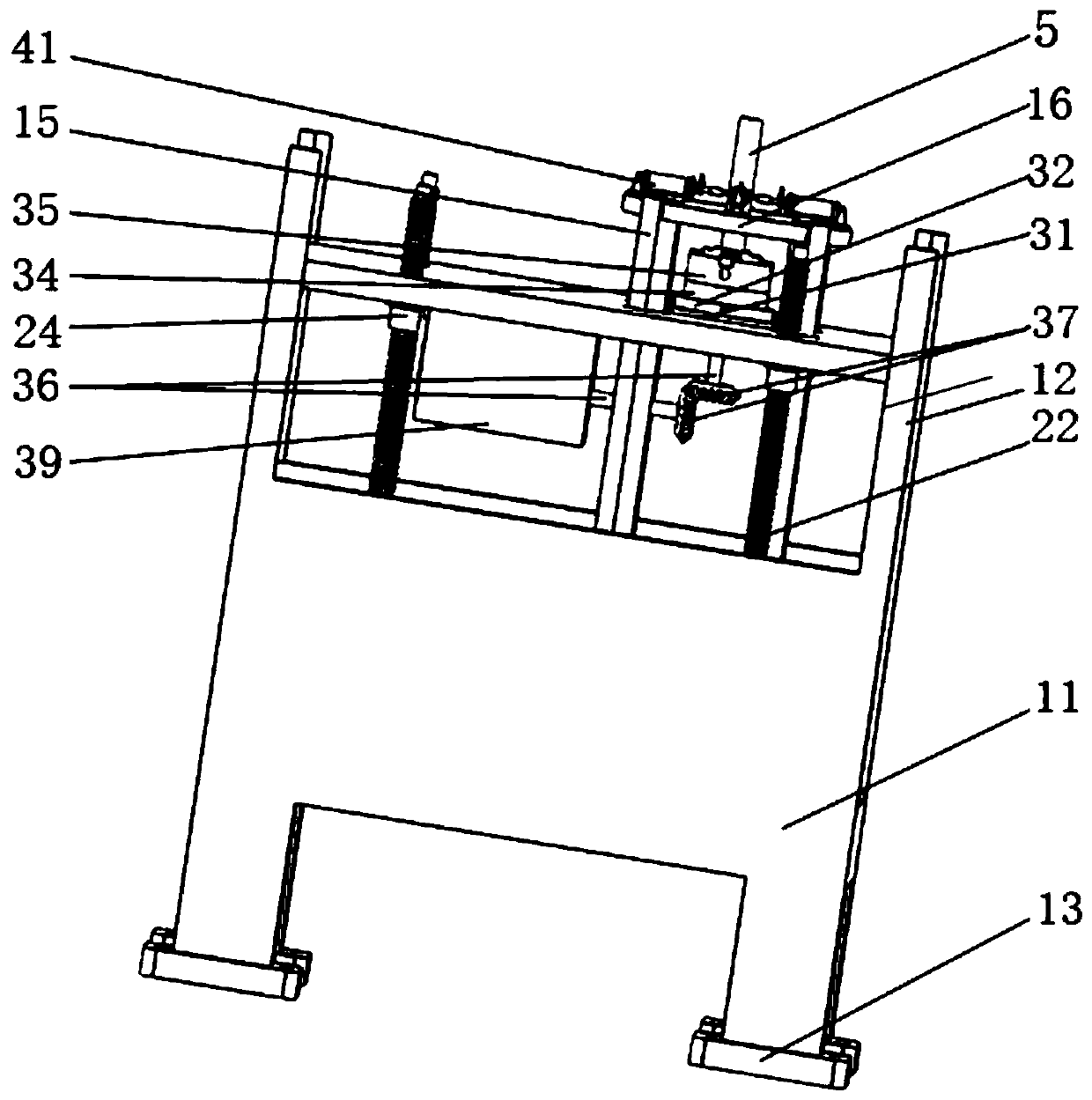

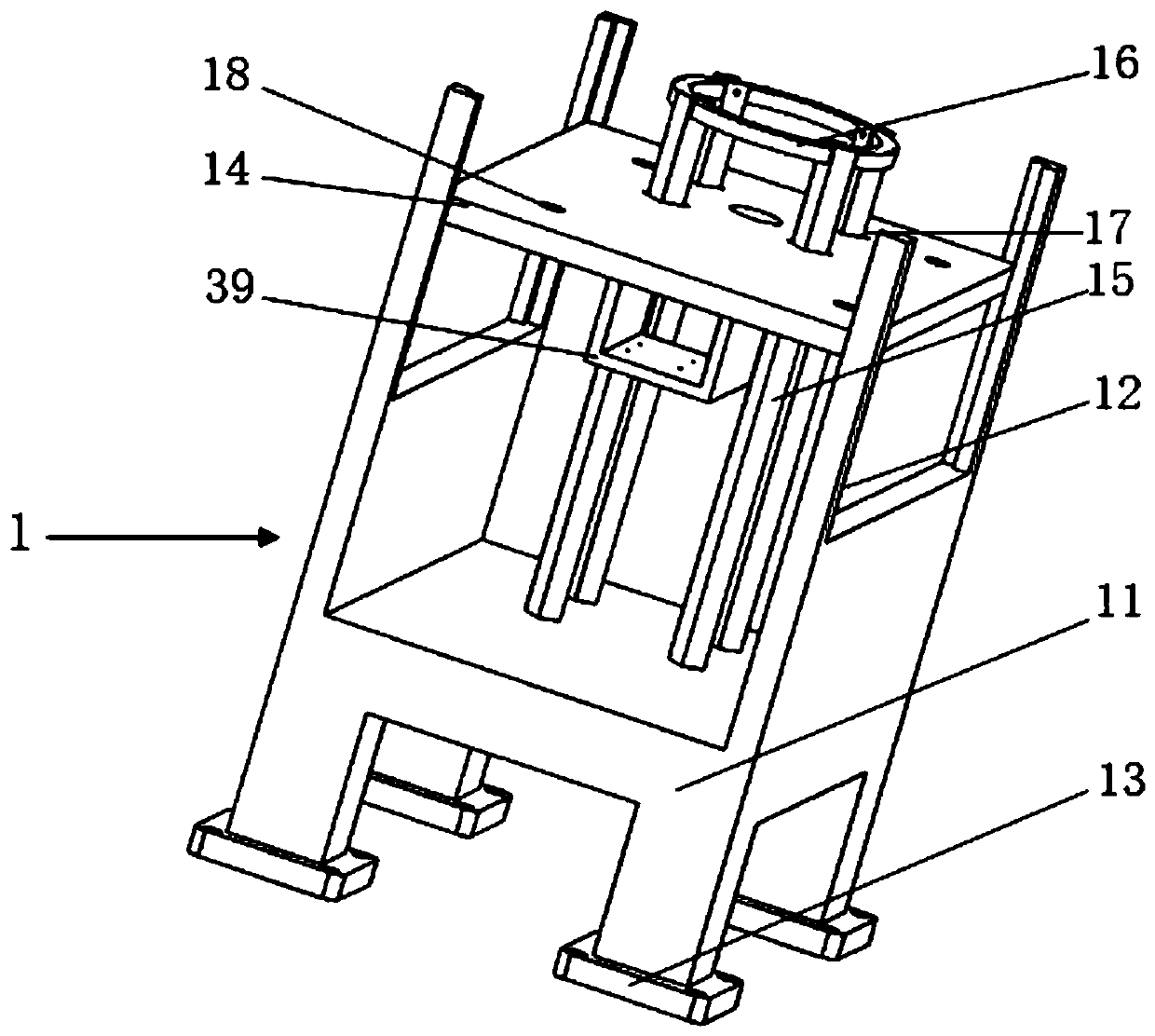

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

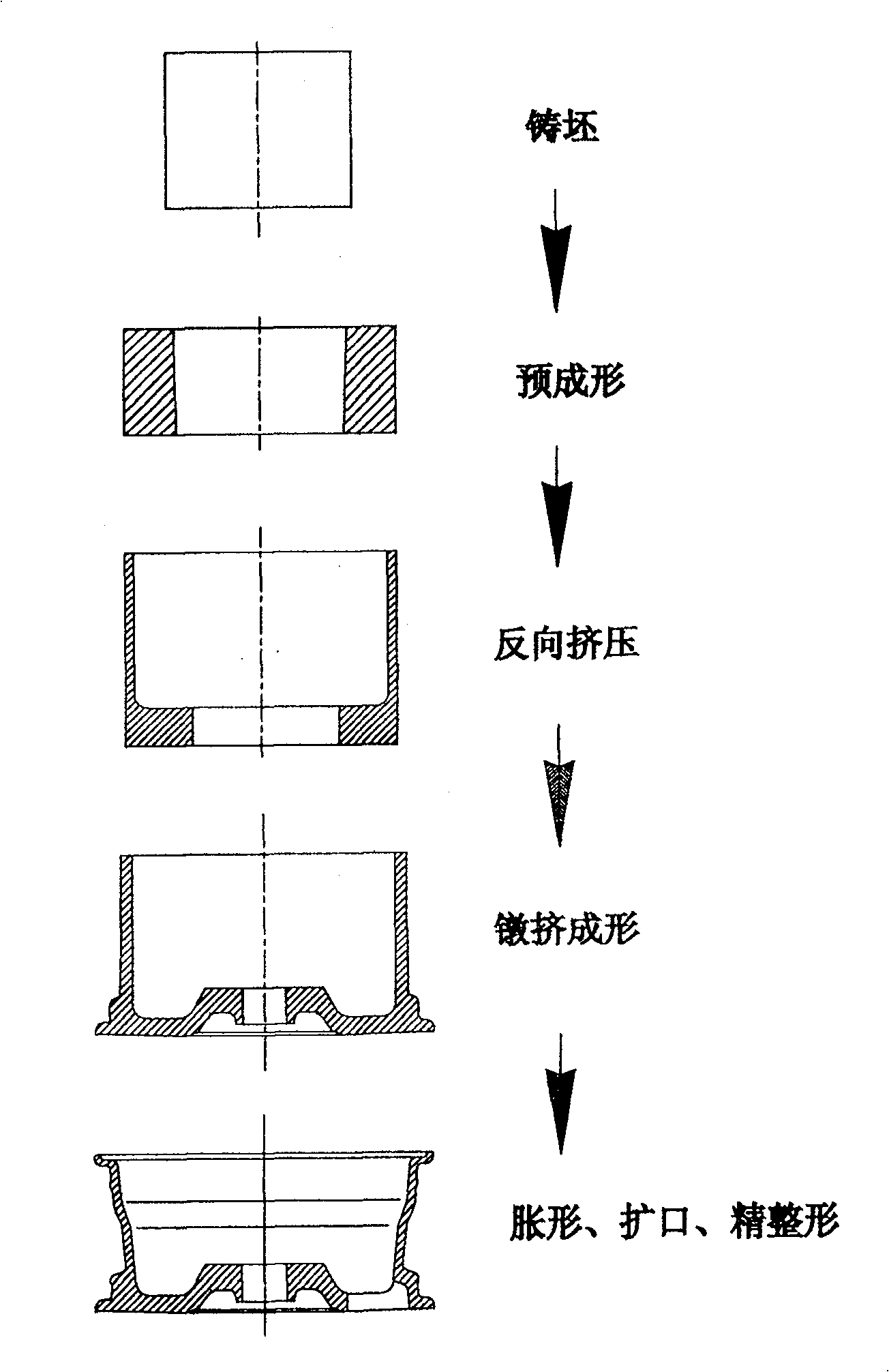

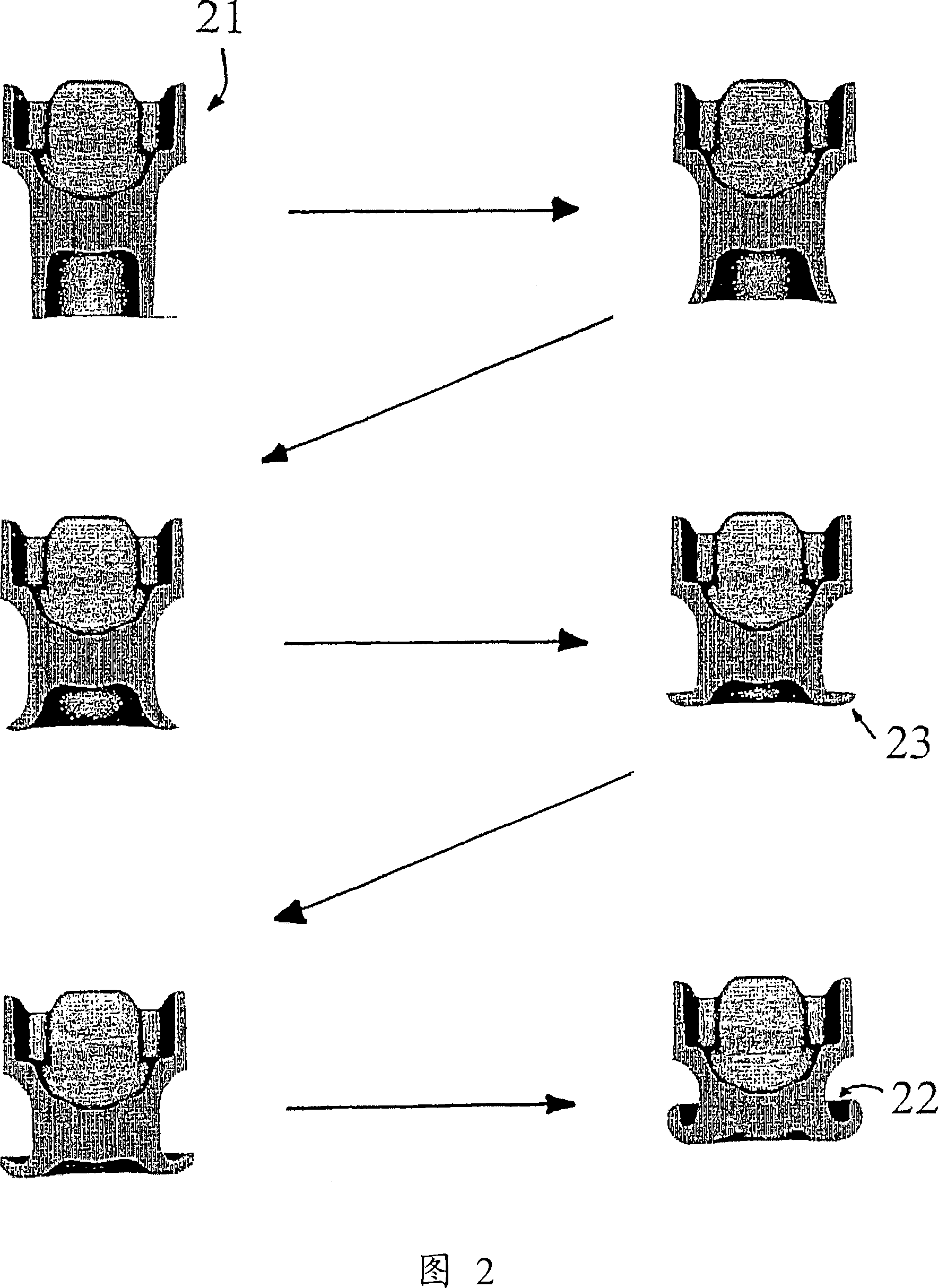

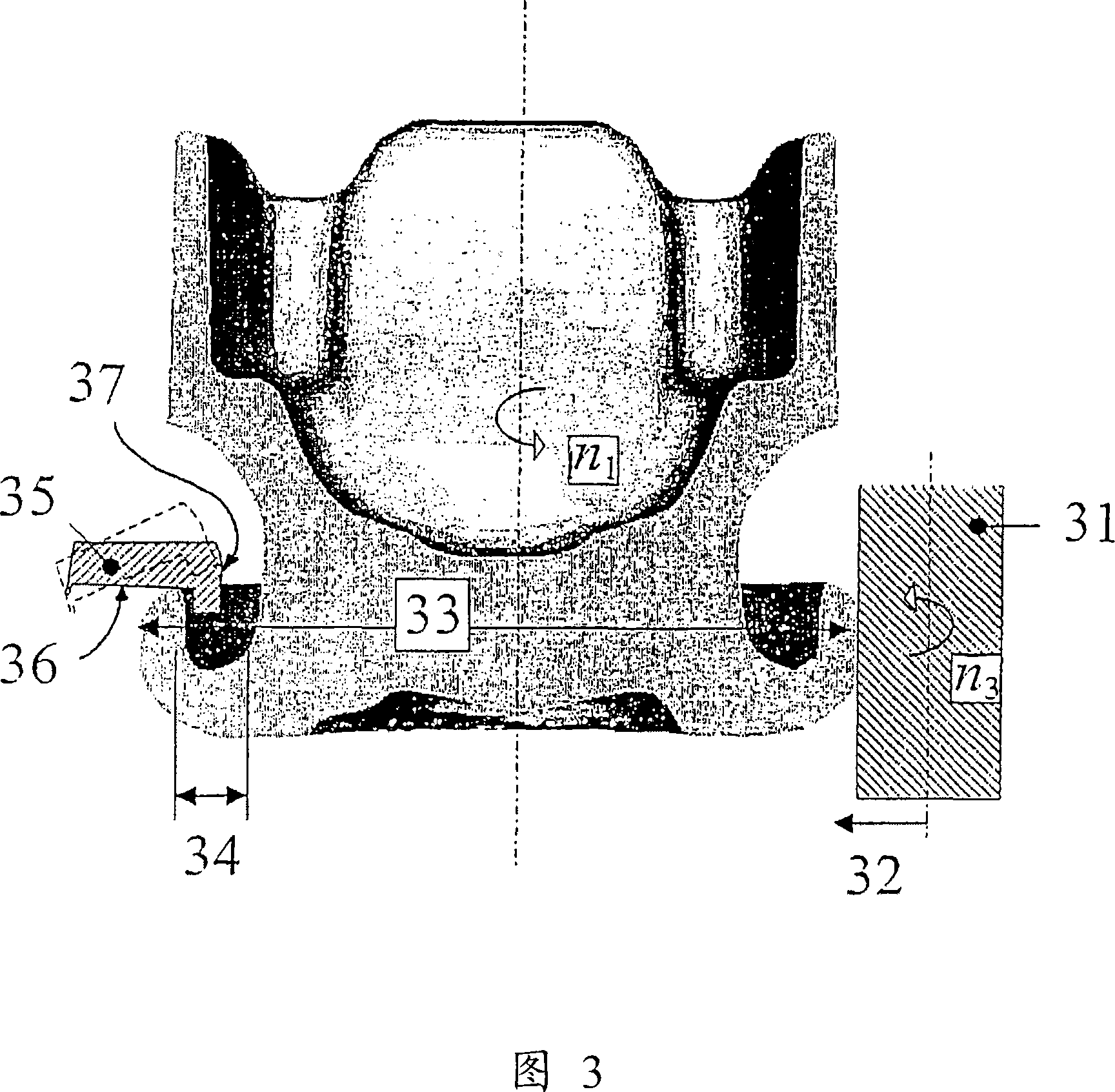

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

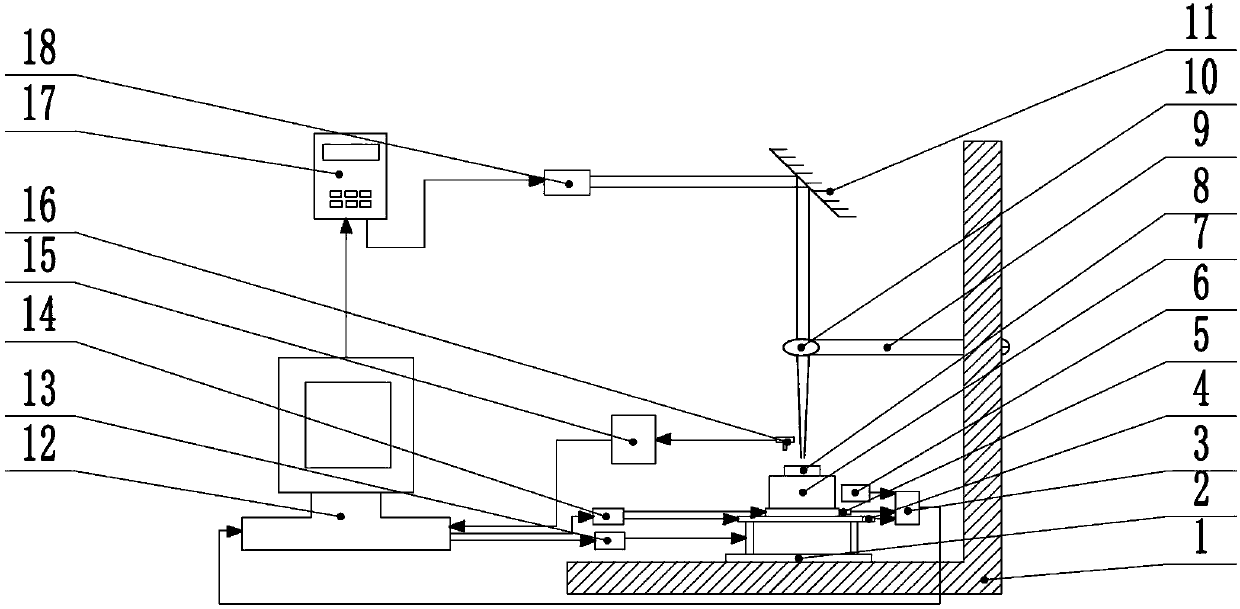

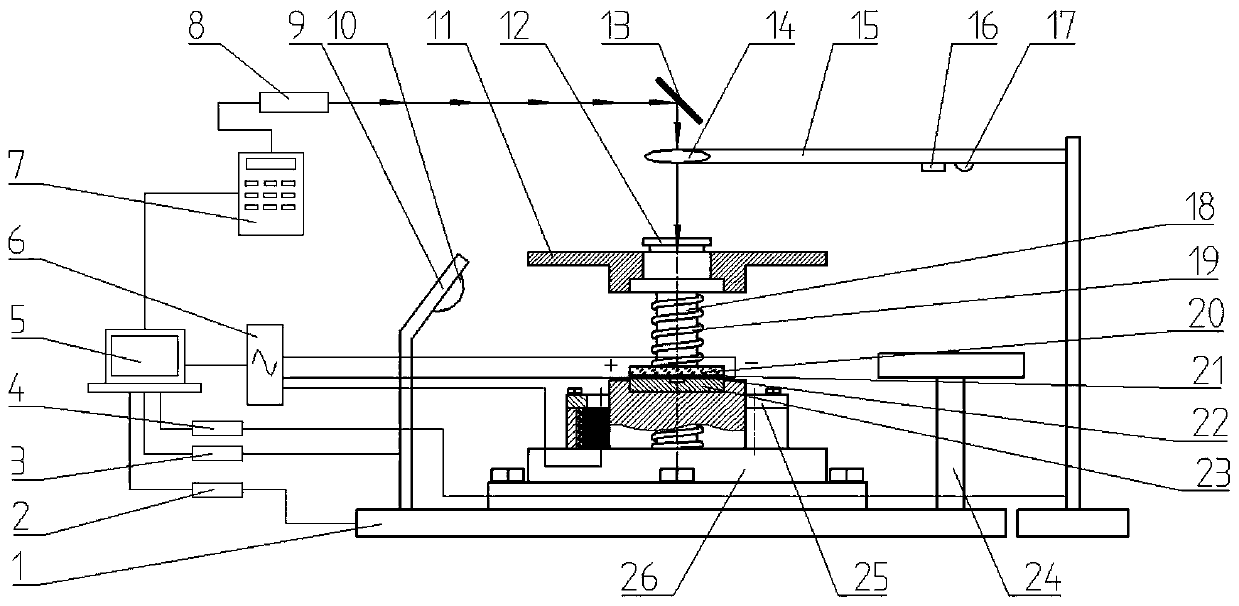

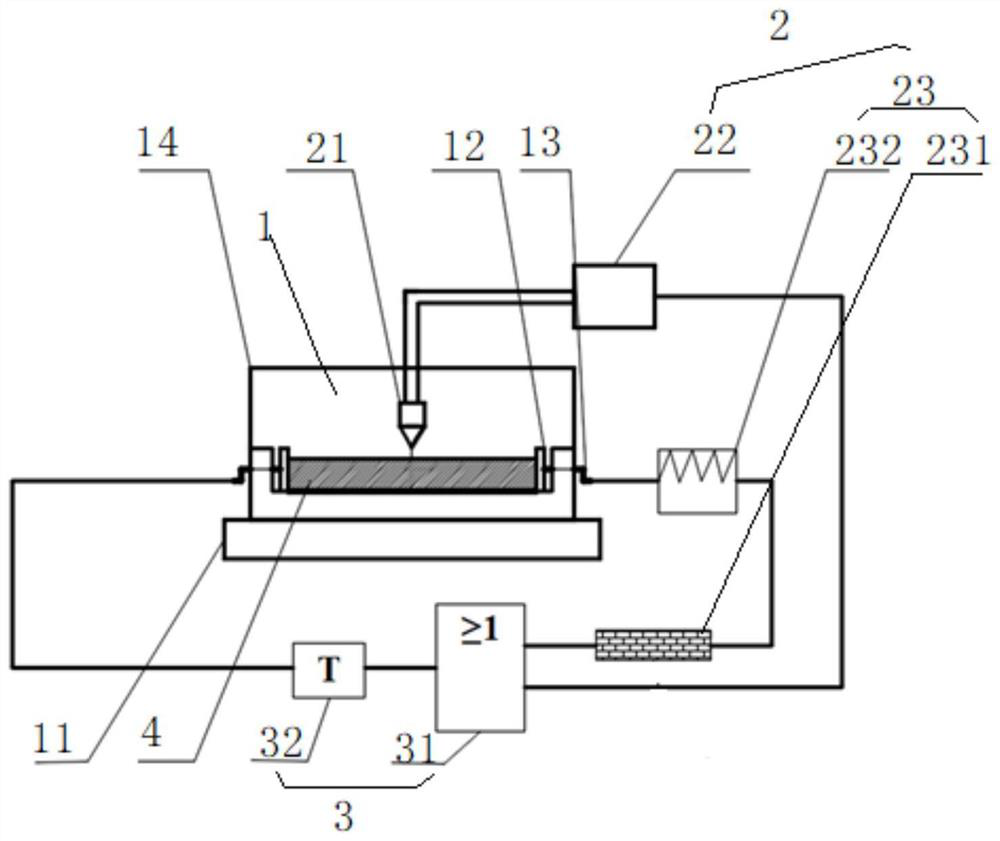

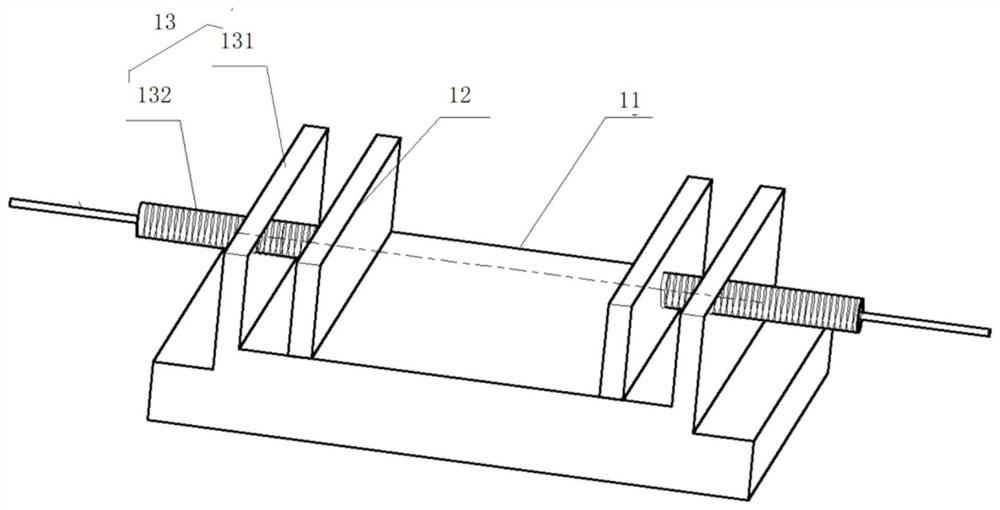

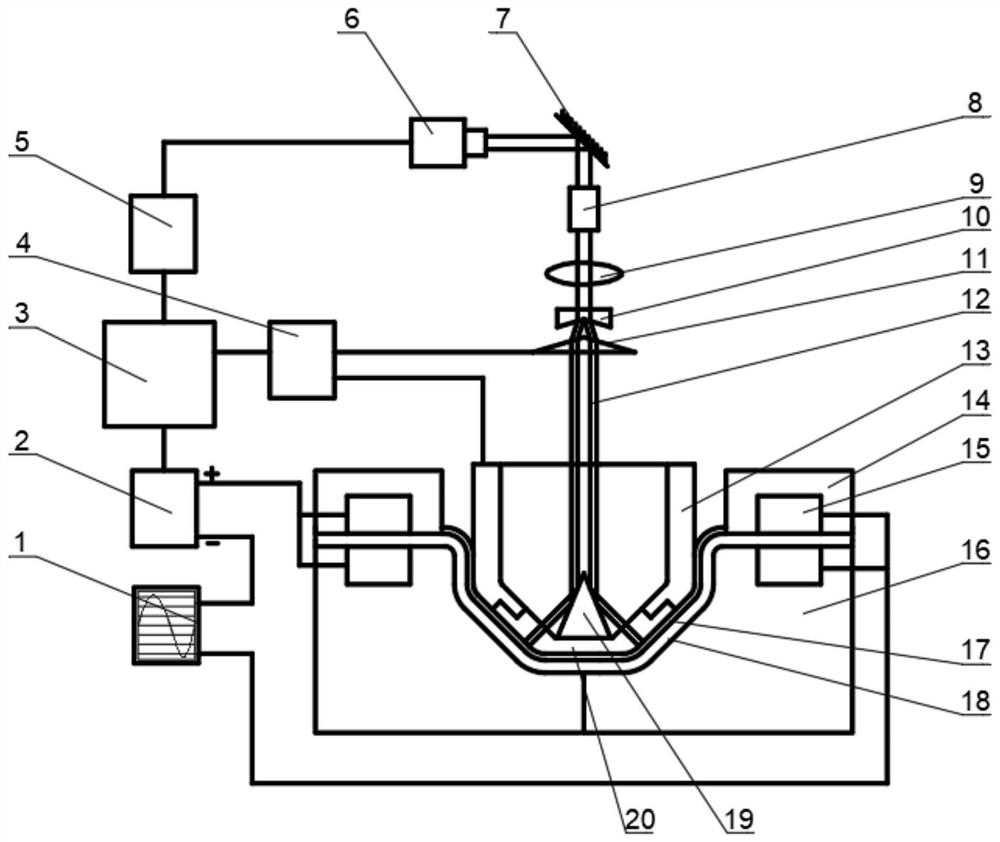

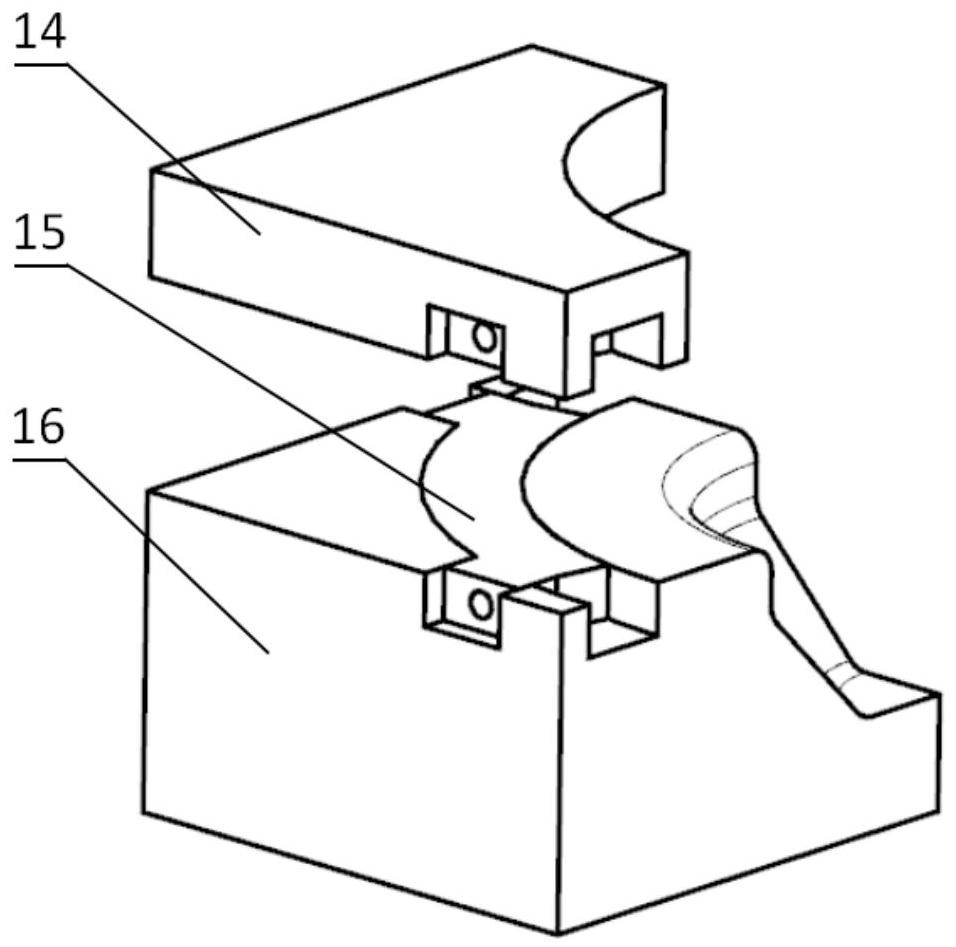

Novel laser indirect impact micro-forming device and method

InactiveCN107520538AGuaranteed forming qualityReduce scrap rateLaser beam welding apparatusControl systemContact type

The invention discloses a novel laser indirect impact micro-forming device and method. The device and method are mainly applied to plastic forming technique and manufacturing of fine micro parts. The device and method solve the problem that a conventional laser impact micro-forming method is difficult in forming, and materials cannot be formed. The device comprises a mold-debug light spot centering assembly, a workpiece positioning assembly, a workpiece assembly, an Nd:YAG pulsed laser system used for impact forming, a CW optical fiber laser system used for heating, an ultrasonic vibration system and a control system. The device can achieve the aim that pulsed laser impact force is adopted to serve as an energy source, meanwhile, ultrasonic vibration is applied to a mold and a workpiece, or, a laser beam sent out by a CW optical fiber laser is used for carrying out non-contact type quasi-static heating on the surface of the workpiece, or, under the joint effect, workpiece micro-forming is achieved; due to the design, work efficiency is improved, design is reasonable, control performance is good, quality and precision of micro-forming parts are ensured, and the device is suitable for industrialized application.

Owner:JIANGSU UNIV

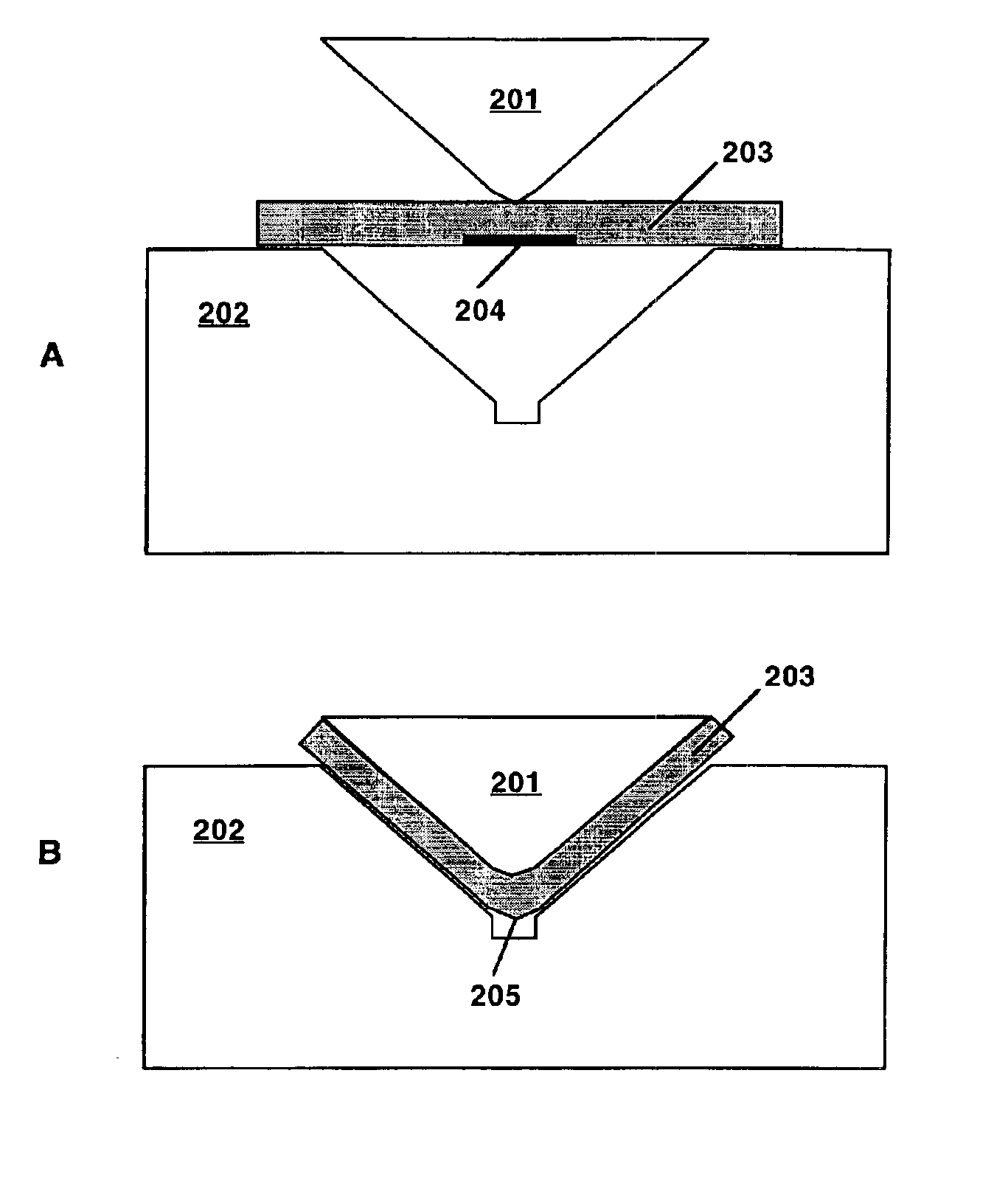

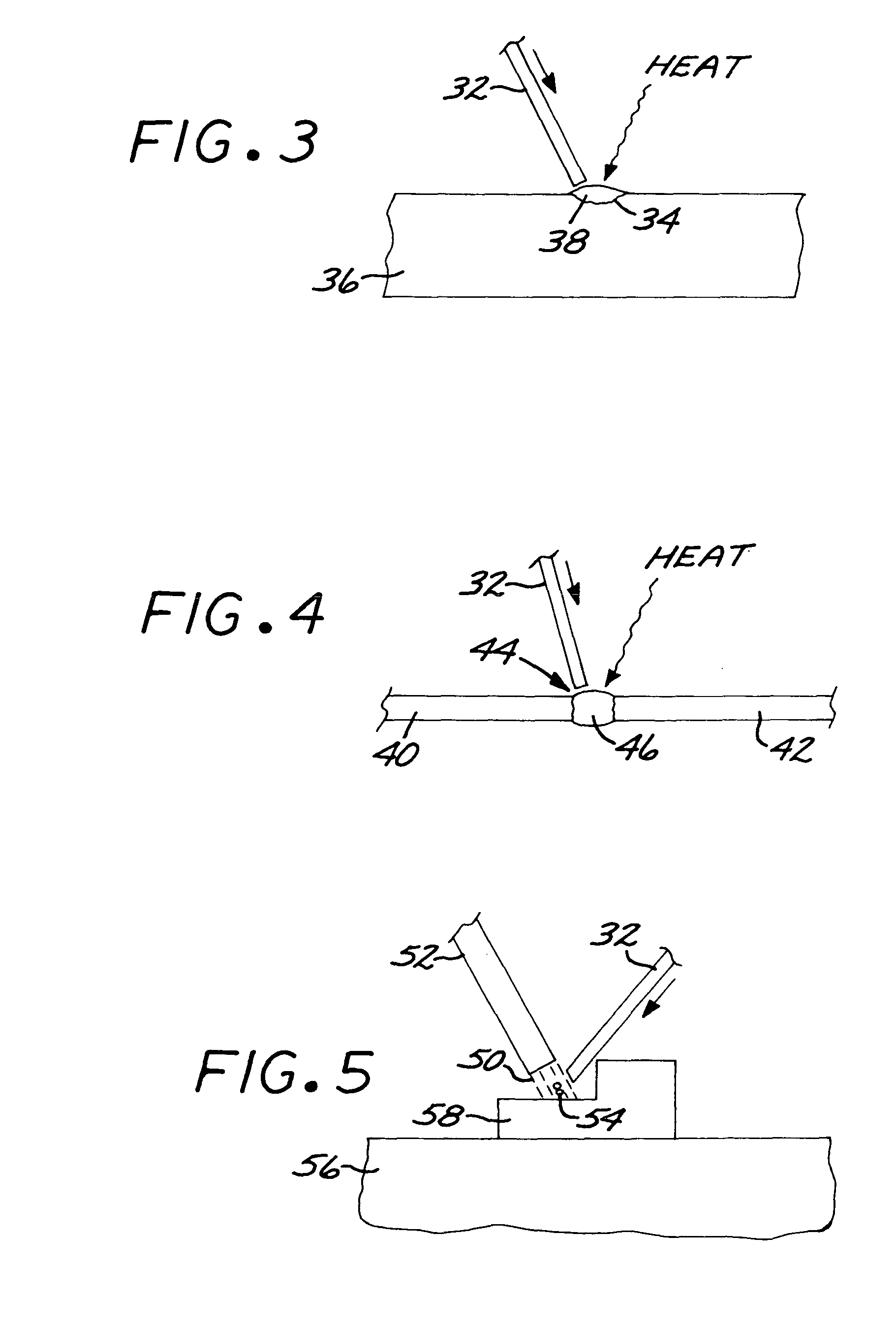

Thick-section metal forming via friction stir processing

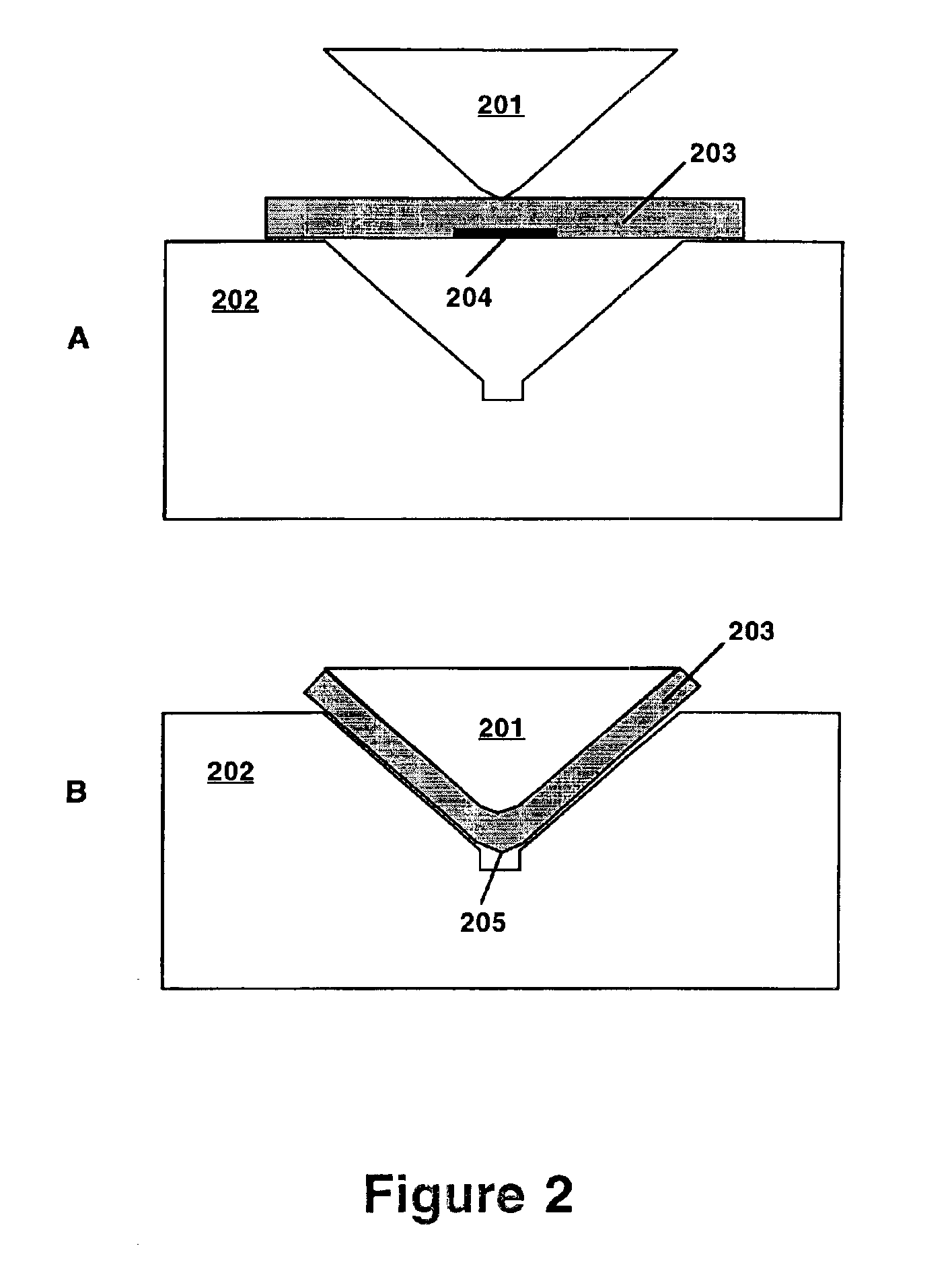

InactiveUS6866180B2Minimize formation of crackReduce flow stressWelding/cutting auxillary devicesAuxillary welding devicesMetal formingRoom temperature

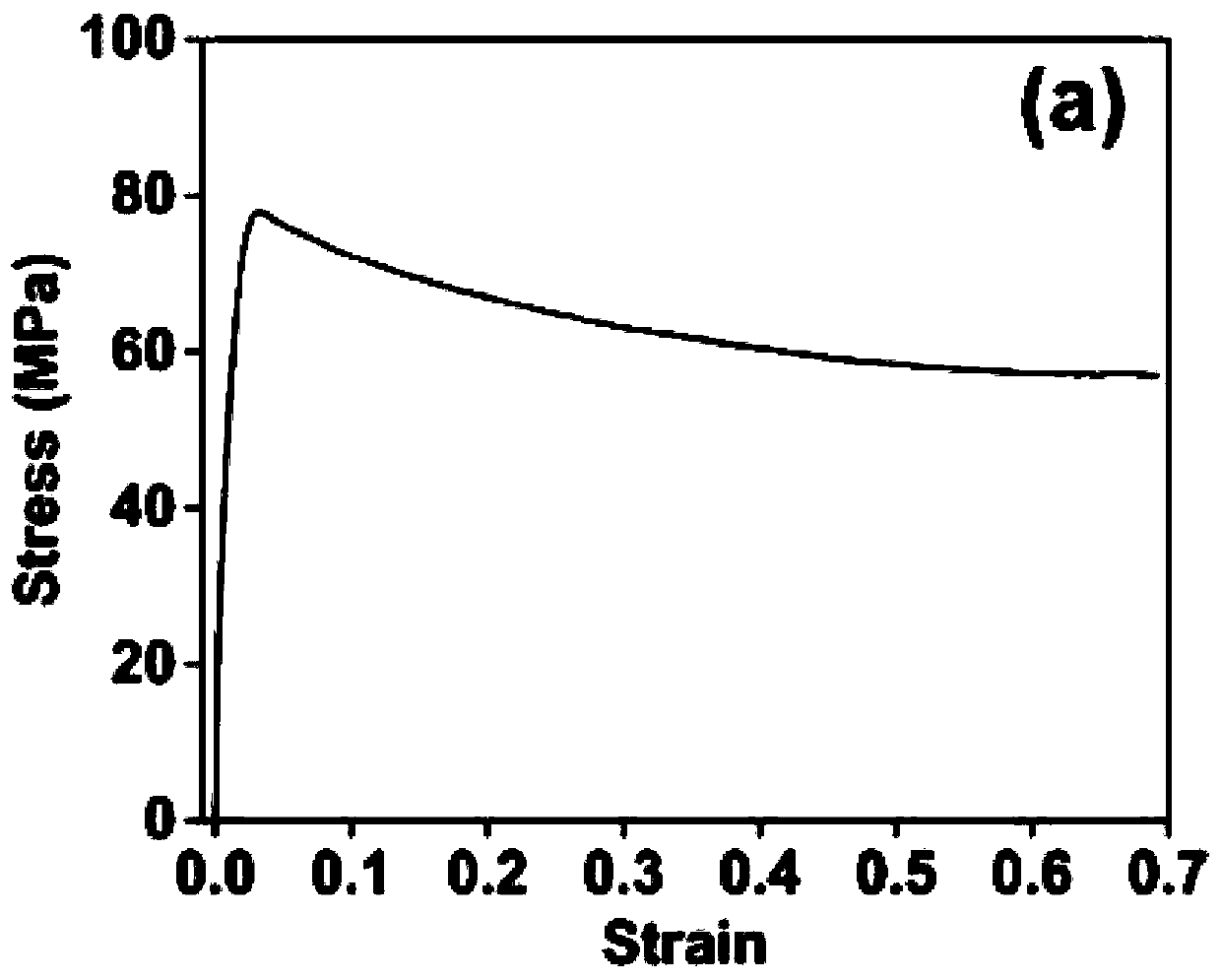

Friction stir processing (FSP) modifies the surface microstructure of metals so that thick-section metal workpieces can be bent over large angles without formation of surface cracks. A thick 2519-T8 aluminum plate (25.4 mm thick and 50.8 mm wide) was friction stir processed across the pre-tensile surface to a depth of 6.3 mm, and was then bent at room temperature over a punch with radius 38.1 mm into a v-shaped die to an 80° bend angle. Whereas unprocessed workpieces of this type exhibited surface cracking at 31° bend angle and failed at 40° bend angle, no cracking was evident for the friction stir processed workpiece up to 80° bend angle.

Owner:TELEDYNE SCI & IMAGING

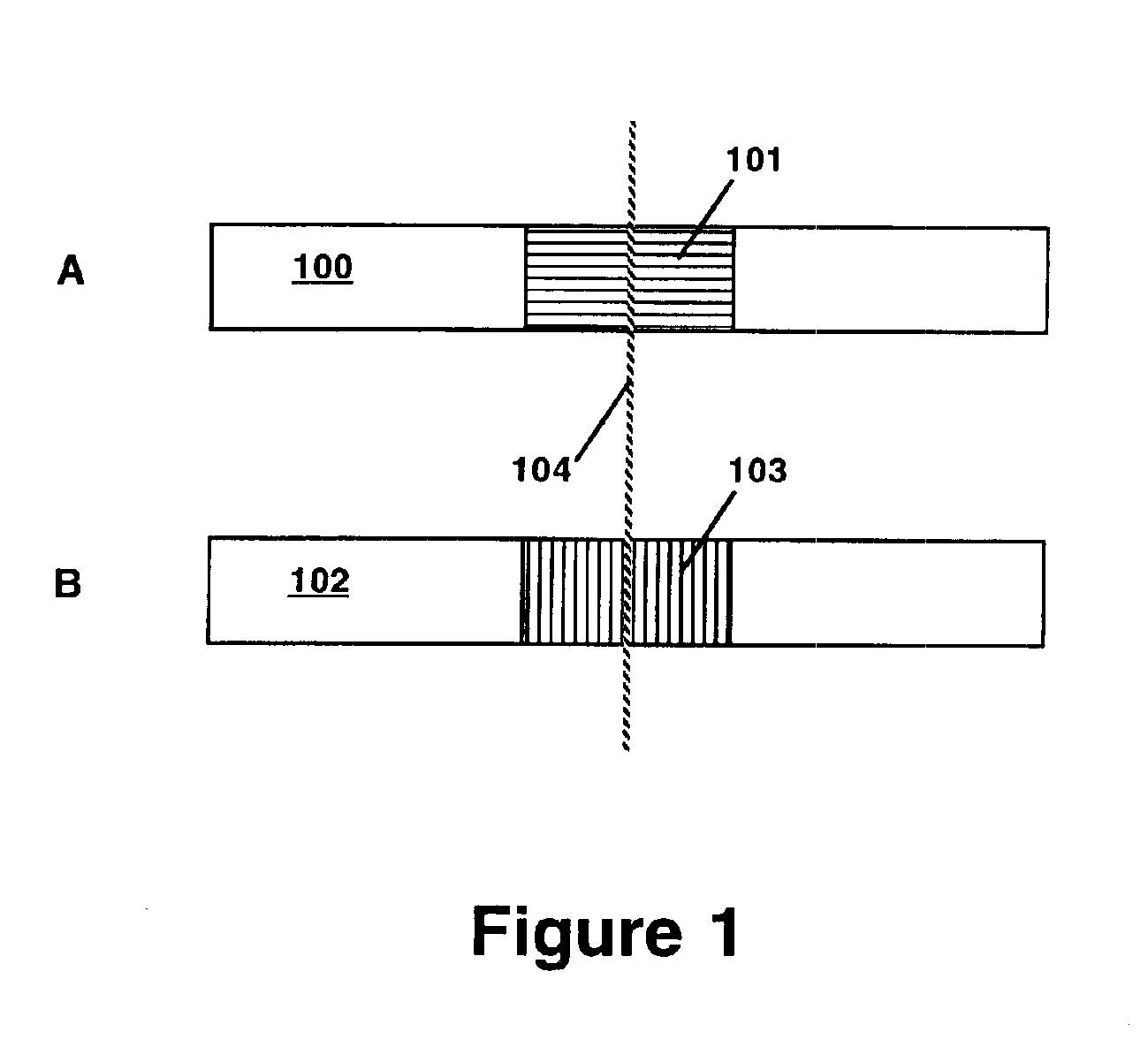

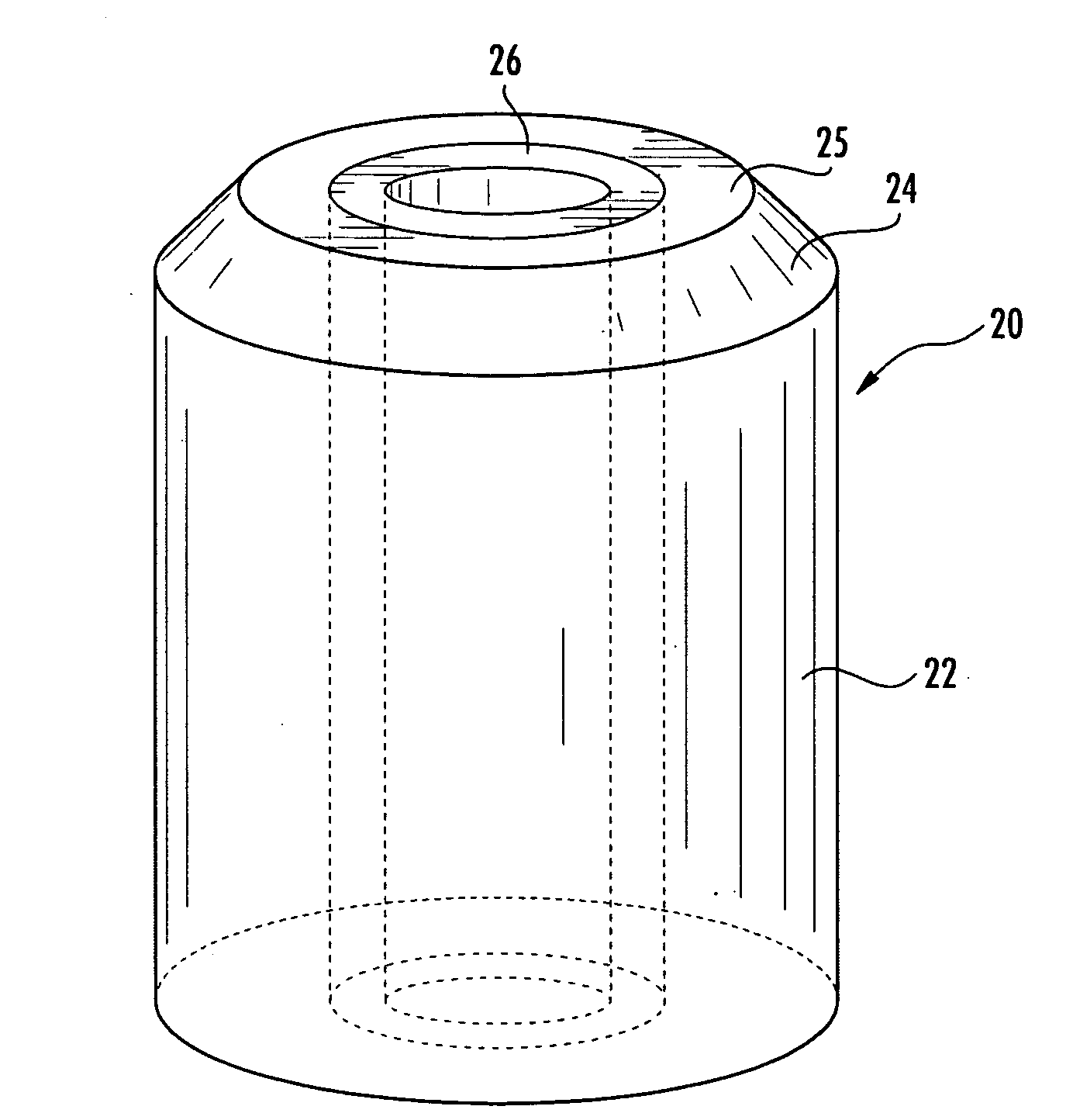

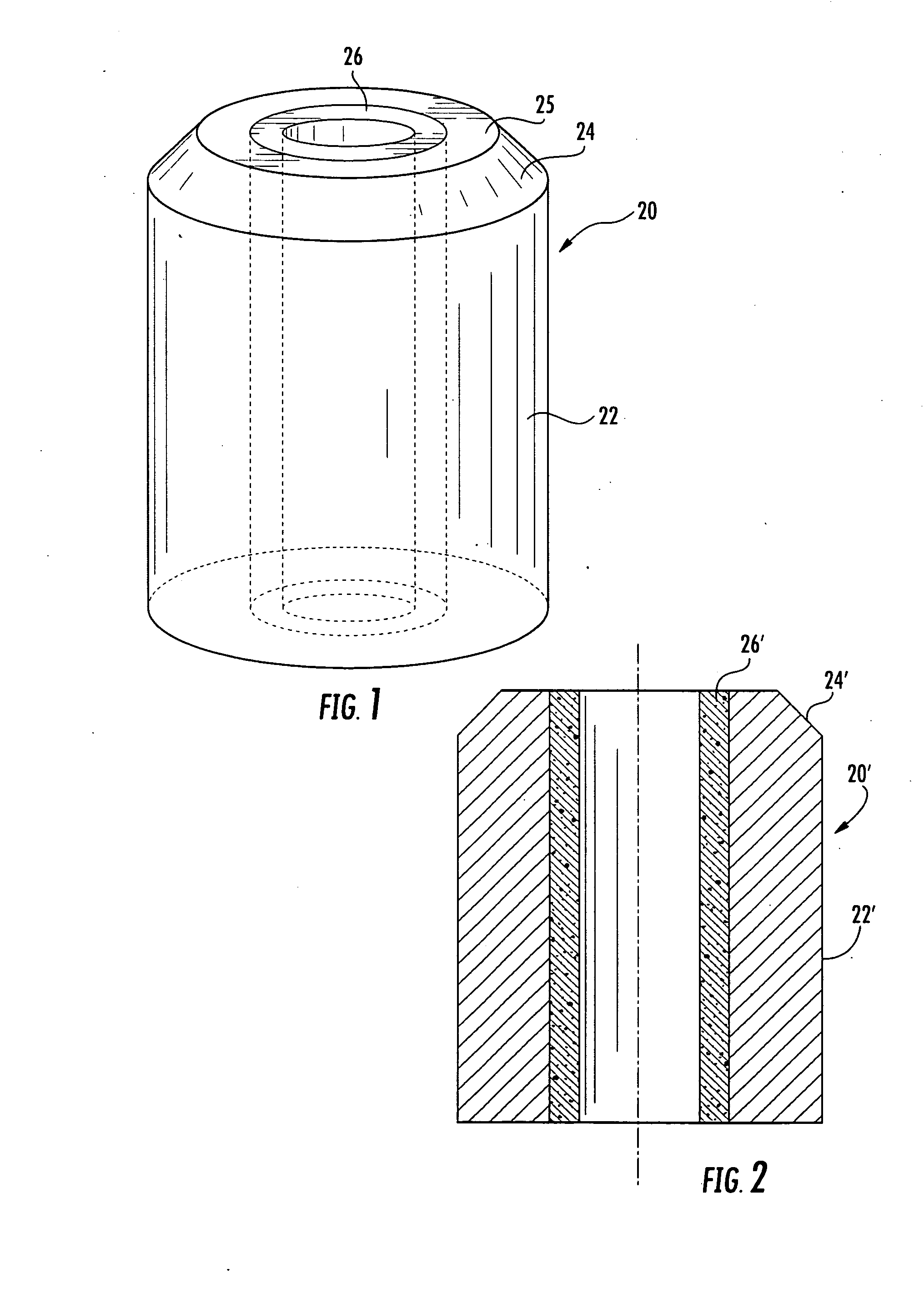

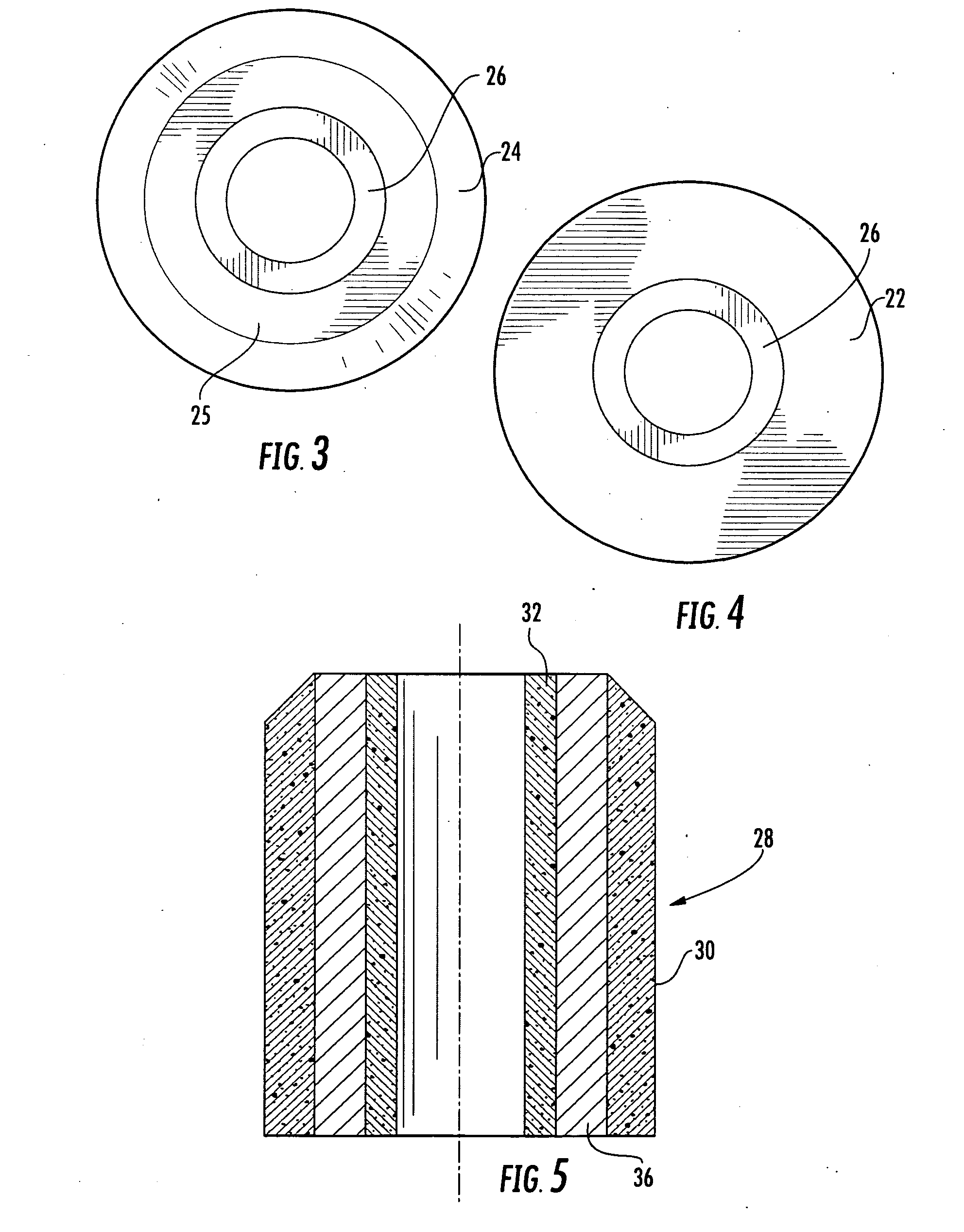

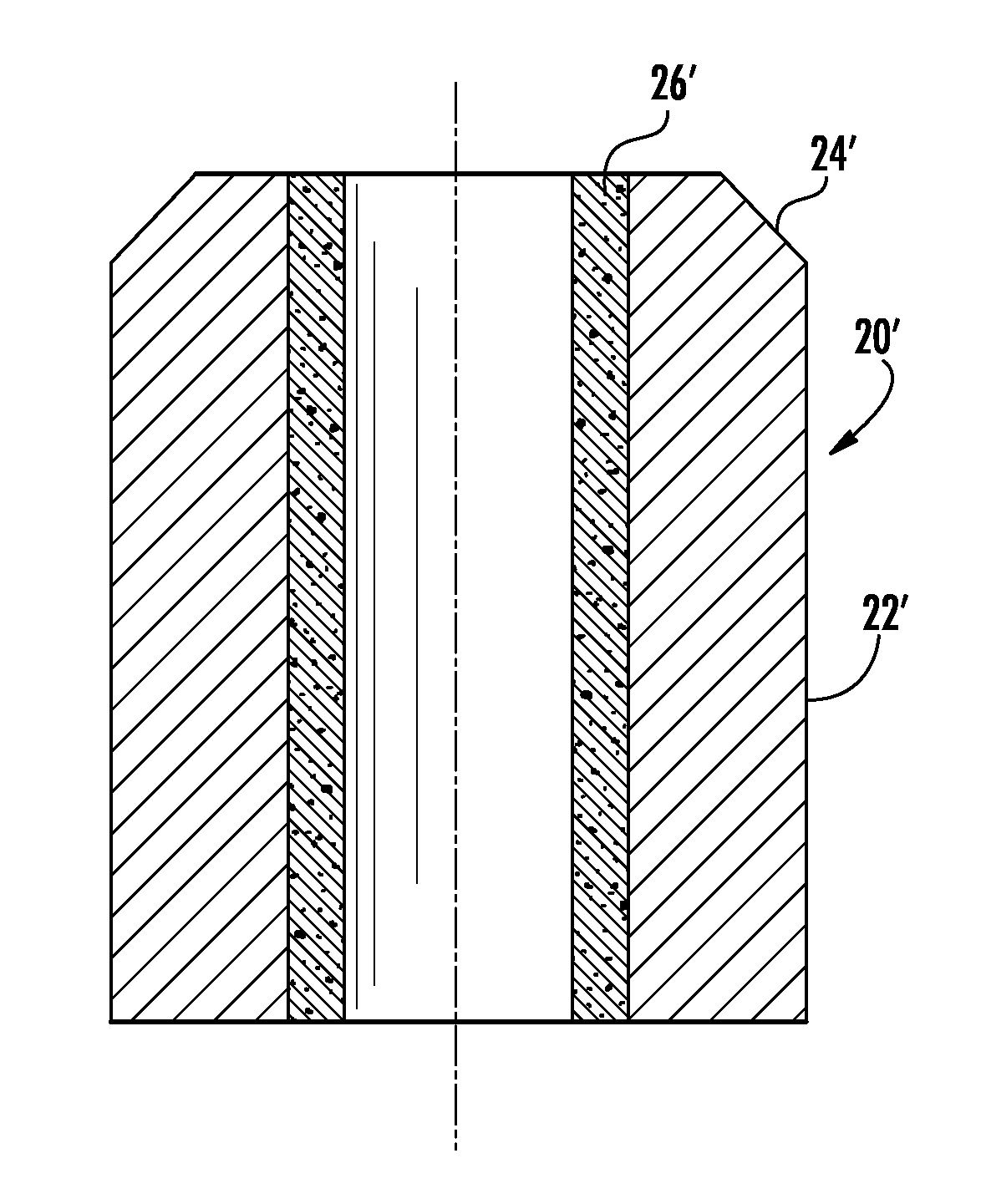

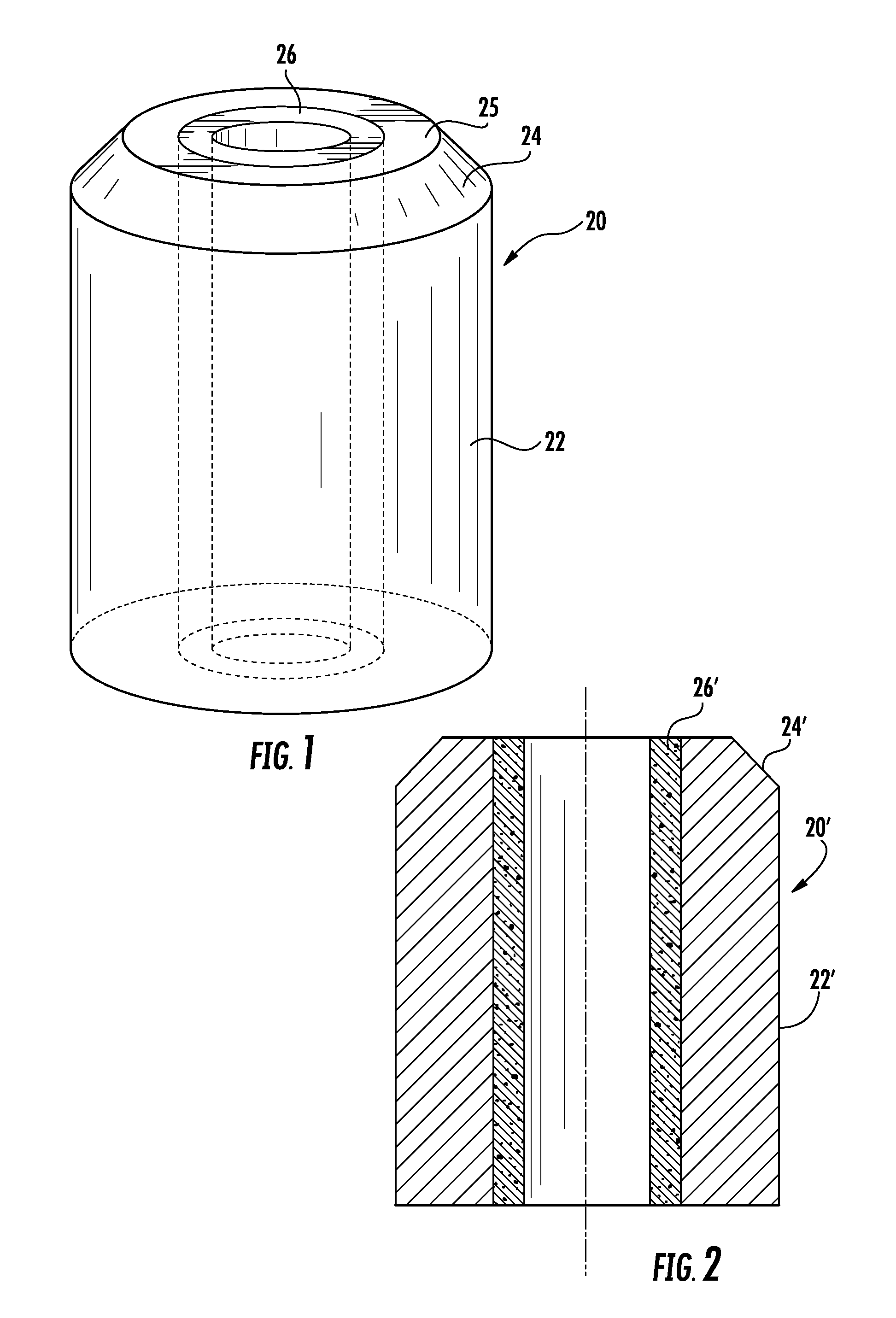

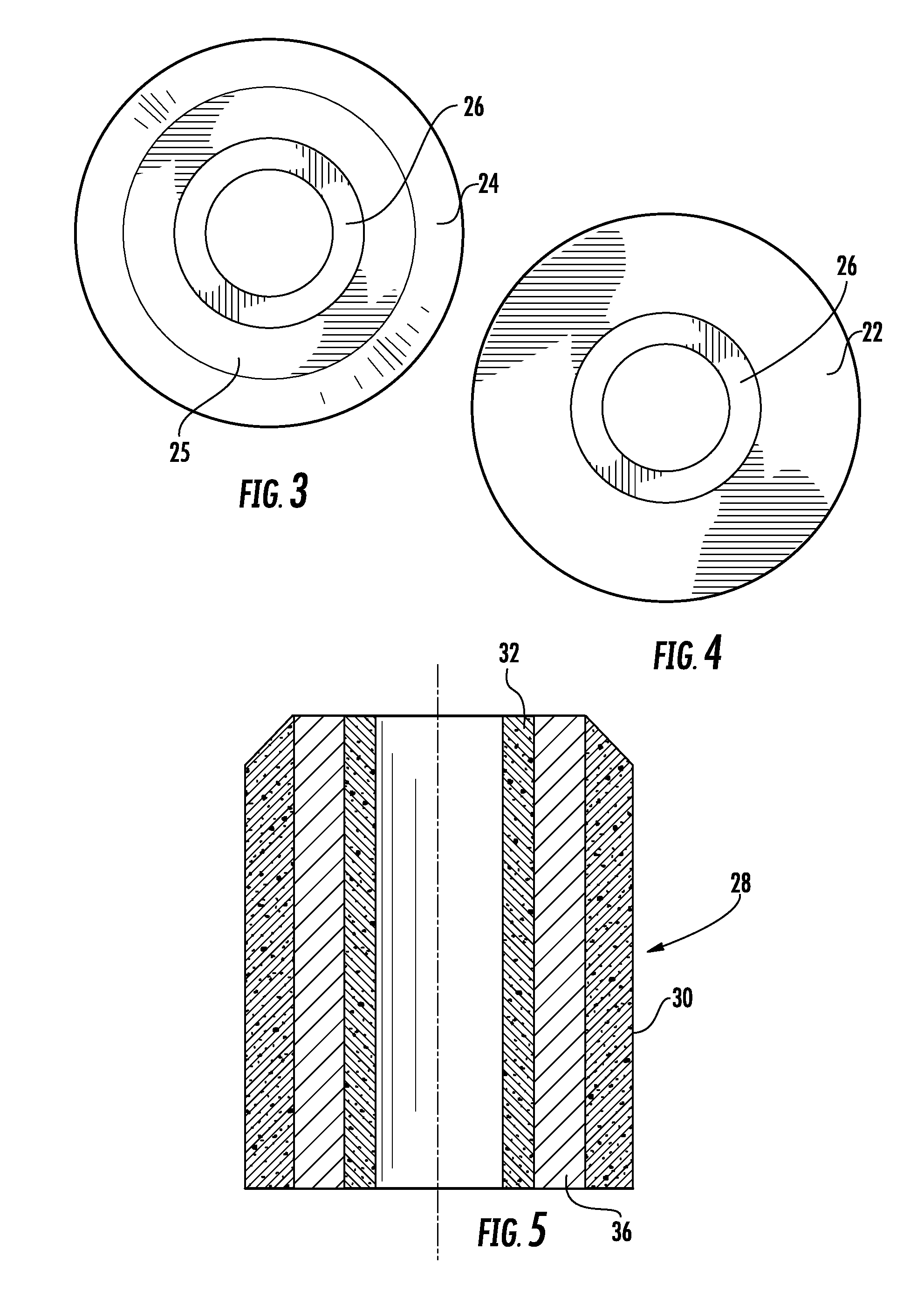

Composite Preform Having a Controlled Fraction of Porosity in at Least One Layer and Methods for Manufacture and Use

InactiveUS20090269605A1Reduce failure rateReduce flow stressExhaust apparatusSilencing apparatusFlow stressPorosity

The invention provides clad billet for hot working plastic deformation processes for the production of clad products, including, but not limited to, clad pipe and tubing by extrusion of a hollow, bicomponent composite billet having a fully dense structural component and a partially dense component of a specialty alloy at a fraction of porosity predetermined to provide a flow stress compatible with that of the structural component. The components are diffusion bonded to the predetermined fraction of porosity in the specialty component by application of heat and pressure over time, including by hot isostatically pressing the billet components. Computer modeling techniques can be used to determine processing conditions for obtaining flow stress compatibility.

Owner:BODYCOTE IMT INC

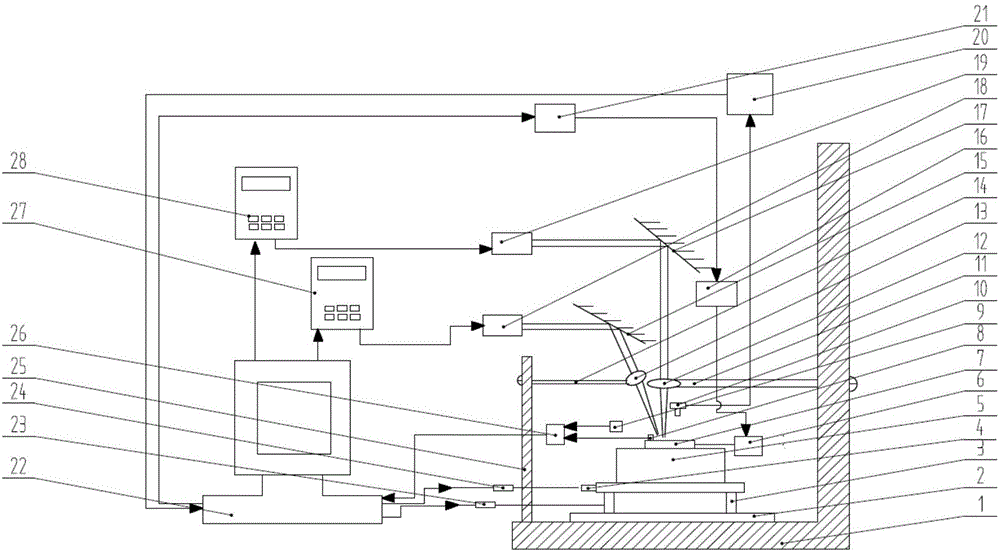

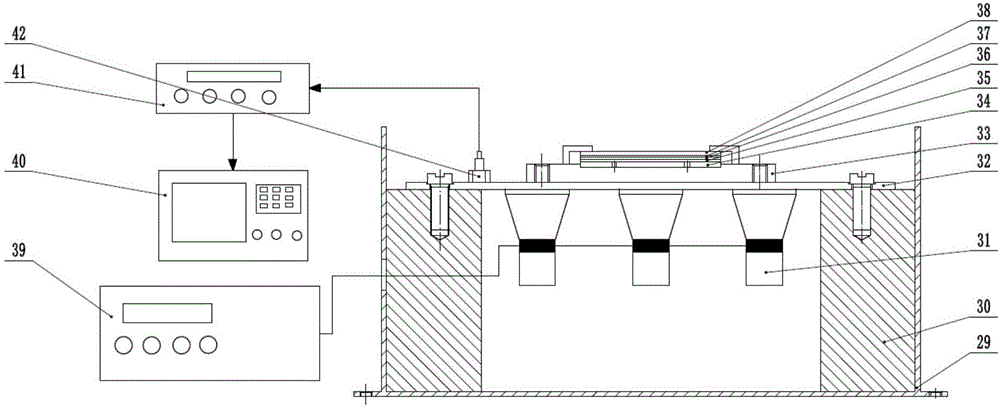

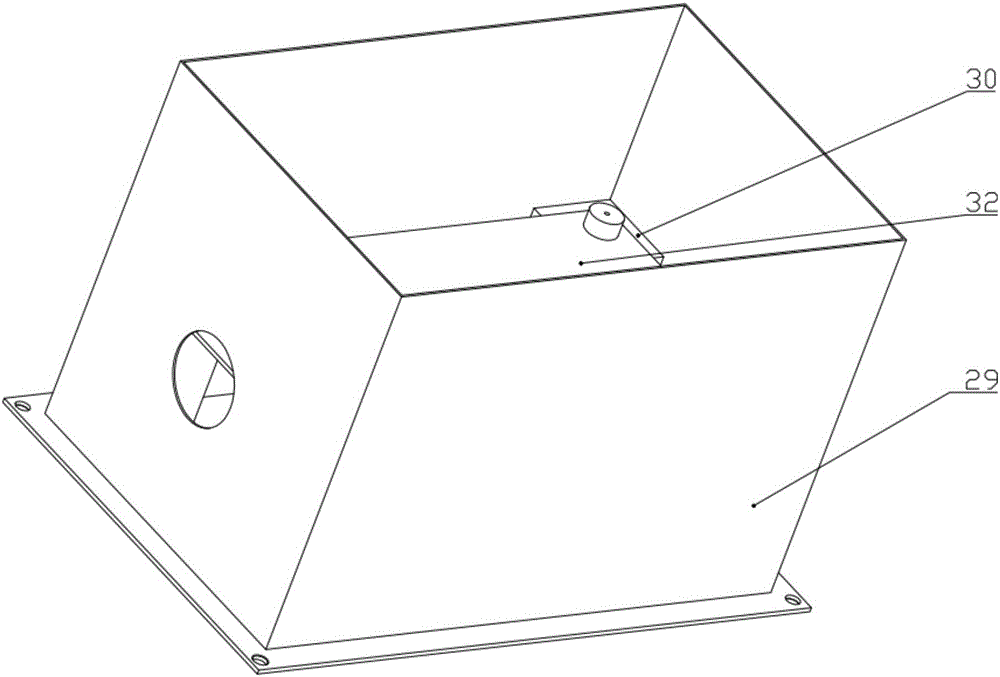

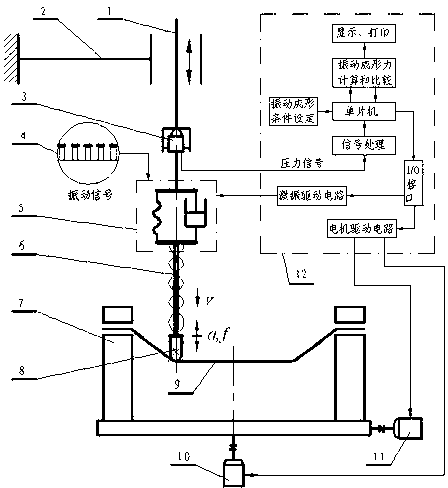

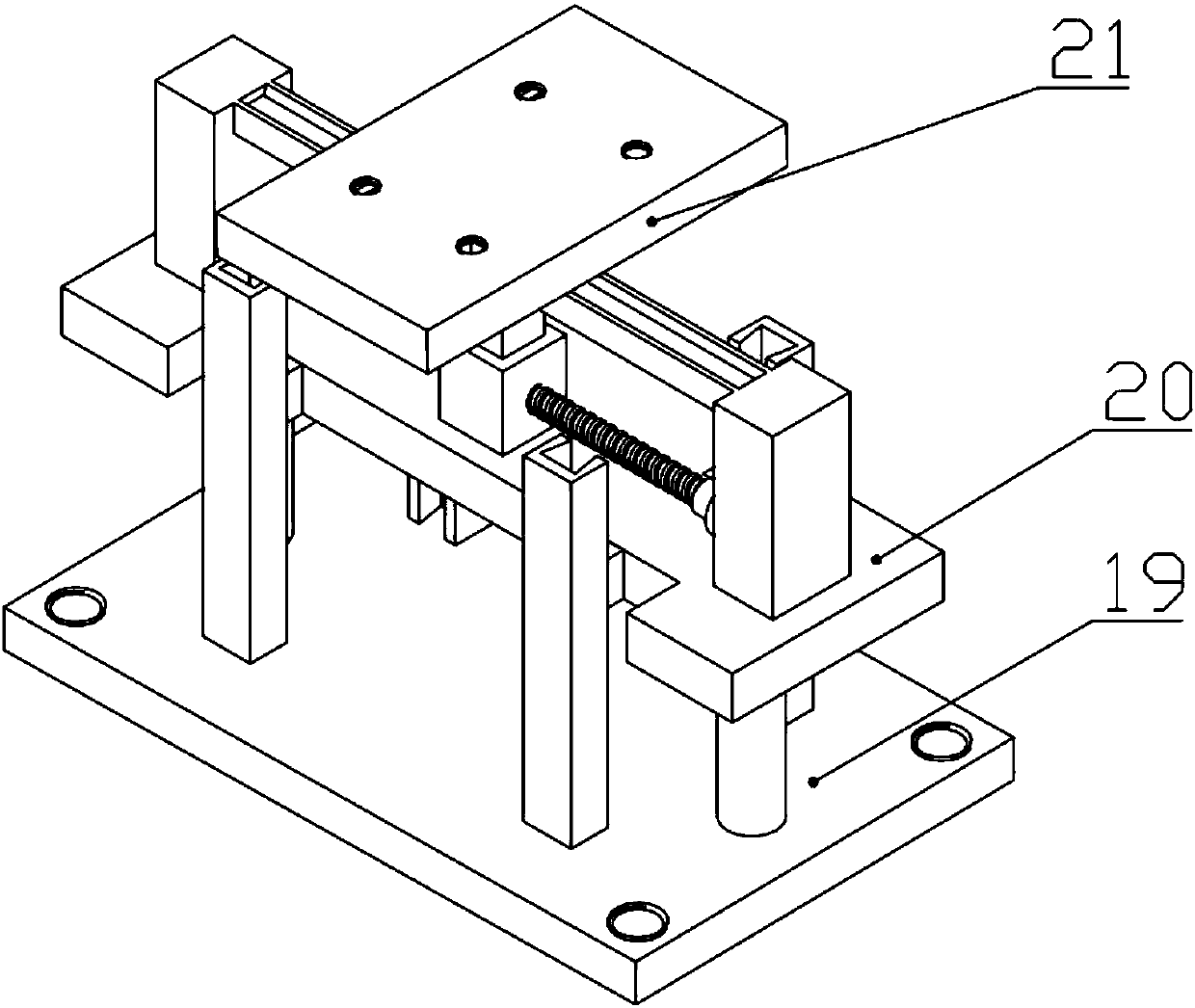

Single-point longitudinal vibration controllable progressive forming system for metal plate

InactiveCN103071726AImprove forming conditionsLighten or wrinkleLongitudinal vibrationParameter control

The invention discloses a single-point longitudinal vibration controllable progressive forming system for a metal plate. The main shaft of the single-point longitudinal vibration controllable progressive forming system for the metal plate is installed on a rack; a force sensor is installed on the shaft end of the main shaft; a vibration signal generator is connected with a vibration exciter; the vibration exciter is installed below the force sensor; a tool head is connected with the vibration exciter via a connecting rod; a workbench is installed just below the main shaft; the input end of a parameter controller is connected with the force sensor; and the output end of the parameter controller is respectively connected with the vibration frequency and amplitude control port of the vibration exciter as well as the X-shaft driving motor control port and the Y-shaft driving motor control port of the workbench. A single-point longitudinal vibration plasticity forming condition of the plate material is established by combining a forming technology parameter, a vibration mode parameter and a forming force parameter, and the parameter controller is used for monitoring and regulating the forming technology parameter and the vibration mode parameter in real time according to the plate material forming technology state and the vibration plasticity forming condition. The single-point longitudinal vibration controllable progressive forming system for the metal plate, which is disclosed by the invention, has the beneficial effects that the technical defects of single-point progressive forming can be overcome, the technology parameter and the vibration mode parameter can be monitored and regulated in real time according to the plate material vibration plasticity forming condition in the forming process, and efficient and precise progressive forming of the metal plate material can be realized.

Owner:JIANGXI UNIV OF SCI & TECH

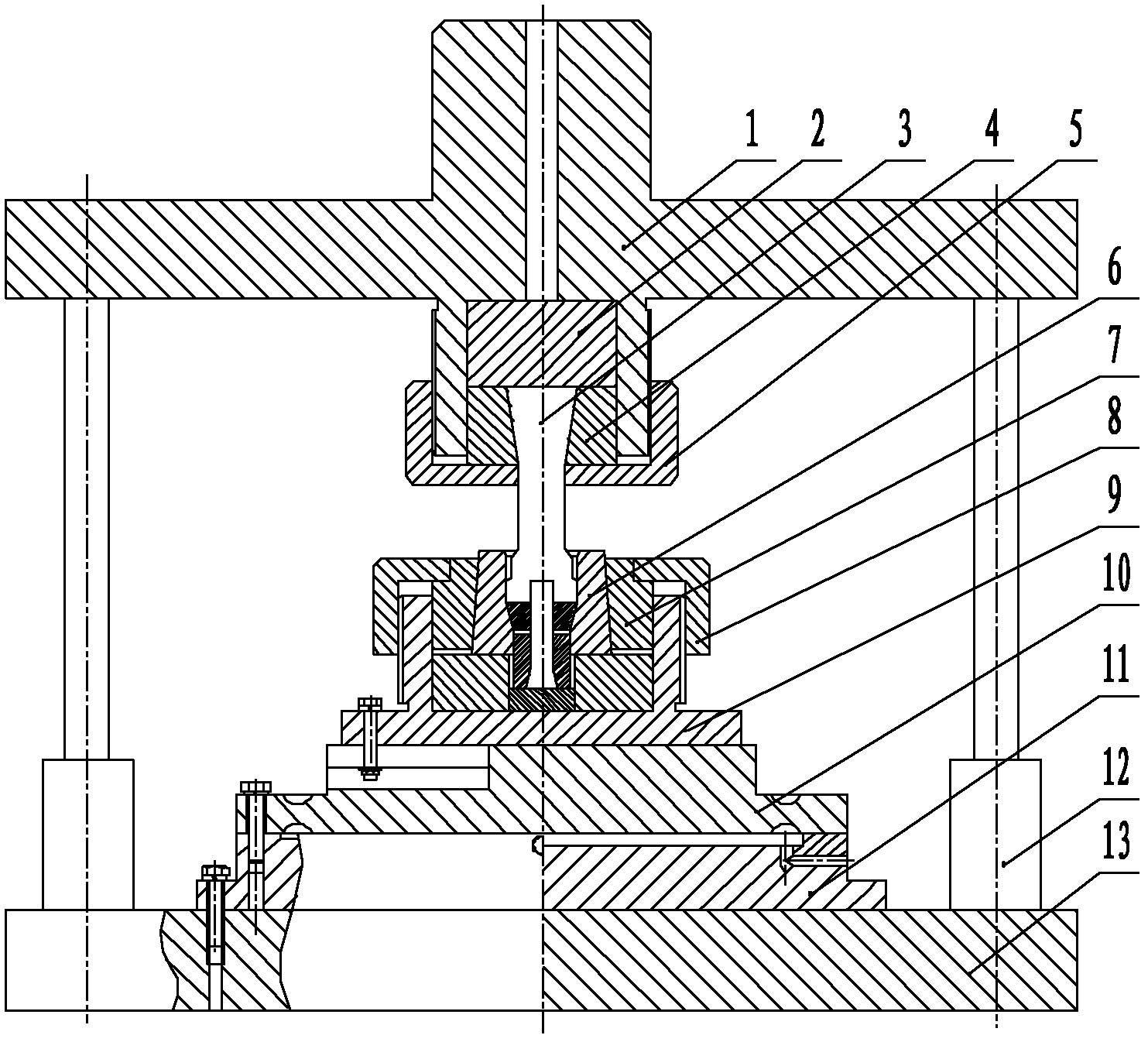

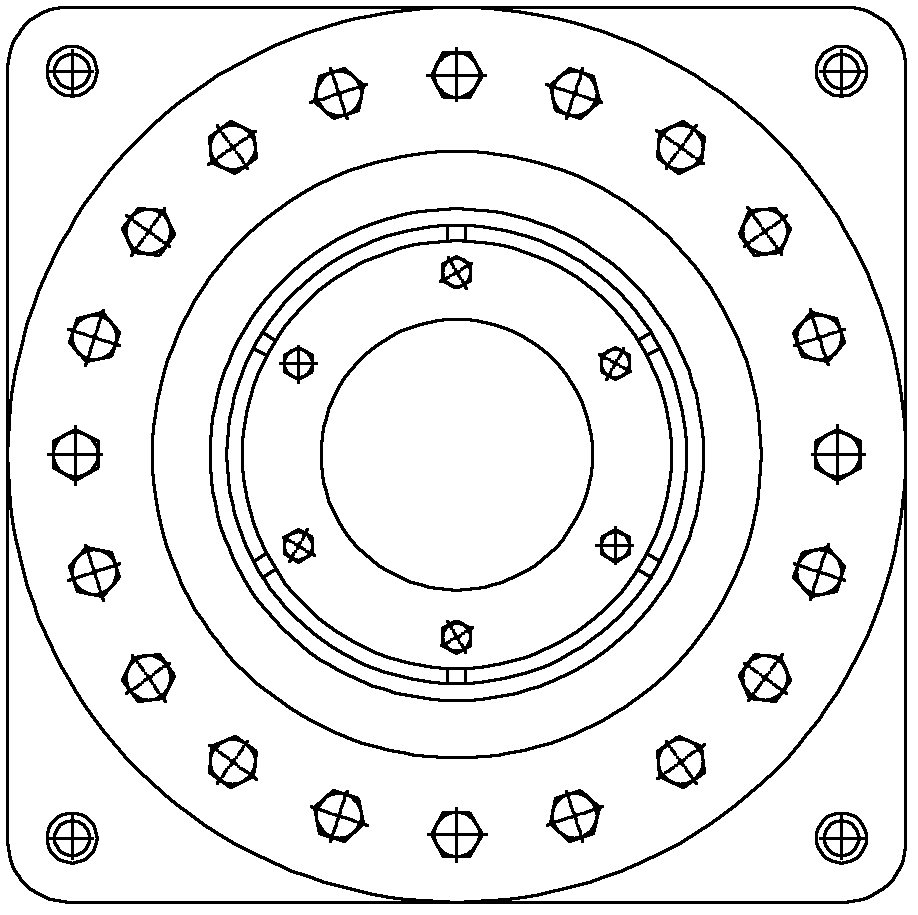

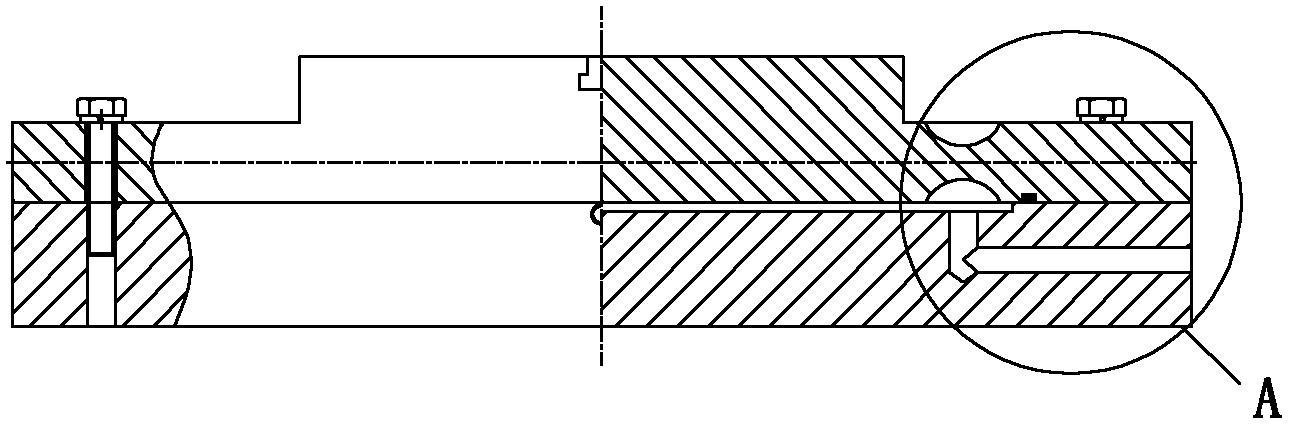

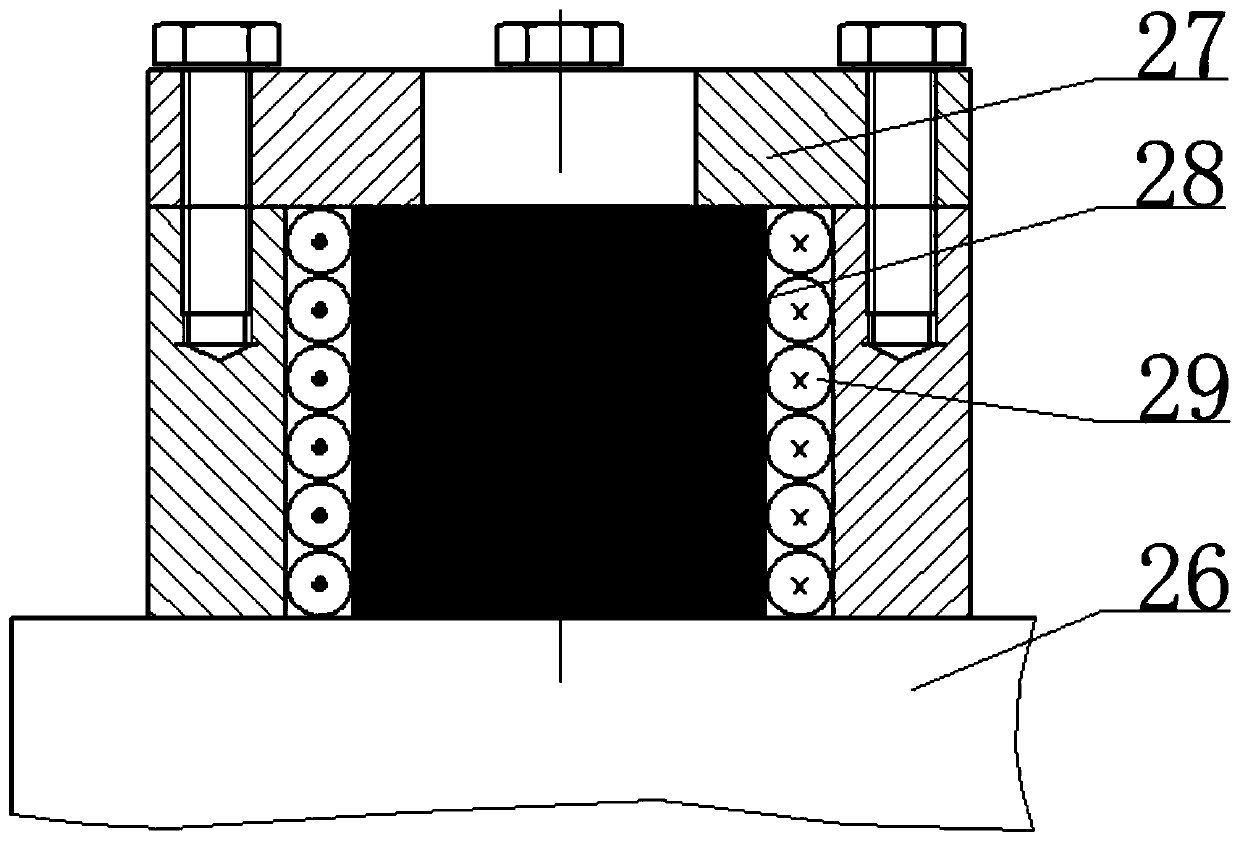

High-frequency flutter cold extruding die

The invention discloses a high-frequency flutter cold extruding die, which comprises a forming mechanism. A male die is fixedly connected with an upper template; a female die is positioned under the male die and is arranged in a female die sleeve; a flutter generation mechanism comprises a vibration table and a high-frequency valve, wherein the vibration table comprises an upper plate and a lower plate; a lug boss is arranged in the middle of the upper plate and is fixedly connected with the female die sleeve; a vertically-symmetrical annular groove is arranged on the upper plate around the lug boss; the section of the annular groove is in an arc shape; a lower groove is arranged in the middle of the upper surface of the lower plate and is communicated with an annular groove on the lower surface of the lower plate; the upper plate is in fixed sealing connection with the lower plate through a fastener; the fastener is positioned at an outer circle of the annular groove; the lower plate is provided with an oil passage through which hydraulic oil enters or exits; one end of the oil passage is communicated with the lower groove; the other end of the oil passage is communicated with the high-frequency valve; and the lower plate is fixedly connected with a lower template. According to the high-frequency flutter cold extruding die disclosed by the invention, enough vibration output force, higher vibration frequency and lower amplitude can be provided; and dimensional precision of complex parts can be ensured while the vibrated extrusion of the complex parts are finished.

Owner:ZHEJIANG UNIV OF TECH

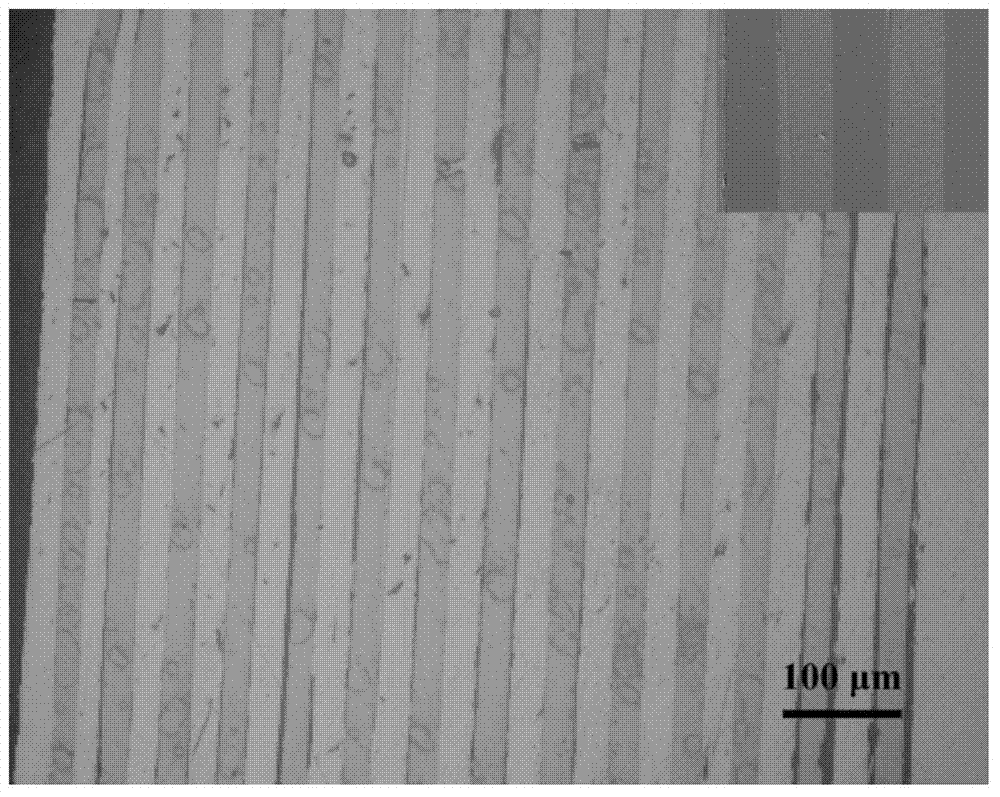

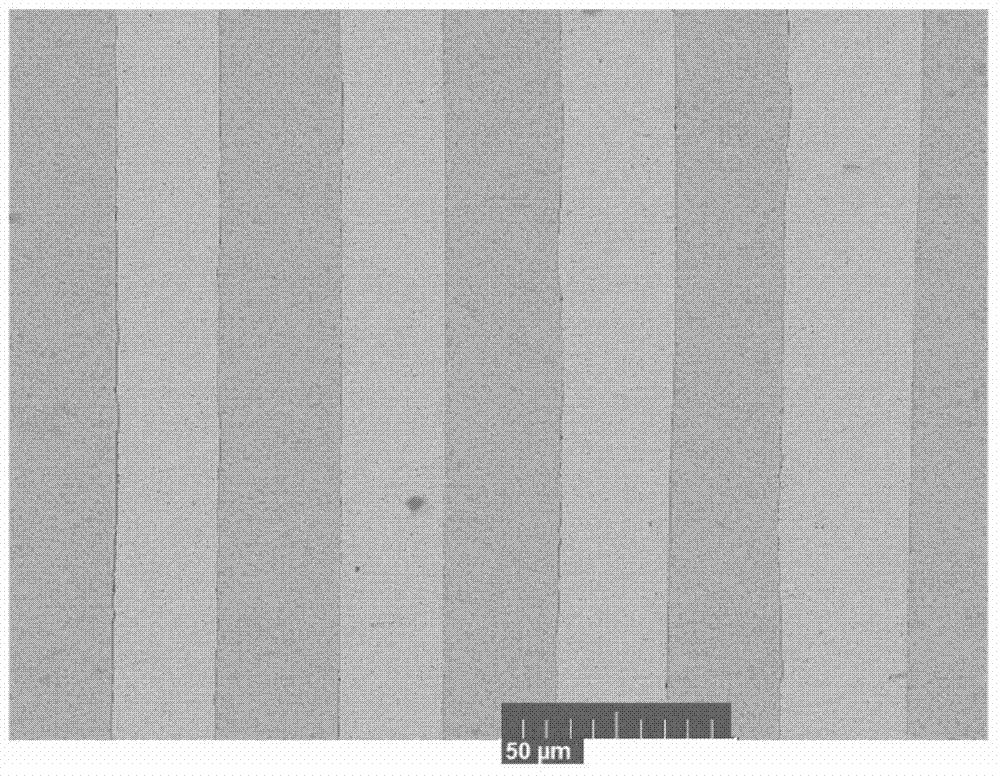

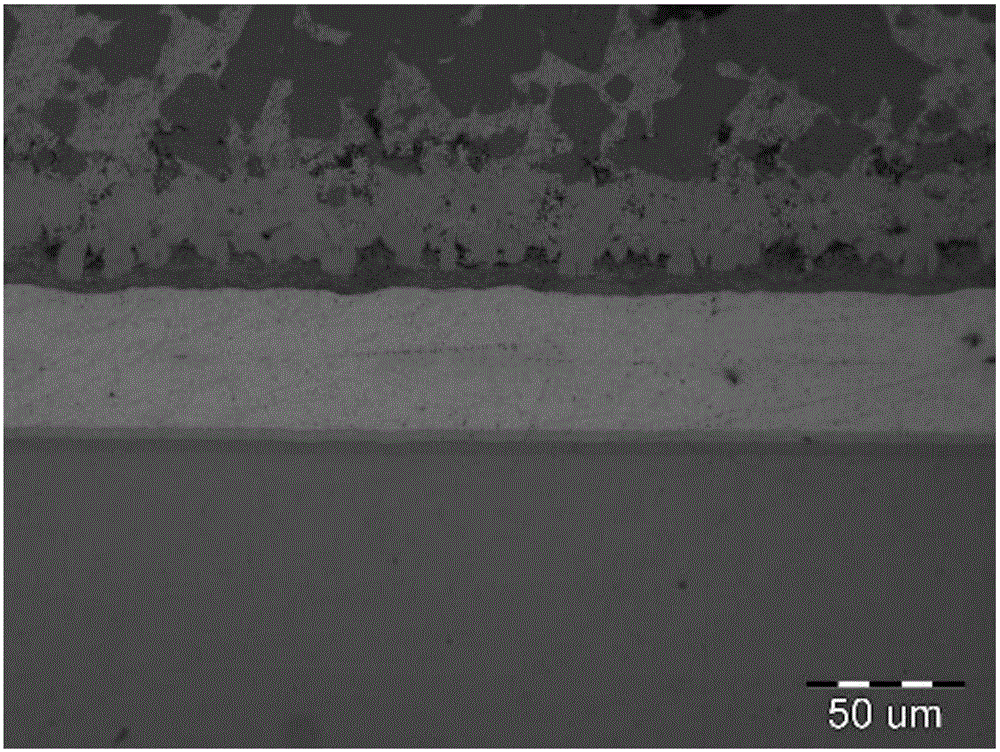

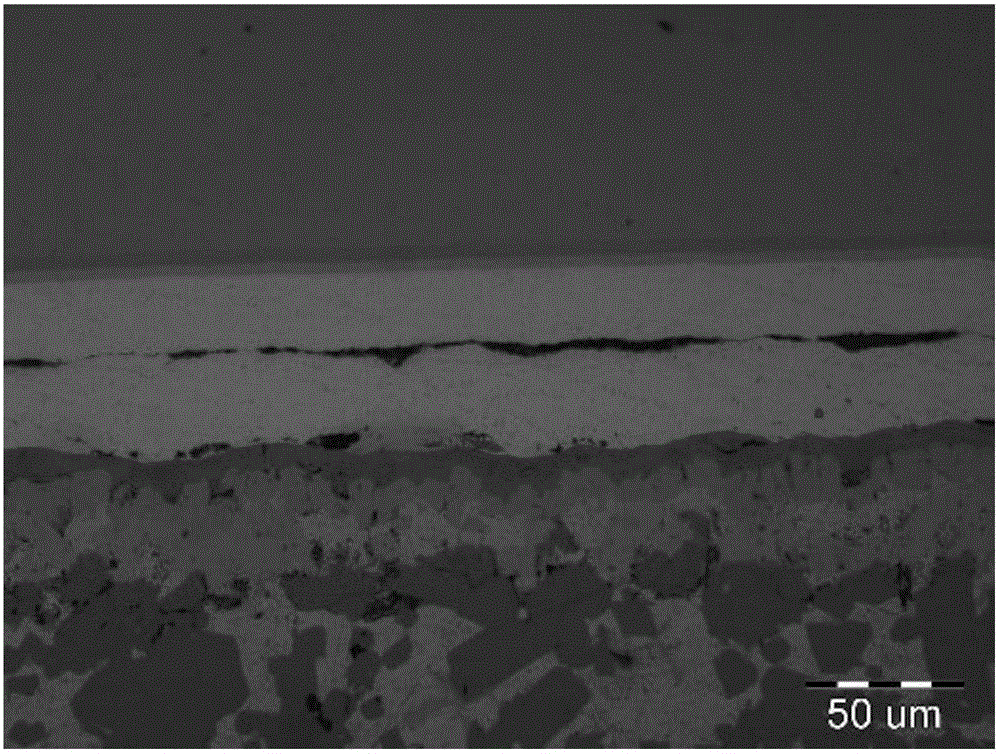

Preparation method of iron-based amorphous alloy-copper multilayer composite plate

ActiveCN103895313AAchieve preparationFlexible and efficient preparation methodLaminationLamination apparatusComposite plateAmorphous metal

The invention discloses a preparation method of an iron-based amorphous alloy-copper multilayer composite plate. By combining a vacuum diffusion bonding technology and a hot rolling bonding technology, the multilayer composite plate is prepared; in processes of vacuum diffusion bonding and hot rolling bonding, processing temperatures are selected to be in an amorphous alloy super-cooled liquid region; by adopting the characteristics of low viscosity, small flow stress and element diffusion acceleration of the amorphous alloy in the super-cooled liquid region, the iron-based amorphous alloy and the copper can be effectively connected, thus the iron-based amorphous alloy-copper multilayer composite plate can be successfully prepared. In a hot rolling process, a thin-layer surface is stressed by shearing force, so that fresh metals in the thin-layer surface are exposed in a short time and contacted and bonded with each other in the presence of pressure, thus effective welding is formed at an interface; in a vacuum annealing process, the element diffusion distance in the interface can be further increased, so that the metallurgy bonding strength can be improved, and the rolling stress can be released.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

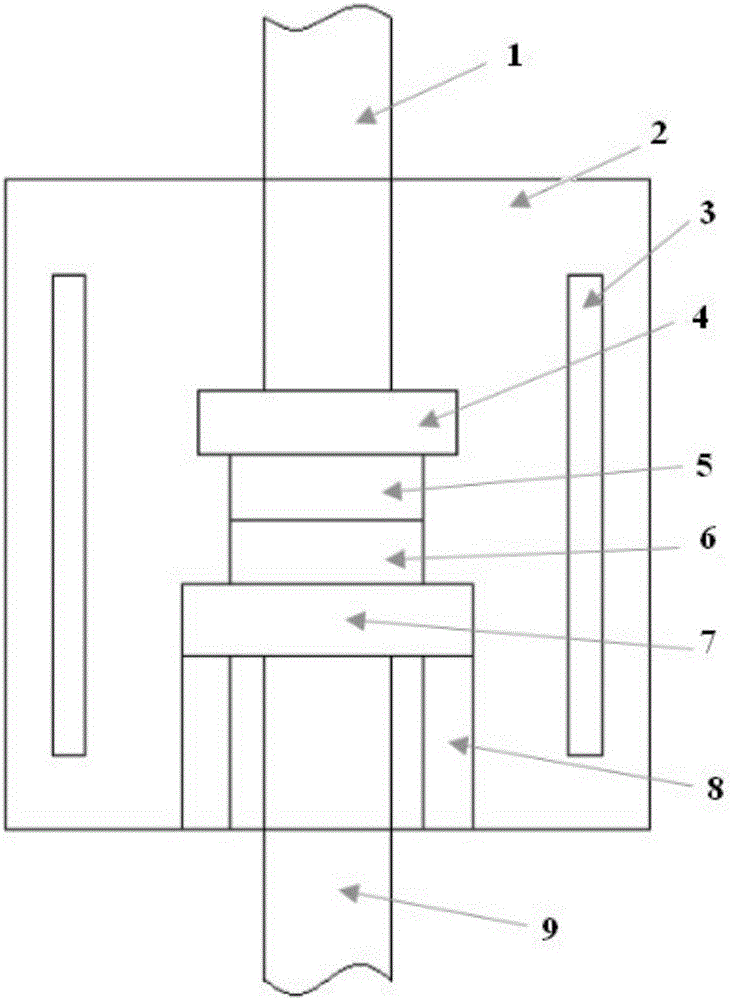

Ultrasonic field auxiliary vacuum diffusion connecting device and method

ActiveCN105689884AIncrease strain rateReduce flow stressNon-electric welding apparatusPhysicsSurface oxidation

The invention relates to an ultrasonic field auxiliary vacuum diffusion connecting device and method, aims at solving the problems that according to an existing vacuum diffusion connecting method, the requirement for a joint surface is strict, a surface oxidization film is hard to remove, the connecting time is long, and connecting temperature reduction and deformation resistance reduction cannot be combined, and belongs to the technical field of diffusion connection. The device comprises an upper pressing head, an upper pressing plate, an upper sample, a lower sample, a lower pressing plate, supporting devices, an ultrasonic tool head, a vacuum chamber and a heating body. The method comprises the steps that to-be-welded base metal is cleaned; the to-be-welded base metal is assembled and placed in the vacuum chamber, the pressure is exerted, and the temperature is increased to the connecting temperature; ultrasonic vibration is exerted; and the pressure is increased, and insulating is completed. The deformation resistance of the base metal is reduced, breaking of a surface oxidization film of the base metal is accelerated, the diffusion behavior is accelerated, the connecting temperature and the connecting pressure are reduced, the connecting time is shortened, and the requirement for the surface state of the to-be-welded base metal is lowered.

Owner:HARBIN PURUISI MATERIAL TECH CO LTD

Precision control device and method for laser indirect impact micro molding

The invention provides a precision control device and method for laser indirect impact micro molding, and relates to the technical field of laser machining of micro electro mechanical system parts. The precision control device comprises a laser loading system, an ultrasonic vibration system, a debugging optical light spot-mold cavity centering assembly, a workpiece assembly and a control system. By means of the precision control device, the impact force of a pulse laser is adopted as an energy source, meanwhile, ultrasonic vibration is applied to a mold and a workpiece, the molding limitationand the molding quality of the workpiece are improved, and the precision control device is suitable for materials which are difficult to mold or cannot be molded by using a conventional laser impact micro molding method. Meanwhile, the movement situation of a motor can be monitored and fed back through a coder, the movement situations of a front-back platform and a left-right platform can be monitored and fed back through a grating ruler displacement sensor, and accordingly the precision of a three-dimensional movable platform can be improved. The precision control device is suitable for achieving large-area mold molding and multi-working-station laser impact molding, so that the workpiece precisely duplicates the morphology of the mold, or batch molding of the workpiece is completed simultaneously, and thus the working efficiency is improved.

Owner:JIANGSU UNIV

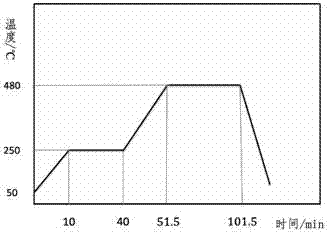

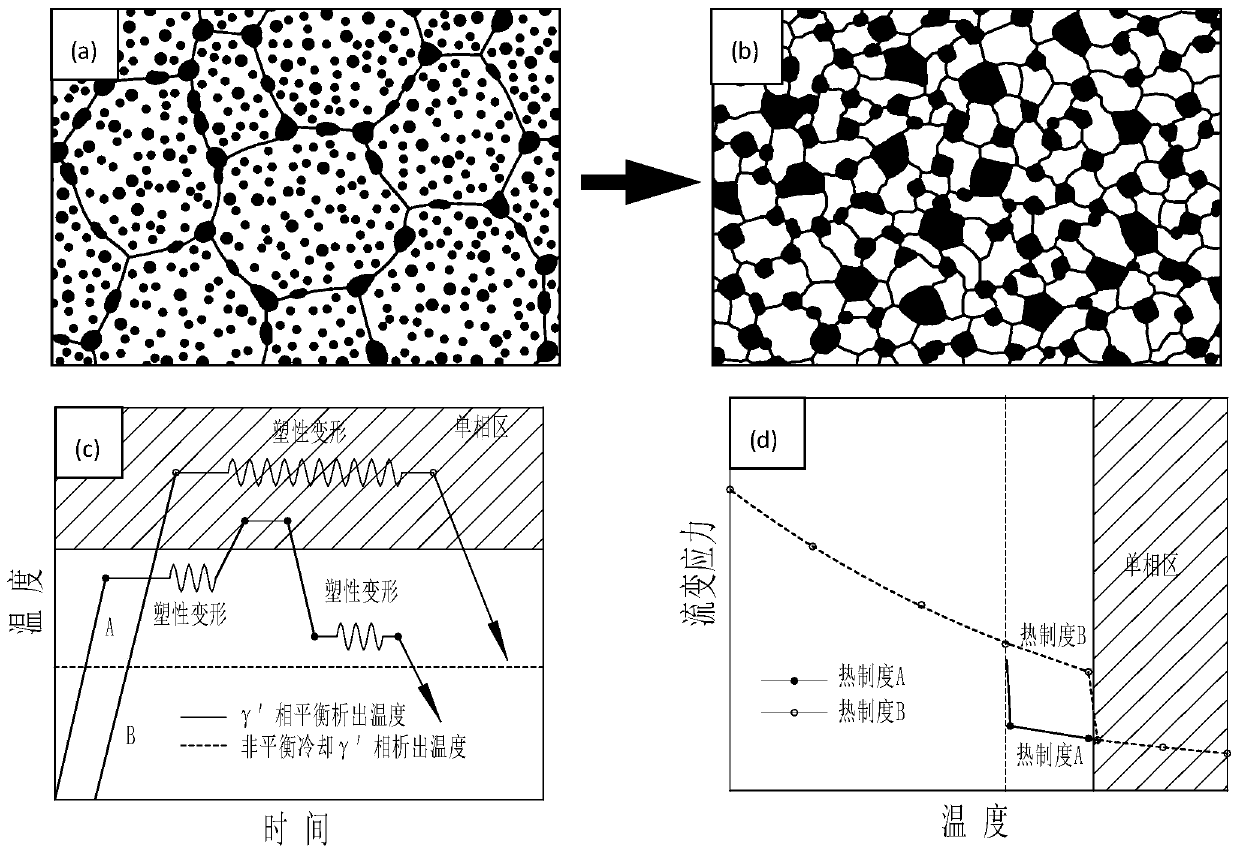

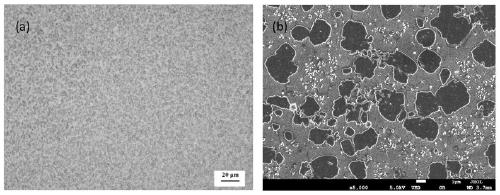

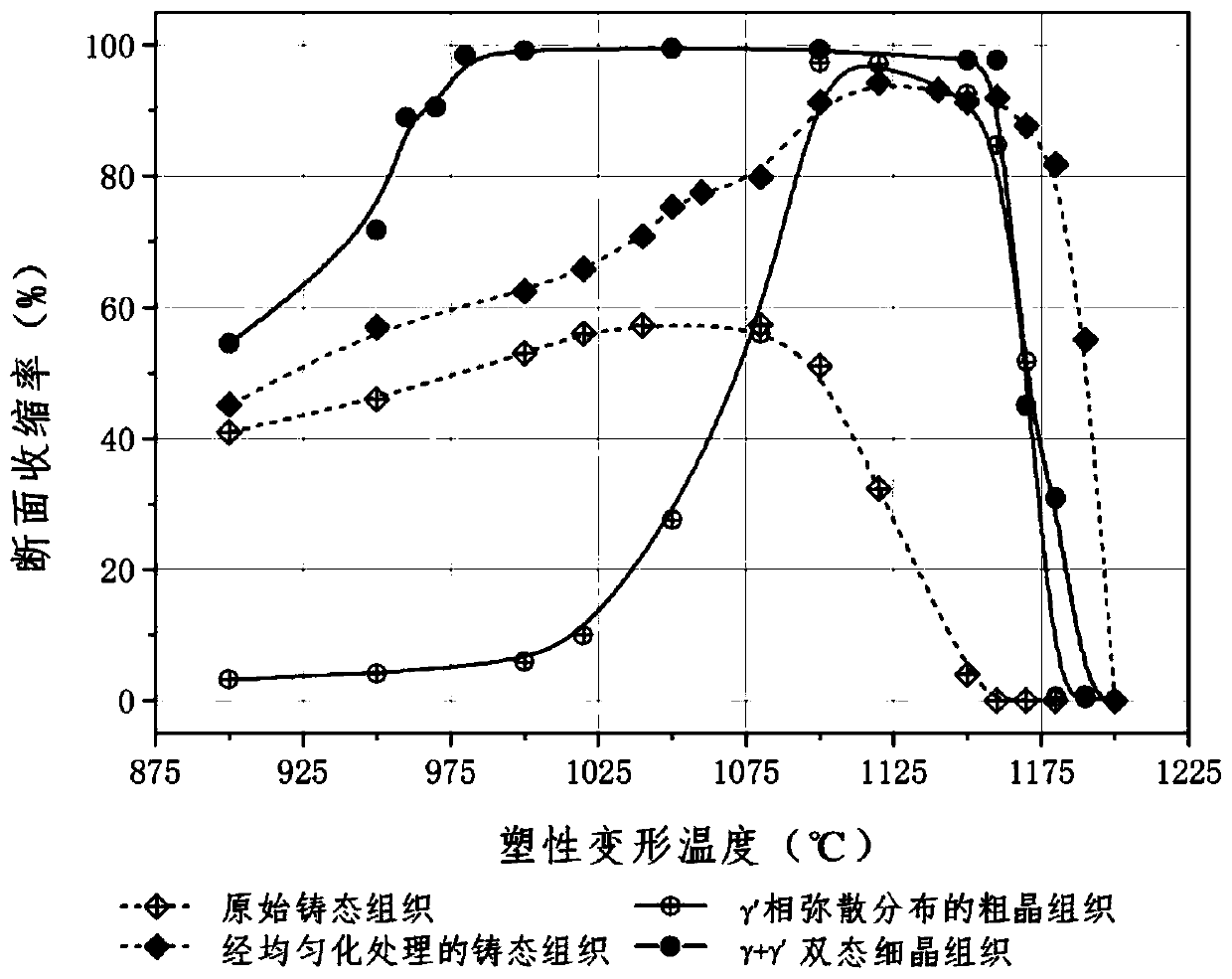

Method of improving hot workability of high-gamma' phase volume fraction nickel-based precipitation strengthening high temperature alloy

The invention relates to the field of material processing, in particular to a method of improving the hot workability of a high-gamma' phase volume fraction nickel-based precipitation strengthening high temperature alloy. The method comprises the following steps of: melting a high-gamma' phase volume fraction nickel-based precipitation strengthening high temperature alloy to obtain a remolten ingot; performing first heat treatment on the remolten ingot, and performing annealing treatment after performing first upsetting and drawing-down to obtain a first bar; carrying out second heat treatmenton the first bar, and obtaining a second bar after performing second upsetting and drawing-down; carrying out third heat treatment on the second bar, and obtaining a third bar after performing thirdupsetting and drawing-down; carrying out fourth heat treatment on the third bar, and obtaining a fourth bar after performing fourth upsetting and drawing-down; and carrying out fifth heat treatment onthe fourth bar, and obtaining a bar with the improved hot workability after performing fifth drawing-down. The method can effectively reduce the flow stress of the material during hot working, and improves the thermoplasticity of the material, thereby improving the hot workability of the material.

Owner:CENT IRON & STEEL RES INST +1

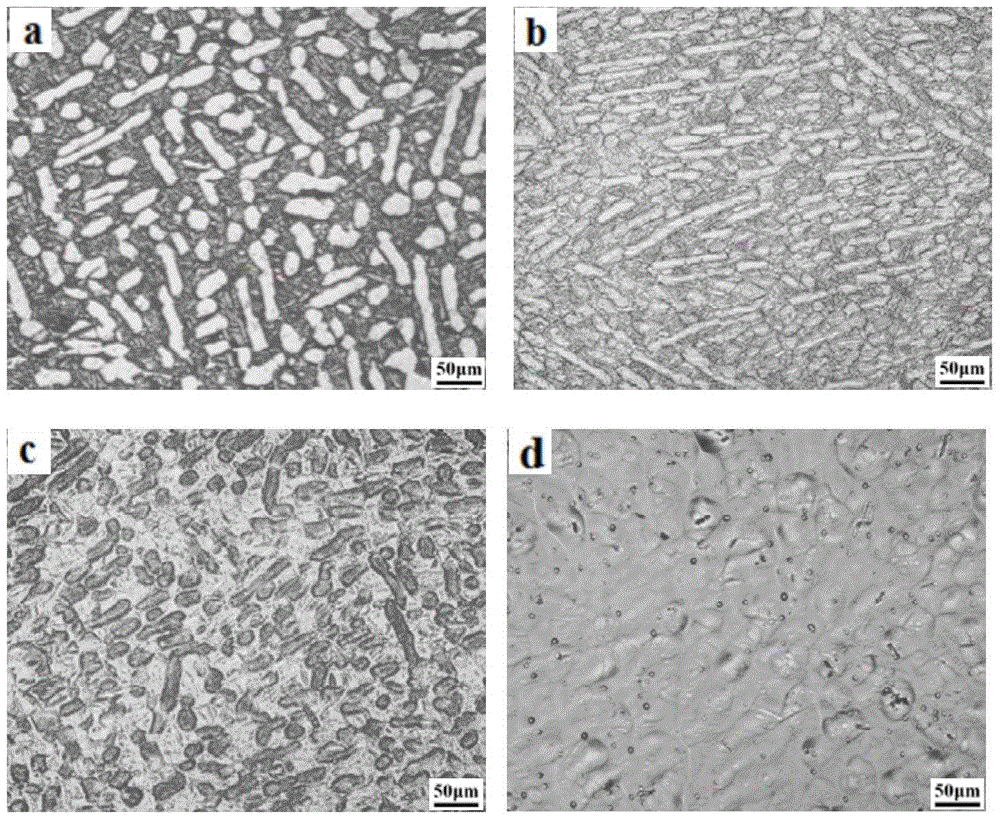

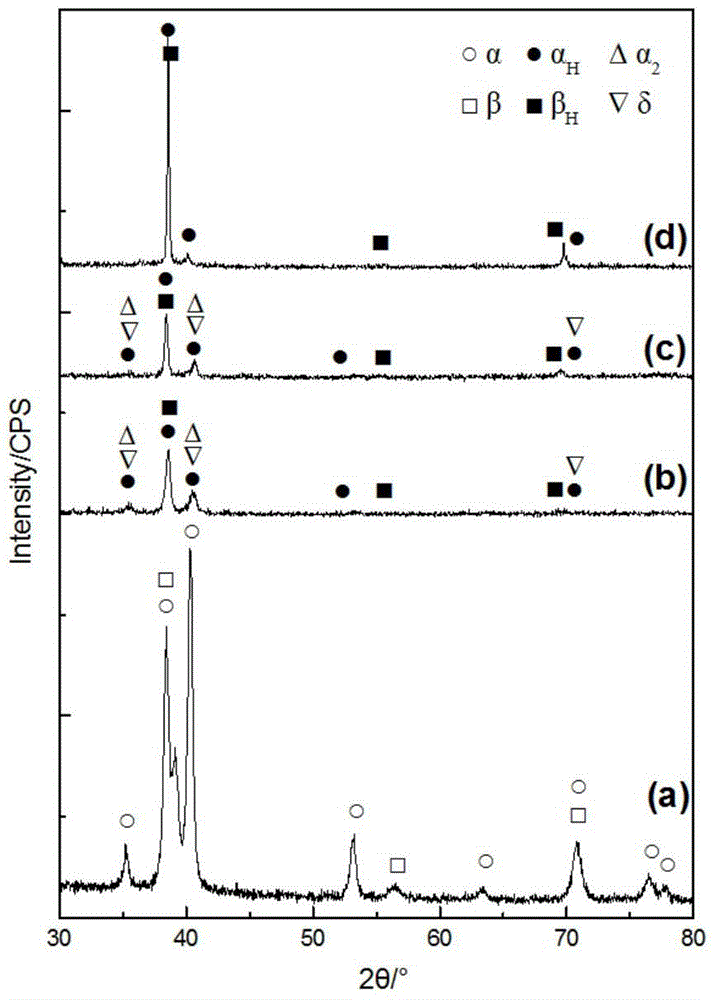

Thermo-hydrogen processing technology for improving room temperature plasticity of TC21 titanium alloy

The invention discloses a thermo-hydrogen processing technology for improving room temperature plasticity of TC21 titanium alloy. The thermo-hydrogen processing technology is characterized in that a TC21 sample is put into a furnace tube of a tubular furnace, the surface of the TC21 sample is covered by a layer of titanium scraps to prevent the TC21 sample from being oxidized, vacuum pumping is conducted, when the vacuum degree in the furnace tube is lower than 1*10-3 Pa, the furnace tube is heated, the temperature is increased to 750 DEG C, nitrogen is led into the furnace tube, the nitrogen pressure in the furnace tube is stabilized to 15-25 kPa, the temperature is preserved for 1-2 hours, the furnace tube is pulled out from the furnace and naturally cooled to the room temperature, and the TC21 sample in the furnace tube is taken out.

Owner:HEFEI UNIV OF TECH

Female die, die and device for plate blank differential temperature drawing molding and drawing method

InactiveCN106180419AReduce radial tensile stressIncrease limit deformationShaping toolsMetal working apparatusCold airMetal machining

The invention relates to the technical field of metal machining, and discloses a female die, die and device for plate blank differential temperature drawing molding and a drawing method. The female die is provided with an air inlet passage used for leading cold air into a groove of the female die, and an exhaust passage used for exhausting the cold air out of the groove; and the die comprises a male die, an edge pressing device and the female die which are sequentially arranged in the vertical direction. The device comprises a pressing machine and the die. The drawing method includes the steps that firstly, a plate blank is tightly pressed between the edge pressing device and the female die; and secondly, the plate blank is drawn in the groove of the female die. By means of the technical scheme, the ultimate deformation degree of the plate blank can be improved, and the drawing performance of the plate blank is further improved.

Owner:北京普惠三航科技有限公司

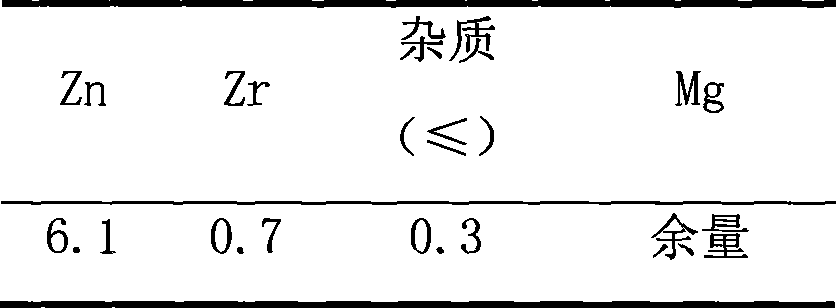

Heat working technological process for high strength deformed magnesium alloy

The invention relates to hot working process of a high-strength deformation magnesium alloy. The method comprises selecting appropriate thermal treatment temperature and time, controlling processes of dissolving of compound phases, exsolution, precipitation and the like, on the basis of stability of different compound phases and different characteristics of thermodynamics and kinetics in magnesium alloys, therefore effectively controlling the histological structure of the alloy for making that the magnesium alloy both have excellent plastic property and obtain high strength. According to the invention, a hot working system is formulated according to the character of magnesium alloy compounds and the system having a wide applicability is prone to realize industrialization scale production, is suitable for magnesium-zincium base aging strengthening type magnesium alloy and is especially suitable for ZK system high-strength deformation magnesium alloy with the zincium bigger than or equal to 6.0.

Owner:CHONGQING UNIV

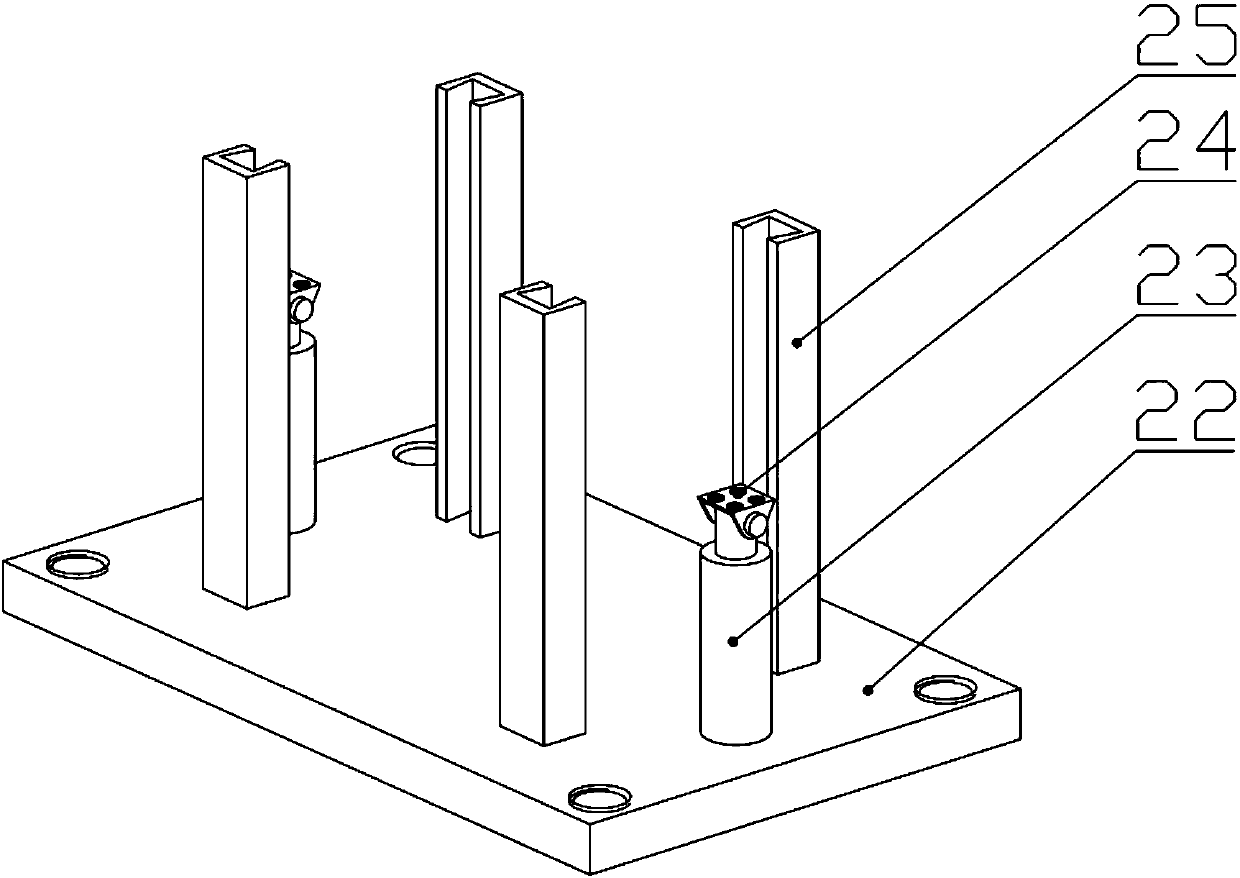

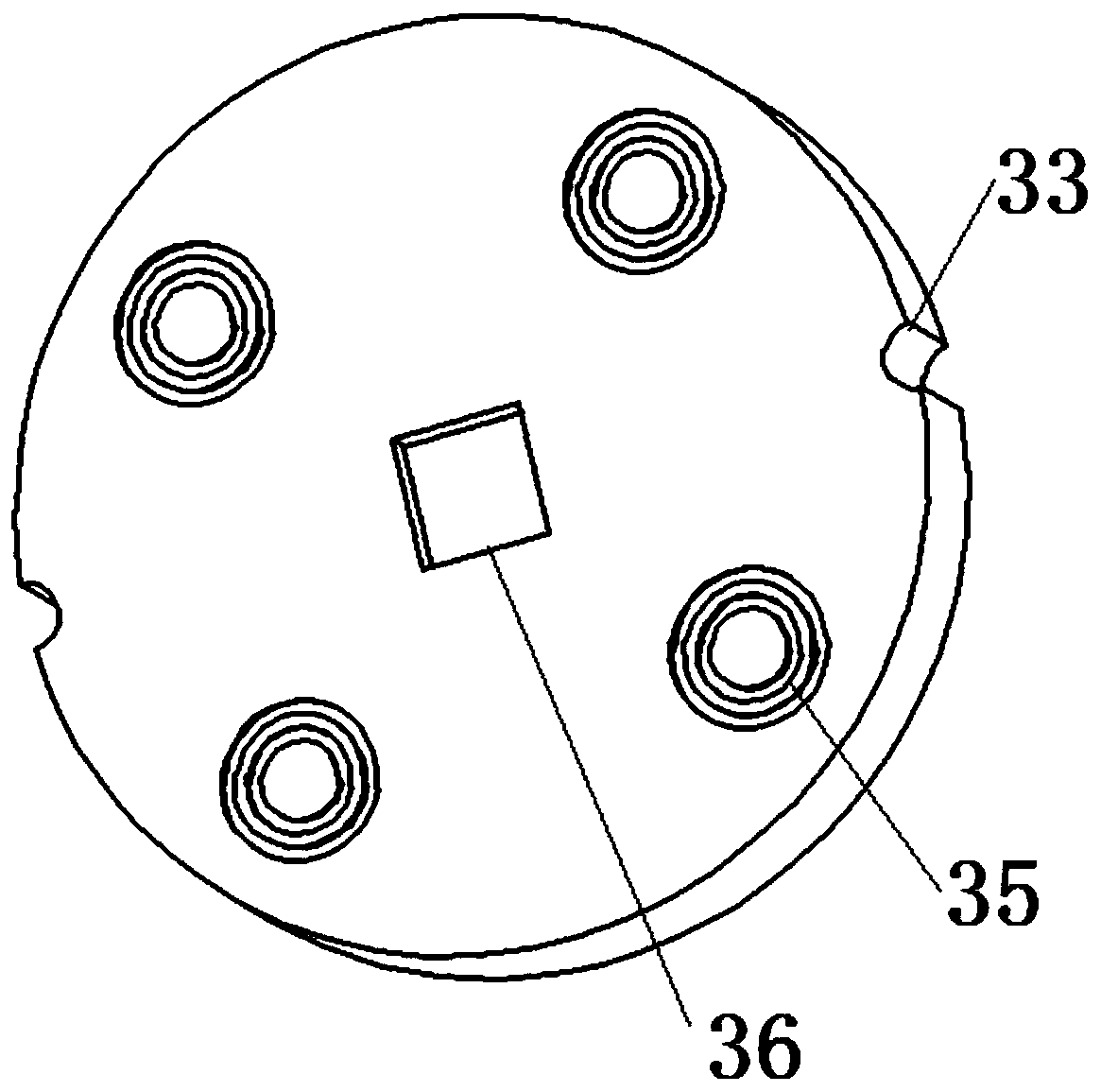

Quick-change-type pulse current processing and laser shock foil composite microforming device capable of automatically centering and adjusting spot diameter and method of quick-change-type pulse current processing and laser shock foil composite microforming device

ActiveCN110614307AAchieve preparationQuality improvementLaser beam welding apparatusControl systemOptoelectronics

The invention discloses a quick-change-type pulse current processing and laser shock foil composite microforming device capable of automatically centering and adjusting spot diameter and a method of the quick-change-type pulse current processing and laser shock foil composite microforming device, and relates to the technical field of advanced manufacturing micro-parts. The quick-change-type pulsecurrent processing and laser shock foil composite microforming device includes a laser emitting system, a space position adjustment system, a control system and a micro-part forming system. The methodcomprises the steps that first, a feature pattern set on a concave die is scanned by a three-dimensional camera, and the position of the feature pattern is compared with the position of a preset theoretical pattern to adjust the horizontal position of a three-dimensional mobile platform; then ultrasonic waves are emitted to an ultrasonic reflection platform and the total time of the whole processis calculated, the distance between the three-dimensional mobile platform and an adjustable-focus lens is calculated, then quick pressing of the device is realized by a magnetic suction device, and apulse current is applied to the two ends of foil; and finally, through pulse laser shock, impact force is generated by using explosion of plasma, and forming of the foil is realized, The accuracy ofa laser action point can be significantly improved, and the forming quality of the metal micro-parts is improved.

Owner:JIANGSU UNIV

Methods for Manufacture and Use of Composite Preform Having a Controlled Fraction of Porosity in at Least One Layer

InactiveUS20120085811A1Reduce flow stressProcess failureSoldering apparatusThin material handlingPorosityFlow stress

The invention provides clad billet for hot working plastic deformation processes for the production of clad products, including, but not limited to, clad pipe and tubing by extrusion of a hollow, bicomponent composite billet having a fully dense structural component and a partially dense component of a specialty alloy at a fraction of porosity predetermined to provide a flow stress compatible with that of the structural component. The components are diffusion bonded to the predetermined fraction of porosity in the specialty component by application of heat and pressure over time, including by hot isostatically pressing the billet components. Computer modeling techniques can be used to determine processing conditions for obtaining flow stress compatibility.

Owner:BODYCOTE IMT INC

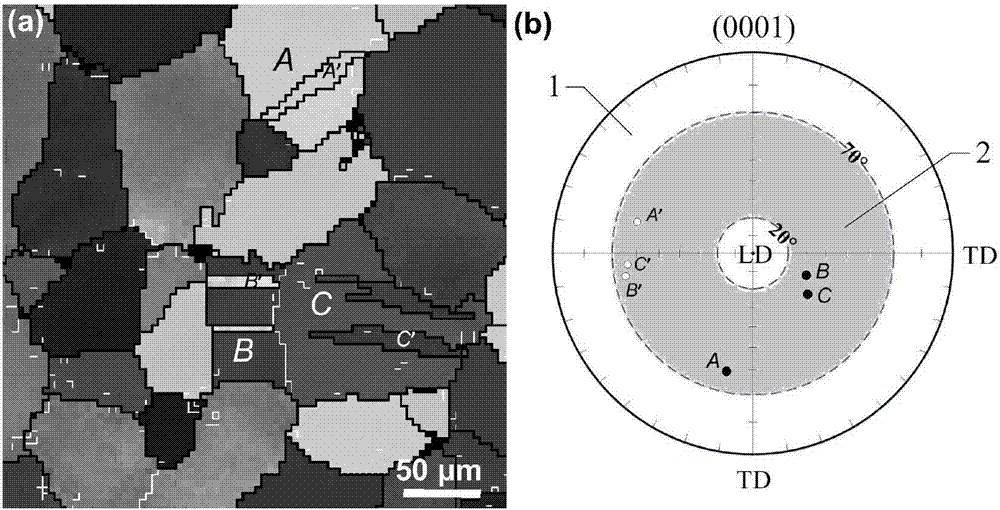

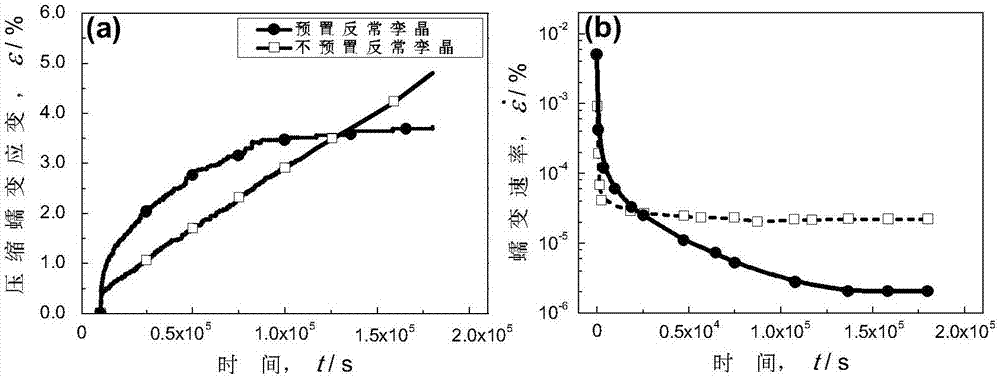

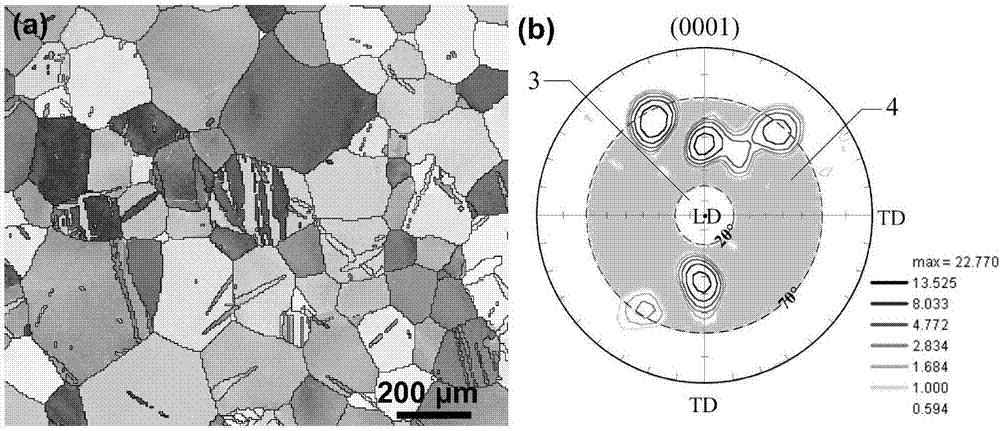

Method for improving high-temperature creep resistance of rare-earth-containing magnesium alloy by virtue of anomalous twin crystals

InactiveCN106978579AImprove high temperature creep resistanceWide range of applicable materialsCrystal twinningRare earth

The invention discloses a method for improving the high-temperature creep resistance of rare-earth-containing magnesium alloy by virtue of anomalous twin crystals. According to the method, the rare-earth containing magnesium alloy is subjected to predeformation treatment in the direction forming a 15-75-degree angle with the normal direction of a base plane at 25-300 DEG C, the true strain amount is 0.001-0.1, {10-12} anomalous twin crystals are prearranged in the rare-earth-containing magnesium alloy through deformation, the rare-earth-containing magnesium alloy with the prearranged anomalous twin crystals and rare-earth-containing magnesium alloy without prearranged anomalous twin crystals are subjected to stretching or compression creep property testing correspondingly within the temperature range from 200 to 350 DEG C, compared with the rare-earth-containing magnesium alloy without anomalous twin crystals, the rare-earth-containing magnesium alloy with the anomalous twin crystals has the advantages that the creep stain is obviously reduced, the steady-state creep rate is obviously lowered, and the creep resistance of is remarkably improved under the equal service conditions. The process which is reasonable in design, low in equipment requirement, convenient to operate, low in cost, high in efficiency and capable of stably improving the high-temperature creep resistance of the rare-earth-containing magnesium alloy is provided.

Owner:CENT SOUTH UNIV

Method for controlling grain size of high-temperature alloy forge piece through heat treatment

InactiveCN110527796AImprove hot workabilityAvoid formingFurnace typesHeat treatment furnacesSolution treatmentIngot

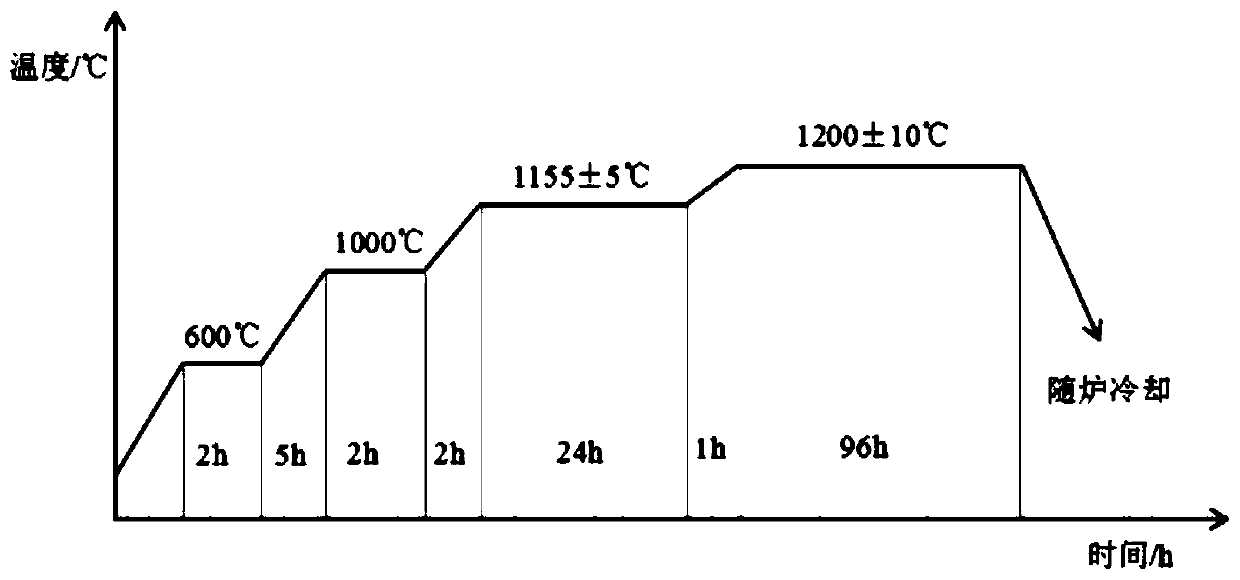

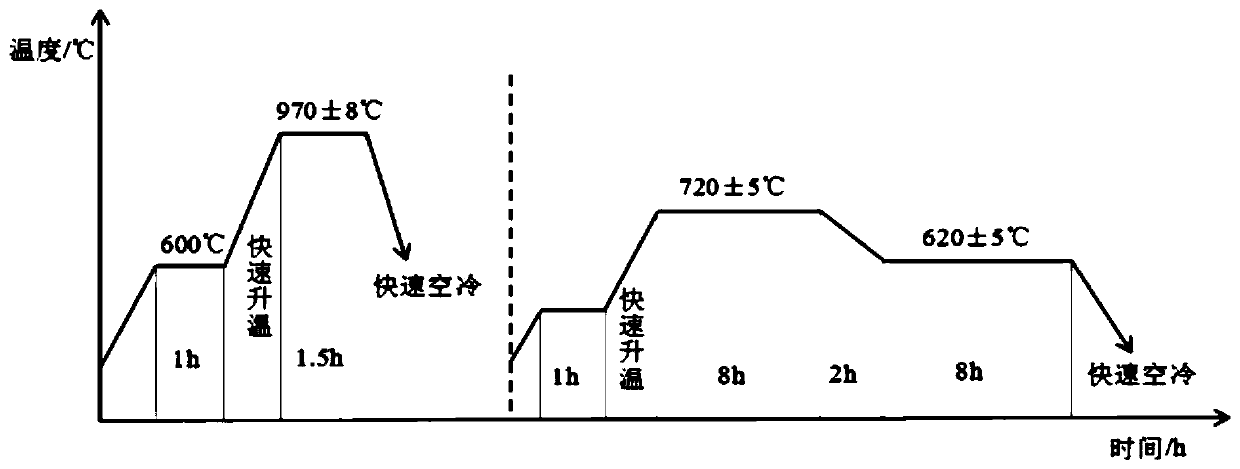

The invention discloses a method for controlling the grain size of a high-temperature alloy forge piece through heat treatment, which comprises the following steps of 1) carrying out two stages of sub-temperature homogenizing annealing and slow cooling, heating a forge piece to 600 DEG C, and keeping the temperature for 2 hours; raising the temperature to 1000 DEG C within 5 hours, and keeping thetemperature for 2 hours; raising the temperature to 1155 + / -5 DEG C within 2 hours, and keeping the temperature for 24 hours; raising the temperature to 1200 + / -10 DEG C within 1 hour, and keeping the temperature for 96 hours; cooling the high-temperature alloy forge piece along with a furnace; 2) carrying out the solid solution and grading failure treatment after forging, heating to 600 DEG C, and keeping the temperature for 1 hour; raising the temperature to 970 + / -8 DEG C within 0.5 hour, and keeping the temperature for 1.5 hours; air cooling; heating to 600 DEG C, and keeping the temperature for 1 hour; raising the temperature to 720 + / -5 DEG C within 0.5 hour, and keeping the temperature for 8 hours; cooling to 620 + / -5 DEG C within 2 hours, and keeping the temperature for 8 hours; air cooling. By adopting the two stages of long-time sub-temperature homogenizing annealing treatment, the brittle laves phases and delta phases in the steel ingot are eliminated, and the formation ofa low-melting-point eutectic phase is avoided; a trace delta phase is separated out during the solid solution treatment process, and the high-temperature lasting notch sensitivity is eliminated; and by carrying out the aging treatment twice, the gamma ''-phase and gamma '-phase particles are dispersed and separated out.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

A labor-saving automobile hub forming method and device thereof

InactiveCN100475429CReduction toolReduce equipmentShaping toolsExtrusion diesEngineeringMechanical engineering

Owner:ZHONGBEI UNIV

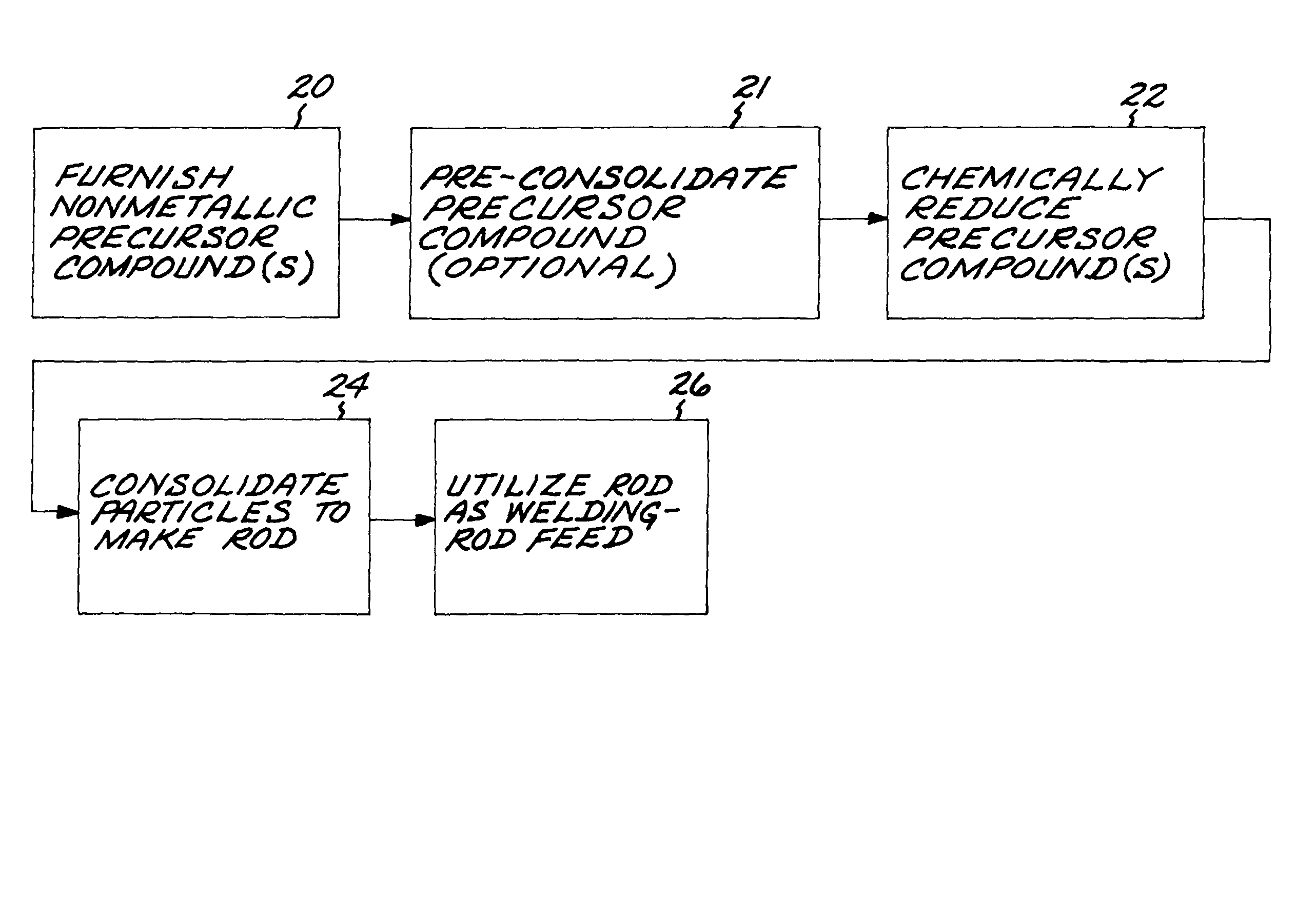

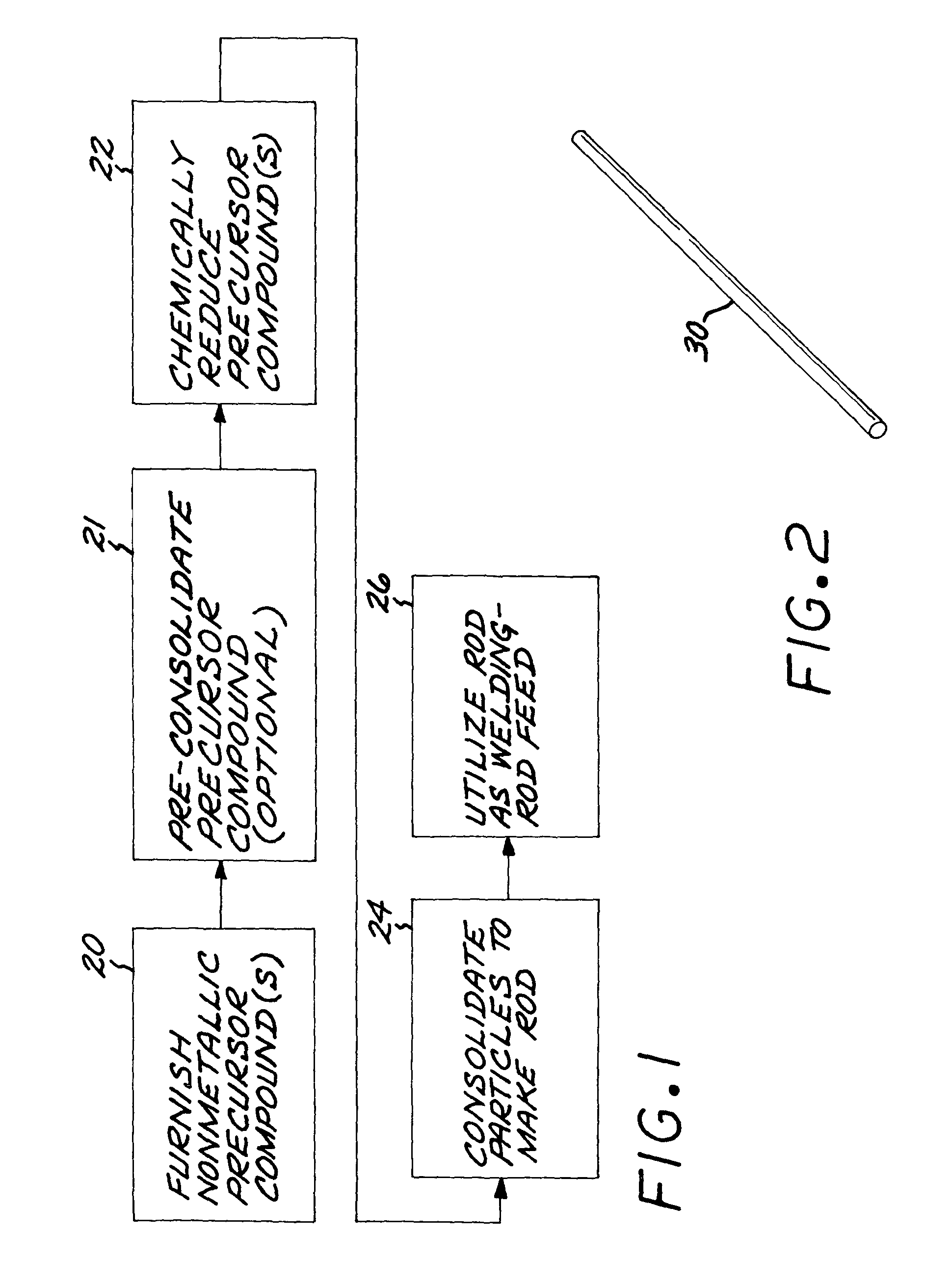

Method for meltless manufacturing of rod, and its use as a welding rod

InactiveUS7727462B2Improve manufacturabilityReduce flow stressWelding/cutting media/materialsSoldering mediaChemical compoundMetallic materials

An article made of a metallic material having its constituent elements is made by furnishing at least one nonmetallic precursor compound, wherein all of the nonmetallic precursor compounds collectively include the constituent elements of the metallic material in their respective constituent-element proportions. The precursor compounds are chemically reduced to produce particles comprising the metallic material, without melting the precursor compounds and without melting the metallic material. The particles may be consolidated into a rod, which may be used as a welding rod in a welding operation. Alternatively, the nonmetallic precursor compounds may be consolidated prior to the chemical reduction.

Owner:GENERAL ELECTRIC CO

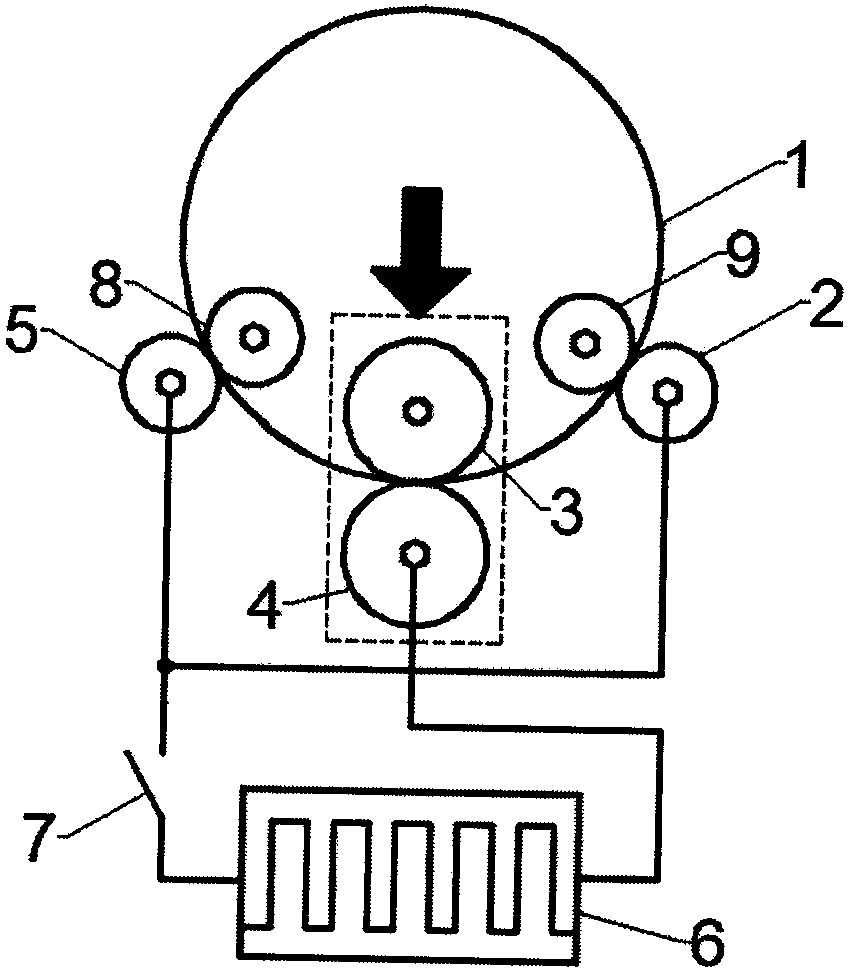

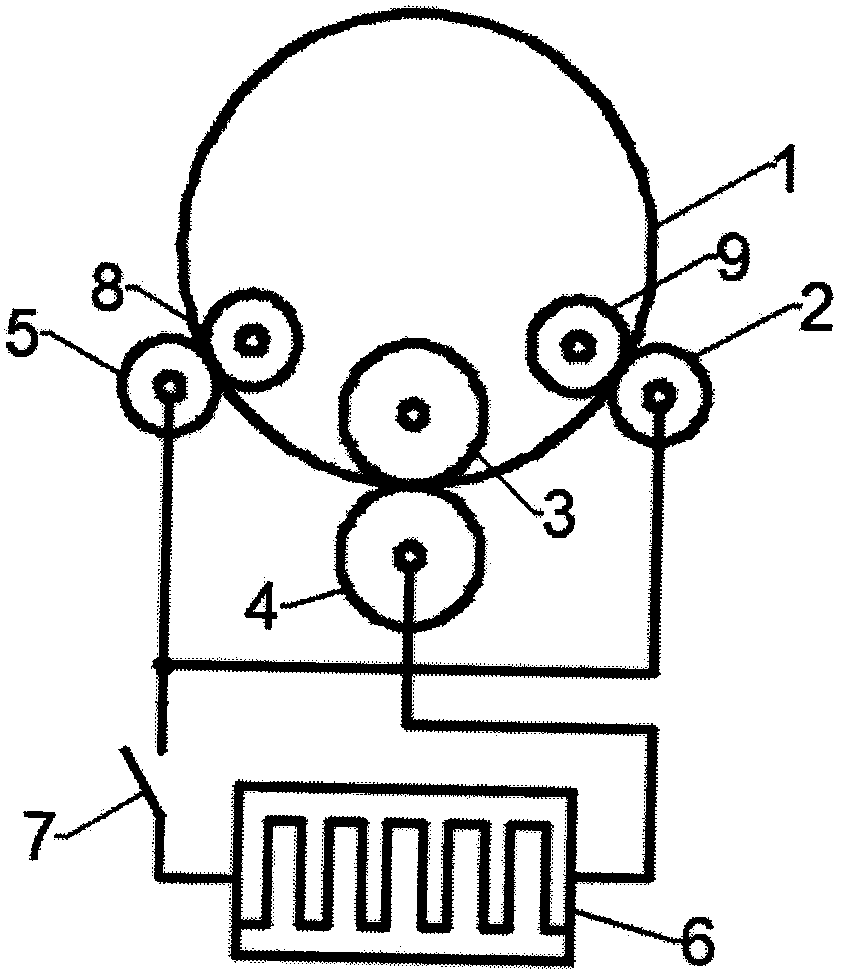

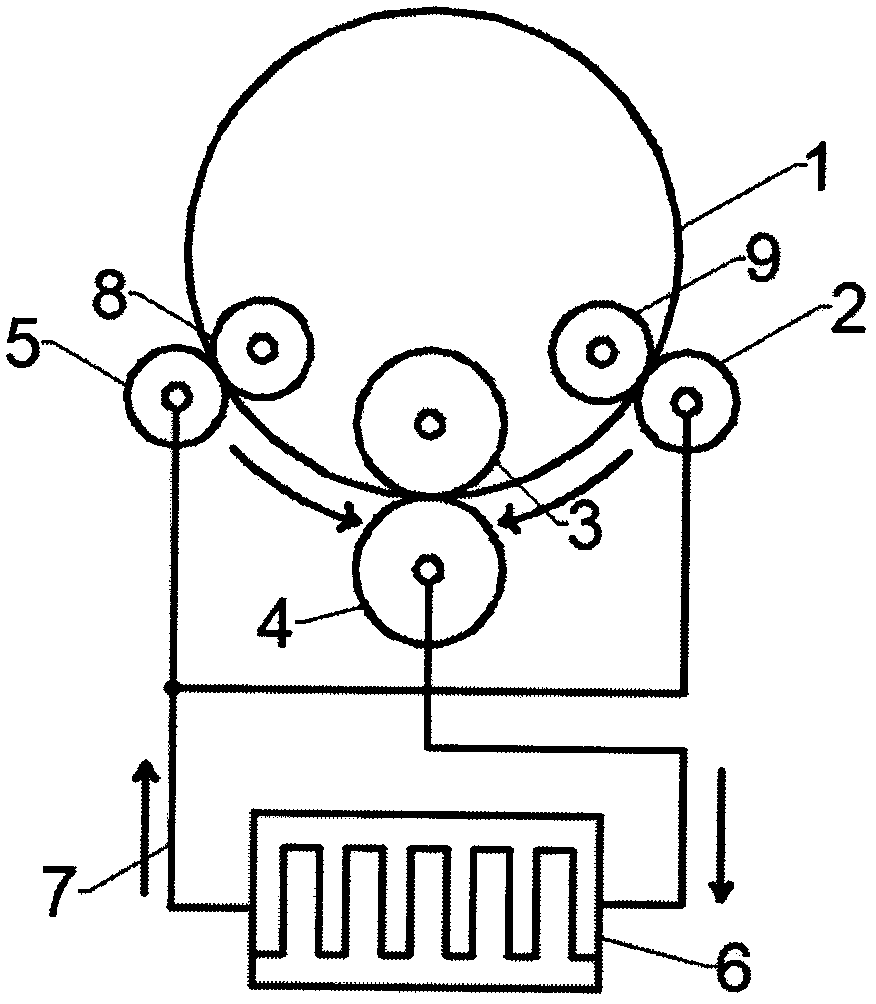

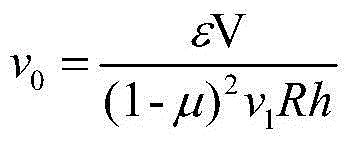

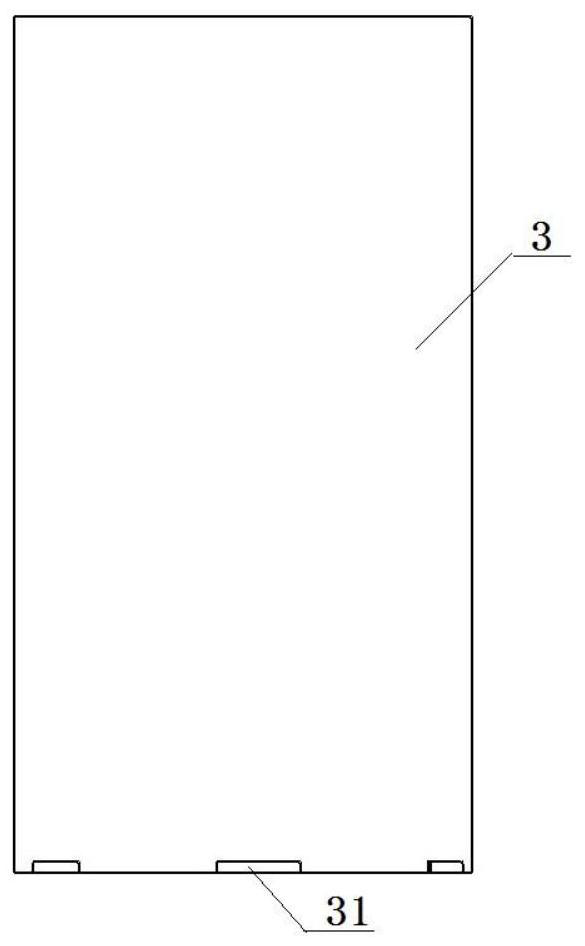

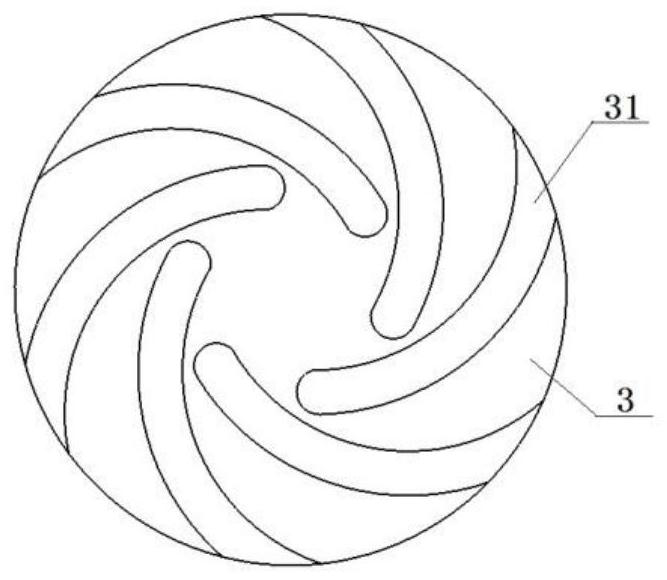

Current-assisted roll forming method of difficult-to-deform material special-shaped section pipe fittings

ActiveCN109482690AImprove plastic deformation abilityReduce flow stressMetal-working feeding devicesPositioning devicesAutomatic controlComposite structure

The invention discloses a current-assisted roll forming method of difficult-to-deform material special-shaped section pipe fittings, belongs to the technical field of difficult-to-deform metal material pipe part forming, and particularly relates to a forming method of the difficult-to-deform material special-shaped section pipe fittings, such as titanium alloy, Ti2AlNb-based intermetallic compounds, and high-strength aluminum alloy. The current-assisted roll forming method of the difficult-to-deform material special-shaped section pipe fittings aims to solve the problems of difficult forming,complex and expensive equipment, low efficiency and great energy consumption of existing pipe difficult-to-deform material special-shaped section pipe fittings. The method comprises the steps of introducing current with a certain frequency into difficult-to-deform metal, improving the plastic deformation performance of the materials, reducing flow stress, and facilitating plastic processing. A forming device required by the forming method is of a composite structure similar to four-axis roll bending and bending, V-shaped angular sections with different angles are obtained by changing the displacement of top and bottom roller shafts in the vertical direction, and the pipe fitting with a certain sectional shape is obtained by continuous processing at different angles. The current-assisted roll forming method of the difficult-to-deform material special-shaped section pipe fittings has the advantages of easy automatic control, high efficiency, low cost, high forming quality, and capabilityof processing pipe fittings with different sectional shapes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

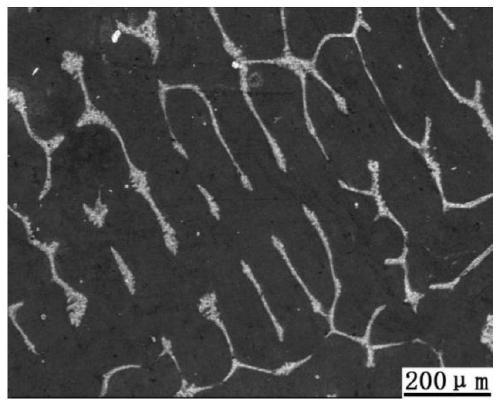

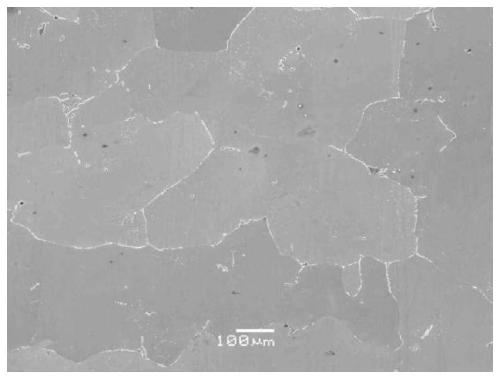

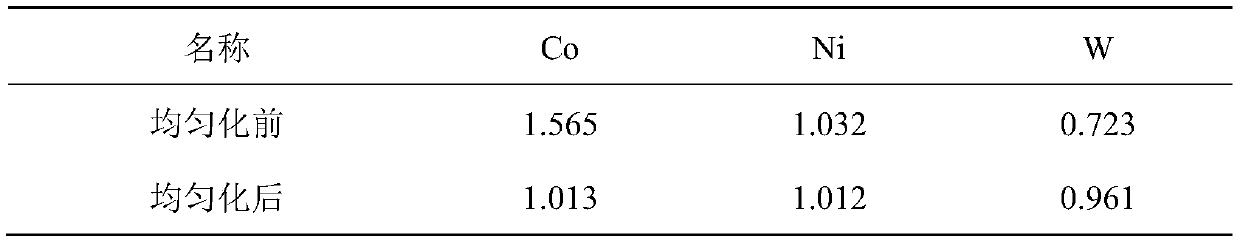

Homogenization process of high-tungsten high-cobalt nickel alloy ingot

PendingCN110423960AEliminate segregationImprove hot and cold processing plasticityRoom temperatureCobalt nickel alloy

The invention provides a homogenization treatment process of a high-tungsten high-cobalt nickel alloy ingot, and belongs to the technical field of metal materials. The basic composition of the alloy comprises the following components of, in percentage by mass, 25-45 wt.% of tungsten, 15-25 wt.% of cobalt and the balance nickel and inevitable impurities. The method comprises the following steps ofcarrying out homogenization treatment on the high-tungsten high-cobalt nickel alloy, putting the high-tungsten high-cobalt nickel alloy ingot into a heat treatment furnace, wherein the furnace loadingtemperature is less than or equal to 600 DEG C; heating to 1150-1250 DEG C, and controlling the heating speed to be 10-80 DEG C / h; keeping the temperature at 1150-1250 DEG C for more than or equal to24 hours; and cooling the heat-treated ingot to 700 DEG C or below along with the furnace, and then air-cooling to the room temperature. According to the high-tungsten high-cobalt nickel alloy cast ingot treated by the process, component segregation is eliminated, the structure is uniform, the hot working plasticity can be improved, and the sound velocity can reach 5529m / s.

Owner:UNIV OF SCI & TECH BEIJING

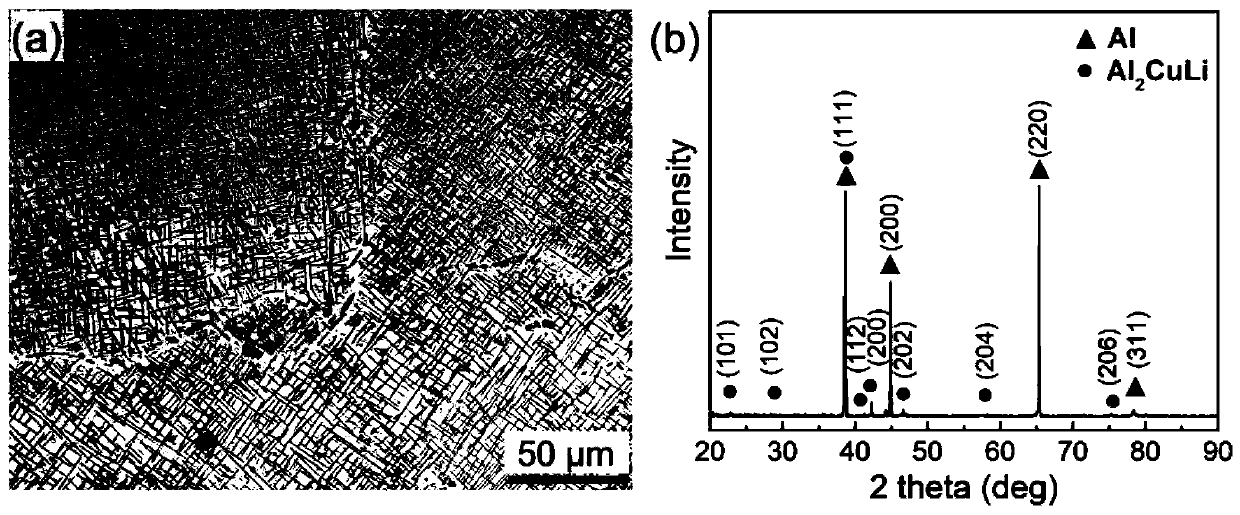

Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation

ActiveCN110541131AImprove the degree of recrystallizationFine grainMicron scaleManufacturing technology

The invention discloses an Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation, and belongs to the technical field of aerospace component manufacturing. Accordingto the process, an Al-Cu-Li alloy can be remarkably promoted to be subject to thermal deformation and recrystallization to obtain an isometric fine crystal structure. The process comprises the following steps of carrying out homogenizing annealing on an alloy ingot to obtain a uniformly-distributed micron-scale T1 phase (Al2CuLi), then performing hot-pressing deformation, and annealing at a hightemperature. According to the process, the high-stability recrystallization structure in the Al-Cu-Li alloy can be obtained controllably, the recrystallization degree is high, the fine crystal effectis obvious, the structure is stable, the alloy texture can be remarkably weakened, the alloy anisotropy is reduced, and therefore the multi-directional bearing performance and the corrosion resistanceof the alloy are improved, the comprehensive service performance of the Al-Cu-Li alloy can be greatly improved, the application range of the Al-Cu-Li alloy in aerospace components can be extended, and the competitiveness of products such as materials / components can be improved

Owner:HARBIN INST OF TECH

Heat load and force load continuous and alternate impact strengthening device and working method thereof

PendingCN113564342AReduce flow stressImprove plasticityHeat treatment process controlControl systemMetallic materials

The invention discloses a heat load and force load continuous and alternate impact strengthening device. The device comprises a sealed objective table, a laser force loading device, a photoelectric control system and a material, the laser force loading device comprises a laser generator and a light path control system, the output end of the laser generator is connected with the sealed objective table, the input end is connected with the output end of the light path control system, the input end of the light path control system is connected with the output end of the photoelectric control system, the input end of the photoelectric control system is connected with the photoelectric control system, and the input end of the photoelectric control system is connected with the end, away from the laser force loading device, of the sealed objective table. The material is arranged in the sealed objective table. The metal material is treated by adopting a method of continuously and alternately acting high-energy pulse heat load and laser impact force load, thermal stress and electronic wind power are introduced into the material by utilizing a high-energy pulse current transient thermal effect, the flow stress of the material is reduced, and the plasticity of the material is improved.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

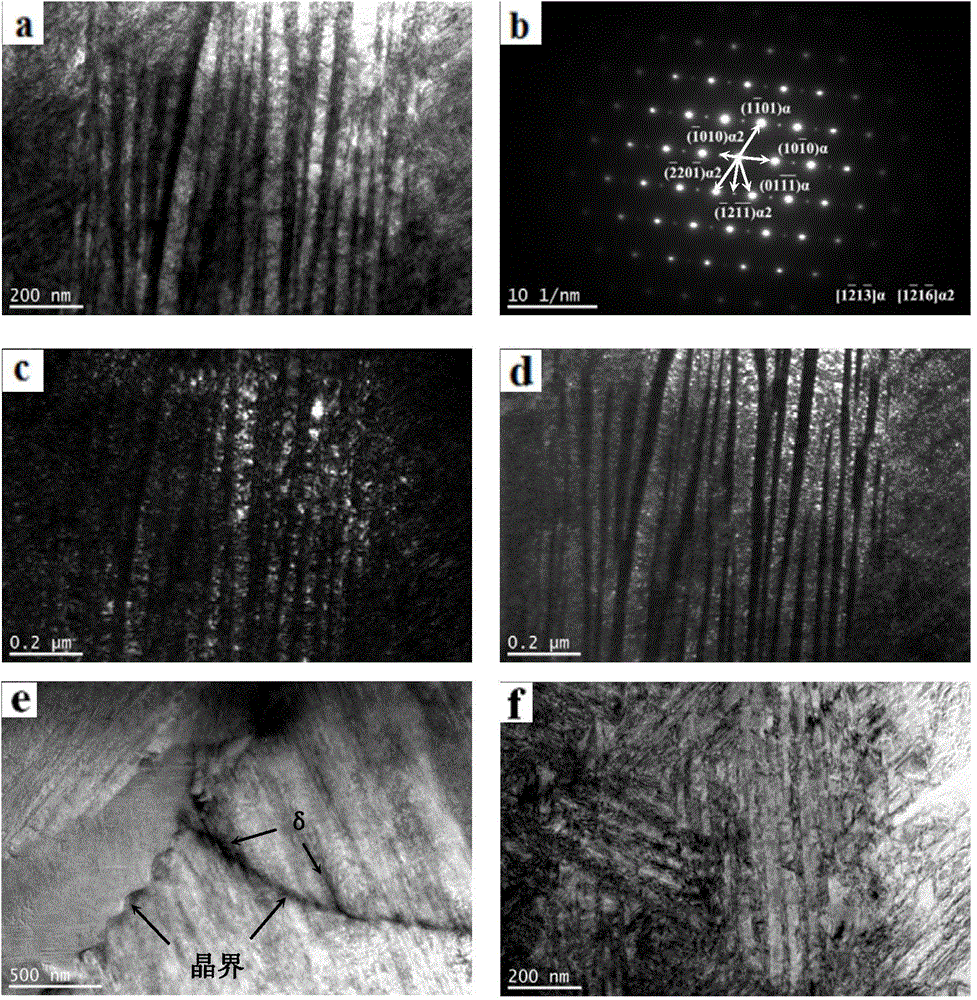

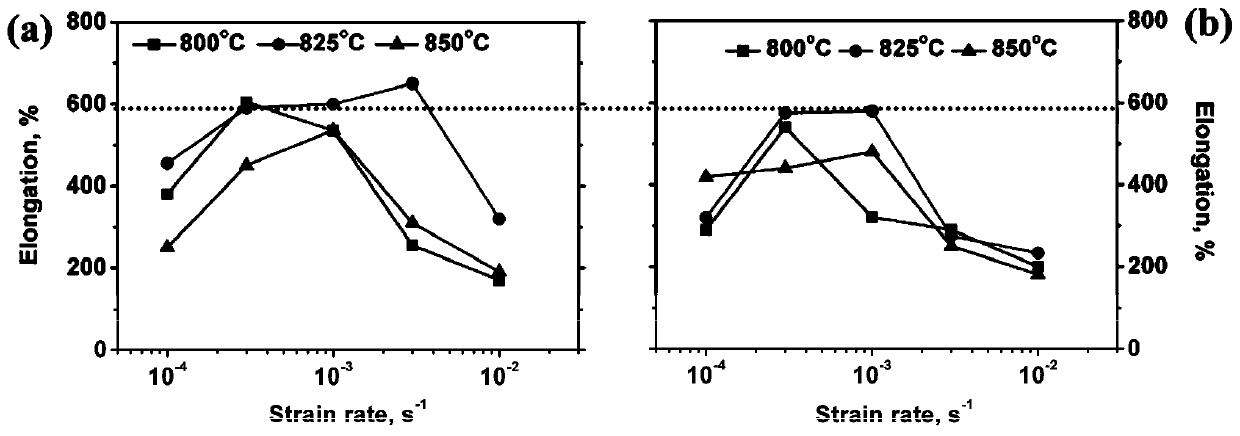

Processing method for realizing super high plasticity performance of titanium alloy welded joint

ActiveCN109702317AReduce flow stressHigh superplastic properties with low flow stressOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingHydrogen atmosphere

The invention discloses a processing method for realizing super high plasticity performance of a titanium alloy welded joint, and belongs to the technical field of titanium alloy welding. The processing method includes the steps that firstly, hydrogenation treatment is conducted on a titanium board to be welded in a pure hydrogen atmosphere; then stirring friction welding is conducted on the titanium board subjected to the hydrogenation treatment to make a welding nugget to be of a tiny laminated structure; and super plasticity tensile deformation is conducted on a joint welding nugget after stirring friction welding, a part of a base metal and the entire welded joint, so that entire super plasticity processing of a titanium alloy workpiece is realized. Through the processing method for realizing the super high plasticity performance of the titanium alloy welded joint, the super plasticity of the titanium alloy welded joint can be obviously improved, the super plasticity temperature and flow stress are lowered, the difficulty of super plasticity forming and the welding cost are lowered greatly, the mechanical performance of a super plasticity forming component is improved, and thesuper plasticity forming of the whole joint is realized; and the processing method for realizing the super high plasticity performance of the titanium alloy welded joint particularly adapts to the super plasticity forming and high temperature forming of the titanium alloy welded joint, and can be applied to manufacture large-scale titanium alloy entire components, partial forming components and the like in space flight and aviation field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Superplastic forming method of complex section ring part of TC11 titanium alloy

The invention discloses a superplastic forming method of a complex section ring part of a TC11 titanium alloy. The superplastic forming method comprises the following steps: the TC11 titanium alloy is heated to 1030-1050 DEG C for undergoing one-way elongation with the total deformation being 20%-40%, and then is air-cooled; the TC11 titanium alloy is heated again to 950-980 DEG C for undergoing repeated upsetting and elongation with the total deformation being 40-65%, and then is air-cooled; the TC11 titanium alloy is kept at the temperature of 950 DEG C for 1.5 hours and then is air-cooled; the TC11 titanium alloy is kept at the temperature of 530 DEG C for 6 hours and then is air-cooled; a fine-grain TC11 titanium alloy blank is thus obtained, and then is heated to the forging temperature, and is upset, punched and leveled to obtain an alloy ring blank; and the rolling formation is performed at the temperature of 880-900 DEG C at the maximal feeding speed of 2.0 mm / s to obtain the complex section ring part of the TC11 titanium alloy. The method can enable the TC11 titanium alloy to be in a superplastic state in the forming process so as to obtain the complex section ring part of the TC11 titanium alloy; and the properties and the size of the complex section ring part both satisfy the requirements. The ring part, mainly serving as a connecting ring and a bearing ring, is widely applied to mechanical equipment of such industrial fields as the aviation field and the aerospace field.

Owner:GUIZHOU ANDA AVIATION FORGING

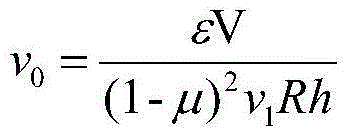

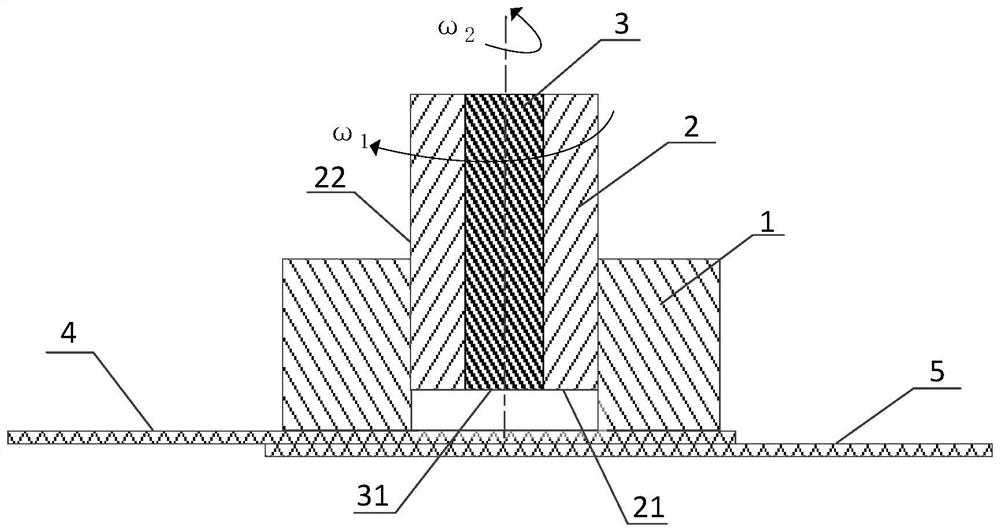

Reverse backfill type friction stir spot welding method

PendingCN114192969AReduce interface distortionReduce macro deformationNon-electric welding apparatusEngineeringHeat engine

The invention discloses a reverse backfill type friction stir spot welding method, and belongs to the technical field of welding. A reverse backfill type friction stir spot welding tool is adopted, the end faces of a stirring needle, a sleeve and a pressing ring are located on the same horizontal plane and integrally pressed down to the upper surface of a welded plate, a welded workpiece is pressed, the stirring needle and the sleeve are rotated, the rotating speed of the sleeve is omega1, the rotating speed of the stirring needle is omega2, reverse rotation is conducted, omega1 is smaller than omega2, and the surface of the welded workpiece is preheated. The sleeve rotates to downwards pierce into the welded plate on the upper side, meanwhile, the stirring needle reversely rotates to upwards draw back until the sleeve rotates to pierce into the surface of the welded plate on the lower side, and metal is squeezed into a cavity of the sleeve; the sleeve and the stirring needle change directions simultaneously, and plastic metal in a cavity of the sleeve is backfilled to the upper surface of the welded plate on the upper side; and the two return to the upper surface of the welded plate on the upper side and stop rotating, welding is completed, and a weldment is obtained. According to the method, heat input in the welding process is greatly reduced, interface metallurgical bonding of a stirring area and a heat engine influence area is improved, and meanwhile residual stress and deformation after test plate welding are reduced.

Owner:SHENYANG AEROSPACE UNIVERSITY

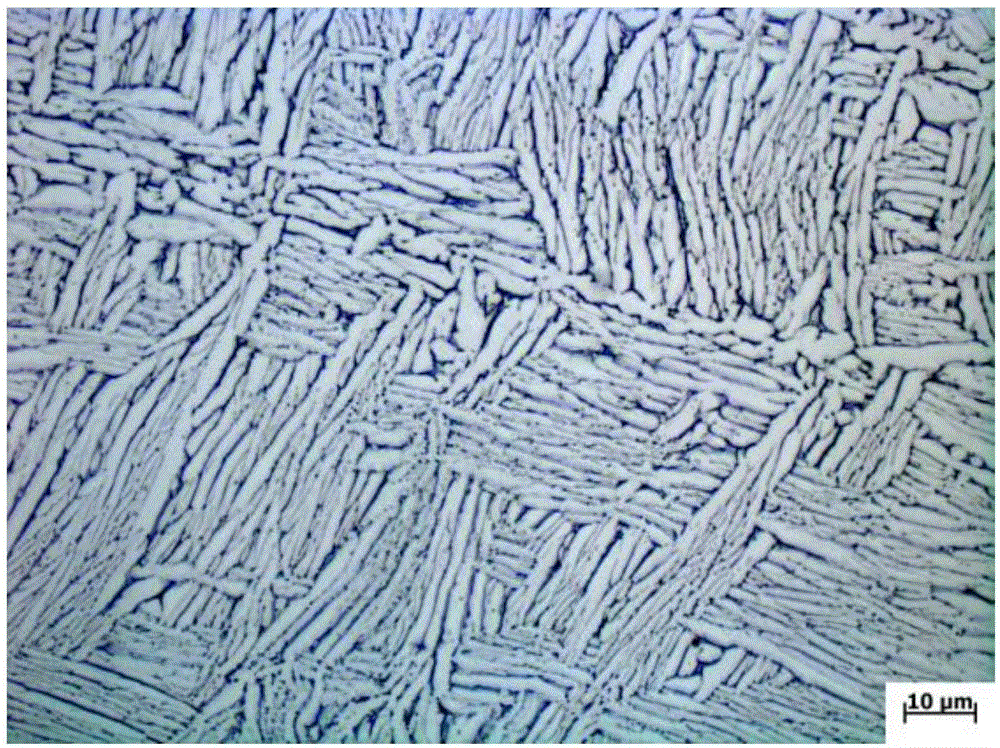

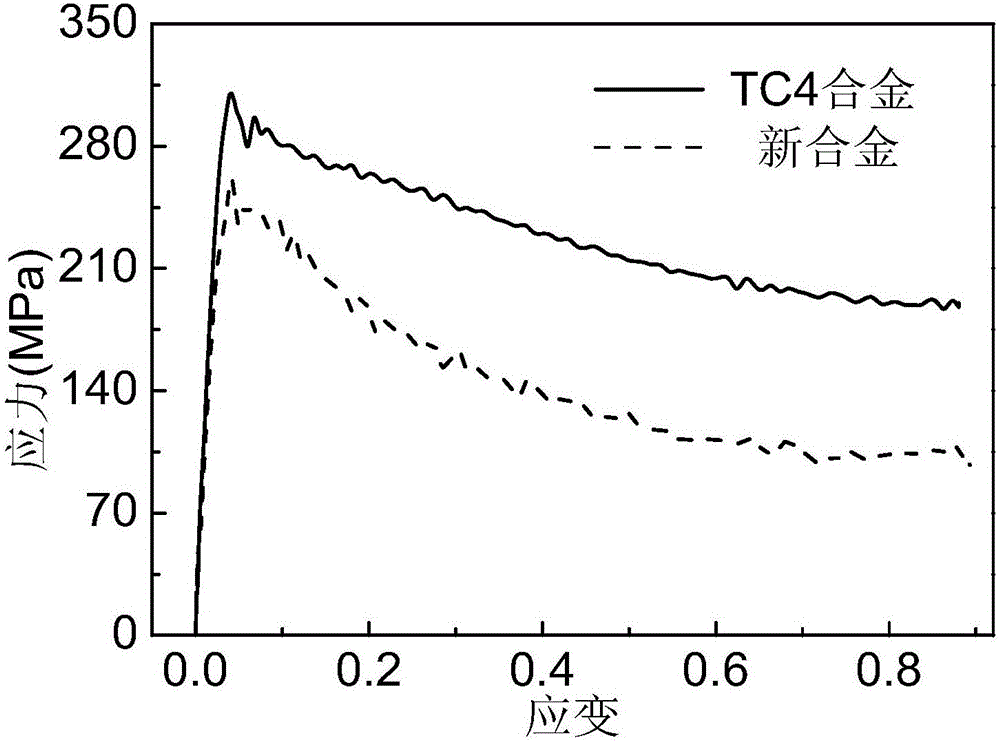

Titanium alloy with excellent hot-workability and preparation method thereof

InactiveCN106544543AReduced rheological resistanceReduce thermal processing costsTitaniumHot working

The invention discloses titanium alloy with excellent hot-workability. The titanium alloy comprises the following alloy elements in percentages by weight: 5.8-6.8% of Al, 3.8-4.8% of V, 0.5-1.5% of Fe, and the balance being titanium and unavoidable impurities. The invention also discloses a preparation method of the titanium alloy, and the method comprises the following steps: preparation of alloy clad, compacting of electrodes and welding, vacuum arc remelting, cogging and forging, free forging, and the like. The Fe element is added, resistance for flowing deformation in plastic deformation of alloy hot-working is reduced, so that compared with TC4 alloy, the cost for hot-working of the alloy is reduced by 15%.

Owner:NANJING UNIV OF TECH

Method for producing rotationally symmetrical, undercut contours

InactiveCN101072650AFast manufacturing processCutting costsMetal-working apparatusPistonsAxial pressureEngineering

Owner:CARL DAN PEDDINGHAUS

Electroplastic auxiliary laser shock drawing forming device and method

The invention discloses an electroplastic auxiliary laser shock drawing forming device and a method, and relates to a laser shock forming technology and the field of electroplastic auxiliary forming.The electroplastic auxiliary laser shock drawing forming device comprises a laser shock device and a trimming die drawing device; a plate material is arranged in the trimming die drawing device, forming is executed for the plate material through the trimming die drawing device, and the laser shock device performs auxiliary processing for the plate material through changing a transmission way of laser. While drawing forming is executed for the plate material, laser shock forming is also executed, thus, forming capability of plate material drawing forming is improved, incompatibility of formingtime of laser shock forming and electric auxiliary forming is overcome, and efficiency of laser shock forming is improved.

Owner:JIANGSU UNIV

Current assisted rolling device for realizing rod surface layer gradient nanocrystallization

The invention discloses a current assisted rolling device for realizing rod surface layer gradient nanocrystallization. The device comprises a frame module, a lifting mechanism whose one end is fixedon the upper surface of the bottom of the frame module, and a rod rotating mechanism fixed in the center of the upper area of the frame module; a rolling mechanism is arranged at the top of the framemodule, and is positioned on the peripheral outer side of the rod rotating mechanism; and the rolling mechanism is overlapped with the axis of the rod rotating mechanism. A rolling technology is combined with current; the current is applied to the plastic deformation process of the surface layers of machined rods, so that the forming capacity of the rods is improved, and the flowing stress is reduced; gradient nanostructures are formed on the surface layers of the machined rods, so that the strength, the hardness and the wear resistance of the rods are further improved, the workpiece comprehensive performance can be further improved, and the service life is effectively prolonged; and the device is simple in structure, can greatly reduce the production cost, and achieves more ideal technical effects.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com