Novel laser indirect impact micro-forming device and method

A micro-forming and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficulty in centering the punch and the die, the temperature of the heated workpiece cannot be guaranteed, and the punch is easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below by taking micro-deep drawing as an example and in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

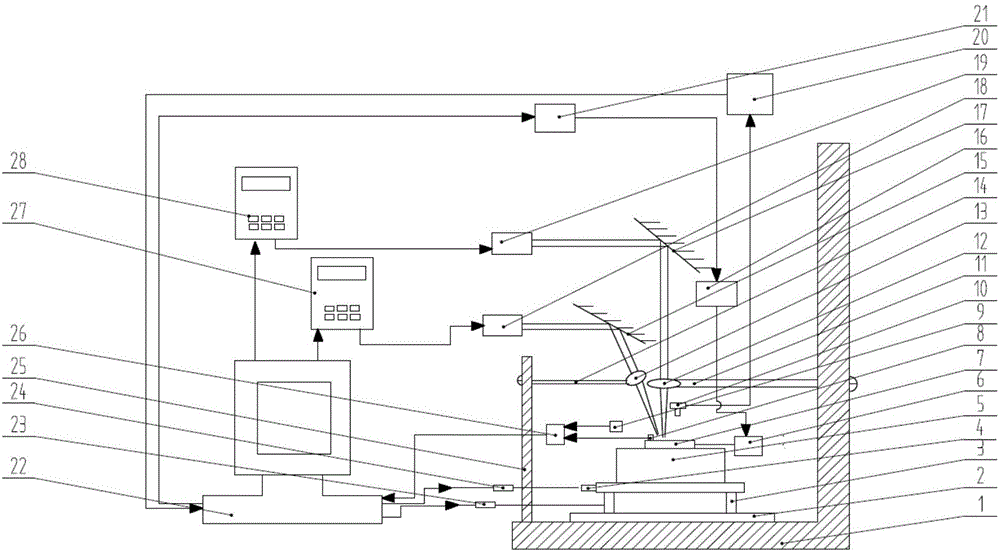

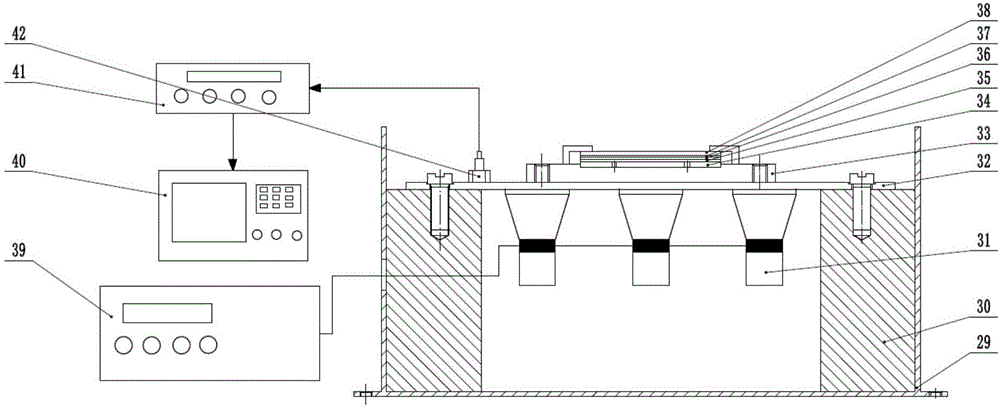

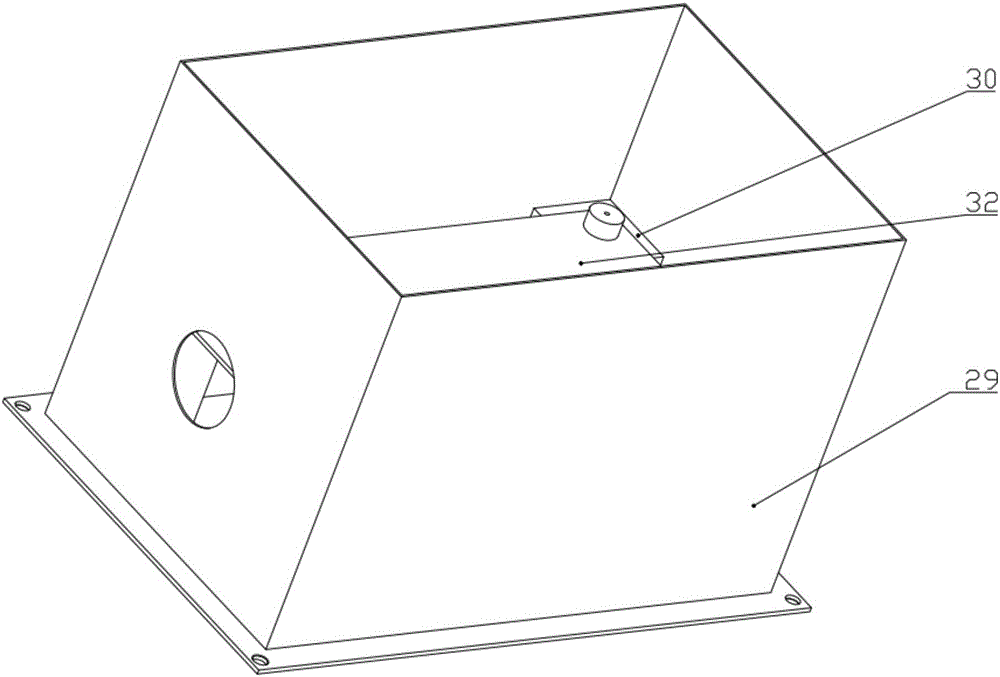

[0044] A novel laser indirect shock microforming device described in the present invention is as follows: figure 1 As shown, it consists of seven parts: mold-adjustment light spot centering component, workpiece positioning component, workpiece component, Nd:YAG pulse laser system for impact forming, CW fiber laser system for heating, ultrasonic vibration system, and control system. .

[0045] combined with figure 1 As shown, the mold-adjustment light spot centering assembly includes a three-dimensional mobile worktable 2 and a CCD sensor 10; the three-dimensional mobile workbench 2 is installed on an L-shaped base 1, and a telescopic cylinder 3 and a motor are installed on the three-dimensional mobile workbench 2 4. Utilize the Nd:YAG pulse laser c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com