Homogenization process of high-tungsten high-cobalt nickel alloy ingot

A nickel alloy and homogenization technology, applied in the field of nickel alloy homogenization process with high tungsten and high cobalt, can solve the research results of no homogenization method and sound velocity test, research and report on alloy homogenization method, no high tungsten and high cobalt found Research on high-cobalt-nickel alloys, etc., to achieve the effects of improving cold and hot working properties, eliminating element segregation, and improving cold and hot working plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) An exemplary high-tungsten and high-cobalt nickel alloy contains, by mass percentage: 35% tungsten, 20% cobalt and the balance nickel.

[0027] 2) According to the element ratio of the alloy described in step 1), the raw materials are weighed, including: metal tungsten bar, metal cobalt plate and metal nickel plate. It was then melted in a vacuum induction furnace and cast into 25kg ingots.

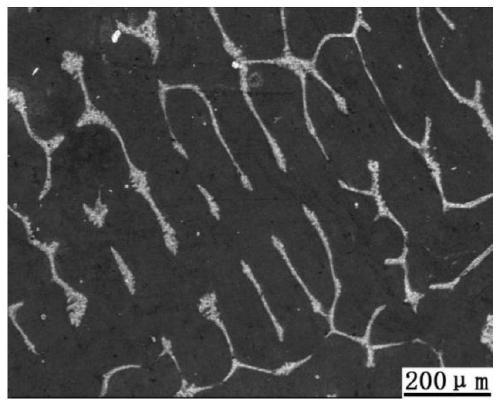

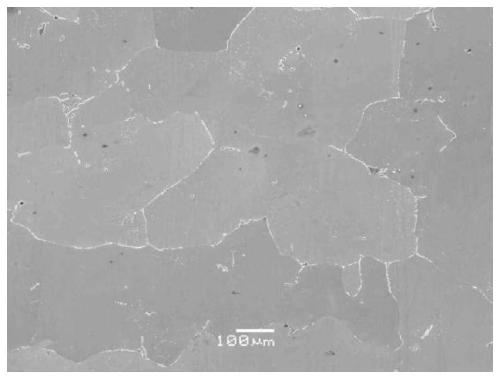

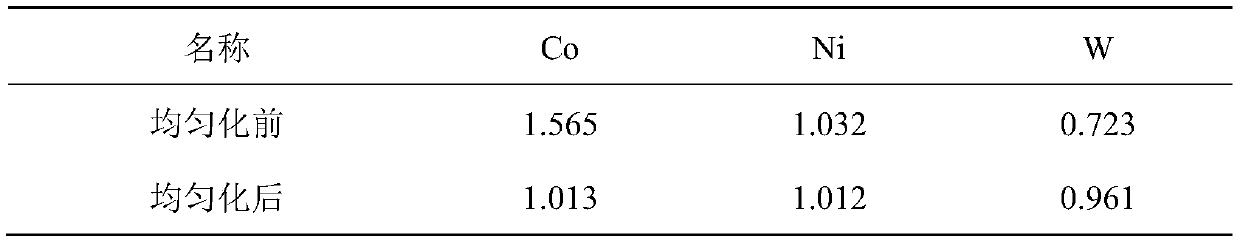

[0028] 3) Cut a 20mm thick disc from the head of the Ni-based alloy ingot by wire cutting, and then cut a 10×10×10mm cube sample at the 1 / 2 radius of the disc. The sample was polished to 7000# step by step with metallographic sandpaper, then mechanically polished, and then CuSO 4 The dendrite structure of the ingot is obtained by chemical etching of the etching liquid, such as figure 1 shown. The energy spectrometer supporting the scanning electron microscope was used to measure the chemical composition of the main elements in the dendrite stem and between the dendrites at di...

Embodiment 2

[0035] 1) An exemplary high-tungsten and high-cobalt nickel alloy contains, by mass percentage: 35% tungsten, 20% cobalt and the balance nickel.

[0036] 2) According to the element ratio of the alloy described in step 1), the raw materials are weighed, including: metal tungsten bar, metal cobalt plate and metal nickel plate. It is then melted in a vacuum induction furnace and cast into 500kg ingots.

[0037] 3) Cut a 20mm thick disc from the head of the Ni-based alloy ingot by wire cutting, and then cut a 10×10×10mm cube sample at the 1 / 2 radius of the disc. The sample was polished to 7000# step by step with metallographic sandpaper, then mechanically polished, and then CuSO 4 The dendrite structure of the ingot is obtained by chemical etching of the etching liquid, such as figure 1 shown. The energy spectrometer supporting the scanning electron microscope was used to measure the chemical composition of the main elements in the dendrite stem and between the dendrites at di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com