Super-austenitic stainless steel high-temperature homogenization processing method

A technology for austenitic stainless steel and homogenization treatment, which is applied in the field of heat treatment of austenitic stainless steel to achieve the effects of improving thermoplasticity, completely eliminating dendrite structure, improving composition and structure uniformity, and high-temperature thermoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Put the cast ingot into a heating furnace, raise the temperature to 1240°C at a rate of 100°C / h, keep it warm for 24 hours, cool down to 1000°C with the furnace, and then take it out of the furnace and air-cool it.

Embodiment 2

[0030] Example 2: Put the cast ingot into the heating furnace, raise the temperature to 1260°C at a rate of 120°C / h, keep it warm for 20h, cool down to 1000°C with the furnace, and then take it out of the furnace and air-cool it.

Embodiment 3

[0031] Example 3: Put the cast ingot into a heating furnace, raise the temperature to 1280°C at a rate of 160°C / h, keep it warm for 16 hours, cool down to 1000°C with the furnace, and then take it out of the furnace and air-cool it.

[0032] After high-temperature homogenization treatment, the homogenization effect can be judged by the following characterization methods:

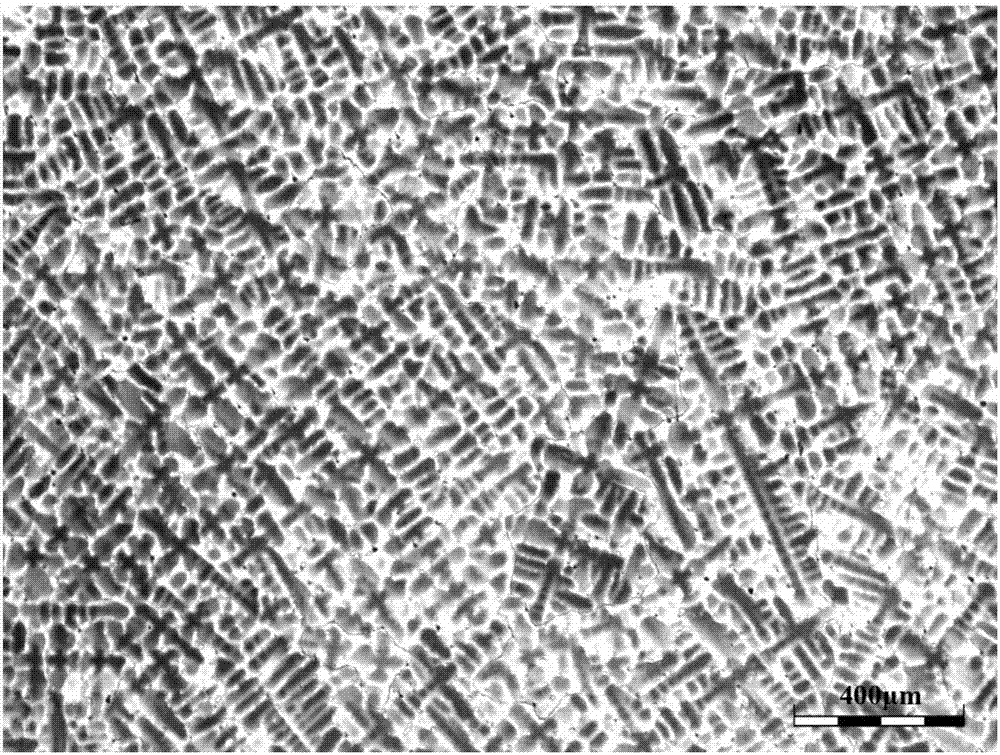

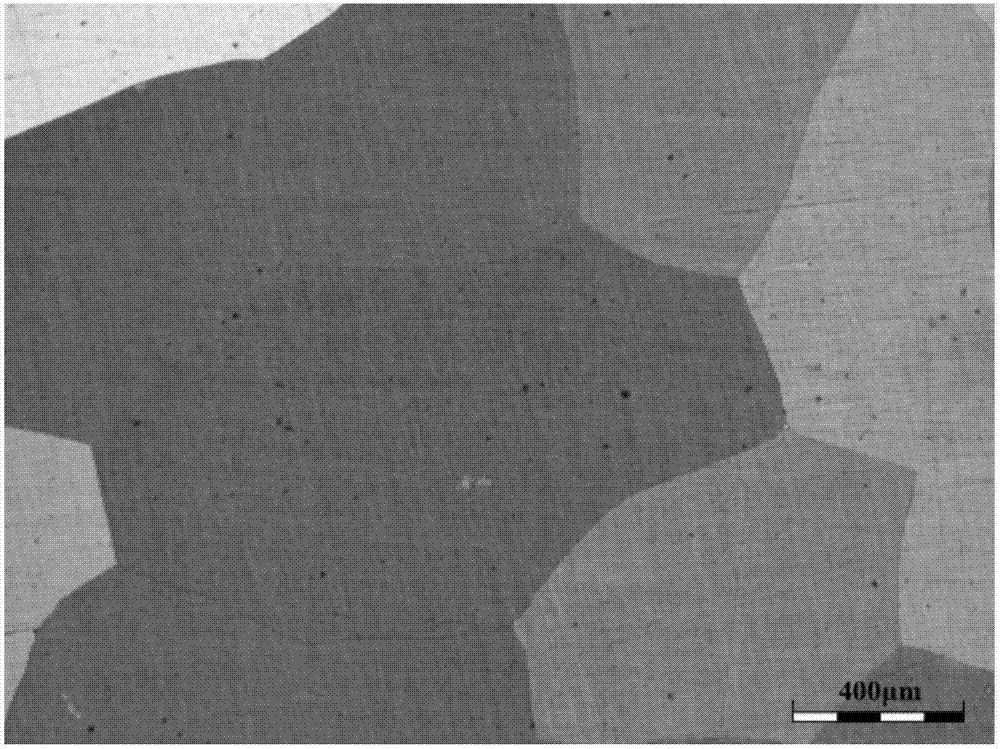

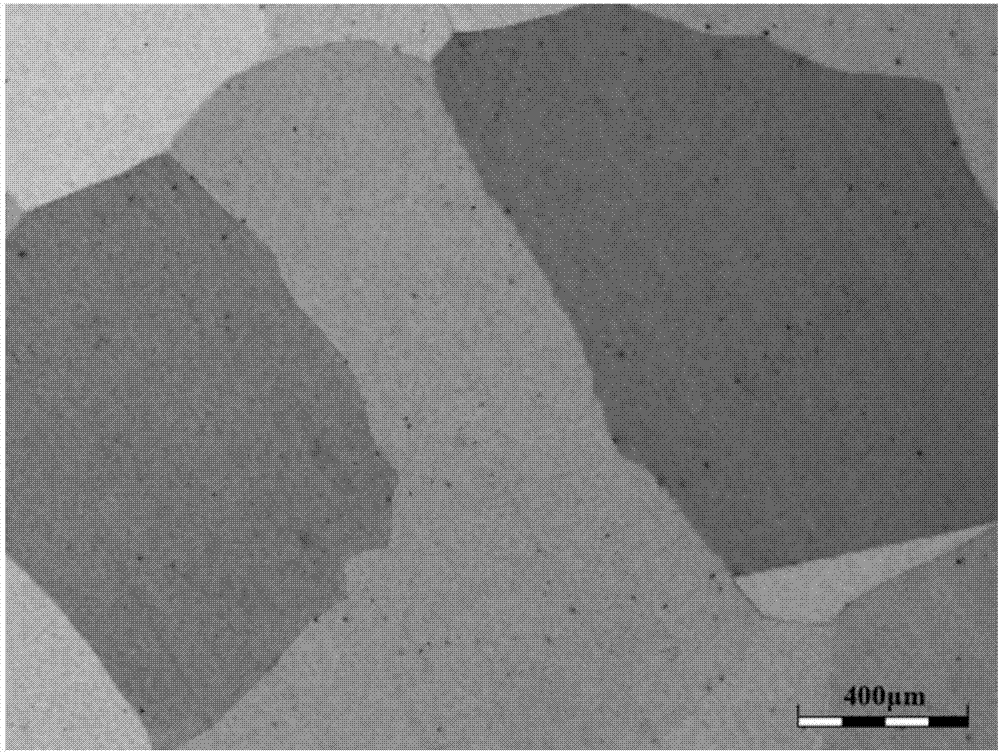

[0033] (1) Dendrite morphology: Observe the dendrite morphology in the core of the ingot before and after high-temperature homogenization treatment and measure the secondary dendrite spacing.

[0034] (2) Dissolution of Sigma phase: observe the size, quantity and distribution of Sigma phase before and after high-temperature homogenization treatment.

[0035] (3) Mo element segregation coefficient: use electron probe to measure interdendritic and dendrite stem Mo element content, and calculate Mo element segregation coefficient according to element segregation coefficient = interdendritic element content / dend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com