Super-strength aluminum alloy drill rod pipe body for super-deep well and manufacturing method for super-strength aluminum alloy drill rod pipe body

An ultra-high-strength, aluminum alloy technology, which is applied to the ultra-high-strength aluminum alloy drill pipe body and its manufacturing field for ultra-deep wells, can solve the problem of affecting the service safety of aluminum alloy drill pipes and widely popularized and used, and the mechanical properties of the alloy at room temperature are reduced. , the high price of alloying elements, etc., to achieve the effect of low cost, elimination of internal segregation of the matrix, and improvement of high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

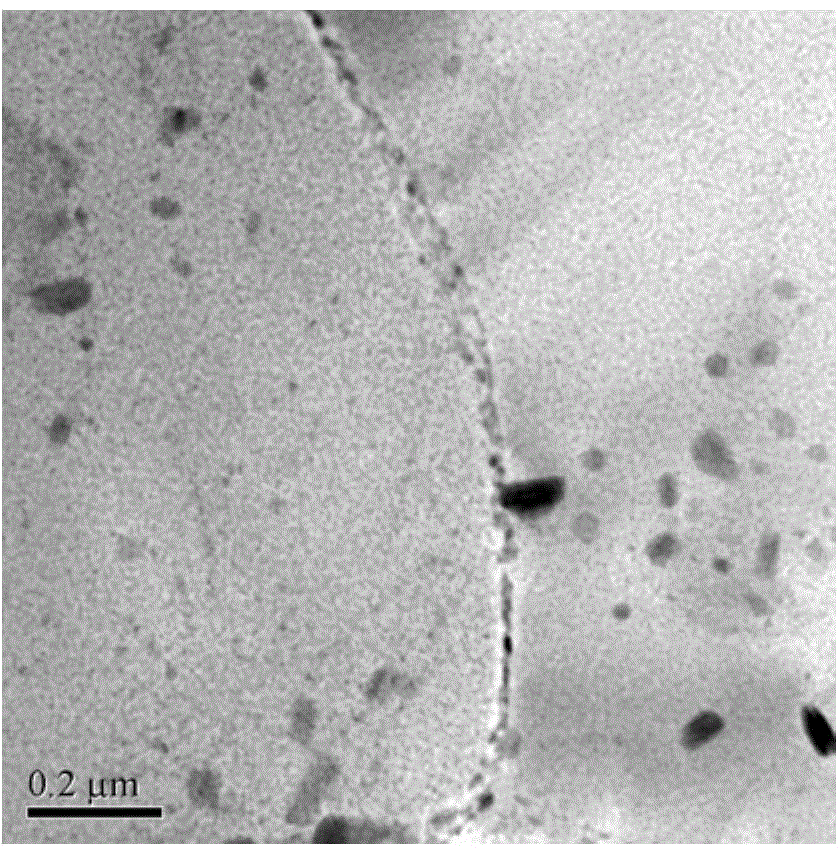

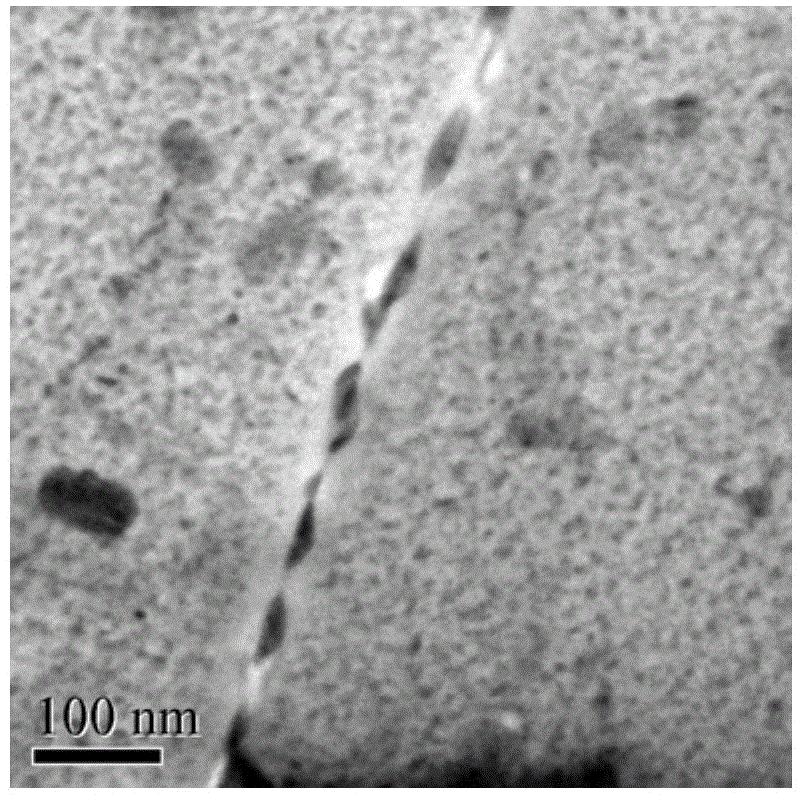

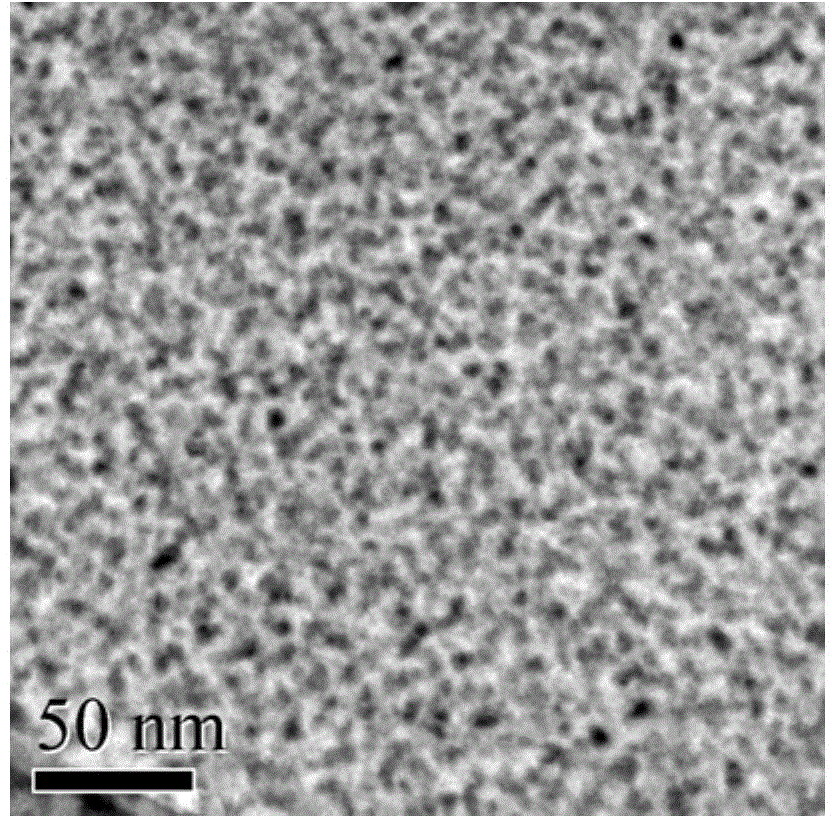

Image

Examples

Embodiment 1

[0033] An ultra-high-strength aluminum alloy drill pipe body for ultra-deep wells. In terms of weight percentage, the composition of the aluminum alloy drill pipe body for ultra-deep wells includes: Cu2.9%, Mg2.8%, Zn10.0%, Mn0. 3%, Fe0.3%, Ni0.5%, Cr0.5%, Ti0.20%, Zr0.2%B0.001%, Yb0.02%, the balance is Al and unavoidable impurities.

[0034] A method for manufacturing an ultra-high-strength aluminum alloy drill pipe body for ultra-deep wells. The above-mentioned raw materials are smelted and cast to obtain a tube blank, and the tube blank is homogenized at 380°C×8h+420°C×12h+460°C×32h, 435 ℃ extrusion deformation, solution quenching treatment at 455℃×2h+470℃×1h, artificial aging treatment for 36h after pre-stretching deformation 4.0%.

[0035] The mechanical properties of the aluminum alloy drill pipe body manufactured by the above method reach: the tensile strength is 735MPa, the yield strength is 704MPa, and the elongation is 8.5%; after 500 hours of heat exposure at 120°C,...

Embodiment 2

[0037] The invention provides an ultra-high-strength aluminum alloy drill pipe body for ultra-deep wells. The composition of the aluminum alloy drill pipe body for ultra-deep wells includes Cu2.1%, Mg2.8%, Zn10.9%. Mn0.3%, Fe0.3%, Ni0.3%, Cr0.5%, Ti0.20%, Zr0.2%B0.001%, Yb0.02%, the balance is Al and unavoidable impurities.

[0038] A method for manufacturing an ultra-high-strength aluminum alloy drill pipe body for ultra-deep wells. The above-mentioned raw materials are smelted and cast to obtain a tube blank, and the above-mentioned tube blank is homogenized at 380°C×8h+420°C×12h+460°C×32h, Extrusion deformation at 440°C, solution quenching treatment at 455°C×2h+470°C×1h, artificial aging treatment for 12h after pre-stretching deformation 4.0%.

[0039] The mechanical properties of the aluminum alloy drill pipe body manufactured by the above method reach: the tensile strength is 713MPa, the yield strength is 675MPa, and the elongation is 8.0%; after 500 hours of heat exposur...

Embodiment 3

[0041]An ultra-high-strength aluminum alloy drill pipe body for ultra-deep wells. In terms of weight percentage, the composition of the aluminum alloy drill pipe body for ultra-deep wells includes: Cu2.3%, Mg3.1%, Zn11.9%, Mn0. 3%, Fe0.3%, Ni0.3%, Cr0.5%, Ti0.20%, Zr0.2%B0.001%, Yb0.05%, the balance is Al and unavoidable impurities.

[0042] A method for manufacturing an ultra-high-strength aluminum alloy drill pipe body for ultra-deep wells. The above-mentioned raw materials are smelted and cast to obtain a tube blank, and the above-mentioned tube blank is homogenized at 380°C×8h+420°C×12h+460°C×32h, Extrusion deformation at 440°C, solution quenching treatment at 455°C×2h+470°C×1h, artificial aging treatment for 48h after pre-stretching deformation 4.0%.

[0043] The mechanical properties of the aluminum alloy manufactured by the above method reach: the tensile strength is 740MPa, the yield strength is 719MPa, and the elongation is 8.5%. 709MPa, elongation 7.0%. Its perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com