Reverse backfill type friction stir spot welding method

A friction stir and spot welding technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of increasing grain size, reducing material fluidity, and difficulty in material backfilling, reducing interface distortion and reducing Macroscopic deformation, beneficial effect of metallurgical bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

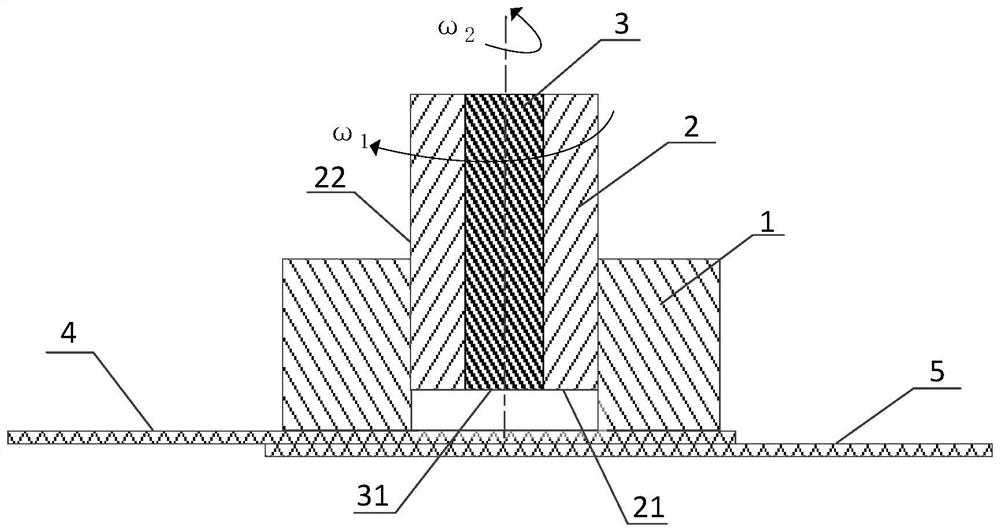

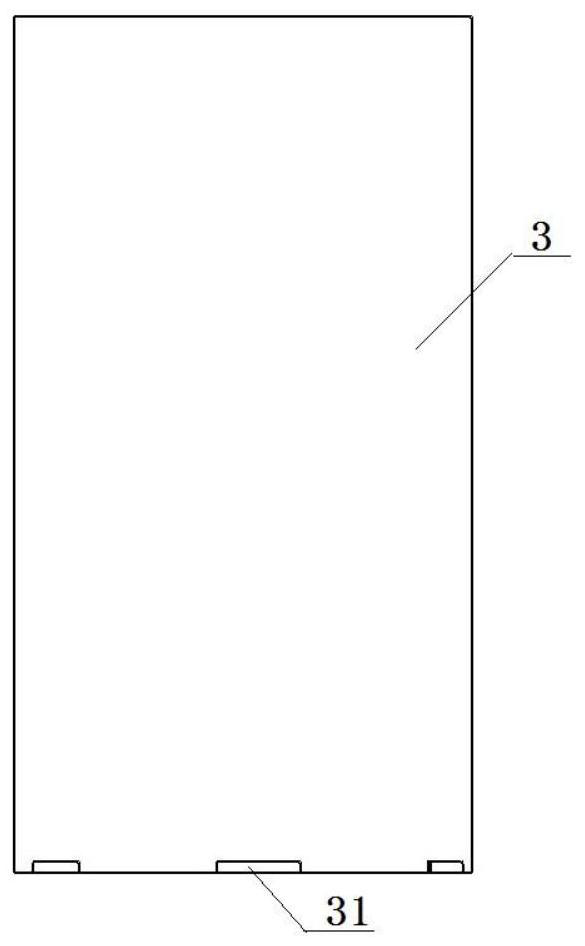

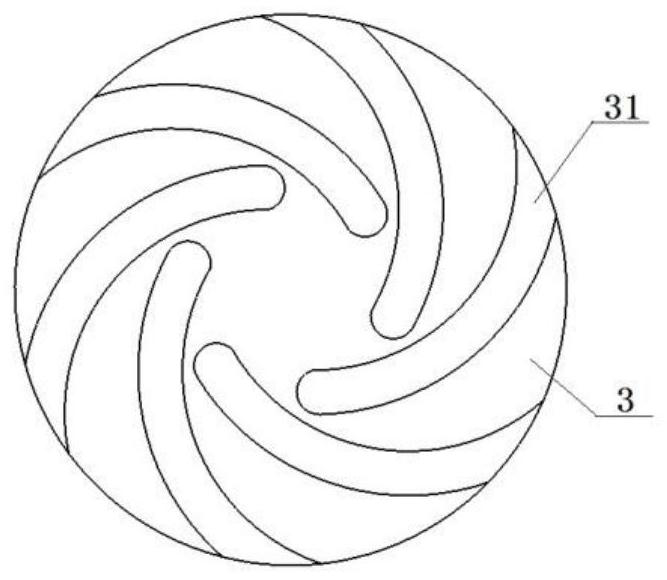

[0062] A reverse backfiltered stirring friction spot welding method is carried out with a reverse backfiltered stirred friction spot welding tool, and the reverse backfilling is mixed by the compression ring 1, the sleeve 2 and the stirring needle 3 in the coaxial. The welding process includes four stages of preheating, lowering, backfilling, and evacuation: reverse backfilling stitling friction spot welding method, reverse backfilling, friction spot welding tool and soldered sheet, cross section structure figure 1 As shown, the front view of the mixing needle 3 is figure 2 As shown, look up image 3 Down; the front view of the sleeve 2 is Figure 4 As shown, look up Figure 5 As shown; the spot welding object is the upper soldered sheet 4, and the lower side is soldered sheet 5. The sleeve 2 has a spiral pass groove 21 on the end surface, and the outer side surface has a large heaven groove 22. The large-scale trough is 30 °, the spacing is 2.5mm, the spiral width and the depth size...

Embodiment 2

[0075] A reverse backfiltered stirring friction spot welding method is carried out with a reverse backfiltered stirred friction spot welding tool, and the reverse backfilling is mixed by the compression ring 1, the sleeve 2 and the stirring needle 3 in the coaxial. The welding process includes four stages of preheating, lowering, backfilling, and evacuation: reverse backfilling stitling friction spot welding method, reverse backfilling, friction spot welding tool and soldered sheet, cross section structure figure 1 As shown, the front view of the mixing needle 3 is figure 2 As shown, look up image 3 Down; the front view of the sleeve 2 is Figure 4 As shown, look up Figure 5 As shown; the spot welding object is the upper soldered sheet 4, and the lower side is soldered sheet 5. The sleeve 2 has a spiral pass groove 21 on the end surface, and the outer side surface has a large heaven groove 22. The large-scale trough is 30 °, the spacing is 2.5mm, the spiral width and the depth size...

Embodiment 3

[0084] A reverse backfiltered stirring friction spot welding method is carried out with a reverse backfiltered stirred friction spot welding tool, and the reverse backfilling is mixed by the compression ring 1, the sleeve 2 and the stirring needle 3 in the coaxial. The welding process includes four stages of preheating, lowering, backfilling, and evacuation: reverse backfilling stitling friction spot welding method, reverse backfilling, friction spot welding tool and soldered sheet, cross section structure figure 1 As shown, the front view of the mixing needle 3 is figure 2 As shown, look up image 3 Down; the front view of the sleeve 2 is Figure 4 As shown, look up Figure 5 As shown; the spot welding object is the upper soldered sheet 4, and the lower side is soldered sheet 5. The sleeve 2 has a spiral pass groove 21 on the end surface, and the outer side surface has a large heaven groove 22. The large-scale trough is 30 °, the spacing is 2.5mm, the spiral width and the depth size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com