Precision control device and method for laser indirect impact micro molding

A precision control and micro-forming technology, which is applied in the field of laser processing and manufacturing and advanced mechanical manufacturing of micron-level parts, can solve the problems of inability to process, friction between the punch and the die, and insufficient forming quality, so as to save time and improve work. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and the mold with 4 rows and 4 columns of array cavities, but the protection scope of the present invention is not limited thereto.

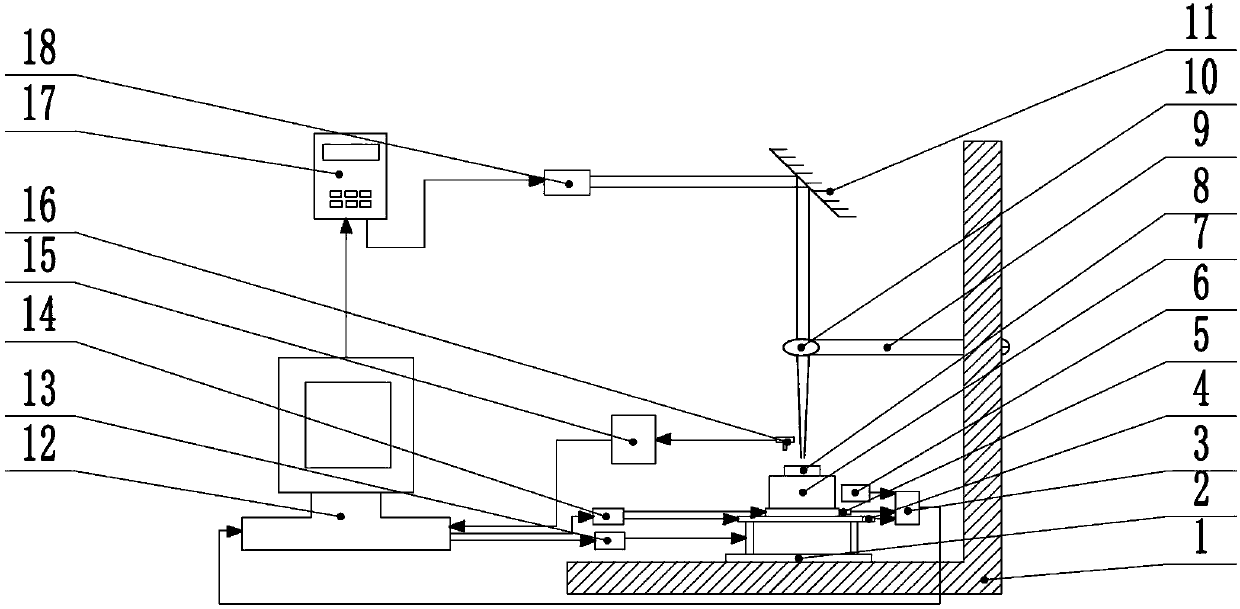

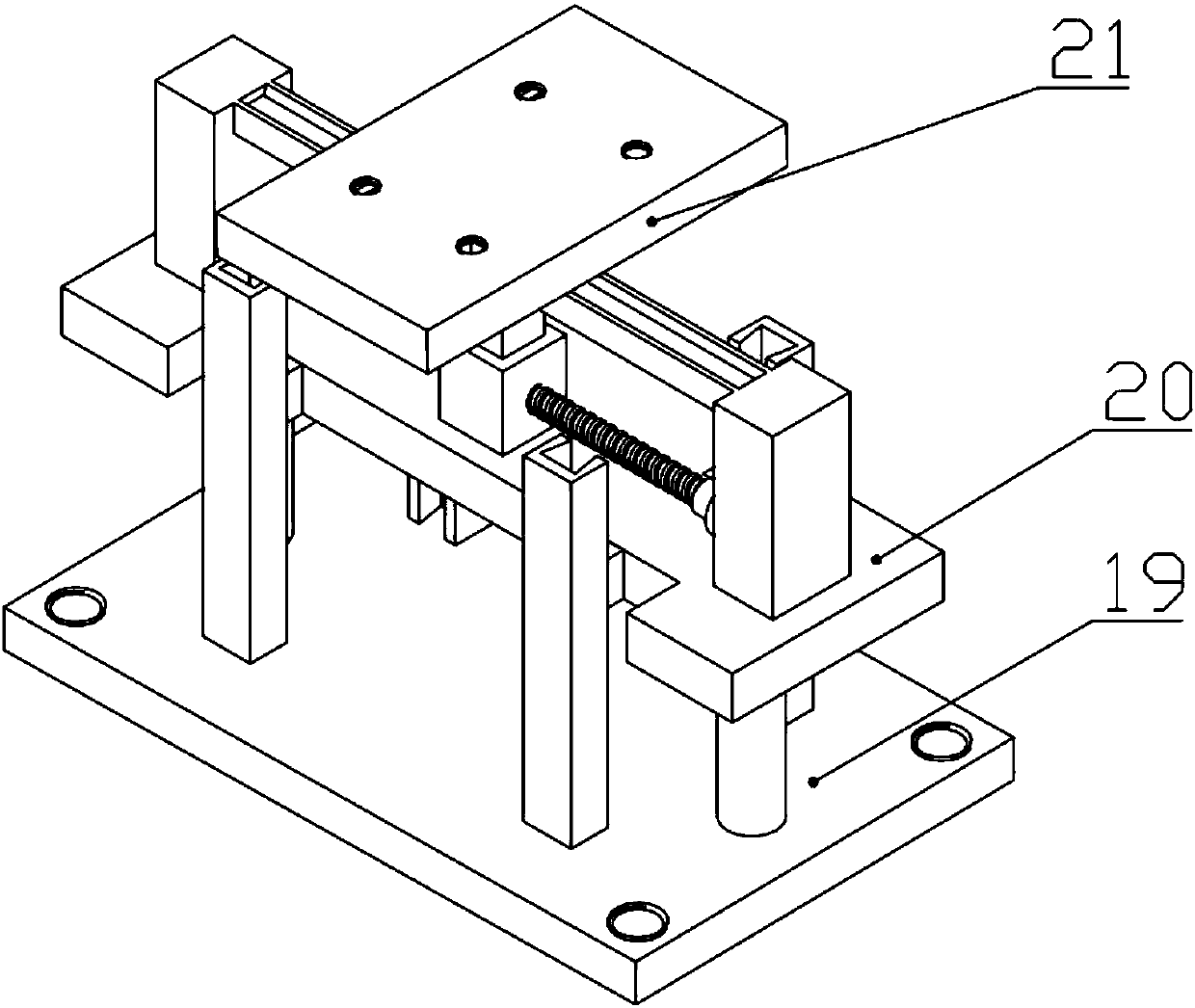

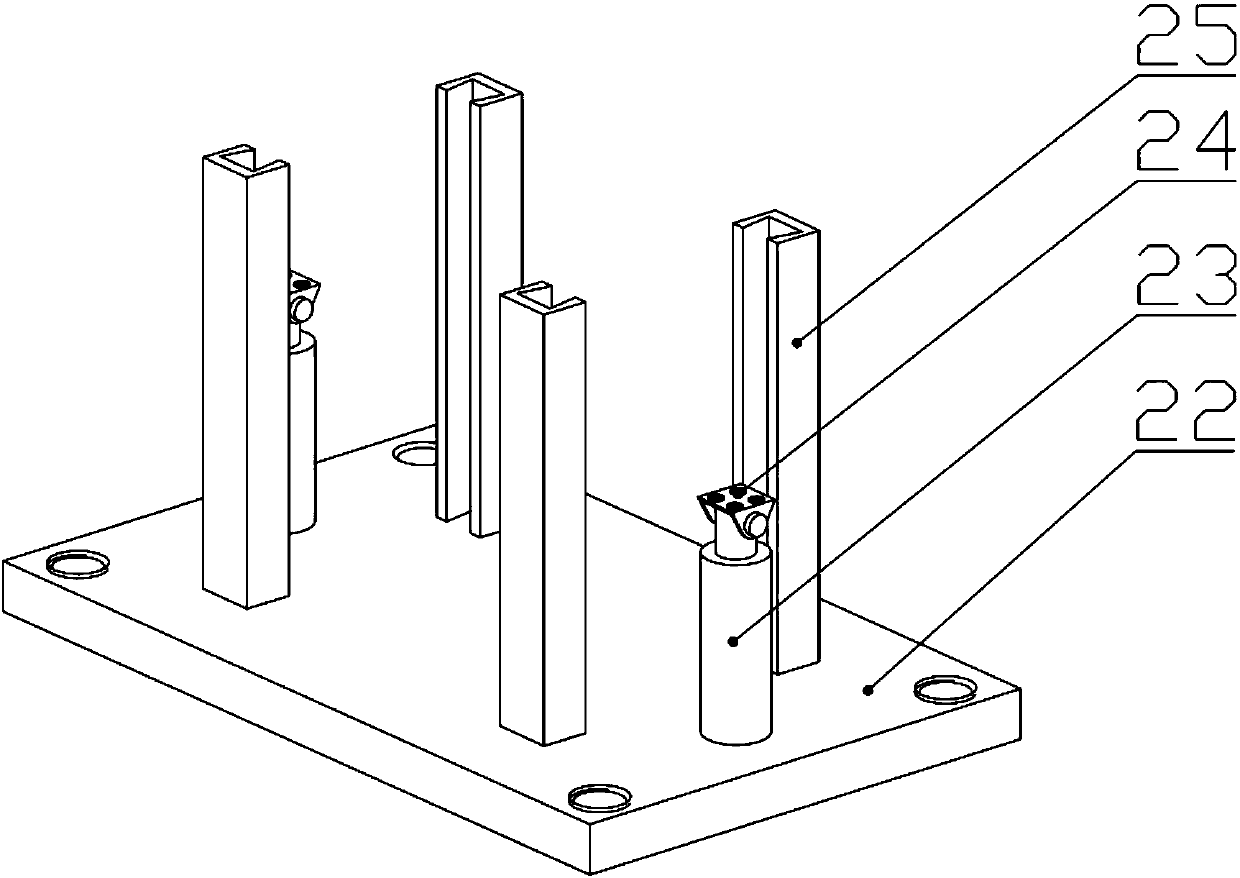

[0044] A precision control device for laser indirect impact micro-forming according to the present invention combined with the attached figure 1 As shown, including laser loading system, ultrasonic vibration system, spot-mold cavity centering component, workpiece component and control system;

[0045] combined with figure 1 As shown, the laser loading system includes an L-shaped base 1, a pulse laser 18, a lens adjustment arm 9, an adjustable focus lens 10, and a total reflection mirror 11; the laser beam emitted by the pulse laser 18 is reflected to the Focus on the adjustable focusing lens 10, and the focused laser beam is irradiated to the debugging light spot—the center position of the mold cavity centering component after debugging; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com