Heat working technological process for high strength deformed magnesium alloy

A technology of deformed magnesium alloy and process method, which is applied in the field of magnesium alloy processing, can solve the problems affecting the processing ability of the product, the decrease of alloy strength and plasticity, and the coarsening of precipitated phases, so as to achieve excellent plasticity, improved thermal deformation ability, Wrinkle-free and crack-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

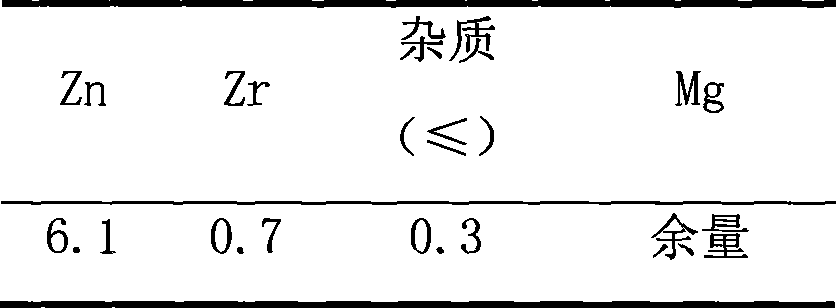

[0012] In one embodiment of the present invention, the alloy system is ZK60, and its chemical composition is shown in Table 1.

[0013] Table 1 Chemical composition of ZK60 alloy (wt%)

[0014]

[0015] Magnesium alloy ingots cast by semi-continuous process were homogenized at 340°C for 14 hours and then cooled to room temperature with the furnace; then heated and kept at 410°C for 85 minutes; then hot extrusion was carried out immediately with an extrusion ratio of 25 and an extrusion speed of 4.6 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com