Heat load and force load continuous and alternate impact strengthening device and working method thereof

A technology of impact strengthening and loading devices, which is applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve problems such as melting, high temperature softening of materials, and ignoring oxidation reactions, etc., to improve plasticity, reduce flow stress, and improve atomic The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

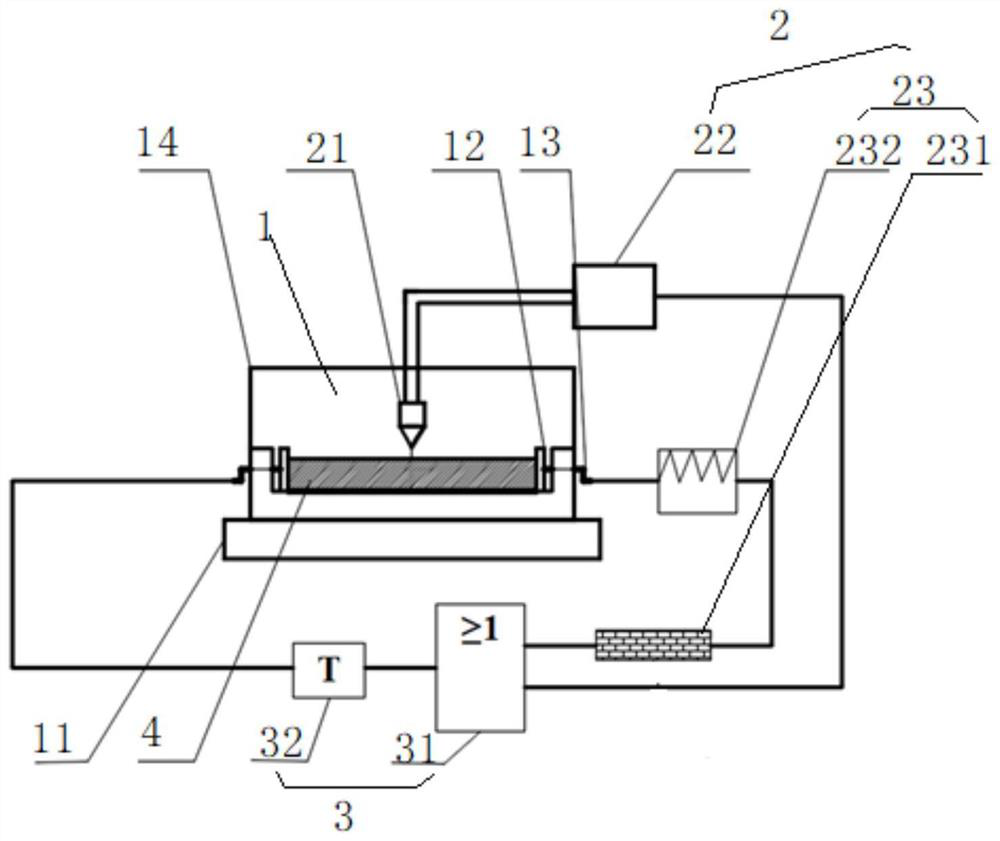

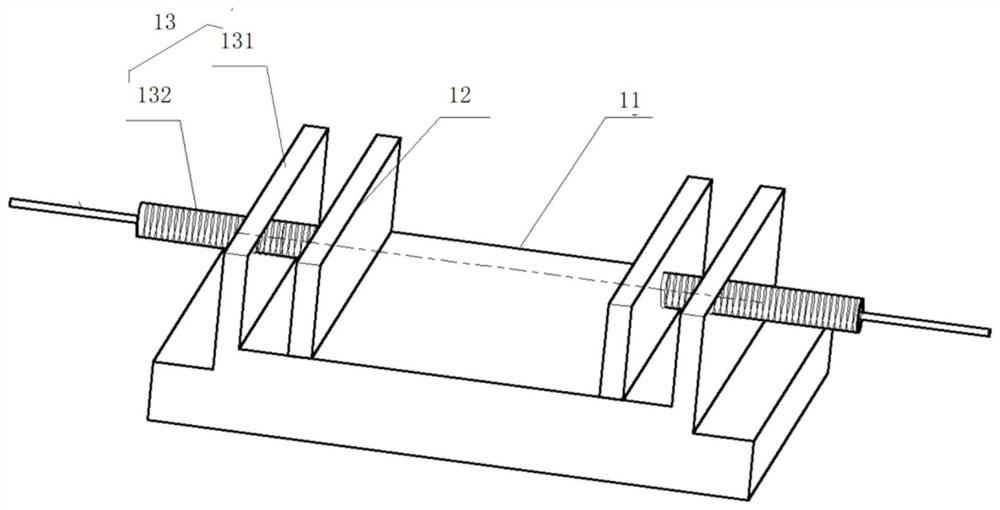

[0040] As shown in the figure, a thermal load continuous alternating impact strengthening device includes: a sealed stage 1, a laser force loading device 2, a photoelectric control system 3 and a material 4, wherein the sealed stage 1 includes a marble platform 11. A set of electrode plates 12, a set of clamping device 13 and a sealing cover 14, wherein the clamping device 13 includes a clamping installation plate 131 and a screw propulsion rod 132, and the electrode plate 12 is relatively arranged on the marble platform 11 Above, the clamping mounting plate 131 is arranged on the marble platform 11 and outside the electrode plate 12, one end of the screw propulsion rod 132 is connected to the electrode plate 12 after passing through the clamping mounting plate 131, and the sealing cover 13 is located on the marble platform 11, the material 4 is located on the marble platform 11, and is located between the two electrode plates 12; the laser force loading device 2 includes a las...

Embodiment 2

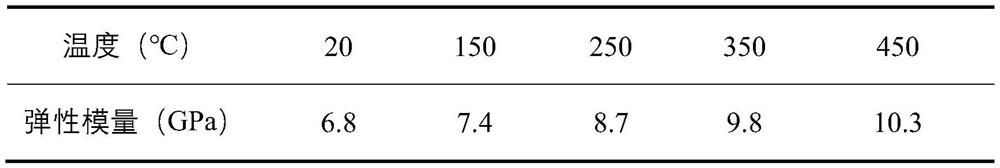

[0059] In this embodiment, the Ti64 plate is taken as the object, and the thermal continuous alternating impact loading effect based on high-energy pulse current and laser shock strengthening is carried out.

[0060] As shown in the figure, a thermal load continuous alternating impact strengthening device includes: a sealed stage 1, a laser force loading device 2, a photoelectric control system 3 and a material 4, wherein the sealed stage 1 includes a marble platform 11. A set of electrode plates 12, a set of clamping device 13 and a sealing cover 14, wherein the clamping device 13 includes a clamping installation plate 131 and a screw propulsion rod 132, and the electrode plate 12 is relatively arranged on the marble platform 11 Above, the clamping mounting plate 131 is arranged on the marble platform 11 and outside the electrode plate 12, one end of the screw propulsion rod 132 is connected to the electrode plate 12 after passing through the clamping mounting plate 131, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com