Current-assisted roll forming method of difficult-to-deform material special-shaped section pipe fittings

A special-shaped cross-section and difficult-to-deform technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of complex heating equipment, low heating efficiency, easy oxidation, etc., to save the process, improve processing performance, Reduce the effect of springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

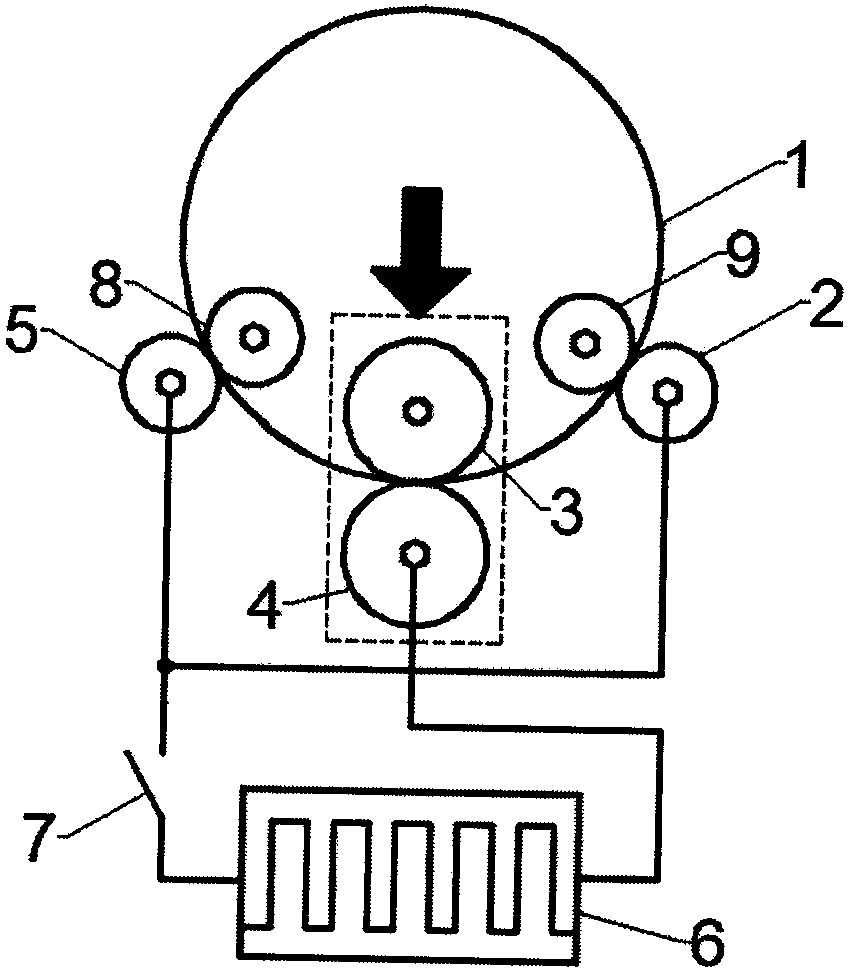

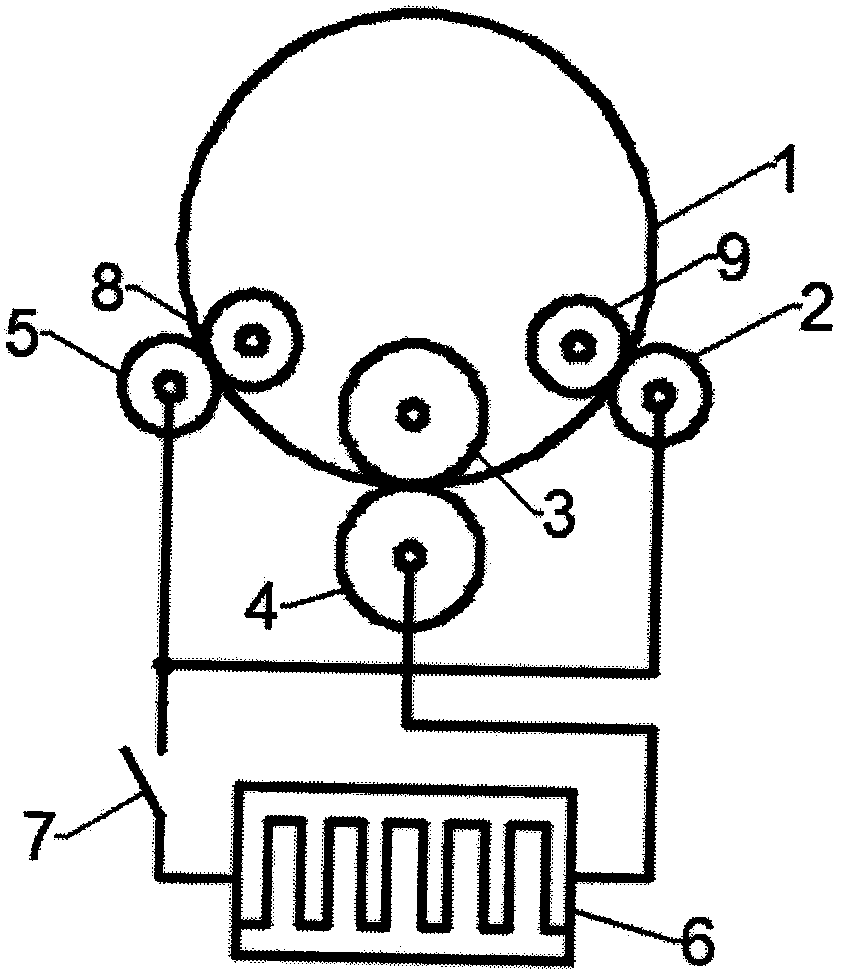

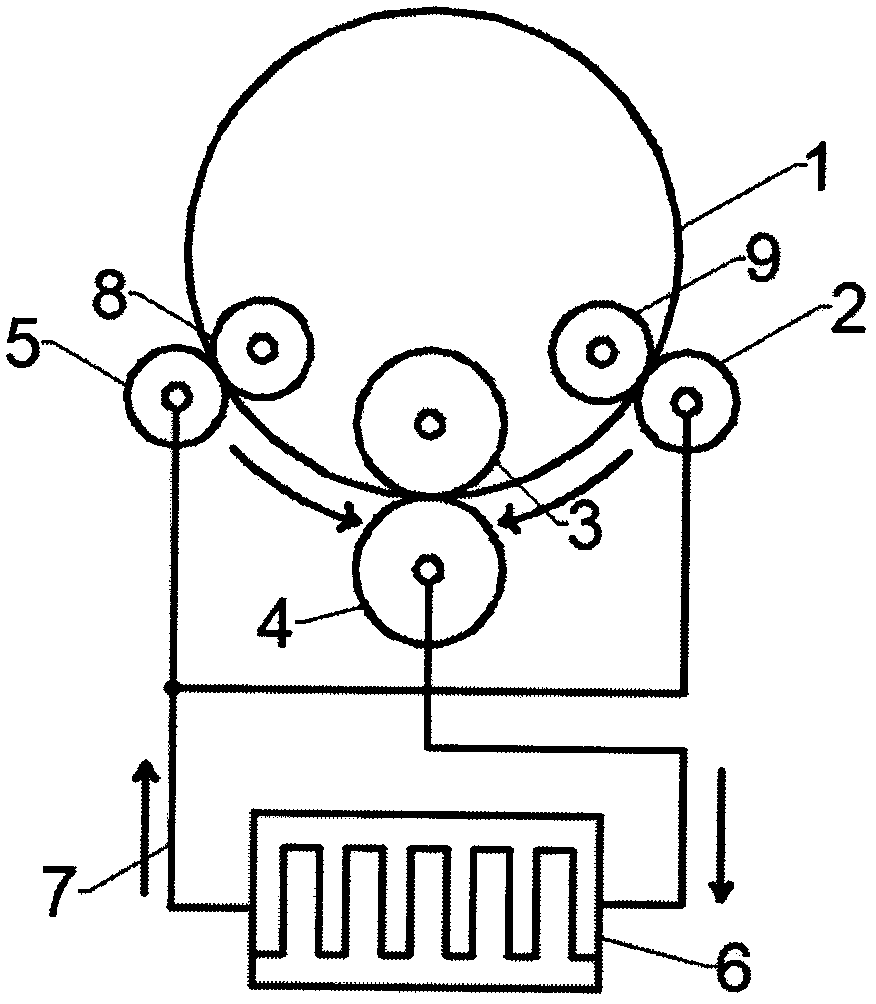

[0039] Example 1: For a titanium alloy with a mass percentage of Ti of 94.5%, a mass percentage of Al of 3%, and a mass percentage of V of 2.5%, the outer diameter of the original pipe fitting is 200mm, the wall thickness is 5mm, the length is 1100mm, the diameter of the middle roller is 40mm, and the rollers on both sides The diameter is 22mm, and the schematic diagram of the forming structure simulation is as follows Figure 7 shown. Place the original pipe 1 between the upper roller 3 and the lower roller 4 in the middle, insert the upper roller 3 into the pipe 1, adjust the height of the upper roller 3, and make the upper roller 3 and the lower roller 4 align the pipe 1 Clamping, then adjust the small rollers 8 and 9 on the left and right sides, so that the four rollers clamp the original pipe fittings in the left and right directions respectively. Closed circuit switch 7 makes the pulse current (current density 12A / mm) that AC power source 6 produces 2 ) flows through t...

Embodiment 2

[0040] Embodiment 2: For the Ti with composition Ti atomic percentage 53.5%, Al atomic percentage 22%, Nb atomic percentage 24%, Mo atomic percentage 0.5% 2 AlNb-based intermetallic compound, the outer diameter of the original pipe is 200mm, the wall thickness is 5mm, the length is 1100mm, the diameter of the middle roller is 40mm, and the diameter of the rollers on both sides is 22mm. Place the original pipe 1 between the upper roller 3 and the lower roller 4 in the middle, insert the upper roller 3 into the pipe 1, adjust the height of the upper roller 3, and make the upper roller 3 and the lower roller 4 align the pipe 1 Clamping, then adjust the small rollers 8 and 9 on the left and right sides, so that the four rollers clamp the original pipe fittings in the left and right directions respectively. The closed circuit switch 7 makes the pulse current (current density 10A / mm) produced by the AC power supply 6 2 ) flows through the switch 7, passes through the left roller sh...

Embodiment 3

[0041] Example 3: For a high-strength aluminum alloy with a composition of 86.05% by mass of Al, 8.9% by mass of Zn, 2.6% by mass of Mg, 2.3% by mass of Cu, and 0.15% by mass of Zr, the outer diameter of the original pipe fitting is 200 mm, and the wall thickness is 5 mm. The length is 1100mm, the diameter of the middle roller is 40mm, and the diameter of the rollers on both sides is 22mm. Place the original pipe 1 between the upper roller 3 and the lower roller 4 in the middle, insert the upper roller 3 into the pipe 1, adjust the height of the upper roller 3, and make the upper roller 3 and the lower roller 4 connect the pipe 1 Clamping, then adjust the small rollers 8 and 9 on the left and right sides, so that the four rollers clamp the original pipe fittings in the left and right directions respectively. Closed circuit switch 7 makes the pulse current (current density 30A / mm) that AC power source 6 produces 2 ) flows through the switch 7, passes through the left roller sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com