Method for controlling grain size of high-temperature alloy forge piece through heat treatment

A technology of superalloy and grain size, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of local coarse grains, over-burning, and narrow forging temperature range of superalloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

[0024] The method for controlling the grain size of superalloy forgings by heat treatment, the preferred steps are:

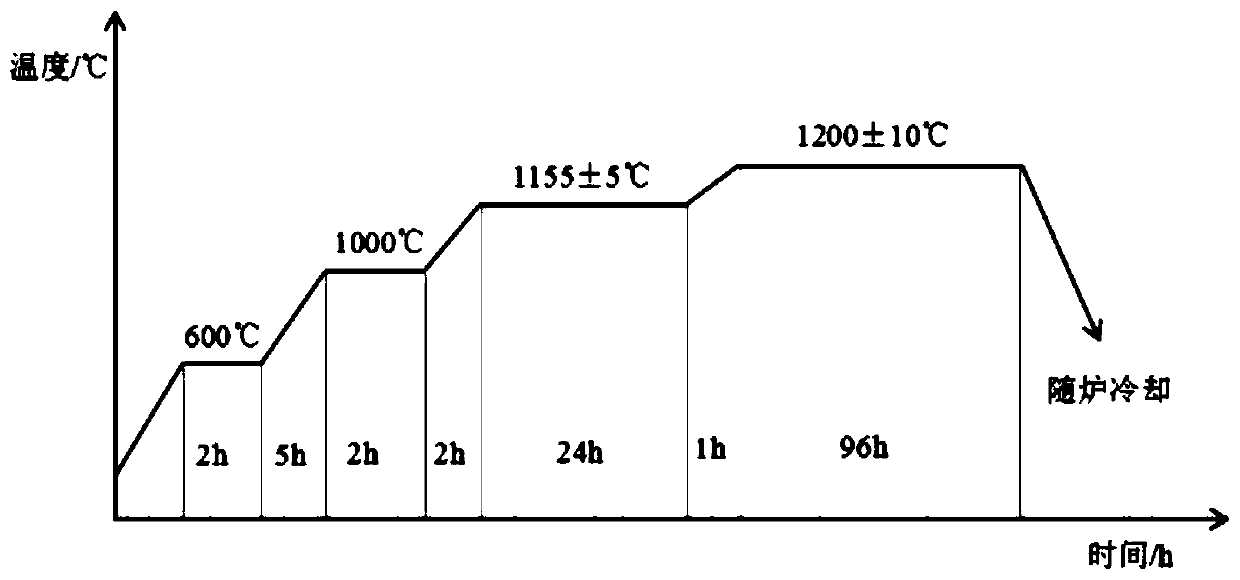

[0025] 1) Two-stage sub-temperature homogenization annealing and slow cooling: raise the temperature of the superalloy forging to 600°C, and keep it at 600°C for 2h; raise the temperature of the superalloy forging from 600°C to 1000°C, and the heating time is 5h; The superalloy forging is heated from 1000°C to 1155±5°C, and the heating time is 2h; the temperature is kept at 1155±5°C for 24h; the superalloy forging is heated from 1155±5°C to 1200±10°C, and the heating time is 1h; 10°C for 96 hours; then cool the superalloy forgings with the furnace;

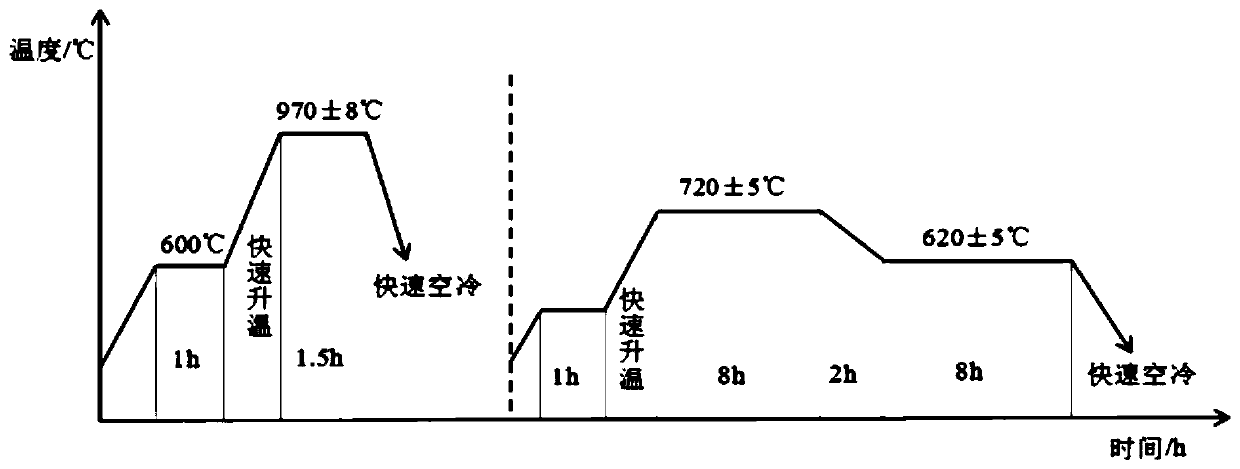

[0026] 2) Solid solution and graded failure treatment after forging: raise the temperature of the superalloy forging to 600°C and keep it at 600°C for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com