High-strength and high-conductivity rare earth copper alloy for contact lines and preparation method thereof

A rare earth copper and contact wire technology is applied in the field of copper alloy materials, which can solve the problems of high tensile strength and low electrical conductivity, and achieve the effects of improving elongation, excellent hot working performance and improving alloy strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

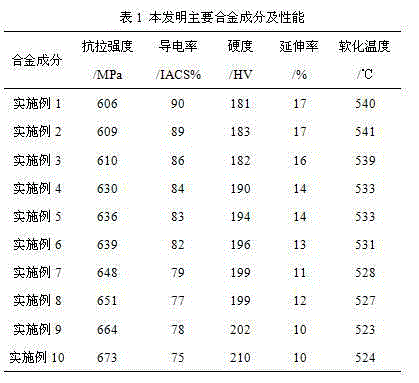

Examples

preparation example Construction

[0024] A preparation method of a high-strength and high-conductivity contact wire rare earth copper alloy comprises the following steps:

[0025] Step 1. Preparation of master alloy: put copper and zirconium in a vacuum non-consumable electrode arc melting furnace for melting, vacuumize to a pressure of 0.05Pa in the furnace, then fill in argon to a pressure of 0.05MPa in the furnace, and heat Melting at 1050-1100°C for 0.5-1h, natural cooling to obtain Cu-Zr master alloy for later use; put copper and rare earth into a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize until the pressure in the furnace is 0.05 Pa, then filled with argon until the furnace pressure is 0.05MPa, heated to 1030-1070°C, smelted for 0.5-1h, and naturally cooled to obtain a Cu-rare earth master alloy for later use;

[0026] Step 2, smelting and mold casting: put copper, zinc, silver, titanium and the Cu-Zr master alloy and Cu-rare earth master alloy obtained in step 1 into ...

Embodiment 1

[0034] A rare-earth copper alloy for high-strength and high-conductivity contact wires. The rare-earth copper alloy is composed of chromium, zirconium, zinc, titanium, silver, copper, rare earth elements and inevitable impurity elements. The percentage by weight is 0.2% chromium, 0.2% zirconium, 0.1% silver, 0.2% zinc, 0.3% titanium, 0.02% cerium, 0.02% iridium, and the balance is copper and unavoidable impurity elements.

[0035] The specific preparation method is:

[0036] Step 1. Preparation of master alloy: put copper and zirconium in a vacuum non-consumable electrode arc melting furnace for melting, vacuumize to a pressure of 0.05Pa in the furnace, then fill in argon to a pressure of 0.05MPa in the furnace, and heat to 1050°C, smelted for 1 hour, and cooled naturally to obtain a Cu-Zr master alloy for later use; put copper and rare earth into a vacuum non-consumable electrode arc melting furnace for smelting, evacuate until the pressure in the furnace is 0.05Pa, and then ...

Embodiment 2

[0044] A rare-earth copper alloy for high-strength and high-conductivity contact wires. The rare-earth copper alloy is composed of chromium, zirconium, zinc, titanium, silver, copper, rare earth elements and inevitable impurity elements. The percentage by weight is 0.3% chromium, 0.2% zirconium, 0.15% silver, 0.2% zinc, 0.2% titanium, 0.05% cerium, and the balance is copper and unavoidable impurity elements.

[0045] The specific preparation method is:

[0046] Step 1. Preparation of master alloy: put copper and zirconium in a vacuum non-consumable electrode arc melting furnace for melting, vacuumize to a pressure of 0.05Pa in the furnace, then fill in argon to a pressure of 0.05MPa in the furnace, and heat to 1050°C, smelted for 1 hour, and cooled naturally to obtain a Cu-Zr master alloy for later use; put copper and rare earth into a vacuum non-consumable electrode arc melting furnace for smelting, evacuate until the pressure in the furnace is 0.05Pa, and then charge Enter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com