A thermomechanical treatment process for al-cu-li alloy based on particle-induced nucleation

A deformation heat treatment, al-cu-li technology, applied in the field of aerospace components, can solve the problems of Al-Cu-Li alloy recrystallization control is difficult to achieve, secondary recrystallization, low structure stability, etc., to achieve the elimination of solid Dissolution treatment process, reduction of anisotropy, and high degree of recrystallization of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

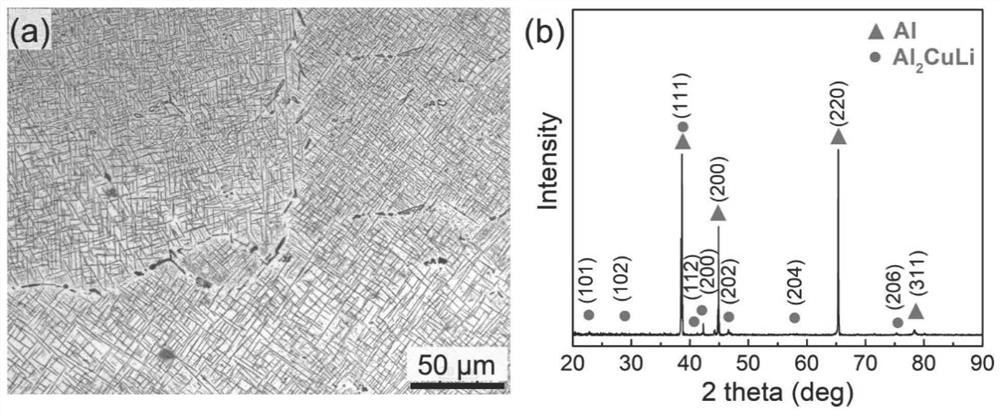

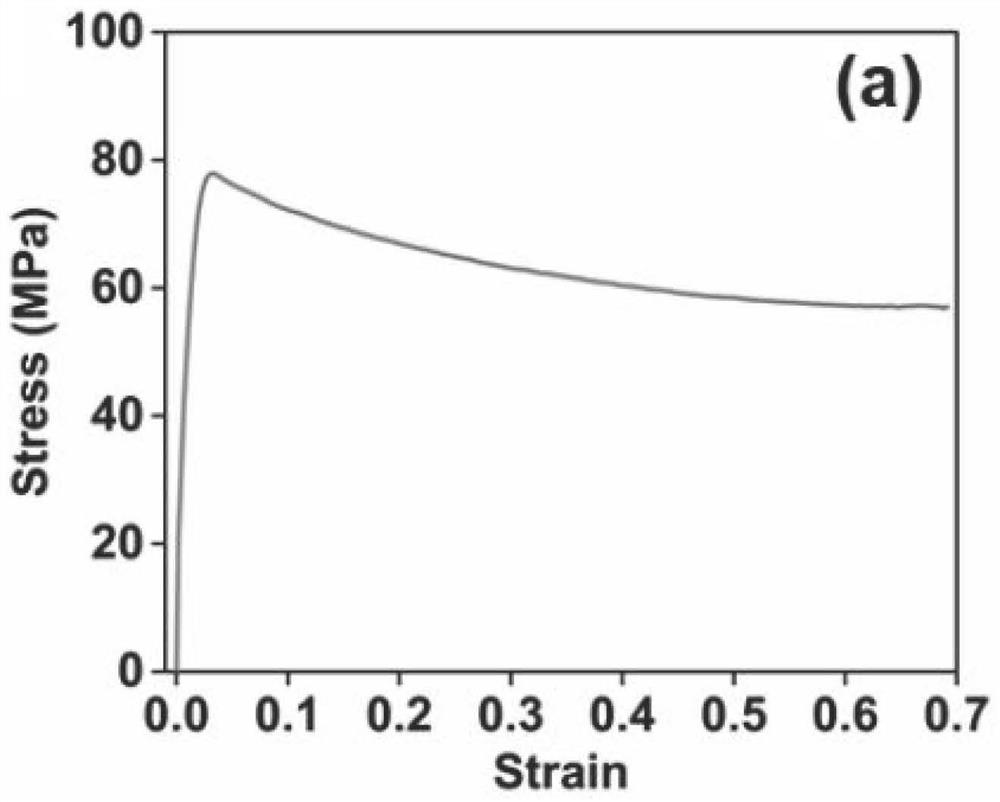

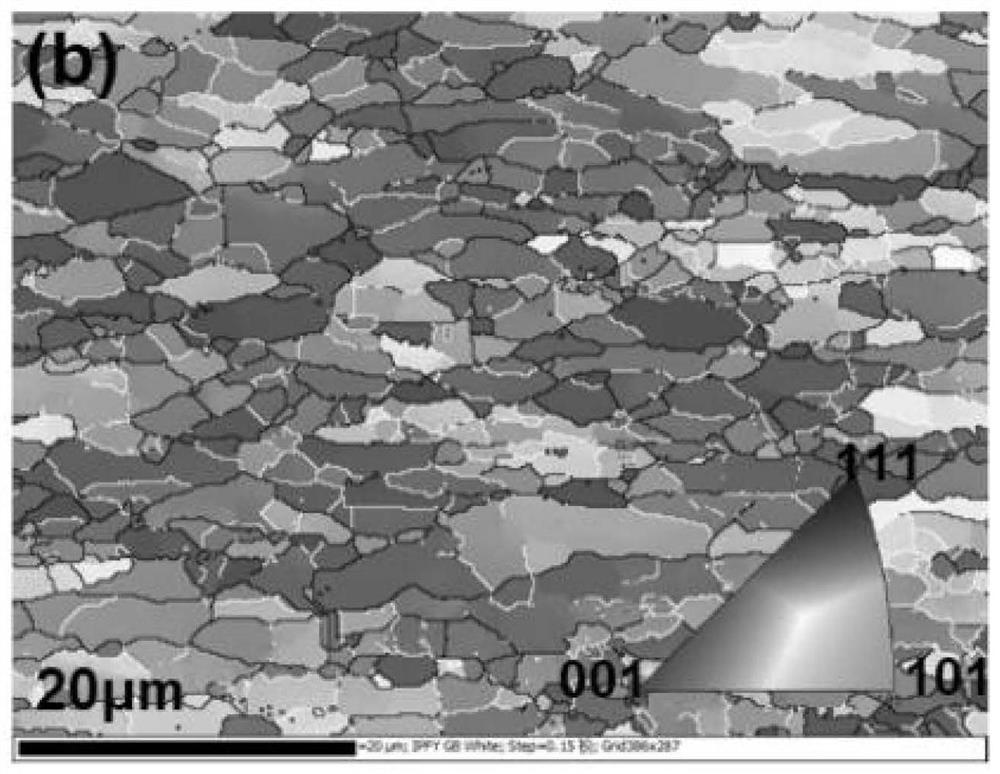

[0035] Example 1. In this example, through homogenization pretreatment before thermal deformation-thermal deformation-high temperature annealing treatment, low deformation resistance, high stability recrystallization structure and remarkable grain refinement effect were successfully obtained in Al-Cu-Li alloy. The alloy composition used in this example is Al-3.8Cu-1.3Li-0.6Mg-0.6Zn-trace amount of Mn / Zr.

[0036] Step 1. Pretreatment: The alloy ingot is pretreated by two-stage homogenization annealing. The alloy ingot is placed in an air furnace, and the first stage of homogenization annealing is performed first: the temperature is raised to 400°C at a rate of 10°C / s. Temperature non-uniformity ≤ ± 10 ° C, keep warm for 6 hours; after that, perform the second stage of homogenization annealing: heat up to 520 ° C at a rate of 10 ° C / s, control the temperature non-uniformity ≤ ± 5 ° C, and control the maximum temperature ≤ 525 ℃, keep warm for 48h, then cool down to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com