A heat treatment process for high-toughness aluminum alloy profiles

An aluminum alloy profile, high toughness technology, applied in the field of aluminum profile processing, can solve problems such as poor heat treatment process treatment effect, and achieve the effects of improving oxidation resistance and high temperature corrosion resistance, improving fluidity, and improving hardening ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

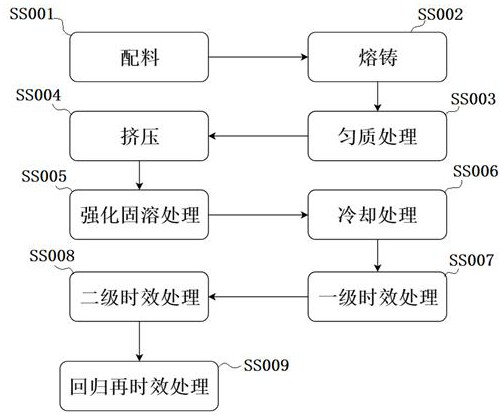

[0032] refer to figure 1 , the present invention is a heat treatment process for a high-toughness aluminum alloy profile, comprising the following steps:

[0033] SS001: Ingredients, prepare alloy raw materials according to the following alloy components and mass percentages, Si: 0.05%, Fe: 0.2%, Cu: 1.6%, Mn: 0.35%, Mg: 2.9%, Cr: 0.18%, Zn: 4.7% , Ti: 0.025%, Ag: 0.2%, rare earth: 0.15%, Ni: 0.05%, Al: balance, compared with the traditional batching scheme, this process adds Ag, rare earth and Ni, through the increase of Ag material, it can suppress The precipitation of the GP area in the matrix alloy accelerates the aging process and improves the hardening ability of the alloy. The combination of rare earth and hydrogen forms LaH, CeH, and LaH deoxidation to reduce the content of inclusions in the alloy, which acts as a purification, reduces the surface tension of the liquid aluminum alloy, and improves Fluidity, rare earth metals can also play a role in metal purification,...

Embodiment 2

[0051] The present invention also provides a technical solution, see figure 1 , the present invention is a heat treatment process for a high-toughness aluminum alloy profile, comprising the following steps:

[0052] SS001: Ingredients, prepare alloy raw materials according to the following alloy components and mass percentages, Si: 0.06%, Fe: 0.2%, Cu: 0.02%, Mn: 0.3%, Mg: 1.5%, Cr: 0.1%, Zn: 4.7% , Ti: 0.045%, Ag: 0.2%, rare earth: 0.15%, Ni: 0.05%, Al:

[0053] Residue, compared with Example 1, this kind of batching scheme reduces the proportion of Cu, Mn, Mg, Cr, improves the proportion of Si, Ti, and then improves and changes the performance of the alloy in this technical scheme through the change of the above proportion , the increase of Si and Ti elements improves the hardness and plastic deformation ability of the alloy;

[0054] Compared with the traditional batching scheme, this process adds Ag, rare earth and Ni. Through the increase of Ag material, the precipitati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com